248:. The percentage of each component varies for each different type of fiber, however, generally, are around 60-80% cellulose, 5–20% lignin, and 20% of moisture, besides hemicellulose and a small percent of residual chemical components. The properties of the fiber change depending on the amount of each component, since the hemicellulose is responsible for the moisture absorption, bio- and thermal degradation whereas lignin ensures thermal stability but is responsible for the UV degradation. The chemical composition of common natural fibers are shown below; these vary depending on whether the fiber is a

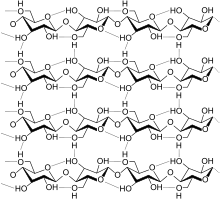

146:. These polysaccharides are also made from multiple subunits of glucose. The difference between cellulose and other complex carbohydrate molecules is how the glucose molecules are linked together. In addition, cellulose is a straight chain polymer, and each cellulose molecule is long and rod-like. This differs from starch, which is a coiled molecule. A result of these differences in structure is that, compared to starch and other carbohydrates, cellulose cannot be broken down into its glucose subunits by any enzymes produced by animals.

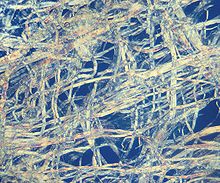

183:, etc. The presence of linear chains of thousands of glucose units linked together allows a great deal of hydrogen bonding between OH groups on adjacent chains, causing them to pack closely into cellulose fibers. As a result, cellulose exhibits little interaction with water or any other solvent. Cotton and wood, for example, are completely insoluble in water and have considerable mechanical strength. Since cellulose does not have a helical structure like amylose, it does not bind to iodine to form a colored product.

113:, who isolated it from plant matter and determined its chemical formula. Cellulose was used to produce the first successful thermoplastic polymer, celluloid, by Hyatt Manufacturing Company in 1870. Production of rayon ("artificial silk") from cellulose began in the 1890s, and cellophane was invented in 1912. In 1893, Arthur D. Little of Boston, invented yet another cellulosic product, acetate, and developed it as a film. The first commercial textile uses for acetate in fiber form were developed by the

98:

2098:

125:

777:. Due to the high swelling propensity of lignocellulosic fibers, a correlation between the zeta potential and the water uptake capability has been observed. Even for the use of waste fibers as a reinforcement in composite materials, sized fibers have been probed by an aqueous test solution. A review on the electrokinetic properties of natural fibers including cellulose and lignocellulosic fibers is found in the Handbook of Natural Fibers.

2108:

219:

Natural fibers are composed by microfibrils of cellulose in a matrix of hemicellulose and lignin. This type of structure and the chemical composition of them is responsible for the mechanical properties that can be observed. Because the natural fibers make hydrogen bonds between the long chains, they

1045:

The cellulose fibers infiltration/filter aid applications can provide a protective layer to filter elements as powdered cellulose, besides promoting improved throughput and clarity. As ashless and non-abrasive filtration, make cleanup effortless after the filtering process without damage in pumps or

952:

Void volume and water absorption: Fibers are fairly porous with a large volume of internal voids. As a result, when the fibers are immersed in the binding material, they absorb a large amount of matrix. High absorption can cause fiber shrinkage and matrix swelling. However, a high void volume

1046:

valves. They effectively filter metallic impurities and absorb up to 100% of emulsified oil and boiler condensates. In general, cellulose fibers in filtration applications can greatly improve filtration performance when used as a primary or remedial precoat in the following ways:

768:

Hydrophilicity, roughness and surface charge determine the interaction of cellulose fibers with an aqueous environment. Already in 1950, the charge at the interface between cotton as the predominant cellulose fiber and an aqueous surrounding was investigated by the

1074:

In comparison with engineered fibers, cellulose fibers have important advantages as low density, low cost, they can be recyclable, and are biodegradable. Due to its advantages cellulose fibers can be used as a substituent for glass fibers in composites materials.

948:

Dimensions: The relationship between the length and diameter of the fibers is a determining factor in the transfer of efforts to the matrix. Additionally, the irregular cross-section and fibrillated appearance of plant fibers helps anchor them within a fragile

93:

The main applications of cellulose fibers are in the textile industry, as chemical filters, and as fiber-reinforcement composites, due to their similar properties to engineered fibers, being another option for biocomposites and polymer composites.

