853:

of crystal control, motion picture cameras and recorders. Their distinguishing feature is their rotor, which is a smooth cylinder of a magnetic alloy that stays magnetized, but can be demagnetized fairly easily as well as re-magnetized with poles in a new location. Hysteresis refers to how the magnetic flux in the metal lags behind the external magnetizing force; for instance, to demagnetize such a material, one could apply a magnetizing field of opposite polarity to that which originally magnetized the material. These motors have a stator like those of capacitor-run squirrel-cage induction motors. On startup, when slip decreases sufficiently, the rotor becomes magnetized by the stator's field, and the poles stay in place. The motor then runs at synchronous speed as if the rotor were a permanent magnet. When stopped and restarted, the poles are likely to form at different locations. For a given design, torque at synchronous speed is only relatively modest, and the motor can run at below synchronous speed. In simple words, it is lagging magnetic field behind magnetic flux.

715:

reversing the connection between the main winding and the start circuit, or by having polarity of main winding switched while start winding is always connected to a capacitor. There are significant differences, however; the use of a speed sensitive centrifugal switch requires that other split-phase motors must operate at, or very close to, full speed. PSC motors may operate within a wide range of speeds, much lower than the motor's electrical speed. Also, for applications like automatic door openers that require the motor to reverse rotation often, the use of a mechanism requires that a motor must slow to a near stop before contact with the start winding is re-established. The 'permanent' connection to the capacitor in a PSC motor means that changing rotation is instantaneous.

598:, small pumps, or small household appliances. In this motor, small single-turn copper "shading coils" create the moving magnetic field. Part of each pole is encircled by a copper coil or strap; the induced current in the strap opposes the change of flux through the coil. This causes a time lag in the flux passing through the shading coil, so that the maximum field intensity moves higher across the pole face on each cycle. This produces a low level rotating magnetic field which is large enough to turn both the rotor and its attached load. As the rotor picks up speed the torque builds up to its full level as the principal magnetic field is rotating relative to the rotating rotor.

844:(which may share the same field coils and rotor as the synchronous motor) or a very light rotor with a one-way mechanism (to ensure that the rotor starts in the "forward" direction). In the latter instance, applying AC power creates chaotic (or seemingly chaotic) jumping movement back and forth; such a motor will always start, but lacking the anti-reversal mechanism, the direction it runs is unpredictable. The Hammond organ tone generator used a non-self-starting synchronous motor (until comparatively recently), and had an auxiliary conventional shaded-pole starting motor. A spring-loaded auxiliary manual starting switch connected power to this second motor for a few seconds.

661:

inductance and higher resistance. The position of the winding creates a small phase shift between the flux of the main winding and the flux of the starting winding, causing the rotor to rotate. When the speed of the motor is sufficient to overcome the inertia of the load, the contacts are opened automatically by a centrifugal switch or electric relay. The direction of rotation is determined by the connection between the main winding and the start circuit. In applications where the motor requires a fixed rotation, one end of the start circuit is permanently connected to the main winding, with the contacts making the connection at the other end.

1085:

teeth on their edges, formed so they are parallel with the shaft. They are the stator poles. One of the pair of discs distributes the coil's flux directly, while the other receives flux that has passed through a common shading coil. The poles are rather narrow, and between the poles leading from one end of the coil are an identical set leading from the other end. In all, this creates a repeating sequence of four poles, unshaded alternating with shaded, that creates a circumferential traveling field to which the rotor's magnetic poles rapidly synchronize. Some stepping motors have a similar structure.

474:. The motor takes its name from the shape of its rotor "windings"- a ring at either end of the rotor, with bars connecting the rings running the length of the rotor. It is typically cast aluminum or copper poured between the iron laminates of the rotor, and usually only the end rings will be visible. The vast majority of the rotor currents will flow through the bars rather than the higher-resistance and usually varnished laminates. Very low voltages at very high currents are typical in the bars and end rings; high efficiency motors will often use cast copper to reduce the resistance in the rotor.

116:

33:

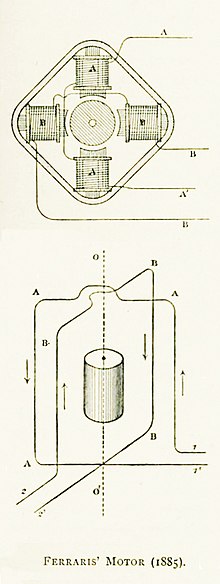

209:. Ferraris demonstrated a working model of his single-phase induction motor in 1885, and Tesla built his working two-phase induction motor in 1887 and demonstrated it at the American Institute of Electrical Engineers in 1888 (although Tesla claimed that he conceived the rotating magnetic field in 1882). In 1888, Ferraris published his research to the Royal Academy of Sciences in Turin, where he detailed the foundations of motor operation; Tesla, in the same year, was granted a United States patent for his own motor. Working from Ferraris's experiments,

1040:

of the applied voltage, lagging it by 90 degrees. This magnetic field passes down perpendicularly through the disc, inducing circular eddy currents in the plane of the disc centered on the field. These induced currents are proportional to the time derivative of the magnetic field, leading it by 90 degrees. This puts the eddy currents in phase with the voltage applied to the voltage coil, just as the current induced in the secondary of a transformer with a resistive load is in phase with the voltage applied to its primary.

985:. The micro speed unit combines two motors and an intermediate gear reducer. These are used for applications where extreme mechanical positioning accuracy and high cycling capability are needed. The micro speed unit combines a “main” conical rotor brake motor for rapid speed and a “micro” conical rotor brake motor for slow or positioning speed. The intermediate gearbox allows a range of ratios, and motors of different speeds can be combined to produce high ratios between high and low speed.

955:

1053:) a torque driving the front of the disc to the right. Similarly, the flux crosses down through the disc to the right current coil where the eddy current flows radially away from the disc center, again producing a torque driving the front of the disc to the right. When the AC polarity reverses, the eddy currents in the disc and the direction of the magnetic flux from the current coils both change, leaving the direction of the torque unchanged.

670:

711:. Also known as a capacitor-run motor, this type of motor uses a non-polarized capacitor with a high voltage rating to generate an electrical phase shift between the run and start windings. PSC motors are the dominant type of split-phase motor in Europe and much of the world, but in North America, they are most frequently used in variable torque applications (like blowers, fans, and pumps) and other cases where variable speeds are desired.

542:, or other devices. A technique sometimes used is star-delta (YΔ) starting, where the motor coils are initially connected in star configuration for acceleration of the load, then switched to delta configuration when the load is up to speed. This technique is more common in Europe than in North America. Transistorized drives can directly vary the applied voltage as required by the starting characteristics of the motor and load.

770:. This greatly eases the problem of starting the massive rotor of a large synchronous motor. They may also be started as induction motors using a squirrel-cage winding that shares the common rotor: once the motor reaches synchronous speed, no current is induced in the squirrel-cage winding so it has little effect on the synchronous operation of the motor, aside from stabilizing the motor speed on load changes.

124:

482:

squirrel-cage motor at rated no-load speed will consume electrical power only to maintain rotor speed against friction and resistance losses. As the mechanical load increases, so will the electrical load – the electrical load is inherently related to the mechanical load. This is similar to a transformer, where the primary's electrical load is related to the secondary's electrical load.

