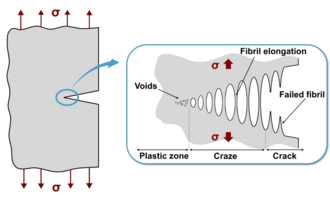

444:, craze growth is necessary but not sufficient for fracture. The critical step in the fracture of most glassy polymer crazes is the initiation of the first large void, defined as several fibril spacing in diameter. This process, known as craze fibril breakdown, is closely linked to the active zone and craze growth at the craze interface. The breakdown of the craze starts gradually as voids coalesce to produce a cavity equal in thickness to the craze itself. Craze breakdown, which leads to crack extension, is crucial to the failure process. However, the detailed mechanisms involved remain a subject of debate among experts, despite the many models that have been suggested.

751:

significant volume of the material while crazing is a more localized phenomenon ad it is more often associated with brittle failure. Shear yielding manifests as plastic deformation in the form of shear bands and is closely associated with the material softening that occurs immediately after yielding. With continued deformation, the material undergoes hardening due to molecular orientation, resulting in the multiplication and propagation of shear bands. Shear bands may form in a material that exhibits strain softening, hence when the conditions which favour crazing are suppressed, polymers will tend to form shear bands.

291:

27:

719:

1410:

2356:

3178:

2889:

1402:

735:

765:

431:

168:

constant volume, crazing is a cavitation process that takes place with an increase in volume. The initiation of crazing normally requires the presence of a dilative component of the stress tensor and can be inhibited by applying hydrostatic pressure. From a solid mechanics perspective this means that a necessary condition for craze nucleation is having a positive value of

108:

335:, spreading into the denser, undeformed polymer. The physical principle behind this instability is the difference in hydrostatic pressure across a curved surface. Any disturbance that introduces curvature can propagate if the pressure difference due to the curvature is significant enough to overcome the surface tension. This condition can be written as:

595:, known as the fracture toughness of the material. This approach allows for the prediction of crack growth and the evaluation of the material's resistance to fracture under various loading conditions. It has been observed that for a crack growing relatively slowly in a stable manner and preceded by a craze, then the relationship between

315:" propagates, while the undeformed polymer outside the zone acts as the rigid "plates" constraining the fluid. As the finger-like structure of the craze tip advances, fibrils form by the deformation of the polymer webs between the fingers, and the interconnected void network emerges naturally right at the craze tip.

747:

yielding and craze yielding due to their distinct microstructural characteristics. Shear yielding involves the material undergoing shear flow with minimal or no change in density. In contrast, craze yielding, is highly localized and the macroscopic behaviors of shear and craze yielding differ significantly.

3264:

In order to have a comprehensive yielding criterion both yielding phenomenon must be taken into account and their dependence on external parameters has to be determined. Only if these conditions are known a proper yield criterion expressed in terms of stress can obtained as a surface encompassing the

271:

This condition is favored by the presence of triaxial tensile stresses, a condition that exist in defects of bulky samples subjected to plane strain. The cavitation involved in crazing allows the material to achieve plastic strain faster. The presence of cracks or defects in bulky samples will favor

132:

term "crasen" meaning "to break", has historically been used to describe a network of fine cracks in the surfaces of glasses and ceramics. This term was naturally extended to describe similar phenomena observed in transparent glassy polymers. Under tensile stress, these polymers develop what appear

746:

point of a material represents the maximum stress it can endure without resulting in a permanent strain after the load is removed, it refers to the stress level required to initiate plastic deformation. When analyzing the yielding behavior of polymers, it is crucial to differentiate between shear

326:

forces, surface tension acts to minimize the surface area, and any disturbance can create a meniscus, a curved surface at the interface between two phases. This causes the polymer chains to pull apart and form a cavity filled with a fibrillar network. This type of instability is well documented in

2896:

Argon proposed an alternative crazing criterion based on a molecular theory for distortional plasticity, he described the process of crazing as a micromechanical problem of elastic-plastic expansion of initially stable micropores produced by a thermally activated mechanism under stress to form a

1417:

Experiments have shown that nelther the Tresca nor the von Mises criterion adequately describes the shear yield behaviour of polymers, because for example the true yield stress is invariably higher in uniaxial compression than in tension, and uniaxial-tensile tests conducted in a pressure chamber

750:

Crazing and shear yielding are the two principal deformation mechanisms inherent to polymers. Those two phenomenon are competitive mechanisms (although they are not mutually exclusive and can coexist), with shear yielding being the more ductile failure mode because it involves the deformation of

439:

Crazes in polymers are typically load-bearing and expand in width and area until a region within the craze breaks down, forming a large void. With further stress or over time, this void can develop into a subcritical crack, growing slowly until it reaches a critical length, causing the sample to

310:

This phenomenon is commonly observed when two flat plates with a layer of liquid between them are forced apart or when adhesive tape is peeled off from a substrate. The hypothesis concerning craze formation states that a wedge-shaped zone of plastically deformed and strain-softened polymer forms

148:

Significant advancements in the understanding of crazing were made in the 1960s and 1970s, illustrating the formation and structure of crazes in various polymers and on the stress conditions necessary for craze formation in polymers. Researchers demonstrated that crazes grow perpendicular to the

1891:

In plane stress the modified von Mises criterion is an ellipse on the principal axis space, but differently from the standard criterion it is shifted with respect to the origin, due to the different behavior of the polymeric materials depending on the hydrostatic component of the stress tensor.

167:

nature of the process. Like other viscoelastic phenomena, this delay results from the thermally activated movements of polymer segments under mechanical stress. Crazing involves a localized or inhomogeneous plastic strain of the material. However, while plastic deformation essentially occurs at

3225:

plane (considering plane stress condition), where the two criteria intersect a transition between the two mechanisms is expected. Considering that polymers have a viscoelastic behaviour an effect of loading rates and temperatures on shear yield stress and on crazing yield is observed. When the

144:

before fracture occurs. Early observations noted the presence of crazes that propagated across specimens without causing immediate failure, indicating their load-bearing capacity and provided further insights into the nature of crazes, describing their appearance and behavior under stress.

1385:

1579:

1184:

2897:

craze nucleus. With his analysis of the condition of craze nucleation he provided a derivation of crazing. This model provides an elegant criterion that can be easily applied for any stress state and it is not based on strain, which is a poor parameter of state:

2881:

114:

113:

110:

109:

115:

1900:

An effective crazing criterion has been proposed in the early 70's by

Sternstein and coworkers. Considering crazing a form of dilatational plasticity, a critical condition that has to be met by the applied stress tensor for crazing to take place is:

822:

encompassing the origin in principal stress space. Yielding does not occur until the stress increases from zero (the origin) to some point on this surface. For isotropic elastic materials with a ductile failure mode, the most used criteria are the

72:

particles, and molecular heterogeneities. Crazes grow normal to the principal (tensile) stress, they may extend up to centimeters in length and fractions of a millimeter in thickness if conditions prevent early failure and crack propagation. The

162:

There is typically a delay between the application of stress and the visible appearance of crazes, indicating a barrier to craze nucleation. The time delay between the application of stress and the nucleation of crazes can be attributed to the

3520:

Sauer, J. A., & Chen, C. C. (1983). Crazing and

Fatigue Behavior in One- and Two-Phase Glassy Polymers. In H. H. Kausch (Ed.), *Crazing in Polymers, Volume 1: Advances in Polymer Science* (Vol. 52/53, pp. 169-223). Springer-Verlag Berlin

2352:, that establishes the boundary between hydrostatic compression and hydrostatic tension. Below this line crazing does not occur because the pressure component of the stress matrix tends to reduce the volume, instead of increasing it.

2694:

434:

The image shows craze formation, growth and breakdown in a polymer under tensile stress. The left section depicts a polymer sample under stress, while the right section provides a detailed view of craze development at the crack

112:

2305:

3111:

2363:

Oxborough and Bowden attempted to create a more comprehensive relationship valid for a general triaxial state of stress. Their assumption is that crazing occurs when the strain in any direction reaches a critical value

1784:

5425:

3533:

Friedrich, K. (1983). Crazes and Shear Bands in Semi-Crystalline

Thermoplastics. In H. H. Kausch (Ed.), *Crazing in Polymers, Volume 1: Advances in Polymer Science* (Vol. 52/53, pp. 226-271). Springer-Verlag Berlin

2490:

1226:

2548:

are again time and temperature dependent parameters. The maximum tensile strain in an isotropic body under a general state of stress defined by the principal stresses is always in the direction of the maximum

3410:

Kramer, E. J., & Berger, L. L. (1990). Effect of

Molecular Variables on Crazing and Fatigue of Polymers. In H. H. Kausch (Ed.), *Crazing in Polymers, Volume 2: Advances in Polymer Science* (pp. 1-67).