1095:

as "bamboo fiber" appears, planting & harvesting bamboo for fiber can, in certain cases, be more sustainable and environmentally friendly than harvesting slower growing trees and clearing existing forest habitats for timber plantations.

137:

Cellulose is a polymer made of repeating glucose molecules attached end to end. A cellulose molecule may be from several hundred to over 10,000 glucose units long. Cellulose is similar in form to complex carbohydrates like

523:

change depending on fiber type and chemical structure present. Information about main mechanical properties are shown in the chart below and can be compared to properties of commonly used fibers such

965:: Cellulosic fibers have a low modulus of elasticity. This determines its use in building components working in post-cracked stage, with high energy absorption and resistance to dynamic forces.

121:

determined the polymer structure of cellulose in 1920. The compound was first chemically synthesized (without the use of any biologically derived enzymes) in 1992, by

Kobayashi and Shoda.

159:

Natural cellulose fibers are still recognizable as being from a part of the original plant because they are only processed as much as needed to clean the fibers for use. For example,

1331:

Bismarck, Alexander; Aranberri-Askargorta, Ibon; Springer, Jürgen; Lampke, Thomas; Wielage, Bernhard; Stamboulis, Artemis; Shenderovich, Ilja; Limbach, Hans-Heinrich (2002).

944:

Since macroscopic characteristics of fibers influence the behavior of the resulting composite, the following physical and mechanical properties are of particular interest:

82:

of cellulose, which can be obtained from the bark, wood or leaves of plants, or from other plant-based material. In addition to cellulose, the fibers may also contain

929:(matrix). This combination mixes the properties of the fiber with the matrix to create a new material that may be stronger than the fiber alone. When combined with

1557:

831:

171:

plant. All "natural" fibers go through a process where they are separated from the parts of the plant that are not used for the end product, usually through

998:. Cellulose-based fibers are of two types, regenerated or pure cellulose such as from the cupro-ammonium process and modified cellulose such as the

1255:

Xue, L. G.; Tabil, L.; Panigrahi, S. (2007). "Chemical

Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review".

1537:

1229:

1477:

1460:

2052:

1037:. Although these artificial fibers were discovered in the mid-nineteenth century, successful modern manufacture began much later.

1444:

953:

contributes to reduced weight, increased acoustic absorption, and low thermal conductivity of the final composite material.

1184:

Cellulose: molecular and structural biology: selected articles on the synthesis, structure, and applications of cellulose

1528:

Mohanty, A. K.; Misra, M.; Hinrichsen, G. (2000). "Biofibres, biodegradable polymers and biocomposites: An overview".

1504:

1191:

1588:

1554:

1293:"Electrokinetic Properties of Cellulose Fibers: Ii. Zeta-Potential Measurements by the Stream-Compression Method"

1334:"Surface characterization of flax, hemp and cellulose fibers; Surface properties and the water uptake behavior"

1091:

plants, but instead a highly processed bamboo pulp that is extruded as fibers. Although the process is not as

252:(obtained from the bark), a core fiber (obtained from the wood), or a leaf fiber (obtained from the leaves).

1053:

Improving the stability of the filter-aid cake to make it more resistant to pressure bumps and interruptions

1152:

1423:

1215:

245:

941:. The table displays different polymer matrices and the cellulose fibers they are often mixed with.

1186:. Brown, R. Malcolm (Richard Malcolm), 1939-, Saxena, I. M. (Inder M.). Dordrecht: Springer. 2007.

1092:

938:

90:, with different percentages of these components altering the mechanical properties of the fibers.

2111:

1421:

Luxbacher, Thomas (January 1, 2020), Kozłowski, Ryszard M.; Mackiewicz-Talarczyk, Maria (eds.),

1125:

1084:

211:

is one of the most common "manufactured" cellulose fibers, and it can be made from wood pulp.

1129:

1033:. They are also not an artificial construction of silk, which is a fibrous polymer of animal

975:

1233:

1939:

1901:

1581:

1050:

Bridging gaps in the filter septum and small mechanical leaks in the gaskets and leaf seats

8:

1914:

1797:

1292:

1056:

Creating a more uniform precoat with no cracks for more effective filtration surface area

770:

2142:

2132:

1436:

1403:

1375:"Influence of chemical treatments on the electrokinetic properties of cellulose fibres"

1333:

1272:

1209:

1105:

922:

881:

520:

118:

1169:

2147:

1909:

1878:

1699:

1510:

1500:

1440:

1395:

1372:

Pothan, Laly A.; Bellman, Cornelia; Kailas, Lekshmi; Thomas, Sabu (January 1, 2002).