1044:

current. This field passes from the pole of one current coil up perpendicularly through the disc and back down through the disc to the pole of the other current coil, with a completed magnetic circuit back to the first current coil. As these fields cross the disc, they pass through the eddy currents induced in it by the voltage coil producing a

734:

1069:

line-to-line loads. Line-to-line loads draw the same current through both current coils and spin the meter twice as fast as a line-to-neutral load drawing the same current through only a single current coil, correctly registering the power drawn by the line-to-line load as twice that of the line-to-neutral load.

1291:

The

Electrical Engineer. (1888). London: Biggs & Co. Pg., 239. new application of the alternating current in the production of rotary motion was made known almost simultaneously by two experimenters, Nikola Tesla and Galileo Ferraris, and the subject has attracted general attention from the fact

1043:

The eddy currents pass directly above the pole pieces of two "current" coils under the disc, each wound with a few turns of heavy-gauge wire whose inductive reactance is small compared to the load impedance. These coils connect the supply to the load, producing a magnetic field in phase with the load

852:

These motors are relatively costly, and are used where exact speed (assuming an exact-frequency AC source) and rotation with low flutter (high-frequency variation in speed) are essential. Applications included tape recorder capstan drives (the motor shaft could be the capstan), and, before the advent

698:

A resistance start motor is a split-phase induction motor with a starter inserted in series with the startup winding, creating reactance. This added starter provides assistance in the starting and initial direction of rotation. The start winding is made mainly of thin wire with fewer turns to make it

689:

which produces a greater phase shift (and so, a much greater starting torque) than both split-phase and shaded pole motors. This motor has a centrifugal switch which disconnects the capacitor once the motor has started. This motor provides high starting torque. A capacitor-start, capacitor-run motor

1084:

Representative are low-torque synchronous motors with a multi-pole hollow cylindrical magnet (internal poles) surrounding the stator structure. An aluminum cup supports the magnet. The stator has one coil, coaxial with the shaft. At each end of the coil are a pair of circular plates with rectangular

876:

are both wound and supplied from an external source, with the torque being a function of the rotor current times the stator current so reversing the current in both rotor and stator does not reverse the rotation. Universal motors can run on AC as well as DC provided the frequency is not so high that

517:

is required. In this case, the rotor has the same number of poles as the stator and the windings are made of wire, connected to slip rings on the shaft. Carbon brushes connect the slip rings to a controller such as a variable resistor that allows changing the motor's slip rate. In certain high-power

481:

with a rotating secondary. When the rotor is not rotating in sync with the magnetic field, large rotor currents are induced; the large rotor currents magnetize the rotor and interact with the stator's magnetic fields to bring the rotor almost into synchronization with the stator's field. An unloaded

1068:

watthour meter the voltage coil is connected between the two "hot" (line) terminals (240 V in North

America) and two separate current coils are connected between the corresponding line and load terminals. No connection to the system neutral is needed to correctly handle combined line-to-neutral and

1056:

The torque is thus proportional to the instantaneous line voltage times the instantaneous load current, automatically correcting for power factor. The disc is braked by a permanent magnet so that speed is proportional to torque and the disc mechanically integrates real power. The mechanical dial on

1039:

has a stator with three coils facing the disc. The magnetic circuit is completed by a C-shaped core of permeable iron. The "voltage" coil above the disc is in parallel with the supply; its many turns have a high inductance/resistance ratio (Q) so its current and magnetic field are the time integral

605:

was made by Barber-Colman several decades ago. It had a single field coil, and two principal poles, each split halfway to create two pairs of poles. Each of these four "half-poles" carried a coil, and the coils of diagonally opposite half-poles were connected to a pair of terminals. One terminal of

568:

An AC servo amplifier, a linear power amplifier, feeds the control winding. The electrical resistance of the rotor is made high intentionally so that the speed–torque curve is fairly linear. Two-phase servo motors are inherently high-speed, low-torque devices, heavily geared down to drive the load.

442:

As an example, a typical four-pole motor running on 60 Hz might have a nameplate rating of 1725 RPM at full load, while its calculated speed is 1800 RPM. The speed in this type of motor has traditionally been altered by having additional sets of coils or poles in the motor that can be switched

843:

makes it difficult to instantly accelerate the rotor from stopped to synchronous speed, these motors normally require some sort of special feature to get started. Some include a squirrel-cage structure to bring the rotor close to synchronous speed. Various other designs use a small induction motor

577:

Single-phase motors do not have a unique rotating magnetic field like multi-phase motors. The field alternates (reverses polarity) between pole pairs and can be viewed as two fields rotating in opposite directions. They require a secondary magnetic field that causes the rotor to move in a specific

533:

Several methods of starting a polyphase motor are used. Where a large inrush current and high starting torque can be permitted, the motor can be started across the line, by applying full line voltage to the terminals (direct-on-line, DOL). Where it is necessary to limit the starting inrush current

485:

This is why a squirrel-cage blower motor may cause household lights to dim upon starting, but does not dim the lights on startup when its fan belt (and therefore mechanical load) is removed. Furthermore, a stalled squirrel-cage motor (overloaded or with a jammed shaft) will consume current limited

213:

introduced the first three-phase induction motor in 1890, a much more capable design that became the prototype used in Europe and the U.S. He also invented the first three-phase generator and transformer and combined them into the first complete AC three-phase system in 1891. The three-phase motor

966:

The high starting torque and low inertia of the conical rotor brake motor has proven to be ideal for the demands of high cycle dynamic drives in applications since the motor was invented, designed and introduced over 50 years ago. This type of motor configuration was first introduced in the US in

714:

A capacitor with a relatively low capacitance, and relatively high voltage rating, is connected in series with the start winding and remains in the circuit during the entire run cycle. Like other split-phase motors, the main winding is used with a smaller start winding, and rotation is changed by

962:

A conical rotor brake motor incorporates the brake as an integral part of the conical sliding rotor. When the motor is at rest, a spring acts on the sliding rotor and forces the brake ring against the brake cap in the motor, holding the rotor stationary. When the motor is energized, its magnetic

690:

has two separate capacitors, one for starting the motor, and another for running it, and has a centrifugal switch to disconnect the starting capacitor, or a back-EMF relay connected in parallel with the auxiliary winding of the motor. This motor provides high starting torque and high efficiency.

925:

Repulsion motors are wound-rotor single-phase AC motors that are a type of induction motor. In a repulsion motor, the armature brushes are shorted together rather than connected in series with the field, as is done with universal motors. By transformer action, the stator induces currents in the

660:

that is 90 electrical degrees to the main winding, always centered directly between the poles of the main winding, and connected to the main winding by a set of electrical contacts. The coils of this winding are wound with fewer turns of smaller wire than the main winding, so it has a lower

185:

published a paper in 1880 that identified the rotating magnetic field principle and that of a two-phase AC system of currents to produce it. Never practically demonstrated, the design was flawed, as one of the two currents was “furnished by the machine itself.” In 1886, English engineer

803:

when its rotor is over excited. It thus appears to the supply to be a capacitor, and could thus be used to correct the lagging power factor that is usually presented to the electric supply by inductive loads. The excitation is adjusted until a near unity power factor is obtained (often

881:

losses become problems. Nearly all universal motors are series-wound because their stators have relatively few turns, minimizing inductance. Universal motors are compact, have high starting torque and can be varied in speed over a wide range with relatively simple controls such as

930:(RS-IR) motor has been used most frequently. The RS-IR motor has a centrifugal switch that shorts all segments of the commutator so that the motor operates as an induction motor once it is close to full speed. Some of these motors also lift the brushes out of contact with source

241:

If the rotor of a squirrel cage motor were to run at the true synchronous speed, the flux in the rotor at any given place on the rotor would not change, and no current would be created in the squirrel cage. For this reason, ordinary squirrel-cage motors run at some tens of

718:

Three-phase motors can be converted to PSC motors by making common two windings and connecting the third via a capacitor to act as a start winding. However, the power rating needs to be at least 50% larger than for a comparable single-phase motor due to an unused winding.

