272:. The preform has a 1 inch by 1 inch round slug that stands up in the mold cavity. During the cycle, the operator loads the jig with slugs and places the jig over the mold. The preforms are released into the cavity of the mold when the slide tray is pulled. When the mold is opened, the lower platen lowers and the mold is hydraulically pushed out to the operator. The heat sheet (all molded parts from that cycle joined together by a parting line rind (flash)) is then placed in a transfer cart to be die cut.

265:

hydraulically closed to full pressure. The mold temperature is about 350 degrees. When the cycle ends (after about 3.5-4.0 minutes), the press opens and the mold is pulled out toward the operator. The operator opens the clam shell mold top and leans the top of the mold back against the press. Exposed is the bottle with the core still inside. While the bottle is still hot, the operator inserts prongs in between the bottle and the steel core and stretches the bottle at the neck to free it from the core.

605:

22:

196:

spoilers, as well as smaller more intricate parts. The material to be molded is positioned in the mold cavity and the heated platens are closed by a hydraulic ram. Bulk molding compound (BMC) or sheet molding compound (SMC), are conformed to the mold form by the applied pressure and heated until the curing reaction occurs. SMC feed material usually is cut to conform to the surface area of the mold. The mold is then cooled and the part removed.

611:

30:

51:

248:

helps to reduce excess flash. Inserts, usually metallic, can also be molded with the plastic. As a side note, remember not to allow any undercuts on the shape, it will make ejection especially difficult. Thermoplastic matrices with an inherent indefinite shelf-life and shorter cycle molding times are widely used and examples are shown in Ref 3.

256:

Compression molding is one of the oldest manufacturing techniques for rubber molding. The process parameters include molding time, temperature, and pressure. Usually, a 300-400 ton clamp pressure is used. The typical mold is shaped like a clam shell with the bottom being the mold cavity. The molding

199:

Materials may be loaded into the mold either in the form of pellets or sheet, or the mold may be loaded from a plasticating extruder. Materials are heated above their melting points, formed and cooled. The more evenly the feed material is distributed over the mold surface, the less flow orientation

280:

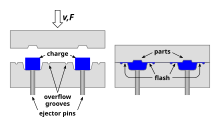

Three types of molds used are the flash plunger-type, straight plunger-type, and the "landed" plunger-type molds. The flash type mold must have an accurate charge of plastic and produces a horizontal flash (excess material protruding from the mold). The straight plunger-type mold allows for some

264:

Compression molded water bottles are made from die-cut 3 inch by 6 inch sheets. One sheet is placed below a core and one sheet of equal size is placed above the core, and then the top of the mold is lowered by hand or by hoist to near shut. The mold is then pushed into the press, and the press is

247:

The use of thermoset plastic compounds characterizes this molding process from many of the other molding processes. These thermosets can be in either preform or granule shapes. Unlike some of the other processes we find that the materials are usually preheated and measured before molding. This

238:

Compression molding is a forming process in which a plastic material is placed directly into a heated metal mold then is softened by the heat and therefore forced to conform to the shape of the mold, as the mold closes. Once molding is completed excess Flash may be removed. Typically, compression

195:

Compression molding was first developed to manufacture composite parts for metal replacement applications, compression molding is typically used to make larger flat or moderately curved parts. This method of molding is greatly used in manufacturing automotive parts such as hoods, fenders, scoops,

148:

can also be compression molded with unidirectional tapes, woven fabrics, randomly oriented fiber mat or chopped strand. The advantage of compression molding is its ability to mold large, fairly intricate parts. Also, it is one of the lowest cost molding methods compared with other methods such as

168:

are produced and a smaller amount of fiber-length degradation is noticeable when compared to injection molding. Compression-molding is also suitable for ultra-large basic shape production in sizes beyond the capacity of extrusion techniques. Materials that are typically manufactured through

206:

Thermoplastic matrices are commonplace in mass production industries. One significant example are automotive applications where the leading technologies are long fibre reinforced thermoplastics (LFT) and glass fiber mat reinforced thermoplastics (GMT).