2972:

267:

133:

to be cracks on their surfaces, often very gradually or after prolonged periods. These fine cracks, or crazes, were noted for their ability to propagate across specimens without causing immediate failure.

4493:

Kramer, E. J., & Berger, L. L. (1990). Fundamental

Processes of Craze Growth and Fracture. In H. H. Kausch (Ed.), *Crazing in Polymers: Volume 2 Advances in Polymer Science* (Vol. 91/92, pp. 1-68).

1986:

378:

2604:

2150:

3543:

Narisawa, I., & Ishikawa, M. (1990). Crazing in semicrystalline thermoplastics. In H. H. Kausch (Ed.), *Crazing in

Polymers Volume 2 Advances in Polymer Science* (pp. 355-389). Springer-Verlag.

1678:

568:

which describes the stress state near the tip of a crack. According to linear elastic fracture mechanics (LEFM), the crack will propagate when the stress intensity factor reaches a critical value

564:

1426:

1031:

2751:

805:

422:

is the radius of curvature. In theory, any disturbance meeting the criteria of the previous equation can grow, but in reality, a predominant wavelength emerges, which grows the quickest.

3261:) are such that the tensile stress for shear yielding is lower than the crazing stress no crazing will be observed on the material and a brittle to ductile transition can be expected.

1022:

2350:

831:

yield criterion based on maximum distortion energy. The latter is the most used and states that yielding of a ductile material begins when the second invariant of deviatoric stress

3223:

686:

2181:

for a general triaxial state of stress, but for what concerns the yield criterion, the constants A and B can be easily evaluated performing experiments in plane stress conditions (

3259:

100:

molecules to undergo significant molecular stretching and disentanglement, if crazing does occur, it is often due to the interaction with second-phase particles incorporated as a

111:

61:(5-30 nm in diameter), constituting about 50% of their volume, whereas cracks do not. Unlike cracks, crazes can transmit load between their two faces through these fibrils.

496:

2389:

2212:

3034:

3007:

2179:

2015:

1886:

1707:

1614:

1219:

4855:

642:

3960:

Sternstein, S. S. and

Ongchin, L. (1969) “Yield criteria for plastic deformation of glassy high polymers in general stress fields,” Polymer Preprints, 10(2), 1117–1124.

1859:

1812:

2359:

Sternstein crazing criterion at different temperatures for biaxial stress state. For a given temperature, crazing does not occur for any stress state below the curves.

400:

81:

light. Consequently, a stressed material with a high density of crazes may appear 'stress-whitened,' as the scattering makes a normally clear material become opaque.

3167:

3140:

2546:

2519:

2082:

856:

593:

193:

2740:

1832:

1393:

however it cannot be used to describe shear yielding in polymers since in those materials the hydrostatic component of the stress tensor affects the yield stress.

2716:

2055:

2035:

708:

613:

519:

469:

420:

3974:

Sternstein, S. S. and Myers, F. A. (1973) “Yielding of glassy polymers in the second quadrant of principal stress space,” J. Macromol. Sci. Phys., B8, 539–571.

2611:

1026:

The criterion assumes that for yield to not occur the stress coordinate must be contained within the cylindrical surface described by the following equation:

3799:

3757:

1421:

The von Mises criterion can be modified to incorporate the effect of pressure on the state of the material by substituting in its original formulation:

2219:

2309:

The crazing criterion is illustrated in the following graph for different temperatures. The curves will be asymptotic to the pure shear line where

3041:

1714:

3374:"Electron microscopy of crazes in polystyrene and rubber modified polystyrene: use of iodine-sulphur eutectic as a craze reinforcing impregnant"

3185:

By combining the criterion for shear yielding and crazing a region can be found in which no yielding can occur. This can be easily seen in the

1380:{\displaystyle \tau _{oct}={\frac {1}{3}}{\sqrt {(\sigma _{1}-\sigma _{2})^{2}+(\sigma _{2}-\sigma _{3})^{2}+(\sigma _{3}-\sigma _{1})^{2}}}}

272:

the initiation of crazing, as these defects are points of high concentration of stresses and can cause the formation of initial microvoids.

3470:. London; New York : New York, NY, USA: Applied Science Publishers; Sole distributor in the USA and Canada, Elsevier Science Pub. Co.

2396:

327:

various classes of materials and the concepts were developed from experiments involving the interpenetration of two fluids with different

4391:

738:

The left draw shows the mechanism of shear yielding. The right section cut from a PS sample reveals the dense network of shear bands.

283:. Consequently, the highest plastic resistance is achieved by maximizing the normal stress on the plane of the craze. The concept of

2902:

200:

4333:

Donald, A.M. and Kramer, E.J. (1981) The

Mechanism for Craze-Tip Advance in Glassy Polymers. Philosophical Magazine A, 43, 857-870.

3983:

Rabinowitz, S. and

Beardmore, P. (1972) “Craze formation and fracture in glassy polymers,” CRC Crit. Rev. Macromol. Sci., 1, 1–45.

1906:

340:

2556:

2089:

4921:

4679:

4642:

4617:

4135:

4017:

3819:

3777:

3562:

3505:

3475:

1621:

1574:{\displaystyle (\sigma _{1}-\sigma _{2})^{2}+(\sigma _{2}-\sigma _{3})^{2}+(\sigma _{3}-\sigma _{1})^{2}=9\tau _{oct}^{2}}

1179:{\displaystyle (\sigma _{1}-\sigma _{2})^{2}+(\sigma _{2}-\sigma _{3})^{2}+(\sigma _{3}-\sigma _{1})^{2}=9\tau _{oct}^{2}}

5211:

Oxborough, R. J.; Bowden, P. B. (1973). "A general critical-strain criterion for crazing in amorphous glassy polymers".

2876:{\displaystyle \sigma _{1}-\nu \sigma _{2}-\nu \sigma _{3}=Y_{1}E+{\frac {X_{1}E}{\sigma _{1}+\sigma _{2}+\sigma _{3}}}}

526:

319:

has demonstrated that meniscus instability is the operative craze tip advancement mechanism in various glassy polymers.

3577:

Kinloch, A. J. (1985). Mechanics and

Mechanisms of Fracture of Thermosetting Epoxy Polymers. In R. J. Morgan (Ed.),

5449:

771:

316:

815:

A yield criterion is a general condition that must be satisfied by the applied stress tensor for yield to occur.

284:

863:

306:

sections through the craze, showing the sequence of events as the craze tip progresses by one fibril spacing.

2312:

5444:

3279:

3188:

3181:

Example of a yield-safe region in plane stress condition, considering both shear yielding and craze yielding.

649:

136:

Crazing in polymers was first identified as a distinct deformation mechanism in the mid-20th century. Unlike

3806:, ASTM International100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, pp. 132–152,

2746:. So the previous equation can be re-written as to define the criterion in terms of the principal stresses:

3229:

5454:

5127:"Yield condition and propagation of Lüders' lines in tension–torsion experiments on poly(vinyl chloride)"

3764:, ASTM International100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, pp. 3–26,

474:

49:

characterized by the formation of a fine network of microvoids and fibrils. These structures (known as

5294:

4761:

4637:. Ellis Horwood series in engineering science. Chichester : New York: E. Horwood; Halsted Press.

4570:

311:

ahead of the craze tip. This deformed polymer constitutes the "fluid" layer into which the craze tip "

64:

Crazes typically initiate when applied tensile stress causes microvoids to nucleate at points of high

4195:"The instability of liquid surfaces when accelerated in a direction perpendicular to their planes. I"

828:

4242:"The penetration of a fluid into a porous medium or Hele-Shaw cell containing a more viscous liquid"

4900:

Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen. Mathematisch-Physikalische Klasse

3324:"Electron microscopy of crazes in glassy polymers: Use of reinforcing impregnants during microtomy"

2367:

2184:

89:

768:

The von Mises yield surfaces in principal stress coordinates circumscribes a cylinder with radius

5247:

5174:"Déformation plastique des hauts polymères vitreux soumis á un système de contraintes quelconque"

5173:

5126:

5079:

4438:

4152:

3323:

3012:

2979:

2157:

1993:

1864:

1685:

1586:

1191:

499:

4241:

4194:

2885:

for plane stress this equation is very similar to the one proposed by Sternstein and coworkers.