1354:

1313:

1197:

1187:

1018:

999:

926:

901:

1407:

1276:

1021:

was discovered in 1865. Rayon and acetate are both artificial fibers, but not fully

1533:

1472:

1432:

1387:

1346:

1305:

1264:

1165:

956:

30:

1153:"Cellulosic fiber reinforced cement-based composites: A review of recent research"

2137:

2101:

1924:

1886:

1679:

1574:

1561:

1022:

1006:

995:

987:

962:

1832:

1972:

1777:

1632:

1391:

821:

811:

774:

229:

97:

1268:

933:, cellulose fibers are used to create some fiber-reinforced materials such as

2126:

1990:

1962:

1949:

1847:

1762:

1605:

1514:

1399:

1374:

1358:

1317:

1201:

925:

are a class of material most often made by the combination of a fiber with a

851:

233:

110:

83:

1982:

1431:, The Textile Institute Book Series, Woodhead Publishing, pp. 323–353,

2047:

2037:

1967:

1742:

1734:

934:

871:

841:

532:

192:

1538:

10.1002/(SICI)1439-2054(20000301)276:1<1::AID-MAME1>3.0.CO;2-W

1330:

1957:

1822:

1807:

1747:

1704:

1637:

861:

524:

191:

Manufactured cellulose fibers come from plants that are processed into a

1478:

10.1002/(SICI)1098-2329(199924)18:4<351::AID-ADV6>3.0.CO;2-X

2027:

2022:

1891:

1757:

1724:

1689:

1614:

1309:

249:

172:

1929:

1869:

1150:

Ardanuy, Mònica; Claramunt, Josep; Toledo Filho, Romildo Dias (2015).

2042:

1837:

1772:

1350:

1026:

891:

196:

22:

1087:

is actually not the fibers that grow in their natural form from the

180:

2010:

1855:

1787:

930:

163:

fibers look like the soft fluffy cotton balls that they come from.

143:

124:

114:

1622:

2069:

2064:

2059:

1919:

1627:

1034:

1010:

991:

208:

1694:

1065:

Precoating easily and rapidly and reducing soluble contamination

2074:

2005:

2000:

1995:

1817:

1802:

1792:

1767:

1752:

1714:

1647:

1088:

911:

528:

241:

237:

160:

139:

87:

195:

and then extruded in the same ways that synthetic fibers like

2079:

2032:

2015:

1934:

1719:

1709:

1684:

1662:

1652:

1597:

1014:

983:

979:

801:

204:

200:

176:

164:

79:

75:

1149:

1827:

1812:

1782:

1674:

1669:

1657:

1642:

1030:

168:

63:

51:

42:

39:

45:

1566:

1371:

1059:

Improving cake release and reducing cleaning requirements

109:

Cellulose was discovered in 1838 by the French chemist

1527:

1005:

The first artificial fiber, commercially promoted as

959:: Similar, on average, to the polypropylene's fibers.

763:

66:

54:

36:

856:

Flax, jute, kenaf, sunhemp, wheat straw, wood fiber

60:

48:

167:fibers look like the strong fibrous strands of the

33:

1422:

1373:

1332:

1291:

1151:

1424:"9 - Electrokinetic properties of natural fibres"

1254:

2124:

1497:Sustainable fashion and textiles design journeys

186:

1290:Mason, S. G.; Goring, D. A. I. (June 1, 1950).

1069:

16:Fibers made with ethers or esters of cellulose

1582:

1461:"Natural fiber polymer composites: A review"

1429:Handbook of Natural Fibres (Second Edition)

1289:

1025:, being a product of a chemically digested

220:have the necessary stiffness and strength.