172:

transmission, there were many inventors in the United States and Europe during the late 19th century trying to develop workable AC motors. The first person to conceive of a rotating magnetic field was Walter Baily, who gave a workable demonstration of his battery-operated

518:

variable-speed wound rotor drives, the slip-frequency energy is captured, rectified, and returned to the power supply through an inverter. With bidirectionally controlled power, the wound rotor becomes an active participant in the energy conversion process, with the

902:

still use special low frequencies such as 16.7 and 25 Hz to overcome the aforementioned problems with losses and reactance. Still widely used, universal traction motors have been increasingly displaced by polyphase AC induction and permanent magnet motors with

525:

Compared to squirrel cage rotors, wound rotor motors are expensive and require maintenance of the slip rings and brushes, but they were the standard form for variable speed control before the advent of compact power electronic devices. Transistorized inverters with

1027:

These are two-phase induction motors with permanent magnets to retard the rotor so its speed is accurately proportional to the power passing through the meter. The rotor is an aluminium-alloy disc, and currents induced into it react with the field from the stator.

91:

does not rely on slip-induction for operation and uses either permanent magnets, salient poles (having projecting magnetic poles), or an independently excited rotor winding. The synchronous motor produces its rated torque at exactly synchronous speed. The

831:

If a conventional squirrel-cage rotor has flats ground on it to create salient poles and increase reluctance, it will start conventionally, but will run synchronously, although it can provide only a modest torque at synchronous speed. This is known as a

624:

Applying AC to the coil created a field that progressed in the gap between the poles. The plane of the stator core was approximately tangential to an imaginary circle on the disc, so the travelling magnetic field dragged the disc and made it rotate.

617:, low-torque shaded-pole motor could be found in traffic-light and advertising-lighting controllers. The pole faces were parallel and relatively close to each other, with the disc centered between them, something like the disc in a watthour

890:

choppers. Compared with induction motors, universal motors do have some drawbacks inherent to their brushes and commutators: relatively high levels of electrical and acoustic noise, low reliability and more frequent required maintenance.

609:

The motor would not start with the terminals open; connecting the common to one made the motor run one way, and connecting the common to the other made it run the other way. These motors were used in industrial and scientific devices.

1048:

on the disc mutually perpendicular to both. Assuming power is flowing to the load, the flux from the left current coil crosses the disc upwards where the eddy current flows radially toward the center of the disc producing (by the

746:

If connections to the rotor coils of a three-phase motor are taken out on slip-rings and fed a separate field current to create a continuous magnetic field (or if the rotor consists of a permanent magnet), the result is called a

340:, that increases with the torque produced. With no load, the speed will be very close to synchronous. When loaded, standard motors have between 2–3% slip, special motors may have up to 7% slip, and a class of motors known as

963:

field generates both an axial and a radial component. The axial component overcomes the spring force, releasing the brake; while the radial component causes the rotor to turn. There is no additional brake control required.

815:

generators that are operated as synchronous motors to pump water to a reservoir at a higher elevation for later use to generate electricity using the same machinery. Six 500-megawatt generators are installed in the

628:

The stator was mounted on a pivot so it could be positioned for the desired speed and then clamped in position. Placing the poles nearer to the center of the disc made it run faster, and toward the edge, slower.

755:

with an independently excited rotor multiphase AC winding set that may experience slip-induction beyond synchronous speeds but like all synchronous motors, does not rely on slip-induction for torque production.

36:

An industrial type of AC motor with electrical terminal box at the top and output rotating shaft on the left. Such motors are widely used for pumps, blowers, conveyors and other industrial machinery.

486:

only by circuit resistance as it attempts to start. Unless something else limits the current (or cuts it off completely) overheating and destruction of the winding insulation is the likely outcome.

87:

rotor current in the rotor AC winding. As a result, the induction motor cannot produce torque near synchronous speed where induction (or slip) is irrelevant or ceases to exist. In contrast, the

1057:

the meter reads disc rotations and the total net energy delivered to the load. (If the load supplies power to the grid, the disc rotates backwards unless prevented by a ratchet, thus making

64:

attached to the output shaft producing a second rotating magnetic field. The rotor magnetic field may be produced by permanent magnets, reluctance saliency, or DC or AC electrical windings.

564:

a control-voltage (AC) winding in quadrature (i.e., 90 degrees phase shifted) with the main winding so as to produce a rotating magnetic field. Reversing phase makes the motor reverse.

417:

71:

operate on similar principles as rotating motors but have their stationary and moving parts arranged in a straight line configuration, producing linear motion instead of rotation.

302:

254:, and loading the motor increases the amount of slip as the motor slows down slightly. Even with no load, internal mechanical losses prevent the slip from being zero.

751:

because the rotor will rotate synchronously with the rotating magnetic field produced by the polyphase electrical supply. Another synchronous motor system is the

804:

automatically). Machines used for this purpose are easily identified as they have no shaft extensions. Synchronous motors are valued in any case because their

257:

The speed of the AC motor is determined primarily by the frequency of the AC supply and the number of poles in the stator winding, according to the relation:

96:

has an independently excited rotor winding that does not rely on the principles of slip-induction of current. The brushless wound-rotor doubly fed motor is a

534:(where the motor is large compared with the short-circuit capacity of the supply), the motor is started at reduced voltage using either series inductors, an

699:

high resistive and less inductive. The main winding is made with thicker wire with larger number of turns which makes it less resistive and more inductive.

828:

Small single-phase AC motors can also be designed with magnetized rotors (or several variations on that idea; see "Hysteresis synchronous motors" below).

246:

slower than synchronous speed. Because the rotating field (or equivalent pulsating field) effectively rotates faster than the rotor, it could be said to

83:(or asynchronous motor) always relies on a small difference in speed between the stator rotating magnetic field and the rotor shaft speed called slip to

752:

926:

rotor, which create torque by repulsion instead of attraction as in other motors. Several types of repulsion motors have been manufactured, but the

1500:

1659:

1633:

1607:

1581:

1015:. The current-to-torque and frequency-to-speed relationships of BLDC motors are linear. While the motor coils are powered by DC, power may be

943:

1879:

Galileo

Ferraris – "Father of three-phase current" – Electrotechnical Congress, Frankfurt 1891, Who Invented the Polyphase Electric Motor?

1871:

1808:

934:. Repulsion motors were developed before suitable motor starting capacitors were available, and few repulsion motors are sold as of 2005.