618:

4714:

4288:

4080:

1837:

1790:

824:

4002:

Properties of Solid Polymeric Materials, Part B - Treatise on Materials Science and Technology

4699:

Brown, N. (1986). Yield Behavior of Polymers. In W. Brostow & R. D. Corneliussen (Eds.),

385:

93:

4004:, Treatise on Materials Science & Technology, vol. 10, Elsevier, pp. 541–598,

5348:

5259:

5220:

5138:

5091:

5044:

4997:

4950:

4867:

4820:

4773:

4726:

4460:

4403:

4356:

4300:

4253:

4206:

4164:

4092:

3910:

3855:

3722:

3651:

3604:

3335:

3274:

3145:

3118:

2524:

2497:

2060:

834:

571:

294:

Diagram illustrating the mechanism of craze tip advancement through meniscus instability.

275:

Crazes grow on the plane of maximum principal stress. Craze fibrils can endure substantial

171:

149:

principal stress and highlighted the critical stress levels required for their initiation.

2725:

1817:

8:

3284:

2689:{\displaystyle \epsilon _{1}={\frac {1}{E}}(\sigma _{1}-\nu \sigma _{2}-\nu \sigma _{3})}

743:

141:

42:

5352:

5263:

5224:

5142:

5095:

5048:

5001:

4954:

4871:

4824:

4777:

4730:

4464:

4407:

4360:

4304:

4257:

4246:

Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences

4210:

4199:

Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences

4168:

4096:

3914:

3859:

3726:

3655:

3608:

3339:

4450:

2743:

2719:

2701:

2040:

2020:

1418:

show that yield stresses of polymers increase significantly with hydrostatic pressure.

1413:

Modified von Mises criterion in principal stress coordinates (plane stress conditions).

710:

is related to the viscoelastic processes at the crack tip that stabilize crack growth.

693:

598:

504:

454:

448:

405:

65:

4785:

4505:

4009:

3425:

3373:

57:. The fundamental difference between crazes and cracks is that crazes contain polymer

5439:

5403:

5399:

5364:

5314:

5275:

5213:

The Philosophical Magazine: A Journal of Theoretical Experimental and Applied Physics

5193:

5154:

5107:

5084:

The Philosophical Magazine: A Journal of Theoretical Experimental and Applied Physics

5060:

5013:

4966:

4917:

4916:. Addison-Wesley series in metallurgy and materials. Reading, Mass.: Addison-Wesley

4836:

4789:

4742:

4675:

4638:

4613:

4590:

4555:

Hui, C. Y., et al. "Micromechanics of crack growth into a craze in a polymer glass."

4525:

4521:

4476:

4419:

4372:

4316:

4269:

4222:

4131:

4108:

4058:

4013:

3936:

3879:

3871:

3815:

3773:

3738:

3667:

3620:

3558:

3501:

3471:

3445:

3441:

3393:

3389:

3351:

3294:

312:

68:

concentration within the polymer, such as those created by scratches, flaws, cracks,

20:

4472:

4344:

4343:

Jensen, Mogens H.; Libchaber, Albert; Pelcé, Pierre; Zocchi, Giovanni (1987-03-01).

290:

5395:

5356:

5306:

5267:

5228:

5185:

5146:

5099:

5052:

5005:

4958:

4898:

von Mises, R. (1913). Mechanik der festen Körper im plastisch-deformablen Zustand.

4875:

4828:

4781:

4762:"Modeling of the competition between shear yielding and crazing in glassy polymers"

4734:

4667:

4582:

4517:

4468:

4411:

4364:

4308:

4261:

4214:

4172:

4100:

4050:

4039:

4005:

3926:

3918:

3863:

3807:

3765:

3730:

3659:

3612:

3437:

3385:

3343:

2892:

Argon crazing criterion (blue) vs Sternstein (red dashed), plane stress conditions.

2550:

441:

298:

wedge of deformed polymer situated ahead of the void fingers and trailing fibrils.

74:

5383:

4586:

1834:

are material parameters that depend on loading rate and temperature. The constant

1409:

26:

3299:

3289:

323:

164:

119:

Crazing and fracture during a tensile test on a transparent polymer (x0.25 speed)

85:

4671:

3997:

2300:{\displaystyle |\sigma _{1}-\sigma _{2}|=A+{\frac {B}{\sigma _{1}+\sigma _{2}}}}

331:. In this scenario, the voided structure of the craze acts like the low-density

5248:"Physical basis of distortional and dilational plastic flow in glassy polymers"

5189:

5150:

4542:

Brown, H. R. "A molecular interpretation of the toughness of glassy polymers."

4176:

3426:"Structure and properties of crazes in polycarbonate and other glassy polymers"

3347:

1401:

129:

5360:

5271:

5232:

5103:

5032:

4938:

4808:

4738:

4659:

4312:

4104:

1861:

is the yield stress in pure shear, since under this stress state the value of

1616:

that is linearly dependent on the hydrostatic component of the stress tensor:

19:

This article is about crazing in polymers. For crazing in ceramic glazes, see

5433:

5407:

5368:

5318:

5279:

5197:

5158:

5111:

5064:

5033:"The effect of hydrostatic pressure on the shear yield behaviour of polymers"

5017:

4970:

4840:

4793:

4746:

4594:

4529:

4480:

4423:

4368:

4320:

4273:

4226:

4112:

4062:

3940:

3875:

3742:

3671:

3624:

3449:

3397:

3355:

819:

276:

5336:

5310:

3177:

3106:{\displaystyle \sigma _{m}={\frac {\sigma _{1}+\sigma _{2}+\sigma _{3}}{3}}}

1779:{\displaystyle \sigma _{m}={\frac {\sigma _{1}+\sigma _{2}+\sigma _{3}}{3}}}

4985:

4984:

Holliday, L.; Mann, J.; Pogany, G. A.; Pugh, H. Ll D.; Gunn, D. A. (1964).

4265:

4218:

3883:

3841:

2084:

Is the first stress invariant and it represent the dilatational component:

808:

77:

of crazes is lower than that of the surrounding material, causing them to

4376:

718:

4715:"A theory for the low-temperature plastic deformation of glassy polymers"

4345:"Effect of gravity on the Saffman-Taylor meniscus: Theory and experiment"

3931:

280:

195:, the first stress invariant that represent the dilatational component:

31:

4054:

3685:

5337:"Viscoelasticity and shear yielding onset in amorphous glassy polymers"

5056:

4962:

4832:

3898:

3762:

Symposium on Effects of Low Temperatures on the Properties of Materials

3663:

3616:

734:

101:

97:

78:

4879:

4415:

3922:

3811:

3769:

3734:

2888:

1396:

818:

A yield criterion expressed in terms of stress can be visualized as a

5009:

4939:"Effect of hydrostatic pressure on mechanical properties of plastics"

4569:

Basu, Sumit; Mahajan, Dhiraj K.; Van der Giessen, Erik (2005-08-23).

3867:

3639:

3592:

722:

A constant strain rate stress-strain curve for a polymer, displaying

53:) typically appear as linear features and frequently precede brittle

4390:

Saintyves, Baudouin; Mora, Serge; Bouchaud, Elisabeth (2019-06-01).

4153:"Craze initiation in poly(methyl methacrylate) under biaxial stress"

3710:

2485:{\displaystyle \epsilon _{c}=Y_{1}(t,T)+{\frac {X_{1}(t,T)}{I_{1}}}}

2355:

140:, most glassy polymers were found to be able to undergo significant

96:

crazing is less frequently observed because of the inability of the

4760:

Estevez, R.; Tijssens, M. G. A.; Van der Giessen, E. (2000-12-01).

4571:"Micromechanics of the growth of a craze fibril in glassy polymers"

4439:"Fluid-driven fingering instability of a confined elastic meniscus"

54:

4504:

McLeish, T. C. B.; Plummer, C. J. G.; Donald, A. M. (1989-09-01).

4455:

2391:) that depends on the hydrostatic component of the stress tensor:

430:

764:

328:

46:

3640:"Craze-like damage in a core-shell rubber-modified epoxy system"

3846:

287:

provides a fundamental explanation for the growth of crazes.