257:

press looked a lot like a ladle filled vertical press used for casting aluminum. Compression molding uses preforms made by an extruder and wink cutter (in which two blades meet at the center to cut the extrudate to length) or a roller die and

281:

inaccuracy in the charge of plastic and produces a vertical flash. The landed plunger type mold must have an accurate charge of plastic, and no flash is produced. Further details are explained in Ref 3.

129:

are maintained until the molding material has cured; this process is known as compression molding method and in case of rubber it is also known as 'Vulcanisation'. The process employs thermosetting

188:

Compression molding is commonly utilized by product development engineers seeking cost effective rubber and silicone parts. Manufacturers of low volume compression molded components include

1212:

936:

404:

Todd, Robert H., Dell K. Allen, and Leo Alting. Manufacturing

Processes Reference Guide. New York: Industrial P, Incorporated, 1993 on page 219-220....

121:

cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, while

203:

Compression molding is also widely used to produce sandwich structures that incorporate a core material such as a honeycomb or polymer foam.

189:

929:

812:

1271:

1222:

1191:

79:

922:

429:

97:

914:

454:

157:; moreover it wastes relatively little material, giving it an advantage when working with expensive compounds.

1207:

1186:

1083:

837:

1261:

1181:

335:

1254:

1176:

992:

589:

1313:

519:

494:

140:

Compression molding is a high-volume, high-pressure method suitable for molding complex, high-strength

1294:

1028:

827:

652:

469:

459:

178:

66:

210:

In compression molding there are six important considerations that an engineer should bear in mind:

1098:

1088:

950:

637:

584:

474:

379:

258:

160:

However, compression molding often provides poor product consistency and difficulty in controlling

688:

579:

564:

544:

1103:

981:

736:

464:

422:

1283:

987:

632:

38:

310:

1003:

998:

971:

889:

229:

Designing the mold for rapid cooling after the material has been compressed into the mold.

8:

1133:

894:

817:

683:

357:

1148:

1066:

807:

781:

751:

711:

693:

642:

594:

574:

117:

in which the molding material, generally preheated, is first placed in an open, heated

1278:

1244:

1164:

976:

798:

716:

415:

154:

118:

114:

61:

1169:

864:

766:

741:

673:

539:

534:

479:

150:

944:

1033:

1019:

884:

771:

761:

529:

1062:

874:

776:

647:

290:

1307:

1249:

1056:

842:

832:

822:

726:

627:

549:

499:

161:

145:

226:

Predicting the required force, to ensure that shot attains the proper shape.

869:

859:

721:

668:

569:

514:

489:

169:

compression molding include: Polyester fiberglass resin systems (SMC/BMC),

1115:

604:

1052:

1024:

959:

879:

678:

559:

554:

72:

1128:

756:

746:

217:

Determining the minimum amount of energy required to heat the material.

141:

21:

1217:

1123:

1093:

963:

524:

509:

484:

269:

165:

1138:

126:

610:

1266:

1143:

1044:

946:

438:

174:

170:

34:

29:

134:

130:

133:

in a partially cured stage, either in the form of granules,

504:

407:

220:

Determining the minimum time required to heat the material.

182:

122:

268:

The preforms for compression molded golf ball centers are

164:, and it is not suitable for some types of parts. Fewer

25:

Compression molding - simplified diagram of the process

275:

1305:

223:Determining the appropriate heating technique.

930:

423:

239:molding machines open along a vertical axis.

937:

923:

430:

416:

242:

214:Determining the proper amount of material.

98:Learn how and when to remove this message

28:

20:

1306:

520:Polyethylene terephthalate (PET, PETE)

918:

460:Cross-linked polyethylene (PEX, XLPE)

455:Acrylonitrile butadiene styrene (ABS)

411:

336:"Introduction to Compression Molding"

233:

200:occurs during the compression stage.

1272:List of environmental health hazards

1192:List of environmental health hazards

251:

44:

276:Typical tools and geometry produced

144:reinforcements. Advanced composite

13:

1077:Miscellaneous additives incl. PHCs

14:

1325:

609:

603:

495:Polybutylene terephthalate (PBT)

470:Poly(methyl methacrylate) (PMMA)

49:

475:Poly(ethyl methacrylate) (PEMA)

398:

380:"What is Compression Moulding?"