2190:

1934:

1397:

1565:

1310:

17:

181:

on 28 June 1879, to the

Physical Society of London. Describing an apparatus nearly identical to Baily's, French electrical engineer

578:

direction. After starting, the alternating stator field is in relative rotation with the rotor. Several methods are commonly used:

1737:

1685:

1325:

519:

470:, which will be found in virtually all domestic and light industrial alternating current motors. The squirrel-cage refers to the

1478:

545:

This type of motor is becoming more common in traction applications such as locomotives, where it is known as the asynchronous

194:. In 1887, American inventor Charles Schenk Bradley was the first to patent a two-phase AC power transmission with four wires.

1830:

1781:

1747:

1721:

1695:

1669:

1643:

1617:

1591:

1453:

1422:

1357:

1276:

1249:

1201:

1171:

1144:

1113:

1711:

1428:

1119:

621:. Each pole face was split, and had a shading coil on one part; the shading coils were on the parts that faced each other.

218:, and other three-phase AC systems were developed by German technician Friedrich August Haselwander and Swedish engineer

1872:

Univ.Prof. Dr.Ing. Martin

Doppelbauer: The invention of the electric motor, Karlsruhe Institute of Technology – KIT

872:

A universal motor is a design that can operate on either AC or DC power. In universal motors the stator and rotor of a

817:

333:

The constant 120 results from combining the conversions of 60 seconds per minute and that each phase requires 2 poles.

107:

motors, and AC and DC mechanically commutated machines in which speed is dependent on voltage and winding connection.

1391:

447:

mean that the frequency of the power supply can also now be varied to provide a smoother control of the motor speed.

2370:

1838:

1927:

812:

2319:

1525:

1516:

894:

Universal motors are widely used in small home appliances and hand power tools. Until the 1970s they dominated

2104:

215:

336:

Actual RPM for an induction motor will be less than this calculated synchronous speed by an amount known as

2452:

355:

1864:

2462:

2175:

2148:

1661:

Audel HVAC Fundamentals, Volume 2: Heating System

Components, Gas and Oil Burners, and Automatic Controls

1583:

Audel HVAC Fundamentals, Volume 2: Heating System

Components, Gas and Oil Burners, and Automatic Controls

1301:

Galileo

Ferraris, "Electromagnetic rotation with an alternating current," Electrican, Vol 36 . pg 360-75.

994:

93:

2472:

2467:

1920:

1073:

1065:

1032:

1004:

908:

795:

One use for this type of motor is its use in a power factor correction scheme. They are referred to as

210:

808:

is much better than that of induction motors, making them preferred for very high power applications.

2547:

2165:

2143:

557:

A typical two-phase AC servo-motor has a squirrel cage rotor and a field consisting of two windings:

84:

100:

that can function exactly at the supply frequency or sub to super multiple of the supply frequency.

2416:

2270:

904:

767:

527:

250:

past the surface of the rotor. The difference between synchronous speed and actual speed is called

2517:

263:

2457:

2008:

455:

57:

2280:

2185:

2114:

1804:

1347:

1103:

899:

887:

514:

243:

1767:

1381:

1239:

1161:

1134:

946:) have the stator on the inside and the rotor on the outside to optimize inertia and cooling.

2411:

2275:

2013:

1993:

1973:

1266:

1008:

796:

178:

115:

1563:

Split Phase

Induction Motor section in Neets module 5: Introduction to Generators and Motors

820:

in

Virginia, USA. When pumping, each unit can produce 642,800 horsepower (479.3 megawatts).

784:

Huge numbers of three phase synchronous motors are now fitted to electric cars. They have a

154:. Faraday is usually given credit for this discovery since he published his findings first.

127:

Drawing from U.S. Patent 381968, illustrating principle of Tesla's alternating current motor

2406:

2299:

2048:

2023:

1562:

1224:

32:

8:

2512:

2215:

2210:

1955:

467:

451:

131:

49:

1268:

The Froehlich/Kent Encyclopedia of Telecommunications: Volume 17 – Television Technology

653:. Compared to the shaded pole motor, these motors provide much greater starting torque.

2578:

2537:

2431:

2386:

2324:

2294:

2248:

2071:

2058:

1545:

931:

151:

1322:

2497:

2401:

2329:

2121:

2109:

2099:

1777:

1743:

1717:

1691:

1665:

1639:

1613:

1587:

1537:

1494:

1449:

1418:

1387:

1353:

1272:

1245:

1197:

1167:

1140:

1109:

1036:

895:

789:

748:

728:

618:

587:

444:

97:

88:

2447:

1865:

Silvanus Phillips Thompson: Polyphase electric currents and alternate current motors

1549:

530:

can now be used for speed control, and wound rotor motors are becoming less common.

443:

on and off to change the speed of magnetic field rotation. However, developments in

219:

2552:

2542:

2482:

2426:

2396:

2344:

2240:

2230:

2220:

2170:

2033:

2003:

1943:

1906:

1893:

1878:

1529:

1012:

1007:(DC) electricity and having electronic commutation systems, rather than mechanical

873:

833:

498:

202:

174:

161:

generated a crude form of alternating current when he designed and built the first

147:

61:

2487:

1900:

1887:

1218:

1163:

Empires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the World

165:. It consisted of a revolving horseshoe magnet passing over two wound-wire coils.

2527:

2477:

2339:

2160:

2138:

2126:

2094:

1998:

1569:

1443:

1412:

1329:

1191:

1050:

1000:

920:

867:

682:

674:

657:

646:

642:

535:

490:

231:

198:

158:

135:

80:

79:

The two main types of AC motors are induction motors and synchronous motors. The

2502:

1470:

970:

Single-speed or two speed motors are designed for coupling to gear motor system

2522:

2421:

2391:

2253:

2205:

2153:

2081:

2018:

1961:

1375:

982:

978:

774:

546:

143:

45:

1292:

that no commutator or connection of any kind with the armature was required."]

1241:

Innovation as a Social Process: Elihu Thomson and the Rise of General Electric

799:. This exploits a feature of the machine where it consumes power at a leading

733:

190:

built an AC motor by expanding upon the induction-repulsion principle and his

2572:

2532:

2200:

1541:

1045:

954:

650:

502:

471:

187:

182:

1533:

1383:

Evolving Technology and Market Structure: Studies in Schumpeterian Economics

2557:

2492:

2180:

1058:

878:

805:

800:

595:

342:

206:

169:

139:

104:

68:

2334:

2265:

681:

A capacitor start motor is a split-phase induction motor with a starting

478:

1410:

974:. Conical rotor brake motors are also used to power micro speed drives.

2225:

2195:

2066:

2028:

1193:

Wizard: The Life and Times of Nikola Tesla : Biography of a Genius

760:

686:

494:

162:

898:(electric, including diesel-electric railway and road vehicles); many

2507:

2260:

2038:

1445:

The Fundamentals of Nuclear Power Generation: Questions & Answers

1016:

785:

766:

Contemporary synchronous motors are frequently driven by solid state

539:

191:

119:

The first AC motor in the world of Italian physicist Galileo Ferraris

1912:

1765:

52:(AC). The AC motor commonly consists of two basic parts, an outside

2289:

2133:

883:

669:

1072:

Other variations of the same design are used for polyphase (e.g.,

606:

each pair was common, so only three terminals were needed in all.