58:

4759:

2967:{\displaystyle \tau _{oct}={\frac {C_{1}}{C_{2}+\sigma _{m}}}}

262:{\displaystyle I_{1}=\sigma _{1}+\sigma _{2}+\sigma _{3}>0}

1405:

Modified von Mises criterion in principal stress coordinates.

1390:

332:

137:

5295:"Role of heterogeneities in the crazing of glassy polymers"

69:

5384:"Crazing limit of polymers in creep and stress relaxation"

5080:"The mechanical behaviour of polymers under high pressure"

4568:

4342:

3756:

Nason, H. K.; Carswell, T. S.; Adams, C. H. (1950-01-01),

1981:{\displaystyle \sigma _{b}=A(t,T)+{\frac {B(t,T)}{I_{1}}}}

373:{\displaystyle \delta \sigma _{h}>{\frac {\Gamma }{R}}}

5077:

4856:"Observations of Deformation Bands in Amorphous Polymers"

4392:"A meniscus fingering instability in viscoelastic fluids"

4130:(2 ed.). Oxford; New York: Oxford University Press.

3491:

3489:

3487:

2599:{\displaystyle \sigma _{1}>\sigma _{2}>\sigma _{3}}

2145:{\displaystyle I_{1}=\sigma _{1}+\sigma _{2}+\sigma _{3}}

5078:

Christiansen, A. W.; Baer, E.; Radcliffe, S. V. (1971).

4437:

Biggins, John S.; Wei, Z.; Mahadevan, L. (2015-05-01).

4126:

McCrum, N. G.; Buckley, C. P.; Bucknall, C. B. (1997).

322:

The meniscus formation is a result of the imbalance of

4983:

4937:

Ainbinder, S. B.; Laka, M. G.; Maiors, I. Yu. (1965).

3496:

Haward, Robert Nobbs; Haward, Robert N., eds. (1997).

3484:

774:

5031:

Rabinowitz, S.; Ward, I. M.; Parry, J. S. C. (1970).

4666:, Dordrecht: Springer Netherlands, pp. 279–339,

4506:"Crazing by disentanglement: non-diffusive reptation"

4389:

4125:

3593:"Toughening mechanisms in elastomer-modified epoxies"

3232:

3191:

3148:

3121:

3044:

3015:

2982:

2905:

2754:

2728:

2704:

2614:

2559:

2527:

2500:

2399:

2370:

2315:

2222:

2187:

2160:

2092:

2063:

2043:

2023:

1996:

1909:

1867:

1840:

1820:

1793:

1717:

1688:

1673:{\displaystyle \tau _{oct}=\tau _{0}-\mu \sigma _{m}}

1624:

1589:

1429:

1229:

1194:

1034:

866:

837:

696:

652:

621:

601:

574:

529:

507:

477:

457:

408:

388:

343:

203:

174:

5178:

Journal of Polymer Science Part A-2: Polymer Physics

5131:

Journal of Polymer Science Part A-2: Polymer Physics

4612:(3 ed.). Boca Raton, FL: Taylor & Francis.

4503:

4040:"Rheological Properties of Polystyrene below 80° C."

3328:

Journal of Polymer Science Part A-2: Polymer Physics

713:

5030:

4936:

4912:MacClintock, Frank A.; Argon, Ali S., eds. (1966).

4436:

4157:

Journal of Polymer Science: Polymer Physics Edition

1397:

The modified von Mises criterion for shear yielding

3991:

3989:

3755:

3253:

3217:

3161:

3134:

3105:

3028:

3001:

2966:

2875:

2734:

2710:

2688:

2598:

2540:

2513:

2484:

2383:

2344:

2299:

2206:

2173:

2144:

2076:

2049:

2029:

2009:

1980:

1880:

1853:

1826:

1806:

1778:

1701:

1672:

1608:

1573:

1379:

1213:

1178:

1016:

850:

799:

702:

680:

636:

607:

587:

559:{\displaystyle K=\sigma _{\infty }{\sqrt {\pi a}}}

558:

513:

490:

463:

414:

394:

372:

261:

187:

4610:Fracture mechanics: fundamentals and applications

3557:. Plastics engineering. New York: Marcel Dekker.

2017:is the stress required to orient the fibrils and

754:

5431:

4911:

4809:"Deformation mechanisms in crystalline polymers"

4289:"Finger-like crack growth in solids and liquids"

3899:"Yielding Behavior of Glassy Amorphous Polymers"

1895:

5210:

4150:

3986:

3970:

3968:

3966:

2057:are time and temperature dependent parameters.

425:

5330:

5328:

4766:Journal of the Mechanics and Physics of Solids

4188:

4186:

3800:"Microscopical Studies of Failure in Polymers"

3758:"Low Temperature Behavior of Organic Plastics"

3461:

3459:

3419:

3417:

3371:

3367:

3365:

3317:

3315:

1389:This criterion is observed quite well by most

800:{\textstyle {\sqrt {\frac {2}{3}}}\sigma _{y}}

157:

4239:

4074:

4072:

3956:

3954:

3952:

3950:

3372:Kambour, R. P.; Russell, R. R. (1971-04-01).

3172:

644:can be described by an equation of the form:

3963:

3495:

3465:

3321:

498:, its propagation can be analyzed using the

5325:

4806:

4658:Bowden, P. B. (1973), Haward, R. N. (ed.),

4286:

4183:

4078:

4037:

3529:

3527:

3456:

3414:

3362:

3312:

827:criterion of maximum tangential stress and

807:around the hydrostatic axis. Also shown is

5334:

4240:Saffman, P.G.; Taylor, G.I. (1958-06-24).

4069:

3998:"Mechanical Properties of Glassy Polymers"

3995:

3947:

3897:Brady, T. E.; Yeh, G. S. Y. (1971-11-01).

3708:

3686:"craze | Etymology of craze by etymonline"

3590:

3500:(2 ed.). London: Chapman & Hall.

84:Crazing is a phenomenon typical of glassy

5252:Journal of Macromolecular Science, Part B

4454:

3930:

3842:"Crazing of Cast Polymethyl Methacrylate"

3709:Hsiao, C. C.; Sauer, J. A. (1950-11-01).

3591:Yee, A. F.; Pearson, R. A. (1986-07-01).

3466:Kinloch, A. J.; Young, Robert J. (1983).

1017:{\displaystyle I_{2}={\frac {1}{6}}\left}

4660:"The Yield Behaviour of Glassy Polymers"

4632:

4607:

3896:

3524:

3176:

2887:

2354:

2345:{\displaystyle \sigma _{1}=-\sigma _{2}}

1408:

1400:

763:

733:

717:

429:

289:

152:

123:

106:

25:

5381:

5171:

5124:

4853:

3839:

3423:

3218:{\displaystyle \sigma _{1}-\sigma _{2}}

681:{\displaystyle K\propto {\dot {a}}^{n}}

317:Stereo-transmission electron microscopy

5432:

4657:

4192:

4043:Industrial & Engineering Chemistry

3797:

3552:

3036:represents the hydrostatic component:

3009:is the octahedral shear stress, while

1709:represents the hydrostatic component:

471:is initiated due to an applied stress

279:across the craze but cannot withstand

5341:Mechanics of Time-Dependent Materials

5292:

5245:

4712:

4081:"Growth of crazes in glassy polymers"

3322:Kambour, R. P.; Holik, A. S. (1969).

4807:Bowden, P. B.; Young, R. J. (1974).

4287:Fields, R. J.; Ashby, M. F. (1976).

4079:Argon, A. S.; Salama, M. M. (1977).

4038:Maxwell, Bryce; Rahm, L. F. (1949).

3711:"On Crazing of Linear High Polymers"

3254:{\displaystyle T,{\dot {\epsilon }}}

759:

440:fracture. For polymers of practical

5335:Marano, C.; Rink, M. (2006-09-01).

3637:

13:

4151:Kawagoe, M.; Kitagawa, M. (1981).

3265:origin in principal stress space.

2214:), so that the condition becomes:

541:

483:

389:

362:

14:

5466:

5418:

4128:Principles of polymer engineering

3798:Newman, Sanford B. (1959-01-01),

730:brittle failure (craze yielding).

726:ductile failure (shear yielding)

714:Craze yielding and shear yielding

491:{\displaystyle \sigma _{\infty }}

4914:Mechanical behavior of materials

3553:Arends, Charles B., ed. (1996).

3169:are time-temperature constants.

