96:

104:

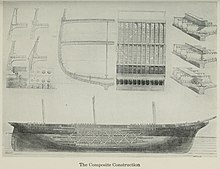

128:, but could not be used on iron hulls. The iron framework of composite ships was less bulky and lighter than timber, so allowing more cargo in a hull of the same external shape. The weight saving was particularly significant. The strength and stiffness allowed sailing vessels to be driven hard as the accumulated straining of the hull did not produce the leaks that would develop in the older wooden built ships.

205:(FRP). Such materials do not warp, crack, or split and are as versatile as traditional pressure treated wood. Composite decking is made through several different processes, and there are a multitude of sizes, shapes, and strengths available. Depending on the type of composite selected the decking materials can be used for a number of other construction projects including fences and sheds.

226:

Cement-polymer composites are being developed and tested as a replacement for traditional cement. The traditional cement used as stucco rapidly deteriorates. The deterioration causes the material to easily crack due to thermo-processes becoming permeable to water and no longer structurally sound. The

213:

In a composite steel deck, the dissimilar materials in question are steel and concrete. A composite steel deck combines the tensile strength of steel with the compressive strength of concrete to improve design efficiency and reduce the material necessary to cover a given area. Additionally, composite

82:

floor slabs. If the beam is not connected firmly to the slab, then the slab transfers all of its weight to the beam and the slab contributes nothing to the load carrying capability of the beam. However, if the slab is connected positively to the beam with studs, then a portion of the slab can be

111:

In 19th-century shipbuilding, composite construction was the use of an iron hull framework which was covered in timber planking to provide the water-tight skin of the hull. If properly insulated fastenings were used on the timber, the underwater hull could be covered with

246:. It was found that 20% crumb rubber can be added to the cement mixture without affecting the appearance of the cement. This new material was tested for strength and durability using American Society for Testing and Materials (

515:

Loutfy, R. O. (2005, April 25). National Center For

Environmental Research, US EPA. Retrieved June 14, 2010, from Final Report: Cement-Polymer Composites From Recycled Polymers for Construction:

83:

assumed to act compositely with the beam. In effect, this composite creates a larger and stronger beam than would be provided by the steel beam alone. The structural engineer may calculate a

375:

311:

172:. This occurs when a steel plate is sandwiched between two wood joists and bolted together. A flitch beam can typically support heavier loads over a longer

400:

30:

is a generic term to describe any building construction involving multiple dissimilar materials. Composite construction is often used in building

139:

was built. Other patents followed, with differing methods of electrically insulating the iron frames and fastenings from the copper sheathing.

364:

228:

218:

can span greater distances between supporting elements and have reduced live load deflection in comparison to previous construction methods.

66:, composite construction exists when two different materials are bound together so strongly that they act together as a single unit from a

516:

549:

231:

in conjunction with

Materials and Electrochemical Research Corporation tested a cement-polymer composite material consisting of

300:

135:

built from the mid-1860s. Early experiments with the system started with a patent issued in 1839, under which the steamer

467:

404:

347:

193:

The traditional decking material is pressure-treated wood. The current material many contractors choose to use is

202:

492:

534:

539:

198:

517:

http://cfpub.epa.gov/ncer_abstracts/index.cfm/fuseaction/display.abstractDetail/abstract/6970/report/F

177:

169:

269:

63:

544:

39:

443:

215:

8:

279:

274:

173:

84:

259:

247:

117:

43:

425:

343:

194:

143:

113:

95:

103:

21:

17:

236:

125:

51:

471:

528:

107:

Internal view of HMS Gannet, with the iron frames and timber planking visible

398:

Composite

Decking. (n.d.). Retrieved June 22, 2010, from ToolBase Services:

168:

is a simple form of composite construction sometimes used in North

American

264:

232:

87:

as one step in analyzing the load carry capability of the composite beam.

239:

165:

151:

121:

67:

47:

35:

79:

31:

132:

243:

75:

340:

The Tea

Clippers, Their History and Development 1833-1875

468:"Composite Steel Joist - Steel Joist Institute (SJI)"

150:, a steam and sail-powered warship, and the clipper

131:Composite hulls were used for the majority of the

526:

333:

331:

299:Rahman, Nabil A.; Booth, Michael (August 2006).

99:Contemporary drawings of composite construction

70:point of view. When this occurs, it is called

328:

229:United States Environmental Protection Agency

221:

362:

298:

337:

188:

57:

102:

94:

381:from the original on September 27, 2007

317:from the original on September 30, 2006

208:

197:. This material is typically made from

527:

183:

42:. There are several reasons to use

13:

493:"Structural Steel in Construction"

365:"Flitch Plate Beams: Design Guide"

301:"Innovative Mid Rise Construction"

176:than an all-wood beam of the same

14:

561:

550:Prestressed concrete construction

342:. Conway Maritime Press Limited.