2365:

2360:

971:

942:

Where speed stability is important, some AC motors (such as some

840:

1514:

Neidhöfer, Gerhard (2007). "Early Three-Phase Power (History)".

2043:

1967:

1773:

591:

53:

1414:

Micromechatronics: Modeling, Analysis, and Design with MATLAB

1264:

1105:

Historical Encyclopedia of Natural and Mathematical Sciences

123:

56:

having coils supplied with alternating current to produce a

1136:

The Gateway to Understanding: Electrons to Waves and Beyond

1379:

1216:

1132:

513:

An alternate design, called the wound rotor, is used when

861:

778:

753:

brushless wound-rotor doubly fed synchronous motor system

685:

inserted in series with the startup winding, creating an

477:

In operation, the squirrel-cage motor may be viewed as a

94:

brushless wound-rotor doubly fed synchronous motor system

1220:

Polyphase Electric Currents and Alternate-current Motors

458:

as pure electrical (not electromechanical) application.

1108:. Springer Science & Business Media. p. 2640.

1417:(Second ed.). Taylor & Francis. p. 141.

1079:

346:

are rated to operate at 100% slip (0 RPM/full stall).

358:

266:

2191:

Dual-rotor permanent magnet induction motor (DRPMIM)

1349:

Biographical Dictionary of the History of Technology

1411:Victor Giurgiutiu; Sergey Edward Lyshevski (2003).

1371:

1369:

1345:

505:, etc. uses some variant of a squirrel-cage motor.

1905:is available for free viewing and download at the

1892:is available for free viewing and download at the

1237:

988:

877:the inductive reactance of the stator winding and

702:

411:

296:

823:

2570:

1366:

737:Three-phase system with rotating magnetic fields

214:design was also worked on by the Swiss engineer

1101:

847:

572:

522:configuration showing twice the power density.

27:Electric motor driven by an AC electrical input

1189:

1166:. Random House Publishing Group. p. 162.

741:

590:and is used in devices requiring low starting

432:= Rotational speed, in revolutions per minute.

317:= Synchronous speed, in revolutions per minute

1928:

1766:George Shultz, George Patrick Shultz (1997).

1556:

1441:

1386:. University of Michigan Press. p. 138.

759:The synchronous motor can also be used as an

450:This kind of rotor is the basic hardware for

1687:Basic Electrical and Electronics Engineering

1638:. Craftsman Book Company. 20 February 2024.

1185:

1183:

773:Synchronous motors are occasionally used as

637:Another common single-phase AC motor is the

201:seem to have been independently invented by

168:Because of AC's advantages in long-distance

1499:: CS1 maint: numeric names: authors list (

1244:. Cambridge University Press. p. 258.

1159:

781:may be the best-known example of such use.

349:The slip of the AC motor is calculated by:

1935:

1921:

1761:

1759:

999:Electronically commutated (EC) motors are

323:= AC power frequency, in cycles per second

1513:

1311:Prodigal Genius: The Life of Nikola Tesla

1180:

977:Motors of this type can also be found on

693:

1805:"13.7. Tesla polyphase induction motors"

1690:. Laxmi Publications. 20 February 2024.

953:

732:

709:permanent-split capacitor (or PSC) motor

668:

664:

552:

508:

122:

114:

31:

1756:

1265:Fritz E. Froehlich; Allen Kent (1998).

1022:

856:

461:

74:

14:

2571:

1664:. John Wiley & Sons. 2 July 2004.

1586:. John Wiley & Sons. 2 July 2004.

1352:. Taylor & Francis. p. 1204.

949:

862:Universal motor and series wound motor

472:rotating exercise cage for pet animals

454:, which is an exception of the use of

1942:

1916:

1380:Arnold Heertje; Mark Perlman (1990).

1122:from the original on 3 December 2016.

561:a constant-voltage (AC) main winding.

412:{\displaystyle S=(N_{s}-N_{r})/N_{s}}

197:"Commutatorless" alternating current

142:'s 1830–31 discovery that a changing

1831:"Bath County Pumped Storage Station"

1742:. Firewall Media. 20 February 2024.

1481:from the original on 14 October 2017

1469:Center, Copyright 2014 Edison Tech.

722:

656:A split-phase motor has a secondary

632:

581:

1217:Silvanus Phillips Thompson (1895).

1133:Matthew M. Radmanesh Ph.D. (2005).

1080:Slow-speed synchronous timing motor

586:A common single-phase motor is the

329:= Number of poles per phase winding

24:

1468:

914:

818:Bath County Pumped Storage Station

811:Some of the largest AC motors are

225:

25:

2590:

1857:

937:

157:In 1832, French instrument maker

1811:from the original on 23 May 2013

1431:from the original on 5 May 2018.

1400:from the original on 5 May 2018.

1889:AC MOTORS AND GENERATORS (1961)

1823:

1797:

1730:

1704:

1678:

1652:

1626:

1600:

1574:

1526:IEEE Power & Energy Society

1507:

1462:

1435:

1404:

1339:

1316:

1304:

989:Electronically commutated motor

813:pumped-storage hydroelectricity

703:Permanent-split capacitor motor

2320:Timeline of the electric motor

1517:IEEE Power and Energy Magazine

1346:Lance Day; Ian McNeil (2003).

1295:

1285:

1258:

1231:

1210:

1153:

1126:

1095:

824:Single-phase synchronous motor

466:Most common AC motors use the

391:

365:

103:Other types of motors include

13:

1:

2105:Dahlander pole changing motor

1196:. Citadel Press. p. 24.

1088:

928:repulsion-start induction-run

216:Charles Eugene Lancelot Brown

1739:Alternating Current Machines

1635:Commercial Electrical Wiring

1448:. Author House. p. 27.

1334:The Case Files: Nikola Tesla

1139:. AuthorHouse. p. 296.

958:AC Motor with sliding rotors

848:Hysteresis synchronous motor

603:reversible shaded-pole motor

573:Single-phase induction motor

297:{\displaystyle N_{s}=120F/p}

7:

2149:Brushless DC electric motor

1713:Electrical Craft Principles

1612:. S. Chand. 8 August 2005.

1323:"Two-Phase Induction Motor"

1238:W. Bernard Carlson (2003).

1019:from AC within the casing.

995:Brushless DC electric motor

909:power semiconductor devices

790:rare-earth permanent magnet

742:Polyphase synchronous motor

639:split-phase induction motor

10:

2595:

992:

918:

865:

726:

438:= Normalised Slip, 0 to 1.

229:

211:Mikhail Dolivo-Dobrovolsky

110:

2440:

2379:

2353:

2308:

2239:

2166:Switched reluctance (SRM)

2144:Brushed DC electric motor

2080:

2057:

1982:

1950:

1471:"History of Transformers"

1336:, The Franklin Institute.

1271:. CRC Press. p. 36.

905:variable-frequency drives

768:variable-frequency drives

707:Another variation is the

134:technology was rooted in

18:Alternating current motor

2354:Experimental, futuristic

2271:Variable-frequency drive

1328:18 November 2012 at the

1102:Ari Ben-Menahem (2009).