1221:is the octahedral shear stress:

5375:

5286:

5239:

5204:

5165:

5118:

5071:

5024:

4977:

4930:

4905:

4892:

4847:

4800:

4753:

4706:

4703:(pp. 98-105). Hanser Publishers

4693:

4651:

4626:

4601:

4577:. Stimuli Responsive Polymers.

4562:

4549:

4536:

4497:

4487:

4430:

4383:

4336:

4327:

4280:

4233:

4144:

4119:

4031:

3977:

3890:

3833:

3791:

3749:

3702:

3678:

3631:

3584:

3571:

3546:

4664:The Physics of Glassy Polymers

4635:Fracture mechanics of polymers

3537:

3514:

3498:The physics of glassy polymers

3468:Fracture behaviour of polymers

3404:

2683:

2638:

2466:

2454:

2435:

2423:

2252:

2224:

1962:

1950:

1938:

1926:

1535:

1508:

1496:

1469:

1457:

1430:

1366:

1339:

1327:

1300:

1288:

1261:

1140:

1113:

1101:

1074:

1062:

1035:

1000:

973:

961:

934:

922:

895:

755:Yielding criteria for polymers

88:, but can also be observed in

16:Yielding mechanism in polymers

1:

5172:Bauwens, Jean-Claude (1967).

4786:10.1016/S0022-5096(00)00016-8

4587:10.1016/j.polymer.2005.05.148

4010:10.1016/s0161-9160(13)70095-4

3581:(pp. 45-67). Springer-Verlag.

3579:Epoxy Resins and Composites I

3424:Kambour, R. P. (1964-01-01).

3305:

3280:Environmental stress cracking

2384:{\displaystyle \epsilon _{c}}

2207:{\displaystyle \sigma _{3}=0}

1896:Yielding criteria for crazing

811:'s hexagonal yield surface.

285:Taylor's meniscus instability

5424:Crazing & shear banding

5400:10.1016/0032-3861(78)90071-x

5037:Journal of Materials Science

4813:Journal of Materials Science

4522:10.1016/0032-3861(89)90325-X

3644:Journal of Materials Science

3638:Sue, Hung-Jue (1992-06-01).

3597:Journal of Materials Science

3442:10.1016/0032-3861(64)90128-4

3390:10.1016/0032-3861(71)90048-6

2154:It is difficult to evaluate

615:and crack propagation speed

426:Craze breakdown and fracture

21:Glaze defects § Crazing

7:

5293:Argon, A. S. (1975-01-01).

4672:10.1007/978-94-010-2355-9_6

4473:10.1209/0295-5075/110/34001

4193:Taylor, G.I. (1950-03-22).

3268:

3029:{\displaystyle \sigma _{m}}

3002:{\displaystyle \tau _{oct}}

2174:{\displaystyle \sigma _{b}}

2010:{\displaystyle \sigma _{b}}

1881:{\displaystyle \sigma _{m}}

1702:{\displaystyle \sigma _{m}}

1609:{\displaystyle \tau _{oct}}

1214:{\displaystyle \tau _{oct}}

158:Craze nucleation and growth

10:

5471:

5299:Pure and Applied Chemistry

5190:10.1002/pol.1967.160050612

5151:10.1002/pol.1970.160080606

4986:"Ductility of Polystyrene"

4860:Journal of Applied Physics

4177:10.1002/pol.1981.180190914

3903:Journal of Applied Physics

3715:Journal of Applied Physics

3348:10.1002/pol.1969.160070809

3173:General yielding criterion

858:reaches a critical value.

637:{\displaystyle {\dot {a}}}

402:is the surface energy and

128:Crazing, derived from the

18:

5361:10.1007/s11043-006-9016-z

5272:10.1080/00222347308201637

5233:10.1080/14786437308221002

5104:10.1080/14786437108227400

4739:10.1080/14786437308220987

4443:EPL (Europhysics Letters)

4313:10.1080/14786437608221089

4105:10.1080/14786437708239790

3996:Sternstein, S.S. (1977),

1854:{\displaystyle \tau _{0}}

1807:{\displaystyle \tau _{0}}

4633:Williams, J. G. (1984).

4608:Anderson, T. L. (2005).

4559:25.15 (1992): 3948-3955.

4546:24.10 (1991): 2752-2756.

4369:10.1103/PhysRevA.35.2221

90:semicrystalline polymers

5450:Deformation (mechanics)

5311:10.1351/pac197543010247

5125:Bauwens, J. C. (1970).

4854:Whitney, Wells (1963).

3840:Russell, E. W. (1950).

3804:Symposium on Microscopy

500:stress intensity factor

451:, once a crack of size

395:{\displaystyle \Gamma }

5382:Brüller, O.S. (1978).

4719:Philosophical Magazine

4293:Philosophical Magazine

4266:10.1098/rspa.1958.0085

4219:10.1098/rspa.1950.0052

4085:Philosophical Magazine

3255:

3219:

3182:

3163:

3136:

3107:

3030:

3003:

2968:

2893:

2877:

2736:

2712:

2690:

2600:

2542:

2515:

2486:

2385:

2360:

2346:

2301:

2208:

2175:

2146:

2078:

2051:

2031:

2011:

1982:

1882:

1855:

1828:

1808:

1780:

1703:

1674:

1610:

1575:

1414:

1406:

1381:

1215:

1180:

1018:

852:

812:

801:

739:

731:

704:

682:

638:

609:

589:

560:

515:

492:

465:

436:

416:

396:

374:

307:

263:

189:

120:

94:thermosetting polymers

35:

5246:Argon, A. S. (1973).

4713:Argon, A. S. (1973).

3256:

3220:

3180:

3164:

3162:{\displaystyle C_{2}}

3137:

3135:{\displaystyle C_{1}}

3108:

3031:

3004:

2969:

2891:

2878:

2737:

2713:

2691:

2601:

2543:

2541:{\displaystyle Y_{1}}

2516:

2514:{\displaystyle X_{1}}

2487:

2386:

2358:

2347:

2302:

2209:

2176:

2147:

2079:

2077:{\displaystyle I_{1}}

2052:

2032:

2012:

1983:

1883:

1856:

1829:

1809:

1781:

1704:

1675:

1611:

1576:

1412:

1404:

1382:

1216:

1181:

1019:

853:

851:{\displaystyle I_{2}}

802:

767:

737:

721:

705:

683:

639:

610:

590:

588:{\displaystyle K_{c}}

561:

516:

493:

466:

433:

417:

397:

375:

293:

264:

190:

188:{\displaystyle I_{1}}

153:Mechanisms of crazing

124:Historical background

118:

29:

5445:Plasticity (physics)

3275:Fracture in polymers

3230:

3226:loading conditions (

3189:

3146:

3119:

3042:

3013:

2980:

2903:

2752:

2735:{\displaystyle \nu }

2726:

2702:

2612:

2557:

2525:

2498:

2397:

2368:

2313:

2220:

2185:

2158:

2090:

2061:

2041:

2021:

1994:

1907:

1865:

1838:

1827:{\displaystyle \mu }

1818:

1791:

1715:

1686:

1622:

1587:

1427:

1227:

1192:

1032:

864:

835:

772:

694:

650:

619:

599:

572:

527:

505:

475:

455:

447:In the framework of

406:

386:

341:

201:

172:

5353:2006MTDM...10..173M

5264:1973JMSB....8..573A

5225:1973PMag...28..547O

5143:1970JPoSB...8..893B

5096:1971PMag...24..451C

5049:1970JMatS...5...29R

5002:1964Natur.202..381H

4955:1965PoMec...1a..50A

4902:, 1913(1), 582-592.