214:

154:

1589:

1575:

1380:Journal of Adhesion Science and Technology

994:). Cellulose fibers are manufactured from

228:The major constituents of natural fibers (

1476:

1420:

1062:Preventing fine particulate bleed-through

128:Cellulose chains linked by hydrogen bonds

1530:Macromolecular Materials and Engineering

1494:

1458:

514:

123:

96:

1257:Journal of Polymers and the Environment

1078:

223:

2125:

785:

132:

1570:

1490:

1488:

2107:

1017:in 1924. A similar product known as

846:Kenaf, pineapple, sisal, wood fiber

1158:Construction and Building Materials

13:

1485:

1437:10.1016/b978-0-12-818782-1.00009-2

990:, and the more recently developed

764:Surface and interfacial properties

14:

2159:

1548:

1459:Saheb, D. N.; Jog, J. P. (1999).

1170:10.1016/j.conbuildmat.2015.01.035

896:Banana, jute, pineapple, sunhemp

2106:

2097:

2096:

29:

1521:

1452:

780:

1465:Advances in Polymer Technology

1414:

1365:

1324:

1283:

1248:

1222:

1176:

1143:

1118:

1:

1111:

1040:

773:method to assess the surface

187:Manufactured cellulose fibers

1298:Canadian Journal of Research

1070:Comparison with other fibers

519:Cellulose fiber response to

7:

1230:"Carbohydrates - Cellulose"

1099:

10:

2164:

1596:

1392:10.1163/156856102317293687

1130:The Free Online Dictionary

1083:What is often marketed as

969:

104:

2092:

1981:

1948:

1900:

1877:

1868:

1846:

1733:

1613:

1604:

1555:Dissolving of Cellulosics

1269:10.1007/s10924-006-0042-3

1013:around 1894, and finally

939:fiber-reinforced plastics

447:

402:

277:

257:

1093:environmentally friendly

974:In the textile industry

215:Structure and properties

155:Natural cellulose fibers

149:

1495:Fletcher, Kate (2008).

550:Tensile strength (MPa)

74:) are fibers made with

1560:April 3, 2013, at the

1214:: CS1 maint: others (

553:Young's modulus (GPa)

129:

101:

1532:. 276–277 (1): 1–24.

1499:. London: Earthscan.

976:regenerated cellulose

515:Mechanical properties

127:

100:

1236:on December 11, 2018

1079:Environmental issues

806:Abaca, bamboo, jute

224:Chemical composition

1029:comprising natural

923:Composite materials

832:Phenol-formaldehyde

786:Composite materials

771:streaming potential

521:mechanical stresses

133:Cellulose structure

1339:Polymer Composites

1310:10.1139/cjr50b-040

1106:Fiber modification

1009:, became known as

1000:cellulose acetates

882:Polyvinyl chloride

267:Hemicellulose (%)

175:, separating from

130:

119:Hermann Staudinger

102:

2120:

2119:

2088:

2087:

1864:

1863:

1446:978-0-12-818782-1

1126:"Cellulose fiber"

1019:cellulose acetate

920:

919:

902:Styrene-butadiene

761:

760:

512:

511:

232:) are cellulose,

117:Company in 1924.

2155:

2110:

2109:

2100:

2099:

1875:

1874:

1611:

1610:

1591:

1584:

1577:

1568:

1567:

1542:

1541:

1525:

1519:

1518:

1492:

1483:

1482:

1480:

1456:

1450:

1449:

1426:

1418:

1412:

1411:

1377:

1369:

1363:

1362:

1351:10.1002/pc.10485

1336:

1328:

1322:

1321:

1295:

1287:

1281:

1280:

1252:

1246:

1245:

1243:

1241:

1232:. Archived from

1226:

1220:

1219:

1213:

1205:

1180:

1174:

1173:

1155:

1147:

1141:

1140:

1138:

1136:

1122:

957:Tensile strength

790:

789:

538:

537:

255:

254:

73:

72:

69:

68:

65:

62:

57:

56:

53:

50:

47:

44:

41:

38:

35:

2163:

2162:

2158:

2157:

2156:

2154:

2153:

2152:

2123:

2122:

2121:

2116:

2084:

1977:

1944:

1896:

1887:Artificial silk

1860:

1842:

1729:

1600:

1595:

1562:Wayback Machine

1551:

1546:

1545:

1526:

1522:

1507:

1493:

1486:

1457:

1453:

1447:

1419:

1415:

1370:

1366:

1329:

1325:

1288:

1284:

1253:

1249:

1239:

1237:

1228:

1227:

1223:

1207:

1206:

1194:

1182:

1181:

1177:

1148:

1144:

1134:

1132:

1124:

1123:

1119:

1114:

1102:

1081:

1072:

1043:

1007:artificial silk

996:dissolving pulp

972:

963:Elastic modulus

927:binder material

788:

783:

766:

677:Softwood kraft

547:Elongation (%)

544:Density (g/cm)

517:

230:lignocelluloses

226:

217:

189:

157:

152:

135:

107:

59:

32:

28:

17:

12:

11:

5:

2161:

2151:

2150:

2145:

2140:

2135:

2118:

2117:

2115:

2114:

2104:

2093:

2090:

2089:

2086:

2085:

2083:

2082:

2077:

2072:

2067:

2062:

2057:

2056:

2055:

2045:

2040:

2035:

2030:

2025:

2020:

2019:

2018:

2013:

2008:

2003:

1993:

1987:

1985:

1979:

1978:

1976:

1975:

1970:

1965:

1960:

1954:

1952:

1946:

1945:

1943:

1942:

1937:

1932:

1927:

1922:

1917:

1912:

1906:

1904:

1902:Semi-synthetic

1898:

1897:

1895:

1894:

1889:

1883:

1881:

1872:

1866:

1865:

1862:

1861:

1859:

1858:

1852:

1850:

1844:

1843:

1841:

1840:

1835:

1830:

1825:

1820:

1815:

1810:

1805:

1800:

1795:

1790:

1785:

1780:

1775:

1770:

1765:

1760:

1755:

1750:

1745:

1739:

1737:

1731:

1730:

1728:

1727:

1722:

1717:

1712:

1707:

1702:

1697:

1692:

1687:

1682:

1677:

1672:

1667:

1666:

1665:

1655:

1650:

1645:

1640:

1635:

1630:

1625:

1619:

1617:

1608:

1602:

1601:

1594:

1593:

1586:

1579:

1571:

1565:

1564:

1550:

1549:External links

1547:

1544:

1543:

1520:

1505:

1484:

1471:(4): 351–363.

1451:

1445:

1413:

1386:(2): 157–178.

1364:

1345:(5): 872–894.

1323:

1304:(6): 323–338.

1282:

1247:

1221:

1192:

1175:

1142:

1116:

1115:

1113:

1110:

1109:

1108:

1101:

1098:

1085:"bamboo fiber"

1080:

1077:

1071:

1068:

1067:

1066:

1063:

1060:

1057:

1054:

1051:

1042:

1039:

971:

968:

967:

966:

960:

954:

950:

918:

917:

914:

908:

907:

904:

898:

897:

894:

888:

887:

884:

878:

877:

874:

868:

867:

864:

858:

857:

854:

848:

847:

844:

838:

837:

834:

828:

827:

824:

822:Nitrile rubber

818:

817:

814:

812:Natural rubber

808:

807:

804:

798:

797:

794:

787:

784:

782:

779:

775:zeta potential

765:

762:

759:

758:

755:

752:

749:

746:

742:

741:

738:

735:

732:

729:

725:

724:

721:

718:

715:

712:

708:

707:

704:

701:

698:

695:

691:

690:

687:

684:

681:

678:

674:

673:

670:

667:

664:

661:

657:

656:

653:

650:

647:

644:

640:

639:

636:

633:

630:

627:

623:

622:

619:

616:

613:

610:

606:

605:

602:

599:

596:

593:

589:

588:

585:

582:

579:

576:

572:

571:

568:

565:

562:

559:

555:

554:

551:

548:

545:

542:

516:

513:

510:

509:

506:

503:

500:

497:

494:

490:

489:

486:

483:

480:

477:

474:

470:

469:

466:

463:

460:

457:

454:

451:

445:

444:

441:

438:

435:

432:

429:

425:

424:

421:

418:

415:

412:

409:

406:

400:

399:

396:

393:

390:

387:

384:

380:

379:

376:

373:

370:

367:

364:

360:

359:

356:

353:

350:

347:

344:

340:

339:

336:

333:

330:

327:

324:

320:

319:

316:

313:

310:

307:

304:

300:

299:

296:

293:

290:

287:

284:

281:

275:

274:

271:

268:

265:

262:

261:Cellulose (%)

259:

258:Type of fiber

225:

222:

216:

213:

188:

185:

156:

153:

151:

148:

134:

131:

106:

103:

15:

9:

6:

4:

3:

2:

2160:

2149:

2146:

2144:

2141:

2139:

2136:

2134:

2131:

2130:

2128:

2113:

2105:

2103:

2095:

2094:

2091:

2081:

2078:

2076:

2073:

2071:

2068:

2066:

2063:

2061:

2058:

2054:

2051:

2050:

2049:

2046:

2044:

2041:

2039:

2036:

2034:

2031:

2029:

2026:

2024:

2021:

2017:

2014:

2012:

2009:

2007:

2004:

2002:

1999:

1998:

1997:

1994:

1992:

1989:

1988:

1986:

1984:

1980:

1974:

1971:

1969:

1966:

1964:

1961:

1959:

1956:

1955:

1953:

1951:

1947:

1941:

1938:

1936:

1933:

1931:

1928:

1926:

1923:

1921:

1918:

1916:

1913:

1911:

1908:

1907:

1905:

1903:

1899:

1893:

1890:

1888:

1885:

1884:

1882:

1880:

1876:

1873:

1871:

1867:

1857:

1854:

1853:

1851:

1849:

1845:

1839:

1836:

1834:

1831:

1829:

1826:

1824:

1821:

1819:

1816:

1814:

1811:

1809:

1806:

1804:

1801:

1799:

1796:

1794:

1791:

1789:

1786:

1784:

1781:

1779:

1776:

1774:

1771:

1769:

1766:

1764:

1761:

1759:

1756:

1754:

1751:

1749:

1746:

1744:

1741:

1740:

1738:

1736:

1732:

1726:

1723:

1721:

1718:

1716:

1713:

1711:

1708:

1706:

1703:

1701:

1698:

1696:

1693:

1691:

1688:

1686:

1683:

1681:

1678:

1676:

1673:

1671:

1668:

1664:

1661:

1660:

1659:

1656:

1654:

1651:

1649:

1646:

1644:

1641:

1639:

1636:

1634:

1631:

1629:

1626:

1624:

1621:

1620:

1618:

1616:

1612:

1609:

1607:

1603:

1599:

1592:

1587:

1585:

1580:

1578:

1573:

1572:

1569:

1563:

1559:

1556:

1553:

1552:

1539:

1535:

1531:

1524:

1516:

1512:

1508:

1506:9781849772778

1502:

1498:

1491:

1489:

1479:

1474:

1470:

1466:

1462:

1455:

1448:

1442:

1438:

1434:

1430:

1425:

1417:

1409:

1405:

1401:

1397:

1393:

1389:

1385:

1381:

1376:

1368:

1360:

1356:

1352:

1348:

1344:

1340:

1335:

1327:

1319:

1315:

1311:

1307:

1303:

1299:

1294:

1286:

1278:

1274:

1270:

1266:

1262:

1258:

1251:

1235:

1231:

1225:

1217:

1211:

1203:

1199:

1195:

1193:9781402053801

1189:

1185:

1179:

1171:

1167:

1163:

1159:

1154:

1146:

1131:

1127:

1121:

1117:

1107:

1104:

1103:

1097:

1094:

1090:

1086:

1076:

1064:

1061:

1058:

1055:

1052:

1049:

1048:

1047:

1038:

1036:

1032:

1028:

1024:

1020:

1016:

1012:

1008:

1003:

1001:

997:

993:

989:

986:, (including

985:

981:

977:

964:

961:

958:

955:

951:

947:

946:

945:

942:

940:

936:

935:biocomposites

932:

928:

924:

915:

913:

910:

909:

905:

903:

900:

899:

895:

893:

890:

889:

885:

883:

880:

879:

875:

873:

870:

869:

865:

863:

860:

859:

855:

853:

852:Polypropylene

850:

849:

845:

843:

840:

839:

835:

833:

830:

829:

825:

823:

820:

819:

815:

813:

810:

809:

805:

803:

800:

799:

795:

792:

791:

778:

776:

772:

756:

753:

750:

747:

744:

743:

739:

736:

733:

730:

727:

726:

722:

719:

716:

713:

710:

709:

705:

702:

699:

696:

693:

692:

688:

685:

682:

679:

676:

675:

671:

668:

665:

662:

659:

658:

654:

651:

648:

645:

642:

641:

637:

634:

631:

628:

625:

624:

620:

617:

614:

611:

608:

607:

603:

600:

597:

594:

591:

590:

586:

583:

580:

577:

574:

573:

569:

566:

563:

560:

557:

556:

552:

549:

546:

543:

540:

539:

536:

534:

530:

526:

522:

507:

504:

501:

498:

495:

492:

491:

487:

484:

481:

478:

475:

472:

471:

467:

464:

461:

458:

455:

452:

450:

446:

442:

439:

436:

433:

430:

427:

426:

422:

419:

416:

413:

410:

407:

405:

401:

397:

394:

391:

388:

385:

382:

381:

377:

374:

371:

368:

365:

362:

361:

357:

354:

351:

348:

345:

342:

341:

337:

334:

331:

328:

325:

322:

321:

317:

314:

311:

308:

305:

302:

301:

297:

294:

291:

288:

285:

282:

280:

276:

272:

269:

266:

263:

260:

256:

253:

251:

247:

243:

239:

235:

234:hemicellulose

231:

221:

212:

210:

206:

202:

198:

194:

184:

182:

178:

174:

170:

166:

162:

147:

145:

141:

126:

122:

120:

116:

112:

111:Anselme Payen

99:

95:

91:

89:

85:

84:hemicellulose

81:

77:

71:

26:

24:

19:

2048:Polyethylene

1529:

1523:

1496:

1468:

1464:

1454:

1428:

1416:

1383:

1379:

1367:

1342:

1338:

1326:

1301:

1297:

1285:

1263:(1): 25–33.

1260:

1256:

1250:

1240:December 10,

1238:. Retrieved

1234:the original

1224:

1183:

1178:

1161:

1157:

1145:

1133:. Retrieved

1120:

1082:

1073:

1044:

1004:

973:

943:

921:

872:Polyurethane

842:Polyethylene

816:Coir, sisal

781:Applications

767:

757:230.0–240.0

533:carbon fiber

529:aramid fiber

518:

448:

403:

292:18.6 – 20.6

278:

227:

218:

190:

158:

136:

108:

92:

21:

20:

18:

1879:Regenerated

1823:Spider silk

1164:: 115–128.

1135:October 22,

978:is used as

862:Polystyrene

525:glass fiber

283:Fiber flax

270:Pectin (%)

264:Lignin (%)

2127:Categories

2028:Modacrylic

2023:Microfiber

1940:Triacetate

1892:Milk fiber

1758:Camel hair

1690:Lotus silk

1112:References

1041:Filtration

740:63.0–67.0

737:3000–3150

703:2000–3500

666:15.0–30.0

449:Leaf fiber

404:Core fiber

303:Seed flax

279:Bast fiber

250:bast fiber

203:are made.

173:harvesting

2143:Materials

2133:Cellulose

2043:Polyester

1915:Diacetate

1870:Synthetic

1773:Chiengora

1515:186246363

1400:0169-4243

1359:0272-8397

1318:1923-4287

1210:cite book

1202:187314758

1027:feedstock

1023:synthetic

916:Oil palm

892:Polyester

655:9.0–38.0

646:1.33–1.5

601:345–1500

578:1.3–1.46

570:5.5–12.6

564:3.0–10.0

493:Henequen

197:polyester

23:Cellulose

2148:Textiles

2102:Category

2011:Technora

1973:Metallic

1856:Asbestos

1798:Pashmina

1763:Cashmere

1558:Archived

1408:94420824

1277:96323385

1100:See also

1035:proteins

982:such as

931:polymers

751:1.4–1.8

734:3.3–3.7

711:S–glass

700:2.5–3.0

694:E–glass

672:4.0–6.0

669:175–220

652:400–700

635:220–938

632:2.0–3.8

618:550–900

604:27.6–80

598:1.2–3.2

595:1.4–1.5

584:393–800

581:1.5–1.8

567:287–597

561:1.5–1.6

389:0.6–0.7

386:68.6–91

372:14–22.4

352:13.6–21

346:45–71.5

332:21.5–23

273:Ash (%)

181:scouring

144:glycogen

115:Celanese

2112:Commons

2070:Vinylon

2065:Vectran

2060:Spandex

1991:Acrylic

1983:Polymer

1950:Mineral

1930:Piñatex

1920:Lyocell

1910:Acetate

1848:Mineral

1778:Guanaco

1628:Bagasse

1606:Natural

1011:viscose

992:Lyocell

970:Textile

949:matrix.