159:

20:of classical architecture, see

509:

485:

460:

436:

418:

392:

356:

292:

74:. One common example involves

46:including increased strength,

1:

285:

203:fiberglass reinforced plastic

120:. Copper sheathing prevented

338:MacGregor, David R. (1983).

7:

253:

10:

566:

15:

497:ConstructionKnowledge.net

222:Cement-polymer composites

214:steel decks supported by

444:"Composite Construction"

170:light frame construction

90:

142:Surviving examples are

116:without the problem of

448:steelconstruction.info

363:DeStefano, P.E., Jim.

270:Framing (construction)

216:composite steel joists

199:wood–plastic composite

189:Composite wood decking

108:

100:

64:structural engineering

58:Structural engineering

28:Composite construction

106:

98:

40:building construction

209:Composite steel deck

50:, and environmental

401:"Composite Decking"

280:Structural analysis

275:Reinforced concrete

85:transformed section

44:composite materials

535:Building materials

372:Structure Magazine

308:Structure Magazine

260:Composite material

248:ASTM International

118:galvanic corrosion

109:

101:

540:Civil engineering

430:Trex Company, Inc

426:"Recycling Facts"

195:composite decking

184:Deck construction

78:beams supporting

557:

519:

513:

507:

506:

504:

503:

489:

483:

482:

480:

479:

470:. Archived from

464:

458:

457:

455:

454:

440:

434:

433:

422:

416:

415:

413:

412:

403:. Archived from

396:

390:

389:

387:

386:

380:

369:

360:

354:

353:

335:

326:

325:

323:

322:

316:

305:

296:

114:copper sheathing

72:composite action

565:

564:

560:

559:

558:

556:

555:

554:

525:

524:

523:

522:

514:

510:

501:

499:

491:

490:

486:

477:

475:

466:

465:

461:

452:

450:

442:

441:

437:

424:

423:

419:

410:

408:

399:

397:

393:

384:

382:

378:

367:

361:

357:

350:

336:

329:

320:

318:

314:

303:

297:

293:

288:

256:

224:

211:

191:

186:

162:

93:

60:

25:

22:composite order

12:

11:

5:

563:

553:

552:

547:

542:

537:

521:

520:

508:

484:

459:

435:

417:

391:

355:

348:

327:

290:

289:

287:

284:

283:

282:

277:

272:

267:

262:

255:

252:

223:

220:

210:

207:

190:

187:

185:

182:

161:

160:House building

158:

92:

89:

59:

56:

52:sustainability

9:

6:

4:

3:

2:

562:

551:

548:

546:

543:

541:

538:

536:

533:

532:

530:

518:

512:

498:

494:

488:

474:on 2014-10-06

473:

469:

463:

449:

445:

439:

431:

427:

421:

407:on 2013-04-16

406:

402:

395:

377:

373:

366:

359:

351:

349:0-85177-256-0

345:

341:

334:

332:

313:

309:

302:

295:

291:

281:

278:

276:

273:

271:

268:

266:

263:

261:

258:

257:

251:

250:) standards.

249:

245:

241:

238:

234:

230:

219:

217:

206:

204:

200:

196:

181:

179:

178:cross section

175:

171:

167:

157:

155:

154:

149:

147:

140:

138:

134:

129:

127:

123:

119:

115:

105:

97:

88:

86:

81:

77:

73:

69:

65:

55:

53:

49:

45:

41:

37:

33:

29:

23:

19:

545:Construction

511:

500:. Retrieved

496:

487:

476:. Retrieved

472:the original

462:

451:. Retrieved

447:

438:

429:

420:

409:. Retrieved

405:the original

394:

383:. Retrieved

371:

358:

339:

319:. Retrieved

307:

294:

265:Construction

240:rubber tires

233:crumb rubber

225:

212:

192:

163:

152:

148: (1878)

145:

141:

136:

130:

110:

71:

61:

27:

26:

166:flitch beam

126:teredo worm

529:Categories

502:2014-11-09

478:2014-11-09

453:2014-11-09

411:2010-06-26

385:2024-05-09

321:2024-05-09

286:References

235:made from

153:Cutty Sark

68:structural

48:aesthetics

36:watercraft

144:HMS

376:Archived

312:Archived

254:See also

237:recycled

133:clippers

80:concrete

32:aircraft

16:For the

122:fouling

346:

244:cement

146:Gannet

38:, and

379:(PDF)

368:(PDF)

315:(PDF)

304:(PDF)

137:Assam

91:Ships

76:steel

18:order

344:ISBN

242:and

174:span

124:and

201:or

62:In

531::

495:.

446:.

428:.

374:.

370:.

330:^

310:.

306:.

180:.

164:A

156:.

54:.

34:,

505:.

481:.

456:.

432:.

414:.

388:.

352:.

324:.

24:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.