907:made possible by modern

528:variable-frequency drive

2371:Superconducting machine

2009:Coil winding technology

1835:Dominion Resources, Inc

1769:Transformers and Motors

1534:10.1109/MPE.2007.904752

1190:Marc J. Seifer (1996).

900:traction power networks

456:rotating magnetic field

236:

58:rotating magnetic field

1837:. 2007. Archived from

1442:M. W. Hubbell (2011).

959:

797:synchronous condensers

738:

694:Resistance start motor

678:

520:wound rotor doubly fed

413:

298:

128:

120:

37:

2412:Power-to-weight ratio

2276:Direct torque control

957:

736:

672:

665:Capacitor start motor

553:Two-phase servo motor

509:Polyphase wound rotor

414:

299:

126:

118:

35:

2407:Open-loop controller

2300:Ward Leonard control

2024:DC injection braking

1716:. 20 February 1995.

1475:edisontechcenter.org

1160:Jill Jonnes (2003).

1023:Watthour-meter motor

857:Other AC motor types

462:Polyphase cage rotor

452:induction regulators

356:

264:

75:Operating principles

2310:History, education,

1956:Alternating current

1568:5 June 2011 at the

950:Sliding rotor motor

641:, commonly used in

468:squirrel-cage rotor

132:Alternating current

50:alternating current

2473:Dolivo-Dobrovolsky

2432:Voltage controller

2387:Blocked-rotor test

2325:Ball bearing motor

2295:Motor soft starter

2249:AC-to-AC converter

2110:Wound-rotor (WRIM)

2072:Electric generator

1609:Electrical Science

960:

932:voltage regulation

739:

679:

409:

294:

129:

121:

38:

2566:

2565:

2402:Open-circuit test

2241:Motor controllers

2122:Synchronous motor

1944:Electric machines

1783:978-0-7506-9948-8

1749:978-81-7008-222-4

1723:978-0-85296-833-8

1697:978-93-81159-25-5

1671:978-0-7645-4207-7

1645:978-1-57218-092-5

1619:978-81-219-2310-1

1593:978-0-7645-4207-7

1455:978-1-4634-2658-3

1424:978-0-203-50371-3

1359:978-0-203-02829-2

1278:978-0-8247-2915-8

1251:978-0-521-53312-6

1203:978-0-8065-1960-9

1173:978-1-58836-000-7

1146:978-1-4184-8740-9

1115:978-3-540-68831-0

1037:electricity meter

896:electric traction

749:synchronous motor

729:Synchronous motor

723:Synchronous motor

633:Split-phase motor

619:electricity meter

588:shaded-pole motor

582:Shaded-pole motor

445:power electronics

177:motor aided by a

98:synchronous motor

89:synchronous motor

16:(Redirected from

2586:

2417:Two-phase system

2397:Electromagnetism

2345:Mouse mill motor

2312:recreational use

2186:Permanent magnet

2115:Linear induction

1968:Permanent magnet

1937:

1930:

1923:

1914:

1913:

1907:Internet Archive

1902:AC MOTORS (1969)

1894:Internet Archive

1851:

1850:

1848:

1846:

1827:

1821:

1820:

1818:

1816:

1801:

1795:

1794:

1792:

1790:

1763:

1754:

1753:

1734:

1728:

1727:

1708:

1702:

1701:

1682:

1676:

1675:

1656:

1650:

1649:

1630:

1624:

1623:

1604:

1598:

1597:

1578:

1572:

1560:

1554:

1553:

1511:

1505:

1504:

1498:

1490:

1488:

1486:

1466:

1460:

1459:

1439:

1433:

1432:

1408:

1402:

1401:

1373:

1364:

1363:

1343:

1337:

1320:

1314:

1308:

1302:

1299:

1293:

1289:

1283:

1282:

1262:

1256:

1255:

1235:

1229:

1228:

1223:. Spon. p.

1214:

1208:

1207:

1187:

1178:

1177:

1157:

1151:

1150:

1130:

1124:

1123:

1099:

874:brushed DC motor

834:reluctance motor

647:air conditioners

643:major appliances

615:adjustable-speed

489:Virtually every

418:

416:

415:

410:

408:

407:

398:

390:

389:

377:

376:

303:

301:

300:

295:

290:

276:

275:

203:Galileo Ferraris

199:induction motors

148:electric current

67:Less common, AC

60:, and an inside

21:

2594:

2593:

2589:

2588:

2587:

2585:

2584:

2583:

2569:

2568:

2567:

2562:

2436:

2375:

2349:

2340:Mendocino motor

2313:

2311:

2304:

2235:

2095:Induction motor

2076:

2053:

1999:Braking chopper

1987:

1985:

1978:

1946:

1941:

1899:The short film

1886:The short film

1860:

1855:

1854:

1844:

1842:

1841:on 4 April 2007

1829:

1828:

1824:

1814:

1812:

1803:

1802:

1798:

1788:

1786:

1784:

1776:. p. 159.

1764:

1757:

1750:

1736:

1735:

1731:

1724:

1710:

1709:

1705:

1698:

1684:

1683:

1679:

1672:

1658:

1657:

1653:

1646:

1632:

1631:

1627:

1620:

1606:

1605:

1601:

1594:

1580:

1579:

1575:

1570:Wayback Machine

1561:

1557:

1512:

1508:

1492:

1491:

1484:

1482:

1467:

1463:

1456:

1440:

1436:

1425:

1409:

1405:

1394:

1378:, Mark Perlman

1374:

1367:

1360:

1344:

1340:

1330:Wayback Machine

1321:

1317:

1309:

1305:

1300:

1296:

1290:

1286:

1279:

1263:

1259:

1252:

1236:

1232:

1215:

1211:

1204:

1188:

1181:

1174:

1158:

1154:

1147:

1131:

1127:

1116:

1100:

1096:

1091:

1082:

1051:right-hand rule

1025:

1001:electric motors

997:

991:

979:overhead cranes

952:

940:

923:

921:Repulsion motor

917:

915:Repulsion motor

870:

868:Universal motor

864:

859:

850:

826:

775:traction motors

744:

731:

725:

705:

696:

683:motor capacitor

673:Schematic of a

667:

658:startup winding

635:

584:

575:

555:

536:autotransformer

511:

491:washing machine

464:

430:

403:

399:

394:

385:

381:

372:

368:

357:

354:

353:

315:

286:

271:

267:

265:

262:

261:

239:

234:

232:Induction motor

228:

226:Induction motor

159:Hippolyte Pixii

136:Michael Faraday

113:

81:induction motor

77:

28:

23:

22:

15:

12:

11:

5:

2592:

2582:

2581:

2564:

2563:

2561:

2560:

2555:

2550:

2545:

2540:

2535:

2530:

2525:

2520:

2515:

2510:

2505:

2500:

2495:

2490:

2485:

2480:

2475:

2470:

2465:

2460:

2455:

2450:

2444:

2442:

2438:

2437:

2435:

2434:

2429:

2424:

2422:Inchworm motor

2419:

2414:

2409:

2404:

2399:

2394:

2392:Circle diagram

2389:

2383:

2381:

2380:Related topics

2377:

2376:

2374:

2373:

2368:

2363:

2357:

2355:

2351:

2350:

2348:

2347:

2342:

2337:

2332:

2330:Barlow's wheel

2327:

2322:

2316:

2314:

2309:

2306:

2305:

2303:

2302:

2297:

2292:

2287:

2286:

2285:

2284:

2283:

2281:Vector control

2278:

2263:

2258:

2257:

2256:

2254:Cycloconverter

2245:

2243:

2237:

2236:

2234:

2233:

2228:

2223:

2218:

2213:

2208:

2203:

2198:

2193:

2188:

2183:

2178:

2173:

2168:

2163:

2158:

2157:

2156:

2151:

2146:

2141:

2131:

2130:

2129:

2124:

2119:

2118:

2117:

2112:

2107:

2102:

2086:

2084:

2078:

2077:

2075:

2074:

2069:

2063:

2061:

2055:

2054:

2052:

2051:

2046:

2041:

2036:

2031:

2026:

2021:

2019:Damper winding

2016:

2011:

2006:

2001:

1996:

1990:

1988:

1984:Components and

1983:

1980:

1979:

1977:

1976:

1970:

1964:

1962:Direct current

1958:

1951:

1948:

1947:

1940:

1939:

1932:

1925:

1917:

1911:

1910:

1897:

1883:

1882:

1875:

1868:

1859:

1858:External links

1856:

1853:

1852:

1822:

1796:

1782:

1755:

1748:

1729:

1722:

1703:

1696:

1677:

1670:

1651:

1644:

1625:

1618:

1599:

1592:

1573:

1555:

1506:

1461:

1454:

1434:

1423:

1403:

1392:

1376:Arnold Heertje

1365:

1358:

1338:

1315:

1303:

1294:

1284:

1277:

1257:

1250:

1230:

1209:

1202:

1179:

1172:

1152:

1145:

1125:

1114:

1093:

1092:

1090:

1087:

1081:

1078:

1024:

1021:

1005:direct-current

993:Main article:

990:

987:

951:

948:

939:

938:Exterior rotor

936:

919:Main article:

916:

913:

866:Main article:

863:

860:

858:

855:

849:

846:

825:

822:

743:

740:

727:Main article:

724:

721:

704:

701:

695:

692:

666:

663:

651:clothes dryers

634:

631:

583:

580:

574:

571:

566:

565:

562:

554:

551:

547:traction motor

515:variable speed

510:

507:

463:

460:

440:

439:

433:

428:

420:

419:

406:

402:

397:

393:

388:

384:

380:

375:

371:

367:

364:

361:

331:

330:

324:

318:

313:

305:

304:

293:

289:

285:

282:

279:

274:

270:

238:

235:

230:Main article:

227:

224:

220:Jonas Wenström

146:can induce an

144:magnetic field

112:

109:

76:

73:

46:electric motor

26:

9:

6:

4:

3:

2:

2591:

2580:

2577:

2576:

2574:

2559:

2556:

2554:

2551:

2549:

2546:

2544:

2541:

2539:

2536:

2534:

2531:

2529:

2526:

2524:

2521:

2519:

2516:

2514:

2511:

2509:

2506:

2504:

2501:

2499:

2496:

2494:

2491:

2489:

2486:

2484:

2481:

2479:

2476:

2474:

2471:

2469:

2466:

2464:

2461:

2459:

2456:

2454:

2451:

2449:

2446:

2445:

2443:

2439:

2433:

2430:

2428:

2425:

2423:

2420:

2418:

2415:

2413:

2410:

2408:

2405:

2403:

2400:

2398:

2395:

2393:

2390:

2388:

2385:

2384:

2382:

2378:

2372:

2369:

2367:

2364:

2362:

2359:

2358:

2356:

2352:

2346:

2343:

2341:

2338:

2336:

2333:

2331:

2328:

2326:

2323:

2321:

2318:

2317:

2315:

2307:

2301:

2298:

2296:

2293:

2291:

2288:

2282:

2279:

2277:

2274:

2273:

2272:

2269:

2268:

2267:

2264:

2262:

2259:

2255:

2252:

2251:

2250:

2247:

2246:

2244:

2242:

2238:

2232:

2229:

2227:

2224:

2222:

2219:

2217:

2216:Piezoelectric

2214:

2212:

2211:Electrostatic

2209:

2207:

2204:

2202:

2199:

2197:

2194:

2192:

2189:

2187:

2184:

2182:

2179:

2177:

2174:

2172:

2169:

2167:

2164:

2162:

2159:

2155:

2152:

2150:

2147:

2145:

2142:

2140:

2137:

2136:

2135:

2132:

2128:

2125:

2123:

2120:

2116:

2113:

2111:

2108:

2106:

2103:

2101:

2098:

2097:

2096:

2093:

2092:

2091:

2088:

2087:

2085:

2083:

2079:

2073:

2070:

2068:

2065:

2064:

2062:

2060:

2056:

2050:

2047:

2045:

2042:

2040:

2037:

2035:

2032:

2030:

2027:

2025:

2022:

2020:

2017:

2015:

2012:

2010:

2007:

2005:

2002:

2000:

1997:

1995:

1992:

1991:

1989:

1981:

1975:

1971:

1969:

1965:

1963:

1959:

1957:

1953:

1952:

1949:

1945:

1938:

1933:

1931:

1926:

1924:

1919:

1918:

1915:

1908:

1904:

1903:

1898:

1895:

1891:

1890:

1885:

1884:

1881:

1880:

1876:

1874:

1873:

1869:

1867:

1866:

1862:

1861:

1840:

1836:

1832:

1826:

1810:

1806:

1800:

1785:

1779:

1775:

1771:

1770:

1762:

1760:

1751:

1745:

1741:

1740:

1733:

1725:

1719:

1715:

1714:

1707:

1699:

1693:

1689:

1688:

1681:

1673:

1667:

1663:

1662:

1655:

1647:

1641:

1637:

1636:

1629:

1621:

1615:

1611:

1610:

1603:

1595:

1589:

1585:

1584:

1577:

1571:

1567:

1564:

1559:

1551:

1547:

1543:

1539:

1535:

1531:

1527:

1523:

1519:

1518:

1510:

1502:

1496:

1480:

1476:

1472:

1465:

1457:

1451:

1447:

1446:

1438:

1430:

1426:

1420:

1416:

1415:

1407:

1399:

1395:

1393:0-472-10192-7

1389:

1385:

1384:

1377:

1372:

1370:

1361:

1355:

1351:

1350:

1342:

1335:

1331:

1327:

1324:

1319:

1312:

1307:

1298:

1288:

1280:

1274:

1270:

1269:

1261:

1253:

1247:

1243:

1242:

1234:

1226:

1222:

1221:

1213:

1205:

1199:

1195:

1194:

1186:

1184:

1175:

1169:

1165:

1164:

1156:

1148:

1142:

1138:

1137:

1129:

1121:

1117:

1111:

1107:

1106:

1098:

1094:

1086:

1077:

1075:

1070:

1067:

1062:

1060:

1054:

1052:

1047:

1046:Lorentz force

1041:

1038:

1034:

1029:

1020:

1018:

1014:

1010:

1006:

1002:

996:

986:

984:

980:

975:

973:

968:

964:

956:

947:

945:

935:

933:

929:

922:

912:

910:

906:

901:

897:

892:

889:

885:

880:

875:

869:

854:

845:

842:

837:

835:

829:

821:

819:

814:

809:

807:

802:

798:

793:

791:

787:

782:

780:

776:

771:

769:

764:

762:

757:

754:

750:

735:

730:

720:

716:

712:

710:

700:

691:

688:

684:

676:

671:

662:

659:

654:

652:

648:

644:

640:

630:

626:

622:

620:

616:

611:

607:

604:

599:

597:

596:electric fans

593:

589:

579:

570:

563:

560:

559:

558:

550:

548:

543:

541:

537:

531:

529:

523:

521:

516:

506:

504:

503:record player

500:

497:, standalone

496:

492:

487:

483:

480:

475:

473:

469:

459:

457:

453:

448:

446:

437:

434:

431:

425:

424:

423:

404:

400:

395:

386:

382:

378:

373:

369:

362:

359:

352:

351:

350:

347:

345:

344:

343:torque motors

339:

334:

328:

325:

322:

319:

316:

310:

309:

308:

291:

287:

283:

280:

277:

272:

268:

260:

259:

258:

255:

253:

249:

245:

233:

223:

221:

217:

212:

208:

204:

200:

195:

193:

189:

188:Elihu Thomson

184:

183:Marcel Deprez

180:

176:

171:

166:

164:

160:

155:

153:

149:

145:

141:

137:

133:

125:

117:

108:

106:

101:

99:

95:

90:

86:

82:

72:

70:

69:linear motors

65:

63:

59:

55:

51:

48:driven by an

47:

43:

34:

30:

19:

2089:

1901:

1888:

1877:

1870:

1863:

1843:. Retrieved

1839:the original

1834:

1825:

1813:. Retrieved

1799:

1789:26 September

1787:. Retrieved

1768:

1738:

1732:

1712:

1706:

1686:

1680:

1660:

1654:

1634:

1628:

1608:

1602:

1582:

1576:

1558:

1521:

1515:

1509:

1483:. Retrieved

1474:

1464:

1444:

1437:

1413:

1406:

1382:

1348:

1341:

1333:

1318:

1306:

1297:

1287:

1267:

1260:

1240:

1233:

1219:

1212:

1192:

1162:

1155:

1135:

1128:

1104:

1097:

1083:

1071:

1063:

1059:net metering

1055:

1042:

1030:

1026:

998:

976:

969:

965:

961:

944:Papst motors

941:

927:

924:

893:

879:eddy current

871:

851:

838:

830:

827:

810:

806:power factor

801:power factor

794:

783:

772:

765:

758:

745:

717:

713:

708:

706:

697:

680:

655:

638:

636:

627:

623:

614:

613:An unusual,

612:

608:

602:

600:

585:

576:

567:

556:

544:

532:

524:

512:

488:

484:

476:

465:

449:

441:

435:

426:

421:

348:

341:

337:

335:

332:

326:

320:

311:

306:

256:

251:

247:

240:

207:Nikola Tesla

196:

170:high voltage

167:

156:

140:Joseph Henry

130:

105:eddy current

102:

78:

66:

41:

39:

29:

2335:Lynch motor

2100:Shaded-pole

1986:accessories

1815:1 September

1074:three-phase

1066:split-phase

1061:possible.)

1033:split-phase

1009:commutators

1003:powered by

677:start motor

479:transformer

2231:Axial flux

2221:Ultrasonic

2196:Servomotor

2176:Doubly fed

2171:Reluctance

2067:Alternator

2059:Generators

2029:Field coil

2014:Commutator

1974:commutated

1972:SC - Self-

1528:: 88–100.

1089:References

761:alternator

687:LC circuit

594:, such as

540:thyristors

495:dishwasher

179:commutator

163:alternator

2579:AC motors

2548:Steinmetz

2463:Davenport

2261:Amplidyne

2161:Universal

2139:Homopolar

2127:Repulsion

2039:Slip ring

1542:1540-7977

1076:) power.

1035:watthour

1017:rectified

972:gearboxes

884:rheostats

788:or other

786:neodymium

675:capacitor

379:−

192:wattmeter

175:polyphase

2573:Category

2553:Sturgeon

2483:Ferraris

2468:Davidson

2290:Metadyne

2206:Traction

2154:Unipolar

2134:DC motor

2090:AC motor

1994:Armature

1845:30 March

1809:Archived

1566:Archived

1550:32896607

1495:cite web

1479:Archived

1429:Archived

1398:Archived

1332:(2011),

1326:Archived

1313:. Pg 115

1120:Archived

839:Because

645:such as

42:AC motor

2543:Sprague

2538:Siemens

2513:Maxwell

2478:Faraday

2427:Starter

2366:Railgun

2361:Coilgun

2201:Stepper

2049:Winding

1013:brushes

841:inertia

152:circuit

138:'s and

111:History

2533:Saxton

2518:Ørsted

2503:Jedlik

2498:Jacobi

2488:Gramme

2453:Barlow

2441:People

2266:Drives

2181:Linear

2082:Motors

2044:Stator

1780:

1774:Newnes

1746:

1720:

1694:

1668:

1642:

1616:

1590:

1548:

1540:

1452:

1421:

1390:

1356:

1275:

1248:

1200:

1170:

1143:

1112:

983:hoists

967:1963.

777:; the

592:torque

422:where

307:where

85:induce

54:stator

44:is an

2558:Tesla

2528:Pixii

2493:Henry

2458:Botto

2448:Arago

2034:Rotor

2004:Brush

1966:PM -

1960:DC -

1954:AC -

1546:S2CID

1524:(5).

1485:5 May

1064:In a

150:in a

62:rotor

2523:Park

2508:Lenz

2226:TEFC

1847:2007

1817:2013

1791:2008

1778:ISBN

1744:ISBN

1718:ISBN

1692:ISBN

1666:ISBN

1640:ISBN

1614:ISBN

1588:ISBN

1538:ISSN

1501:link

1487:2018

1450:ISBN

1419:ISBN

1388:ISBN

1354:ISBN

1273:ISBN

1246:ISBN

1198:ISBN

1168:ISBN

1141:ISBN

1110:ISBN

1011:and

981:and

886:and

649:and

338:slip

252:slip

248:slip

237:Slip

205:and

1530:doi

888:PWM

779:TGV

499:fan

281:120

244:RPM

40:An

2575::

1833:.

1807:.

1772:.

1758:^

1544:.

1536:.

1520:.

1497:}}

1493:{{

1477:.

1473:.

1427:.

1396:.

1368:^

1225:87

1182:^

1118:.

1031:A

911:.

836:.

792:.

763:.

601:A

549:.

538:,

501:,

493:,

222:.

1936:e

1929:t

1922:v

1909:.

1896:.

1849:.

1819:.

1793:.

1752:.

1726:.

1700:.

1674:.

1648:.

1622:.

1596:.

1552:.

1532::

1522:5

1503:)

1489:.

1458:.

1362:.

1281:.

1254:.

1227:.

1206:.

1176:.

1149:.

436:S

429:r

427:N

405:s

401:N

396:/

392:)

387:r

383:N

374:s

370:N

366:(

363:=

360:S

327:p

321:F

314:s

312:N

292:p

288:/

284:F

278:=

273:s

269:N

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.