793:Matrix

745:Carbon

728:Aramid

649:2.0–14

638:44–128

558:Cotton

392:5–16.7

369:3.7–13

209:viscose

105:History

2138:Fibers

2075:Vinyon

2053:UHMWPE

2038:Olefin

2006:Kevlar

2001:Twaron

1996:Aramid

1968:Basalt

1963:Carbon

1833:Vicuña

1818:Tendon

1808:Rabbit

1803:Qiviut

1793:Mohair

1768:Catgut

1753:Byssus

1748:Angora

1743:Alpaca

1735:Animal

1715:Rattan

1705:Raffia

1648:Cotton

1633:Bamboo

1598:Fibers

1513:

1503:

1443:

1406:

1398:

1357:

1316:

1275:

1200:

1190:

1089:bamboo

980:fibers

912:Rubber

796:Fiber

643:Sisal

626:Ramie

587:10–30

541:Fiber

531:, and

488:0.6–1

482:10–24

476:47–78

473:Sisal

462:15–17

456:56–63

453:Abaca

437:18–22

434:21–24

431:41–48

417:18–24

414:15–21

411:37–49

408:Kenaf

383:Ramie

366:57–77

358:0.5–2

349:12–26

329:15–19

326:31–57

323:Kenaf

312:24–26

309:21–23

306:43–47

242:pectin

238:lignin

161:cotton

140:starch

88:lignin

80:esters

76:ethers

25:fibers

2080:Zylon

2033:Nylon

2016:Nomex

1958:Glass

1935:Rayon

1925:Modal

1788:Llama

1720:Sisal

1710:Ramie

1685:Kenaf

1680:Kapok

1663:Linen

1653:Fique

1638:Bashō

1623:Abacá

1615:Plant

1404:S2CID

1273:S2CID

1015:rayon

988:modal

984:rayon

906:Jute

886:Wood

876:Wood

866:Wood

836:Jute

826:Jute

802:Epoxy

754:4000

723:86.0

720:4570

706:70.0

689:40.0

686:1000

660:Coir

612:1.48

609:Hemp

592:Flax

575:Jute

499:13.1

496:77.6

479:7–11

428:Jute

363:Hemp

343:Jute

205:Rayon

201:nylon

177:chaff

165:Linen

150:Types

1828:Wool

1813:Silk

1783:Hair

1725:Wood

1700:Pine

1695:Piña

1675:Jute

1670:Hemp

1658:Flax

1643:Coir

1511:OCLC

1501:ISBN

1441:ISBN

1396:ISSN

1355:ISSN

1314:ISSN

1242:2018

1216:link

1198:OCLC

1188:ISBN

1137:2021

1031:wood

937:and

748:1.4

731:1.4

717:2.8

714:2.5

697:2.5

680:1.5

663:1.2

629:1.5

615:1.6

502:4–8

459:7–9

443:0.8

423:2–4

395:1.9

378:0.8

375:0.9

355:0.2

338:2–5

295:2.3

289:2.2

244:and

193:pulp

169:flax

142:and

86:and

1838:Yak

1534:doi

1473:doi

1433:doi

1388:doi

1347:doi

1306:doi

1302:28b

1265:doi

1166:doi

621:70

485:10

286:71

246:ash

207:or

199:or

78:or

2129::

1509:.

1487:^

1469:18

1467:.

1463:.

1439:,

1427:,

1402:.

1394:.

1384:16

1382:.

1378:.

1353:.

1343:23

1341:.

1337:.

1312:.

1300:.

1296:.

1271:.

1261:15

1259:.

1212:}}

1208:{{

1196:.

1162:79

1160:.

1156:.

1128:.

1002:.

683:–

535:.

527:,

508:–

505:–

468:3

465:–

440:–

420:–

398:–

335:–

318:5

315:–

298:–

240:,

236:,

179:,

64:oʊ

58:,-

52:oʊ

43:lj

1590:e

1583:t

1576:v

1540:.

1536::

1517:.

1481:.

1475::

1435::

1410:.

1390::

1361:.

1349::

1320:.

1308::

1279:.

1267::

1244:.

1218:)

1204:.

1172:.

1168::

1139:.

70:/

67:z

61:l

55:s

49:l

46:ʊ

40:ɛ

37:s

34:ˈ

31:/

27:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.