4872:1963JAP....34.3633W

4825:1974JMatS...9.2034B

4778:2000JMPSo..48.2585E

4731:1973PMag...28..839A

4701:Failure of Plastics

4465:2015EL....11034001B

4408:2019PhFl...31f3108S

4361:1987PhRvA..35.2221J

4305:1976PMag...33...33F

4258:1958RSPSA.245..312S

4211:1950RSPSA.201..192T

4169:1981JPoSB..19.1423K

4097:1977PMag...36.1217A

4055:10.1021/ie50477a036

3915:1971JAP....42.4622B

3860:1950Natur.165...91R

3727:1950JAP....21.1071H

3656:1992JMatS..27.3098S

3609:1986JMatS..21.2462Y

3340:1969JPoSB...7.1393K

2606:) and is given by:

1570:

1175:

142:plastic deformation

5455:Fracture mechanics

5057:10.1007/PL00020253

4963:10.1007/BF00861894

4833:10.1007/BF00540553

3690:www.etymonline.com

3664:10.1007/BF01154125

3617:10.1007/BF01114293

3555:Polymer toughening

3251:

3215:

3183:

3159:

3132:

3103:

3026:

2999:

2964:

2894:

2873:

2732:

2708:

2686:

2596:

2538:

2511:

2482:

2381:

2361:

2342:

2297:

2204:

2171:

2142:

2074:

2047:

2027:

2007:

1978:

1878:

1851:

1824:

1804:

1776:

1699:

1670:

1606:

1571:

1550:

1415:

1407:

1377:

1211:

1176:

1155:

1014:

848:

813:

797:

740:

732:

700:

678:

634:

605:

585:

556:

511:

488:

461:

449:fracture mechanics

437:

412:

392:

370:

308:

259:

185:

121:

86:amorphous polymers

36:

5394:(10): 1195–1198.

4996:(4930): 381–382.

4943:Polymer Mechanics

4923:978-0-201-04545-1

4880:10.1063/1.1729277

4866:(12): 3633–3634.

4819:(12): 2034–2051.

4772:(12): 2585–2617.

4681:978-94-010-2355-9

4644:978-0-85312-685-0

4619:978-0-8493-1656-2

4581:(18): 7504–7518.

4416:10.1063/1.5097685

4396:Physics of Fluids

4349:Physical Review A

4252:(1242): 312–329.

4205:(1065): 192–196.

4137:978-0-19-856527-7

4019:978-0-12-341841-8

3923:10.1063/1.1659831

3909:(12): 4622–4630.

3821:978-0-8031-6569-4

3812:10.1520/stp46955s

3779:978-0-8031-6485-7

3770:10.1520/stp46232s

3735:10.1063/1.1699546

3721:(11): 1071–1083.

3650:(11): 3098–3107.

3564:978-0-8247-9474-3

3507:978-0-412-62460-5

3477:978-0-85334-186-4

3295:Rubber toughening

3248:

3101:

2962:

2871:

2711:{\displaystyle E}

2636:

2480:

2295:

2050:{\displaystyle B}

2030:{\displaystyle A}

1976:

1774:

1375:

1257:

888:

785:

784:

760:Yielding criteria

703:{\displaystyle n}

669:

631:

608:{\displaystyle K}

554:

514:{\displaystyle K}

464:{\displaystyle a}

415:{\displaystyle R}

368:

138:inorganic glasses

116:

5462:

5412:

5411:

5379:

5373:

5372:

5332:

5323:

5322:

5305:(1–2): 247–272.

5290:

5284:

5283:

5258:(3–4): 573–596.

5243:

5237:

5236:

5208:

5202:

5201:

5184:(6): 1145–1156.

5169:

5163:

5162:

5122:

5116:

5115:

5090:(188): 451–467.

5075:

5069:

5068:

5028:

5022:

5021:

5010:10.1038/202381a0

4981:

4975:

4974:

4934:

4928:

4927:

4909:

4903:

4896:

4890:

4889:

4887:

4886:

4851:

4845:

4844:

4804:

4798:

4797:

4757:

4751:

4750:

4710:

4704:

4697:

4691:

4690:

4689:

4688:

4655:

4649:

4648:

4630:

4624:

4623:

4605:

4599:

4598:

4566:

4560:

4553:

4547:

4540:

4534:

4533:

4516:(9): 1651–1655.

4501:

4495:

4494:Springer-Verlag.

4491:

4485:

4484:

4458:

4434:

4428:

4427:

4387:

4381:

4380:

4355:(5): 2221–2227.

4340:

4334:

4331:

4325:

4324:

4284:

4278:

4277:

4237:

4231:

4230:

4190:

4181:

4180:

4163:(9): 1423–1433.

4148:

4142:

4141:

4123:

4117:

4116:

4091:(5): 1217–1234.

4076:

4067:

4066:

4049:(9): 1988–1993.

4035:

4029:

4028:

4027:

4026:

3993:

3984:

3981:

3975:

3972:

3961:

3958:

3945:

3944:

3934:

3894:

3888:

3887:

3868:10.1038/165091a0

3837:

3831:

3830:

3829:

3828:

3795:

3789:

3788:

3787:

3786:

3753:

3747:

3746:

3706:

3700:

3699:

3697:

3696:

3682:

3676:

3675:

3635:

3629:

3628:

3603:(7): 2462–2474.

3588:

3582:

3575:

3569:

3568:

3550:

3544:

3541:

3535:

3531:

3522:

3518:

3512:

3511:

3493:

3482:

3481:

3463:

3454:

3453:

3421:

3412:

3411:Springer-Verlag.

3408:

3402:

3401:

3369:

3360:

3359:

3334:(8): 1393–1403.

3319:

3260:

3258:

3257:

3252:

3250:

3249:

3241:

3224:

3222:

3221:

3216:

3214:

3213:

3201:

3200:

3168:

3166:

3165:

3160:

3158:

3157:

3141:

3139:

3138:

3133:

3131:

3130:

3112:

3110:

3109:

3104:

3102:

3097:

3096:

3095:

3083:

3082:

3070:

3069:

3059:

3054:

3053:

3035:

3033:

3032:

3027:

3025:

3024:

3008:

3006:

3005:

3000:

2998:

2997:

2973:

2971:

2970:

2965:

2963:

2961:

2960:

2959:

2947:

2946:

2936:

2935:

2926:

2921:

2920:

2882:

2880:

2879:

2874:

2872:

2870:

2869:

2868:

2856:

2855:

2843:

2842:

2832:

2828:

2827:

2817:

2809:

2808:

2796:

2795:

2780:

2779:

2764:

2763:

2741:

2739:

2738:

2733:

2717:

2715:

2714:

2709:

2695:

2693:

2692:

2687:

2682:

2681:

2666:

2665:

2650:

2649:

2637:

2629:

2624:

2623:

2605:

2603:

2602:

2597:

2595:

2594:

2582:

2581:

2569:

2568:

2551:principal stress

2547:

2545:

2544:

2539:

2537:

2536:

2520:

2518:

2517:

2512:

2510:

2509:

2491:

2489:

2488:

2483:

2481:

2479:

2478:

2469:

2453:

2452:

2442:

2422:

2421:

2409:

2408:

2390:

2388:

2387:

2382:

2380:

2379:

2351:

2349:

2348:

2343:

2341:

2340:

2325:

2324:

2306:

2304:

2303:

2298:

2296:

2294:

2293:

2292:

2280:

2279:

2266:

2255:

2250:

2249:

2237:

2236:

2227:

2213:

2211:

2210:

2205:

2197:

2196:

2180:

2178:

2177:

2172:

2170:

2169:

2151:

2149:

2148:

2143:

2141:

2140:

2128:

2127:

2115:

2114:

2102:

2101:

2083:

2081:

2080:

2075:

2073:

2072:

2056:

2054:

2053:

2048:

2036:

2034:

2033:

2028:

2016:

2014:

2013:

2008:

2006:

2005:

1987:

1985:

1984:

1979:

1977:

1975:

1974:

1965:

1945:

1919:

1918:

1887:

1885:

1884:

1879:

1877:

1876:

1860:

1858:

1857:

1852:

1850:

1849:

1833:

1831:

1830:

1825:

1813:

1811:

1810:

1805:

1803:

1802:

1785:

1783:

1782:

1777:

1775:

1770:

1769:

1768:

1756:

1755:

1743:

1742:

1732:

1727:

1726:

1708:

1706:

1705:

1700:

1698:

1697:

1679:

1677:

1676:

1671:

1669:

1668:

1653:

1652:

1640:

1639:

1615:

1613:

1612:

1607:

1605:

1604:

1580:

1578:

1577:

1572:

1569:

1564:

1543:

1542:

1533:

1532:

1520:

1519:

1504:

1503:

1494:

1493:

1481:

1480:

1465:

1464:

1455:

1454:

1442:

1441:

1386:

1384:

1383:

1378:

1376:

1374:

1373:

1364:

1363:

1351:

1350:

1335:

1334:

1325:

1324:

1312:

1311:

1296:

1295:

1286:

1285:

1273:

1272:

1260:

1258:

1250:

1245:

1244:

1220:

1218:

1217:

1212:

1210:

1209:

1185:

1183:

1182:

1177:

1174:

1169:

1148:

1147:

1138:

1137:

1125:

1124:

1109:

1108:

1099:

1098:

1086:

1085:

1070:

1069:

1060:

1059:

1047:

1046:

1023:

1021:

1020:

1015:

1013:

1009:

1008:

1007:

998:

997:

985:

984:

969:

968:

959:

958:

946:

945:

930:

929:

920:

919:

907:

906:

889:

881:

876:

875:

857:

855:

854:

849:

847:

846:

806:

804:

803:

798:

796:

795:

786:

777:

776:

709:

707:

706:

701:

687:

685:

684:

679:

677:

676:

671:

670:

662:

643:

641:

640:

635:

633:

632:

624:

614:

612:

611:

606:

594:

592:

591:

586:

584:

583:

565:

563:

562:

557:

555:

547:

545:

544:

520:

518:

517:

512:

497:

495:

494:

489:

487:

486:

470:

468:

467:

462:

442:molecular weight

421:

419:

418:

413:

401:

399:

398:

393:

379:

377:

376:

371:

369:

361:

356:

355:

268:

266:

265:

260:

252:

251:

239:

238:

226:

225:

213:

212:

194:

192:

191:

186:

184:

183:

117:

75:refractive index

5470:

5469:

5465:

5464:

5463:

5461:

5460:

5459:

5430:

5429:

5421:

5416:

5415:

5380:

5376:

5333:

5326:

5291:

5287:

5244:

5240:

5209:

5205:

5170:

5166:

5123:

5119:

5076:

5072:

5029:

5025:

4982:

4978:

4935:

4931:

4924:

4910:

4906:

4897:

4893:

4884:

4882:

4852:

4848:

4805:

4801:

4758:

4754:

4711:

4707:

4698:

4694:

4686:

4684:

4682:

4656:

4652:

4645:

4631:

4627:

4620:

4606:

4602:

4567:

4563:

4554:

4550:

4541:

4537:

4502:

4498:

4492:

4488:

4435:

4431:

4388:

4384:

4341:

4337:

4332:

4328:

4285:

4281:

4238:

4234:

4191:

4184:

4149:

4145:

4138:

4124:

4120:

4077:

4070:

4036:

4032:

4024:

4022:

4020:

3994:

3987:

3982:

3978:

3973:

3964:

3959:

3948:

3895:

3891:

3854:(4186): 91–96.

3838:

3834:

3826:

3824:

3822:

3796:

3792:

3784:

3782:

3780:

3754:

3750:

3707:

3703:

3694:

3692:

3684:

3683:

3679:

3636:

3632:

3589:

3585:

3576:

3572:

3565:

3551:

3547:

3542:

3538:

3532:

3525:

3519:

3515:

3508:

3494:

3485:

3478:

3464:

3457:

3422:

3415:

3409:

3405:

3370:

3363:

3320:

3313:

3308:

3300:Polymer physics

3290:Viscoelasticity

3271:

3240:

3239:

3231:

3228:

3227:

3209:

3205:

3196:

3192:

3190:

3187:

3186:

3175:

3153:

3149:

3147:

3144:

3143:

3126:

3122:

3120:

3117:

3116:

3091:

3087:

3078:

3074:

3065:

3061:

3060:

3058:

3049:

3045:

3043:

3040:

3039:

3020:

3016:

3014:

3011:

3010:

2987:

2983:

2981:

2978:

2977:

2955:

2951:

2942:

2938:

2937:

2931:

2927:

2925:

2910:

2906:

2904:

2901:

2900:

2864:

2860:

2851:

2847:

2838:

2834:

2833:

2823:

2819:

2818:

2816:

2804:

2800:

2791:

2787:

2775:

2771:

2759:

2755:

2753:

2750:

2749:

2744:Poisson's ratio

2727:

2724:

2723:

2720:Young's modulus

2703:

2700:

2699:

2677:

2673:

2661:

2657:

2645:

2641:

2628:

2619:

2615:

2613:

2610:

2609:

2590:

2586:

2577:

2573:

2564:

2560:

2558:

2555:

2554:

2532:

2528:

2526:

2523:

2522:

2505:

2501:

2499:

2496:

2495:

2474:

2470:

2448:

2444:

2443:

2441:

2417:

2413:

2404:

2400:

2398:

2395:

2394:

2375:

2371:

2369:

2366:

2365:

2336:

2332:

2320:

2316:

2314:

2311:

2310:

2288:

2284:

2275:

2271:

2270:

2265:

2251:

2245:

2241:

2232:

2228:

2223:

2221:

2218:

2217:

2192:

2188:

2186:

2183:

2182:

2165:

2161:

2159:

2156:

2155:

2136:

2132:

2123:

2119:

2110:

2106:

2097:

2093:

2091:

2088:

2087:

2068:

2064:

2062:

2059:

2058:

2042:

2039:

2038:

2022:

2019:

2018:

2001:

1997:

1995:

1992:

1991:

1970:

1966:

1946:

1944:

1914:

1910:

1908:

1905:

1904:

1898:

1872:

1868:

1866:

1863:

1862:

1845:

1841:

1839:

1836:

1835:

1819:

1816:

1815:

1798:

1794:

1792:

1789:

1788:

1764:

1760:

1751:

1747:

1738:

1734:

1733:

1731:

1722:

1718:

1716:

1713:

1712:

1693:

1689:

1687:

1684:

1683:

1664:

1660:

1648:

1644:

1629:

1625:

1623:

1620:

1619:

1594:

1590:

1588:

1585:

1584:

1565:

1554:

1538:

1534:

1528:

1524:

1515:

1511:

1499:

1495:

1489:

1485:

1476:

1472:

1460:

1456:

1450:

1446:

1437:

1433:

1428:

1425:

1424:

1399:

1369:

1365:

1359:

1355:

1346:

1342:

1330:

1326:

1320:

1316:

1307:

1303:

1291:

1287:

1281:

1277:

1268:

1264:

1259:

1249:

1234:

1230:

1228:

1225:

1224:

1199:

1195:

1193:

1190:

1189:

1170:

1159:

1143:

1139:

1133:

1129:

1120:

1116:

1104:

1100:

1094:

1090:

1081:

1077:

1065:

1061:

1055:

1051:

1042:

1038:

1033:

1030:

1029:

1003:

999:

993:

989:

980:

976:

964:

960:

954:

950:

941:

937:

925:

921:

915:

911:

902:

898:

894:

890:

880:

871:

867:

865:

862:

861:

842:

838:

836:

833:

832:

791:

787:

775:

773:

770:

769:

762:

757:

716:

695:

692:

691:

672:

661:

660:

659:

651:

648:

647:

623:

622:

620:

617:

616:

600:

597:

596:

579:

575:

573:

570:

569:

546:

540:

536:

528:

525:

524:

506:

503:

502:

482:

478:

476:

473:

472:

456:

453:

452:

428:

407:

404:

403:

387:

384:

383:

360:

351:

347:

342:

339:

338:

324:surface tension

247:

243:

234:

230:

221:

217:

208:

204:

202:

199:

198:

179:

175:

173:

170:

169:

160:

155:

126:

107:

24:

17:

12:

11:

5:

5468:

5458:

5457:

5452:

5447:

5442:

5428:

5427:

5420:

5419:External links

5417:

5414:

5413:

5374:

5347:(3): 173–184.

5324:

5285:

5238:

5219:(3): 547–559.

5203:

5164:

5137:(6): 893–901.

5117:

5070:

5023:

4976:

4929:

4922:

4904:

4891:

4846:

4799:

4752:

4725:(4): 839–865.

4705:

4692:

4680:

4650:

4643:

4625:

4618:

4600:

4561:

4557:Macromolecules

4548:

4544:Macromolecules

4535:

4496:

4486:

4429:

4382:

4335:

4326:

4279:

4232:

4182:

4143:

4136:

4118:

4068:

4030:

4018:

3985:

3976:

3962:

3946:

3889:

3832:

3820:

3790:

3778:

3748:

3701:

3677:

3630:

3583:

3570:

3563:

3545:

3536:

3523:

3513:

3506:

3483:

3476:

3455:

3413:

3403:

3384:(4): 237–246.