838:Category:Plastics applications

585:Styrene maleic anhydride (SMA)

580:Polyvinylidene chloride (PVDC)

565:Polytetrafluoroethylene (PTFE)

372:

350:

328:

303:

1:

545:Poly(p-phenylene oxide) (PPO)

296:

1262:Persistent organic pollutant

1223:Toxic Substances Control Act

1182:Persistent organic pollutant

465:Ethylene vinyl acetate (EVA)

437:

137:-like masses, or preforms.

7:

1255:Great Pacific garbage patch

1177:Great Pacific garbage patch

590:Styrene-acrylonitrile (SAN)

505:Polyetheretherketone (PEEK)

284:

69:. The specific problem is:

10:

1330:

1218:Japan Toxic Substances Law

1013:Miscellaneous plasticizers

311:"Moulding | Walker Rubber"

192:, 3D, STYS, and Aero MFG.

181:(PPS), and many grades of

1292:

1237:

1213:European REACH regulation

1208:California Proposition 65

1200:

1157:

1114:

1076:

1043:

1012:

958:

951:polyhalogenated compounds

907:

852:

828:High-performance plastics

797:

790:

702:

661:

653:High-performance plastics

618:

601:

445:

179:Poly(p-phenylene sulfide)

638:Fibre-reinforced plastic

575:Polyvinyl chloride (PVC)

689:Biodegradable additives

243:Process characteristics

1104:Perfluorooctanoic acid

540:Polyphenyl ether (PPE)

535:Polyoxymethylene (POM)

480:Polyacrylic acid (PAA)

382:. Coventive Composites

42:

26:

1284:Biodegradable plastic

633:Thermosetting polymer

530:Polylactic acid (PLA)

32:

24:

1295:Identification codes

895:Foam food containers

818:Engineering plastics

80:improve this article

65:to meet Knowledge's

1134:Endocrine disruptor

732:Compression molding

684:Polymer stabilizers

111:Compression molding

33:Compression molded

1149:Polymer fume fever

808:Commodity plastics

782:Rotational molding

752:Fiberglass molding

712:Injection moulding

694:Filler (materials)

643:Corrugated plastic

595:Tritan copolyester

550:Polypropylene (PP)

500:Polycarbonate (PC)

234:Process definition

43:

27:

1314:Molding processes

1301:

1300:

1279:Plastic recycling

1245:Plastic pollution

1231:

1230:

1165:Plastic pollution

945:Health issues of

903:

902:

799:Plastics industry

717:Plastic extrusion

570:Polyurethane (PU)

560:Polysulfone (PES)

515:Polyethylene (PE)

490:Polybutylene (PB)

315:Walker Rubber Ltd

252:Process schematic

155:injection molding

108:

107:

100:

67:quality standards

58:This article may

37:boots before the

16:Method of molding

1321:

1170:Rubber pollution

1020:Organophosphates

939:

932:

925:

916:

915:

795:

794:

767:Filament winding

742:Transfer molding

669:Polymer additive

613:

607:

555:Polystyrene (PS)

432:

425:

418:

409:

408:

392:

391:

389:

387:

376:

370:

369:

367:

365:

358:"DKM-DH Machine"

354:

348:

347:

345:

343:

332:

326:

325:

323:

321:

307:

151:transfer molding

103:

96:

92:

89:

83:

53:

52:

45:

1329:

1328:

1324:

1323:

1322:

1320:

1319:

1318:

1304:

1303:

1302:

1297:

1288:

1233:

1232:

1227:

1196:

1153:

1110:

1072:

1039:

1008:

954:

943:

909:

899:

848:

786:

772:Solvent bonding

762:Plastic welding

704:

698:

657:

620:

614:

608:

599:

510:Polyester (PEs)

447:

441:

436:

401:

396:

395:

385:

383:

378:

377:

373:

363:

361:

356:

355:

351:

341:

339:

334:

333:

329:

319:

317:

309:

308:

304:

299:

287:

278:

254:

245:

236:

113:is a method of

104:

93:

87:

84:

77:

54:

50:

17:

12:

11:

5:

1327:

1317:

1316:

1299:

1298:

1293:

1290:

1289:

1287:

1286:

1281:

1276:

1275:

1274:

1269:

1264:

1259:

1258:

1257:

1241:

1239:

1235:

1234:

1229:

1228:

1226:

1225:

1220:

1215:

1210:

1204:

1202:

1198:

1197:

1195:

1194:

1189:

1184:

1179:

1174:

1173:

1172:

1161:

1159:

1155:

1154:

1152:

1151:

1146:

1141:

1136:

1131:

1126:

1120:

1118:

1112:

1111:

1109:

1108:

1107:

1106:

1096:

1091:

1086:

1080:

1078:

1074:

1073:

1071:

1070:

1063:Vinyl chloride

1060:

1057:Polycarbonates

1049:

1047:

1041:

1040:

1038:

1037:

1031:

1022:

1016:

1014:

1010:

1009:

1007:

1006:

1001:

996:

990:

985:

979:

974:

968:

966:

956:

955:

942:

941:

934:

927:

919:

913:

911:

905:

904:

901:

900:

898:

897:

892:

887:

882:

877:

872:

870:Packaging film

867:

862:

856:

854:

853:Specific goods

850:

849:

847:

846:

840:

835:

830:

825:

820:

815:

810:

804:

802:

792:

788:

787:

785:

784:

779:

777:Vacuum forming

774:

769:

764:

759:

754:

749:

744:

739:

734:

729:

724:

719:

714:

708:

706:

700:

699:

697:

696:

691:

686:

681:

676:

671:

665:

663:

659:

658:

656:

655:

650:

648:Polymeric foam

645:

640:

635:

630:

624:

622:

616:

615:

602:

600:

598:

597:

592:

587:

582:

577:

572:

567:

562:

557:

552:

547:

542:

537:

532:

527:

525:Polyimide (PI)

522:

517:

512:

507:

502:

497:

492:

487:

485:Polyamide (PA)

482:

477:

472:

467:

462:

457:

451:

449:

443:

442:

435:

434:

427:

420:

412:

406:

405:

400:

397:

394:

393:

371:

349:

327:

301:

300:

298:

295:

294:

293:

291:Matrix molding

286:

283:

277:

274:

253:

250:

244:

241:

235:

232:

231:

230:

227:

224:

221:

218:

215:

146:thermoplastics

106:

105:

57:

55:

48:

15:

9:

6:

4:

3:

2:

1326:

1315:

1312:

1311:

1309:

1296:

1291:

1285:

1282:

1280:

1277:

1273:

1270:

1268:

1265:

1263:

1260:

1256:

1253:

1252:

1251:

1250:Garbage patch

1248:

1247:

1246:

1243:

1242:

1240:

1236:

1224:

1221:

1219:

1216:

1214:

1211:

1209:

1206:

1205:

1203:

1199:

1193:

1190:

1188:

1185:

1183:

1180:

1178:

1175:

1171:

1168:

1167:

1166:

1163:

1162:

1160:

1156:

1150:

1147:

1145:

1142:

1140:

1137:

1135:

1132:

1130:

1127:

1125:

1122:

1121:

1119:

1117:

1116:Health issues

1113:

1105:

1102:

1101:

1100:

1097:

1095:

1092:

1090:

1087:

1085:

1082:

1081:

1079:

1075:

1068:

1064:

1061:

1058:

1054:

1051:

1050:

1048:

1046:

1042:

1035:

1032:

1030:

1026:

1023:

1021:

1018:

1017:

1015:

1011:

1005:

1002:

1000:

997:

994:

991:

989:

986:

983:

980:

978:

975:

973:

970:

969:

967:

965:

961:

957:

952:

948:

940:

935:

933:

928:

926:

921:

920:

917:

912:

906:

896:

893:

891:

890:Shopping bags

888:

886:

883:

881:

878:

876:

873:

871:

868:

866:

863:

861:

858:

857:

855:

851:

845:(Agriculture)

844:

843:Plasticulture

841:

839:

836:

834:

831:

829:

826:

824:

823:Geosynthetics

821:

819:

816:

814:

811:

809:

806:

805:

803:

800:

796:

793:

789:

783:

780:

778:

775:

773:

770:

768:

765:

763:

760:

758:

755:

753:

750:

748:

745:

743:

740:

738:

735:

733:

730:

728:

727:Thermoforming

725:

723:

720:

718:

715:

713:

710:

709:

707:

701:

695:

692:

690:

687:

685:

682:

680:

677:

675:

672:

670:

667:

666:

664:

660:

654:

651:

649:

646:

644:

641:

639:

636:

634:

631:

629:

628:Thermoplastic

626:

625:

623:

617:

612:

606:

596:

593:

591:

588:

586:

583:

581:

578:

576:

573:

571:

568:

566:

563:

561:

558:

556:

553:

551:

548:

546:

543:

541:

538:

536:

533:

531:

528:

526:

523:

521:

518:

516:

513:

511:

508:

506:

503:

501:

498:

496:

493:

491:

488:

486:

483:

481:

478:

476:

473:

471:

468:

466:

463:

461:

458:

456:

453:

452:

450:

444:

440:

433:

428:

426:

421:

419:

414:

413:

410:

403:

402:

381:

375:

359:

353:

337:

331:

316:

312:

306:

302:

292:

289:

288:

282:

273:

271:

266:

262:

260:

249:

240:

228:

225:

222:

219:

216:

213:

212:

211:

208:

204:

201:

197:

193:

191:

186:

184:

180:

176:

172:

167:

163:

158:

156:

152:

147:

143:

138:

136:

132:

128:

124:

120:

116:

112:

102:

99:

91:

88:February 2020

81:

76:

74:

68:

64:

63:

56:

47:

46:

40:

36:

31:

23:

19:

960:Plasticizers

908:Environment

860:Blister pack

813:Construction

731:

722:Blow molding

399:Bibliography

384:. Retrieved

374:

362:. Retrieved

352:

340:. Retrieved

330:

318:. Retrieved

314:

305:

279:

267:

263:

255:

246:

237:

209:

205:

202:

198:

194:

187:

159:

139:

110:

109:

94:

85:

78:Please help

70:

59:

41:are removed.

18:

1201:Regulations

1053:Bisphenol A

737:Calendering

679:Plasticizer

619:Mechanical

82:if you can.

73:readability

1129:Carcinogen

1094:Organotins

964:Phthalates

910:and health

757:Pultrusion

747:Laminating

705:processing

386:October 1,

297:References

259:die cutter

166:knit lines

142:fiberglass

1158:Pollution

1124:Teratogen

1055:(BPA, in

703:Plastics

674:Colorants

662:Additives

446:Chemical

342:March 19,

190:PrintForm

1308:Category

1139:Diabetes

1045:Monomers

1025:Adipates

947:plastics

801:segments

791:Products

439:Plastics

338:. eFunda

285:See also

270:extruded

162:flashing

127:pressure

60:require

1267:Dioxins

1187:Dioxins

1144:Obesity

885:Cutlery

875:Bottles

364:July 9,

320:May 19,

115:molding

62:cleanup

39:flashes

984:(BBzP)

953:(PHCs)

865:Chairs

833:Nurdle

175:Vespel

171:Torlon

131:resins

35:rubber

1238:Waste

1084:PBDEs

995:(DOP)

621:types

448:types

360:. DKM

135:putty

71:poor

1099:PFCs

1089:PCBs

1065:(in

1029:DEHA

1004:DINP

999:DIDP

993:DEHP

988:DIHP

972:DIBP

949:and

880:Bags

388:2018

366:2023

344:2013

322:2021

183:PEEK

153:and

125:and

123:heat

119:mold

1067:PVC

1034:DOA

982:BBP

977:DBP

185:.

1310::

962::

313:.

261:.

177:,

173:,

1069:)

1059:)

1036:)

1027:(

938:e

931:t

924:v

431:e

424:t

417:v

390:.

368:.

346:.

324:.

101:)

95:(

90:)

86:(

75:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.