3361:

3310:

3309:

3307:

3304:

3303:

3302:

3297:

3292:

3287:

3282:

3277:

3270:

3267:

3247:

3244:

3238:

3235:

3212:

3208:

3204:

3199:

3195:

3174:

3171:

3156:

3152:

3129:

3125:

3100:

3094:

3090:

3086:

3081:

3077:

3073:

3068:

3064:

3057:

3052:

3048:

3023:

3019:

2996:

2993:

2990:

2986:

2958:

2954:

2950:

2945:

2941:

2934:

2930:

2924:

2919:

2916:

2913:

2909:

2867:

2863:

2859:

2854:

2850:

2846:

2841:

2837:

2831:

2826:

2822:

2815:

2812:

2807:

2803:

2799:

2794:

2790:

2786:

2783:

2778:

2774:

2770:

2767:

2762:

2758:

2731:

2707:

2685:

2680:

2676:

2672:

2669:

2664:

2660:

2656:

2653:

2648:

2644:

2640:

2635:

2632:

2627:

2622:

2618:

2593:

2589:

2585:

2580:

2576:

2572:

2567:

2563:

2535:

2531:

2508:

2504:

2477:

2473:

2468:

2465:

2462:

2459:

2456:

2451:

2447:

2440:

2437:

2434:

2431:

2428:

2425:

2420:

2416:

2412:

2407:

2403:

2378:

2374:

2339:

2335:

2331:

2328:

2323:

2319:

2291:

2287:

2283:

2278:

2274:

2269:

2264:

2261:

2258:

2254:

2248:

2244:

2240:

2235:

2231:

2226:

2203:

2200:

2195:

2191:

2168:

2164:

2139:

2135:

2131:

2126:

2122:

2118:

2113:

2109:

2105:

2100:

2096:

2071:

2067:

2046:

2026:

2004:

2000:

1973:

1969:

1964:

1961:

1958:

1955:

1952:

1949:

1943:

1940:

1937:

1934:

1931:

1928:

1925:

1922:

1917:

1913:

1897:

1894:

1875:

1871:

1848:

1844:

1823:

1801:

1797:

1773:

1767:

1763:

1759:

1754:

1750:

1746:

1741:

1737:

1730:

1725:

1721:

1696:

1692:

1667:

1663:

1659:

1656:

1651:

1647:

1643:

1638:

1635:

1632:

1628:

1603:

1600:

1597:

1593:

1568:

1563:

1560:

1557:

1553:

1549:

1546:

1541:

1537:

1531:

1527:

1523:

1518:

1514:

1510:

1507:

1502:

1498:

1492:

1488:

1484:

1479:

1475:

1471:

1468:

1463:

1459:

1453:

1449:

1445:

1440:

1436:

1432:

1398:

1395:

1372:

1368:

1362:

1358:

1354:

1349:

1345:

1341:

1338:

1333:

1329:

1323:

1319:

1315:

1310:

1306:

1302:

1299:

1294:

1290:

1284:

1280:

1276:

1271:

1267:

1263:

1256:

1253:

1248:

1243:

1240:

1237:

1233:

1208:

1205:

1202:

1198:

1173:

1168:

1165:

1162:

1158:

1154:

1151:

1146:

1142:

1136:

1132:

1128:

1123:

1119:

1115:

1112:

1107:

1103:

1097:

1093:

1089:

1084:

1080:

1076:

1073:

1068:

1064:

1058:

1054:

1050:

1045:

1041:

1037:

1012:

1006:

1002:

996:

992:

988:

983:

979:

975:

972:

967:

963:

957:

953:

949:

944:

940:

936:

933:

928:

924:

918:

914:

910:

905:

901:

897:

893:

887:

884:

879:

874:

870:

845:

841:

794:

790:

783:

780:

761:

758:

756:

753:

715:

712:

699:

675:

668:

665:

658:

655:

630:

627:

604:

582:

578:

553:

550:

543:

539:

535:

532:

510:

485:

481:

460:

427:

424:

411:

391:

367:

364:

359:

354:

350:

346:

277:tensile forces

258:

255:

250:

246:

242:

237:

233:

229:

224:

220:

216:

211:

207:

182:

178:

159:

156:

154:

151:

130:Middle English

125:

122:

15:

9:

6:

4:

3:

2:

5467:

5456:

5453:

5451:

5448:

5446:

5443:

5441:

5438:

5437:

5435:

5426:

5423:

5422:

5409:

5405:

5401:

5397:

5393:

5389:

5385:

5378:

5370:

5366:

5362:

5358:

5354:

5350:

5346:

5342:

5338:

5331:

5329:

5320:

5316:

5312:

5308:

5304:

5300:

5296:

5289:

5281:

5277:

5273:

5269:

5265:

5261:

5257:

5253:

5249:

5242:

5234:

5230:

5226:

5222:

5218:

5214:

5207:

5199:

5195:

5191:

5187:

5183:

5179:

5175:

5168:

5160:

5156:

5152:

5148:

5144:

5140:

5136:

5132:

5128:

5121:

5113:

5109:

5105:

5101:

5097:

5093:

5089:

5085:

5081:

5074:

5066:

5062:

5058:

5054:

5050:

5046:

5042:

5038:

5034:

5027:

5019:

5015:

5011:

5007:

5003:

4999:

4995:

4991:

4987:

4980:

4972:

4968:

4964:

4960:

4956:

4952:

4948:

4944:

4940:

4933:

4925:

4919:

4915:

4908:

4901:

4895:

4881:

4877:

4873:

4869:

4865:

4861:

4857:

4850:

4842:

4838:

4834:

4830:

4826:

4822:

4818:

4814:

4810:

4803:

4795:

4791:

4787:

4783:

4779:

4775:

4771:

4767:

4763:

4756:

4748:

4744:

4740:

4736:

4732:

4728:

4724:

4720:

4716:

4709:

4702:

4696:

4683:

4677:

4673:

4669:

4665:

4661:

4654:

4646:

4640:

4636:

4629:

4621:

4615:

4611:

4604:

4596:

4592:

4588:

4584:

4580:

4576:

4572:

4565:

4558:

4552:

4545:

4539:

4531:

4527:

4523:

4519:

4515:

4511:

4507:

4500:

4490:

4482:

4478:

4474:

4470:

4466:

4462:

4457:

4452:

4448:

4444:

4440:

4433:

4425:

4421:

4417:

4413:

4409:

4405:

4401:

4397:

4393:

4386:

4378:

4374:

4370:

4366:

4362:

4358:

4354:

4350:

4346:

4339:

4330:

4322:

4318:

4314:

4310:

4306:

4302:

4298:

4294:

4290:

4283:

4275:

4271:

4267:

4263:

4259:

4255:

4251:

4247:

4243:

4236:

4228:

4224:

4220:

4216:

4212:

4208:

4204:

4200:

4196:

4189:

4187:

4178:

4174:

4170:

4166:

4162:

4158:

4154:

4147:

4139:

4133:

4129:

4122:

4114:

4110:

4106:

4102:

4098:

4094:

4090:

4086:

4082:

4075:

4073:

4064:

4060:

4056:

4052:

4048:

4044:

4041:

4034:

4021:

4015:

4011:

4007:

4003:

3999:

3992:

3990:

3980:

3971:

3969:

3967:

3957:

3955:

3953:

3951:

3942:

3938:

3933:

3932:2027.42/71330

3928:

3924:

3920:

3916:

3912:

3908:

3904:

3900:

3893:

3885:

3881:

3877:

3873:

3869:

3865:

3861:

3857:

3853:

3849:

3848:

3843:

3836:

3823:

3817:

3813:

3809:

3805:

3801:

3794:

3781:

3775:

3771:

3767:

3763:

3759:

3752:

3744:

3740:

3736:

3732:

3728:

3724:

3720:

3716:

3712:

3705:

3691:

3687:

3681:

3673:

3669:

3665:

3661:

3657:

3653:

3649:

3645:

3641:

3634:

3626:

3622:

3618:

3614:

3610:

3606:

3602:

3598:

3594:

3587:

3580:

3574:

3566:

3560:

3556:

3549:

3540:

3530:

3528:

3517:

3509:

3503:

3499:

3492:

3490:

3488:

3479:

3473:

3469:

3462:

3460:

3451:

3447:

3443:

3439:

3435:

3431:

3427:

3420:

3418:

3407:

3399:

3395:

3391:

3387:

3383:

3379:

3375:

3368:

3366:

3357:

3353:

3349:

3345:

3341:

3337:

3333:

3329:

3325:

3318:

3316:

3311:

3301:

3298:

3296:

3293:

3291:

3288:

3286:

3283:

3281:

3278:

3276:

3273:

3272:

3266:

3262:

3245:

3242:

3236:

3233: