27:

1817:

77:. As such, fillers, produced by more than 700 companies, rank among the world's major raw materials and are contained in a variety of goods for daily consumer needs. The top filler materials used are ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), kaolin, talc, and carbon black. Filler materials can affect the tensile strength, toughness, heat resistance, color, clarity, etc. A good example of this is the addition of

1823:

217:

102:

159:

295:

formulated system due to their extremely low bulk density. However, these limitations can be mostly if not entirely overcome through the use of formulation modifications, additives, and other surface treatments. Despite these potential challenges, Polymer Foam Beads can be added to formulated systems when weight or cost savings in a finished good are required.

286:. Nanoparticles are more widely used than nanoplates and nanofibers but nanoplates are starting to become more widely used. Nanoplates are like conventional platy fillers like talc and mica except the thickness is much smaller. The advantages of adding nanofillers include creating a gas barrier and their flame-retardant properties.

294:

Polymer Foam Beads can have a bulk density as low as 0.011 g/cc and range in size from 45 microns to over 8 mm. Common drawbacks to using

Polymer Foam Beads in formulated systems include static, temperature, and chemical resistance limitations and difficulty achieving a homogenous blend within a

1007:

will reduce the weld strength by as much as 32%. The strength of the plastic after welding would decrease with an increasing amount of fillers in the matrix compared to the bulk material. Use of abrasive fillers can affect the tool used for welding. Abrasive fillers will degrade the welding tools

149:

Kaolin is mainly used in plastics for its anti-blocking characteristics as well as an infrared absorber in laser marking. It increases impact strength and heat resistance. Metakolinite is used to stabilize PVC. Kaolin has also been shown to increase the abrasion resistance and can replace carbon

879:

is also an important factor influencing fatigue resistance. If stress is higher than the particles adhesion a crack will form/propagate. Fiber ends are areas where cracks initiate most often due to the high stress on fiber ends with lower adhesion. Talc is a filler that can be used to increase

138:

as a base with a large percentage in composition. Calcium carbonate powder accounts for 97% of the composition will bring white/opaque products more whiteness. So manufacturers can reduce the usage of white masterbatch. With a smaller percentage, calcium carbonate powder can be used for color

866:

resistance depending on the filler type and shape. In general fillers create small discontinuities in the matrix. This can contribute to crack initiation point. If the filler is brittle fatigue resistance will be low, whereas if the filler is very

705:

a, b, c, d are constants depending on the type of filler. "a" relates to stress concentration and is based on adhesion characteristics of the filler material. "b" is normally 0.67. c and d are constants that are inversely related to particle

1024:

Undeniably the importance of filler masterbatch in improving the physical properties of plastics, especially minimizing cost and production efficiency. With the advantage of price and stability, plastic filler supports the production of:

1020:

Filler is widely used in the production process of plastic products. Filler is used to changing the properties of the original plastic. By using plastic filler, manufacturers can save production costs as well as raw materials.

770:

In general fillers will increase impact resistance. The contributing factors that improve impact resistance is particle size, particle shape and particle rigidity. Fibers improve impact resistance the most due to their large

126:

can be used to make a composite. These additions can improve molding productivity by decreasing the cooling rate. They can also increase the operating temperatures of materials and provide insulation for electrical wiring.

122:

Referred to as "chalk" in the plastic industry, calcium carbonate is derived from limestone and marble. It is used in many applications including PVC's and unsaturated polyesters. As much as 90% CaCO

762:, while the addition of elastic filler materials can reduce the value slightly. Filler materials increase the modulus due to their rigidity or stiffness and good adhesion with the polymeric matrix.

1012:

of filler material is to compare weld strength to resin strength. This can be hard to do since many filler materials contain different level of additives that change the mechanical behavior.

2424:

963:

The better the filler bonds with the matrix the better creep resistance will be. Many interactions will have a positive influence. Glass beads and fibers both have been shown to improve

246:

and tensile strength, There is normally not an economic benefit for adding glass as a filler material. Some disadvantages of having glass in the matrix include low surface quality, high

208:

strength. Wollastonite competes with platy filler substances like mica and talc and also can be used to replace glass fibers when creating thermoplastics and thermosets.

89:

are the main subgroups of filler materials. Particulates are small particles of filler that are mixed in the matrix where size and aspect ratio are important.

775:. Low hardness fillers will decrease impact strength. Particle size, within a specific range can increase the impact strengths based on the filler material.

750:

Polymers with smaller additions of filler follow this equation closely. In general addition of filler materials will increase the modulus. The additions of

49:) that can improve specific properties, make the product cheaper, or a mixture of both. The two largest segments for filler material use is elastomers and

2148:

1318:"Physical–mechanical properties and morphology of filled low-density polypropylene: Comparative study on calcium carbonate with oil shale and coal ashes"

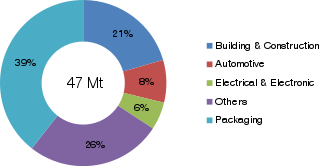

53:. Worldwide, more than 53 million tons of fillers (with a total sum of approximately US$ 18 billion) are used every year in application areas such as

1079:

896:

have been shown to do better than glass in some base materials. In general fibrous materials are better at deflecting heat than particle fillers.

838:

of the material. Particle size and shape are contributing factors. Smaller particle size increase wear resistance because they cause less debris.

1443:

2141:

654:

is the most used method to evaluate filler materials. The tensile strength of the composite can be calculated using the equation

250:

when melted, poor weldability, and warpage. The addition of glass beads will help with oil absorption and chemical resistance.

2024:

1472:

177:

with silica. In the plastic industry, it is used for packaging and food applications due to its long-term thermal stability.

2483:

2434:

2403:

1164:

2134:

1641:

892:

polymers are negligibly affected by filler material. Glass fiber additions are used the most to deflect the most heat.

1602:

1260:

1212:

1174:

1096:

234:, and long glass fibers. in plastics by tonnage. Glass fibers are used to increase the mechanical properties of the

907:

resistance is heavily impacted by filler materials. The equation below shows the creep strain of a filled material:

2126:

1666:

1202:

2419:

2398:

2295:

2049:

330:. Gravel, stone, and sand are used to reduce the cost of concrete. Rebars are used to strengthen the concrete.

1440:

Handbook of

Fillers (4th Edition) - 8. The Effect of Fillers on the Mechanical Properties of Filled Materials.

1008:

faster, for example, the surface of the ultrasonic horn in contact with the plastic. The best way to test the

85:. Most of the filler materials used in plastics are mineral or glass based filler materials. Particulates and

2473:

2393:

303:

Masonry filler is used to repair cracks and holes in exterior walls and is typically made using cement and

1369:

2535:

2466:

2388:

2204:

1801:

1582:

1240:

282:

and fire-resistant fillers. Nanofillers can be broken out into three groups nanoplates, nanofibers, and

1731:

1706:

834:

Matrix and filler both contribute to wear resistance. In general a filler is selected to decrease the

2506:

2240:

2039:

1864:

1681:

1671:

651:

1494:

2310:

2300:

2162:

1849:

1796:

1686:

193:

1900:

1791:

1776:

1756:

20:

1136:

1112:

2315:

2193:

1948:

1676:

1634:

1444:

https://app.knovel.com/hotlink/pdf/id:kt00CQMQQ7/handbook-fillers-4th/effect-fillers-mechanical

1282:

995:

can increase the resin's ability to transmit ultrasonic waves. For electromagnetic welding and

139:

products. In addition, it brings final plastic products a more bright and more glossy surface.

1302:

2495:

2199:

1844:

239:

2530:

2215:

2210:

2183:

2101:

847:

279:

259:

150:

black as a filler material and improve the flow properties of glass-reinforced substances.

8:

2345:

2106:

2029:

1943:

1895:

1357:

968:

964:

904:

174:

888:

Filler materials have a large influence on thermal deformation in crystalline polymers.

2525:

2360:

2278:

2019:

1993:

1963:

1923:

1854:

1806:

1786:

1556:

1521:

1482:

1339:

1252:

984:

872:

863:

720:

263:

42:

971:

resistance. Water absorption will decrease the creep resistance of a filled material.

2490:

2456:

2376:

2188:

2010:

1928:

1627:

1598:

1594:

1560:

1525:

1468:

1343:

1290:

1256:

1208:

1170:

1092:

996:

988:

751:

220:

170:

2381:

2076:

1978:

1953:

1885:

1751:

1746:

1691:

1590:

1552:

1517:

1460:

1329:

1248:

1084:

243:

197:

93:

are small circular strands that can be very long and have very high aspect ratios.

2156:

1394:

1088:

2245:

2231:

2096:

1983:

1973:

1741:

889:

843:

839:

759:

716:

2274:

2086:

1988:

1859:

1508:

Stewart, Richard (March 2007). "ANTEC™ 2007 & Plastics

Encounter @ ANTEC".

62:

1077:

Pelzl, Bernhard; Wolf, Rainer; Kaul, Bansi Lal (2018). "Plastics, Additives".

2519:

2461:

2268:

2054:

2044:

2034:

1938:

1839:

1761:

1711:

1564:

1529:

1464:

1455:

Malloy, Robert A. (2010-10-07). "Plastic Part Design for

Injection Molding".

893:

304:

235:

82:

2081:

2071:

1933:

1880:

1781:

1726:

1701:

983:

of the plastic. This also depends on the type of welding process used. For

967:

resistance in some materials. Aluminum oxide also has a positive effect on

772:

283:

189:

26:

2327:

1816:

2264:

2236:

2171:

2091:

1890:

1771:

1766:

1009:

1004:

980:

231:

135:

2340:

1968:

1958:

1057:

205:

1334:

1317:

2429:

2335:

2305:

2175:

1736:

1721:

1696:

992:

868:

275:

247:

143:

101:

2350:

876:

851:

835:

315:

70:

46:

1822:

2478:

2355:

2256:

2158:

1650:

230:

filler materials come in a few diverse forms: glass beads, short

74:

58:

50:

38:

1241:"Modifying Specific Properties: Mechanical Properties – Fillers"

216:

319:

1015:

723:) of a filled polymer can be found using the equation below:

327:

227:

200:

and high hardness. This filler can improve moisture content,

158:

90:

86:

66:

54:

258:

Coal and shale oil fly ashes have been used as a filler for

1716:

1619:

1000:

784:

755:

323:

201:

166:

78:

1457:

Plastic Part Design for

Injection Molding: An Introduction

979:

Additions of filler materials can drastically affect the

1395:"Functional Fillers and Specialty Minerals for Plastics"

854:

powder are common fillers that improve wear resistance.

1113:"Fillers Market Report: Global Industry Analysis, 2024"

278:. They have a high aspect ratio and are mainly used as

1358:

https://www.buildbase.co.uk/link/1/3434147_31669_t.pdf

169:, a soft mineral and generally more expensive than

37:

materials are particles added to resin or binders (

334:Table Of Filler Materials and Physical Properties

974:

862:Filler can have a negative or positive effect on

274:Nanofiller have a particle size of less than 100

2517:

1280:

765:

1283:"About Calcium Carbonate in filler masterbatch"

1080:Ullmann's Encyclopedia of Industrial Chemistry

2142:

1635:

1076:

945:(t) = is strain of matrix or unfilled polymer

153:

113:

1162:

791:) for plastic materials can be calculated:

2149:

2135:

1642:

1628:

1281:European Plastic, Company (June 5, 2019).

1016:Applications of filler in plastic industry

1580:

1333:

959:=is the Young's Modulus of filled polymer

16:Particles added to improve its properties

1322:Journal of Vinyl and Additive Technology

1129:

641:

215:

204:resistance, thermal stability, and high

180:

173:. It is derived from layering sheets of

157:

100:

25:

1507:

1315:

1200:

223:filler (left) and fiber fillers (right)

2518:

1732:Polyethylene terephthalate (PET, PETE)

1454:

1434:

1238:

1083:. Weinheim: Wiley-VCH. pp. 1–57.

883:

2130:

1672:Cross-linked polyethylene (PEX, XLPE)

1667:Acrylonitrile butadiene styrene (ABS)

1623:

1576:

1574:

1432:

1430:

1428:

1426:

1424:

1422:

1420:

1418:

1416:

1414:

1234:

1232:

1230:

1228:

1226:

1224:

1196:

1194:

1192:

1190:

1188:

1186:

1158:

1156:

1154:

1137:"Market Study: Fillers (3rd edition)"

857:

743:= Modulus of unfilled resin or binder

289:

2484:List of environmental health hazards

2404:List of environmental health hazards

1166:Introduction to Plastics Engineering

1163:Shrivastava, Anshuman (2018-05-15).

695:= tensile strength of polymer matrix

1442:ChemTec Publishing. Retrieved from

1370:"Filler materials Used In Concrete"

646:

13:

2289:Miscellaneous additives incl. PHCs

1571:

1557:10.1002/j.1941-9635.2011.tb01931.x

1522:10.1002/j.1941-9635.2007.tb00070.x

1411:

1221:

1183:

1151:

778:

710:

14:

2547:

1309:

938:(t) = is strain of filled polymer

307:. Manufacturers include Toupret.

298:

196:structure with a relatively high

109:used widely as a filler material.

30:Plastic consumption uses by field

1821:

1815:

1707:Polybutylene terephthalate (PBT)

1682:Poly(methyl methacrylate) (PMMA)

1595:10.1016/b978-188420717-4.50005-1

1253:10.1016/b978-185617370-4/50006-3

1201:Gilbert, Marianne (2016-09-27).

310:

1687:Poly(ethyl methacrylate) (PEMA)

1536:

1501:

1448:

1387:

1362:

1245:Additives for Plastics Handbook

688:= tensile strength of composite

2050:Category:Plastics applications

1797:Styrene maleic anhydride (SMA)

1792:Polyvinylidene chloride (PVDC)

1777:Polytetrafluoroethylene (PTFE)

1350:

1274:

1105:

1070:

975:Weldability of plastic fillers

952:= is Young's Modulus of matrix

269:

1:

1757:Poly(p-phenylene oxide) (PPO)

1089:10.1002/14356007.a20_459.pub2

1063:

830:= Interlaminar shear strength

766:Impact resistance (toughness)

105:Powder calcium carbonate CaCO

2474:Persistent organic pollutant

2435:Toxic Substances Control Act

2394:Persistent organic pollutant

1677:Ethylene vinyl acetate (EVA)

1649:

1589:, Elsevier, pp. 15–27,

1587:Handbook of Plastics Joining

1247:, Elsevier, pp. 19–35,

1204:Brydson's Plastics Materials

811:K = Proportionality constant

253:

7:

2467:Great Pacific garbage patch

2389:Great Pacific garbage patch

1802:Styrene-acrylonitrile (SAN)

1717:Polyetheretherketone (PEEK)

1051:

1032:Blown film & lamination

875:will be fatigue resistant.

702:= volume fraction of filler

10:

2552:

2430:Japan Toxic Substances Law

2225:Miscellaneous plasticizers

154:Magnesium hydroxide (talc)

18:

2504:

2449:

2425:European REACH regulation

2420:California Proposition 65

2412:

2369:

2326:

2288:

2255:

2224:

2170:

2163:polyhalogenated compounds

2119:

2064:

2040:High-performance plastics

2009:

2002:

1914:

1873:

1865:High-performance plastics

1830:

1813:

1657:

318:filler materials include

142:

1850:Fibre-reinforced plastic

1787:Polyvinyl chloride (PVC)

1465:10.3139/9783446433748.fm

1438:Wypych, George. (2016).

1374:www.engineeringcivil.com

1139:. Ceresana. January 2014

899:

746:Φ = Filler concentration

211:

96:

1901:Biodegradable additives

1035:Extrusion (pipe, sheet)

262:that could be used for

114:Calcium carbonate (CaCO

21:Filler (disambiguation)

2316:Perfluorooctanoic acid

1752:Polyphenyl ether (PPE)

1747:Polyoxymethylene (POM)

1692:Polyacrylic acid (PAA)

447:Silica (Precipitated)

224:

163:

110:

31:

2496:Biodegradable plastic

1845:Thermosetting polymer

1742:Polylactic acid (PLA)

1551:(4): 25. April 2011.

1239:Murphy, John (2001),

642:Mechanical properties

219:

161:

104:

29:

2507:Identification codes

2107:Foam food containers

2030:Engineering plastics

1545:Plastics Engineering

1510:Plastics Engineering

1316:Krasnou, I. (2021).

880:fatigue resistance.

848:molybdenum disulfide

836:friction coefficient

820:D = Sliding distance

19:For other uses, see

2346:Endocrine disruptor

1944:Compression molding

1896:Polymer stabilizers

1583:"Vibration Welding"

884:Thermal deformation

572:Magnetite/Hematite

555:Diatomaceous earth

357:Aspect Ratio/Shape

335:

181:Wollastonite (CaSiO

175:magnesium hydroxide

2536:Plastics additives

2361:Polymer fume fever

2020:Commodity plastics

1994:Rotational molding

1964:Fiberglass molding

1924:Injection moulding

1906:Filler (materials)

1855:Corrugated plastic

1807:Tritan copolyester

1762:Polypropylene (PP)

1712:Polycarbonate (PC)

1581:PDL Staff (1997),

1459:. pp. I–XIV.

1301:has generic name (

1207:. William Andrew.

1169:. William Andrew.

985:ultrasonic welding

858:Fatigue resistance

758:will increase the

731:(1 + 2.5Φ + 14.1Φ)

362:Calcium Carbonate

333:

290:Polymer foam beads

225:

164:

134:is used in filler

111:

32:

2513:

2512:

2491:Plastic recycling

2457:Plastic pollution

2443:

2442:

2377:Plastic pollution

2157:Health issues of

2115:

2114:

2011:Plastics industry

1929:Plastic extrusion

1782:Polyurethane (PU)

1772:Polysulfone (PES)

1727:Polyethylene (PE)

1702:Polybutylene (PB)

1474:978-3-446-40468-7

1335:10.1002/vnl.21869

1038:Injection Molding

997:hot plate welding

989:calcium carbonate

752:calcium carbonate

639:

638:

623:Titanium Dioxide

280:scratch resistant

264:injection molding

221:Glass microsphere

171:calcium carbonate

2543:

2382:Rubber pollution

2232:Organophosphates

2151:

2144:

2137:

2128:

2127:

2007:

2006:

1979:Filament winding

1954:Transfer molding

1881:Polymer additive

1825:

1819:

1767:Polystyrene (PS)

1644:

1637:

1630:

1621:

1620:

1614:

1613:

1612:

1611:

1578:

1569:

1568:

1540:

1534:

1533:

1505:

1499:

1498:

1492:

1488:

1486:

1478:

1452:

1446:

1436:

1409:

1408:

1406:

1405:

1399:Phantom Plastics

1391:

1385:

1384:

1382:

1381:

1366:

1360:

1354:

1348:

1347:

1337:

1313:

1307:

1306:

1300:

1296:

1294:

1286:

1278:

1272:

1271:

1270:

1269:

1236:

1219:

1218:

1198:

1181:

1180:

1160:

1149:

1148:

1146:

1144:

1133:

1127:

1126:

1124:

1123:

1117:www.ceresana.com

1109:

1103:

1102:

1074:

652:Tensile strength

647:Tensile strength

336:

332:

244:flexural modulus

198:specific gravity

2551:

2550:

2546:

2545:

2544:

2542:

2541:

2540:

2516:

2515:

2514:

2509:

2500:

2445:

2444:

2439:

2408:

2365:

2322:

2284:

2251:

2220:

2166:

2155:

2121:

2111:

2060:

1998:

1984:Solvent bonding

1974:Plastic welding

1916:

1910:

1869:

1832:

1826:

1820:

1811:

1722:Polyester (PEs)

1659:

1653:

1648:

1618:

1617:

1609:

1607:

1605:

1579:

1572:

1543:"ANTEC® 2011".

1542:

1541:

1537:

1506:

1502:

1490:

1489:

1480:

1479:

1475:

1453:

1449:

1437:

1412:

1403:

1401:

1393:

1392:

1388:

1379:

1377:

1376:. 16 March 2008

1368:

1367:

1363:

1355:

1351:

1314:

1310:

1298:

1297:

1288:

1287:

1279:

1275:

1267:

1265:

1263:

1237:

1222:

1215:

1199:

1184:

1177:

1161:

1152:

1142:

1140:

1135:

1134:

1130:

1121:

1119:

1111:

1110:

1106:

1099:

1075:

1071:

1066:

1054:

1041:Nonwoven fabric

1018:

987:, fillers like

977:

958:

951:

944:

937:

926:

922:

918:

914:

902:

886:

860:

829:

802:

798:

790:

781:

779:Wear resistance

768:

760:elastic modulus

742:

730:

721:Young's modulus

717:elastic modulus

713:

711:Elastic modulus

701:

694:

687:

676:

674:

670:

666:

662:

649:

644:

538:

518:

498:Barium Sulfate

313:

301:

292:

272:

256:

214:

187:

184:

156:

147:

133:

125:

120:

117:

108:

99:

24:

17:

12:

11:

5:

2549:

2539:

2538:

2533:

2528:

2511:

2510:

2505:

2502:

2501:

2499:

2498:

2493:

2488:

2487:

2486:

2481:

2476:

2471:

2470:

2469:

2453:

2451:

2447:

2446:

2441:

2440:

2438:

2437:

2432:

2427:

2422:

2416:

2414:

2410:

2409:

2407:

2406:

2401:

2396:

2391:

2386:

2385:

2384:

2373:

2371:

2367:

2366:

2364:

2363:

2358:

2353:

2348:

2343:

2338:

2332:

2330:

2324:

2323:

2321:

2320:

2319:

2318:

2308:

2303:

2298:

2292:

2290:

2286:

2285:

2283:

2282:

2275:Vinyl chloride

2272:

2269:Polycarbonates

2261:

2259:

2253:

2252:

2250:

2249:

2243:

2234:

2228:

2226:

2222:

2221:

2219:

2218:

2213:

2208:

2202:

2197:

2191:

2186:

2180:

2178:

2168:

2167:

2154:

2153:

2146:

2139:

2131:

2125:

2123:

2117:

2116:

2113:

2112:

2110:

2109:

2104:

2099:

2094:

2089:

2084:

2082:Packaging film

2079:

2074:

2068:

2066:

2065:Specific goods

2062:

2061:

2059:

2058:

2052:

2047:

2042:

2037:

2032:

2027:

2022:

2016:

2014:

2004:

2000:

1999:

1997:

1996:

1991:

1989:Vacuum forming

1986:

1981:

1976:

1971:

1966:

1961:

1956:

1951:

1946:

1941:

1936:

1931:

1926:

1920:

1918:

1912:

1911:

1909:

1908:

1903:

1898:

1893:

1888:

1883:

1877:

1875:

1871:

1870:

1868:

1867:

1862:

1860:Polymeric foam

1857:

1852:

1847:

1842:

1836:

1834:

1828:

1827:

1814:

1812:

1810:

1809:

1804:

1799:

1794:

1789:

1784:

1779:

1774:

1769:

1764:

1759:

1754:

1749:

1744:

1739:

1737:Polyimide (PI)

1734:

1729:

1724:

1719:

1714:

1709:

1704:

1699:

1697:Polyamide (PA)

1694:

1689:

1684:

1679:

1674:

1669:

1663:

1661:

1655:

1654:

1647:

1646:

1639:

1632:

1624:

1616:

1615:

1603:

1570:

1535:

1500:

1491:|journal=

1473:

1447:

1410:

1386:

1361:

1349:

1308:

1273:

1261:

1220:

1213:

1182:

1175:

1150:

1128:

1104:

1097:

1068:

1067:

1065:

1062:

1061:

1060:

1053:

1050:

1049:

1048:

1045:

1042:

1039:

1036:

1033:

1030:

1017:

1014:

976:

973:

961:

960:

956:

953:

949:

946:

942:

939:

935:

928:

927:

924:

920:

916:

912:

901:

898:

885:

882:

859:

856:

832:

831:

827:

824:

821:

818:

815:

812:

805:

804:

800:

796:

788:

780:

777:

767:

764:

748:

747:

744:

740:

733:

732:

728:

712:

709:

708:

707:

703:

699:

696:

692:

689:

685:

678:

677:

672:

668:

664:

660:

658:

648:

645:

643:

640:

637:

636:

633:

630:

627:

624:

620:

619:

616:

613:

610:

607:

603:

602:

599:

596:

593:

590:

586:

585:

582:

579:

576:

573:

569:

568:

565:

562:

559:

556:

552:

551:

548:

545:

542:

539:

536:

532:

531:

528:

525:

522:

519:

516:

512:

511:

508:

505:

502:

499:

495:

494:

491:

488:

485:

482:

478:

477:

474:

471:

468:

465:

461:

460:

457:

454:

451:

448:

444:

443:

440:

437:

434:

431:

427:

426:

423:

420:

417:

414:

410:

409:

406:

403:

400:

397:

393:

392:

389:

386:

383:

380:

376:

375:

372:

369:

366:

363:

359:

358:

355:

349:

348:Mohs Hardness

346:

340:

312:

309:

300:

299:Masonry filler

297:

291:

288:

271:

268:

266:applications.

260:thermoplastics

255:

252:

213:

210:

186:

182:

179:

162:Block of talc.

155:

152:

146:

141:

131:

123:

119:

115:

112:

106:

98:

95:

15:

9:

6:

4:

3:

2:

2548:

2537:

2534:

2532:

2529:

2527:

2524:

2523:

2521:

2508:

2503:

2497:

2494:

2492:

2489:

2485:

2482:

2480:

2477:

2475:

2472:

2468:

2465:

2464:

2463:

2462:Garbage patch

2460:

2459:

2458:

2455:

2454:

2452:

2448:

2436:

2433:

2431:

2428:

2426:

2423:

2421:

2418:

2417:

2415:

2411:

2405:

2402:

2400:

2397:

2395:

2392:

2390:

2387:

2383:

2380:

2379:

2378:

2375:

2374:

2372:

2368:

2362:

2359:

2357:

2354:

2352:

2349:

2347:

2344:

2342:

2339:

2337:

2334:

2333:

2331:

2329:

2328:Health issues

2325:

2317:

2314:

2313:

2312:

2309:

2307:

2304:

2302:

2299:

2297:

2294:

2293:

2291:

2287:

2280:

2276:

2273:

2270:

2266:

2263:

2262:

2260:

2258:

2254:

2247:

2244:

2242:

2238:

2235:

2233:

2230:

2229:

2227:

2223:

2217:

2214:

2212:

2209:

2206:

2203:

2201:

2198:

2195:

2192:

2190:

2187:

2185:

2182:

2181:

2179:

2177:

2173:

2169:

2164:

2160:

2152:

2147:

2145:

2140:

2138:

2133:

2132:

2129:

2124:

2118:

2108:

2105:

2103:

2102:Shopping bags

2100:

2098:

2095:

2093:

2090:

2088:

2085:

2083:

2080:

2078:

2075:

2073:

2070:

2069:

2067:

2063:

2057:(Agriculture)

2056:

2055:Plasticulture

2053:

2051:

2048:

2046:

2043:

2041:

2038:

2036:

2035:Geosynthetics

2033:

2031:

2028:

2026:

2023:

2021:

2018:

2017:

2015:

2012:

2008:

2005:

2001:

1995:

1992:

1990:

1987:

1985:

1982:

1980:

1977:

1975:

1972:

1970:

1967:

1965:

1962:

1960:

1957:

1955:

1952:

1950:

1947:

1945:

1942:

1940:

1939:Thermoforming

1937:

1935:

1932:

1930:

1927:

1925:

1922:

1921:

1919:

1913:

1907:

1904:

1902:

1899:

1897:

1894:

1892:

1889:

1887:

1884:

1882:

1879:

1878:

1876:

1872:

1866:

1863:

1861:

1858:

1856:

1853:

1851:

1848:

1846:

1843:

1841:

1840:Thermoplastic

1838:

1837:

1835:

1829:

1824:

1818:

1808:

1805:

1803:

1800:

1798:

1795:

1793:

1790:

1788:

1785:

1783:

1780:

1778:

1775:

1773:

1770:

1768:

1765:

1763:

1760:

1758:

1755:

1753:

1750:

1748:

1745:

1743:

1740:

1738:

1735:

1733:

1730:

1728:

1725:

1723:

1720:

1718:

1715:

1713:

1710:

1708:

1705:

1703:

1700:

1698:

1695:

1693:

1690:

1688:

1685:

1683:

1680:

1678:

1675:

1673:

1670:

1668:

1665:

1664:

1662:

1656:

1652:

1645:

1640:

1638:

1633:

1631:

1626:

1625:

1622:

1606:

1604:9781884207174

1600:

1596:

1592:

1588:

1584:

1577:

1575:

1566:

1562:

1558:

1554:

1550:

1546:

1539:

1531:

1527:

1523:

1519:

1515:

1511:

1504:

1496:

1484:

1476:

1470:

1466:

1462:

1458:

1451:

1445:

1441:

1435:

1433:

1431:

1429:

1427:

1425:

1423:

1421:

1419:

1417:

1415:

1400:

1396:

1390:

1375:

1371:

1365:

1359:

1353:

1345:

1341:

1336:

1331:

1327:

1323:

1319:

1312:

1304:

1292:

1284:

1277:

1264:

1262:9781856173704

1258:

1254:

1250:

1246:

1242:

1235:

1233:

1231:

1229:

1227:

1225:

1216:

1214:9780323370226

1210:

1206:

1205:

1197:

1195:

1193:

1191:

1189:

1187:

1178:

1176:9780323396196

1172:

1168:

1167:

1159:

1157:

1155:

1138:

1132:

1118:

1114:

1108:

1100:

1098:9783527306732

1094:

1090:

1086:

1082:

1081:

1073:

1069:

1059:

1056:

1055:

1047:Thermoforming

1046:

1043:

1040:

1037:

1034:

1031:

1028:

1027:

1026:

1022:

1013:

1011:

1006:

1002:

999:additions of

998:

994:

990:

986:

982:

972:

970:

966:

954:

947:

940:

933:

932:

931:

910:

909:

908:

906:

897:

895:

894:Carbon fibers

891:

881:

878:

874:

870:

865:

855:

853:

849:

845:

841:

837:

825:

822:

819:

816:

813:

810:

809:

808:

794:

793:

792:

786:

776:

774:

763:

761:

757:

753:

745:

738:

737:

736:

726:

725:

724:

722:

718:

704:

697:

690:

683:

682:

681:

657:

656:

655:

653:

634:

631:

628:

625:

622:

621:

617:

614:

611:

608:

605:

604:

600:

597:

594:

591:

588:

587:

583:

580:

577:

574:

571:

570:

566:

563:

560:

557:

554:

553:

549:

546:

543:

540:

534:

533:

529:

526:

523:

520:

514:

513:

509:

506:

503:

500:

497:

496:

492:

489:

486:

483:

480:

479:

475:

472:

469:

466:

464:Carbon Black

463:

462:

458:

455:

452:

449:

446:

445:

441:

438:

435:

432:

429:

428:

425:20-100 Plate

424:

421:

418:

415:

412:

411:

407:

404:

401:

398:

396:Wollastonite

395:

394:

390:

387:

384:

381:

378:

377:

373:

370:

367:

364:

361:

360:

356:

354:

350:

347:

345:

341:

338:

337:

331:

329:

325:

321:

317:

311:Other fillers

308:

306:

305:hydrated lime

296:

287:

285:

284:nanoparticles

281:

277:

267:

265:

261:

251:

249:

245:

241:

237:

236:thermoplastic

233:

229:

222:

218:

209:

207:

203:

199:

195:

191:

178:

176:

172:

168:

160:

151:

145:

140:

137:

128:

103:

94:

92:

88:

84:

83:polypropylene

80:

76:

72:

68:

64:

60:

56:

52:

48:

44:

40:

36:

28:

22:

2172:Plasticizers

2120:Environment

2072:Blister pack

2025:Construction

1934:Blow molding

1905:

1608:, retrieved

1586:

1548:

1544:

1538:

1516:(3): 24–38.

1513:

1509:

1503:

1456:

1450:

1439:

1402:. Retrieved

1398:

1389:

1378:. Retrieved

1373:

1364:

1352:

1325:

1321:

1311:

1299:|first=

1276:

1266:, retrieved

1244:

1203:

1165:

1141:. Retrieved

1131:

1120:. Retrieved

1116:

1107:

1078:

1072:

1029:Blow molding

1023:

1019:

978:

962:

929:

903:

887:

861:

833:

806:

782:

773:aspect ratio

769:

749:

734:

714:

679:

650:

442:10-30 Plate

352:

343:

339:Filler Type

314:

302:

293:

273:

257:

232:glass fibers

226:

190:Wollastonite

188:

165:

148:

129:

121:

69:, coatings,

34:

33:

2531:Papermaking

2413:Regulations

2265:Bisphenol A

1949:Calendering

1891:Plasticizer

1831:Mechanical

1143:7 September

1010:weldability

981:weldability

817:E = Modulus

799:= KμPDW/(EI

606:Zinc Oxide

589:Halloysite

550:1-10 Plate

530:1-10 Plate

473:0.014-0.25

408:5-30 Fiber

391:5-40 Plate

374:1-3 Blocky

270:Nanofillers

136:masterbatch

2520:Categories

2341:Carcinogen

2306:Organotins

2176:Phthalates

2122:and health

1969:Pultrusion

1959:Laminating

1917:processing

1610:2019-02-15

1404:2019-02-20

1380:2019-04-03

1356:Buildbase

1328:: 94–103.

1268:2019-02-14

1122:2019-02-14

1064:References

1058:Adulterant

601:5-20 Tube

584:~1 Blocky

567:2-10 Disc

535:MDH Mg(OH)

515:ATH Al(OH)

456:0.005-0.1

353:(Microns)

351:Mean Size

276:nanometres

206:dielectric

43:composites

2526:Materials

2370:Pollution

2336:Teratogen

2267:(BPA, in

1915:Plastics

1886:Colorants

1874:Additives

1658:Chemical

1565:0091-9578

1530:0091-9578

1493:ignored (

1483:cite book

1344:244252984

890:Amorphous

873:composite

814:P = force

787:volume (W

510:~1 Round

493:~1 Round

481:Dolomite

476:~1 Round

459:~1 Round

322:, stone,

254:Fly ashes

248:viscosity

240:thermoset

71:adhesives

2351:Diabetes

2257:Monomers

2237:Adipates

2159:plastics

2013:segments

2003:Products

1651:Plastics

1291:cite web

1052:See also

877:Adhesion

852:graphite

823:W = load

635:1 Round

618:1 Round

615:0.05-10

501:4.0-4.5

467:1.7-1.9

450:1.9-2.1

416:2.8-2.9

382:2.7-2.8

371:0.02-30

342:Density

316:Concrete

242:such as

194:acicular

75:sealants

59:plastics

51:plastics

47:concrete

39:plastics

2479:Dioxins

2399:Dioxins

2356:Obesity

2097:Cutlery

2087:Bottles

930:where:

919:(t) = E

869:ductile

864:fatigue

844:alumina

807:where:

735:where:

632:0.1-10

507:0.1-30

430:Kaolin

422:5-1000

388:0.5-20

344:(g/cm)

192:has an

2196:(BBzP)

2165:(PHCs)

2077:Chairs

2045:Nurdle

1601:

1563:

1528:

1471:

1342:

1259:

1211:

1173:

1095:

1044:Raffia

993:kaolin

850:, and

840:silica

680:where

578:5.5-6

561:5.5-6

558:2-2.5

547:0.5-8

544:2.5-3

524:2.5-3

504:3-3.5

487:3.5-4

439:0.2-8

419:2.5-4

405:1-500

326:, and

320:gravel

144:Kaolin

91:Fibers

87:fibers

73:, and

67:paints

63:rubber

35:Filler

2450:Waste

2296:PBDEs

2207:(DOP)

1833:types

1660:types

1340:S2CID

1005:glass

969:creep

965:creep

915:(t)/ε

905:Creep

900:Creep

727:E = E

706:size.

667:(1-aΦ

626:4.23

598:1-20

592:2.54

581:1-50

564:4-30

527:5-80

521:2.42

490:1-30

484:2.85

413:Mica

379:Talc

328:rebar

228:Glass

212:Glass

97:Types

55:paper

2311:PFCs

2301:PCBs

2277:(in

2241:DEHA

2216:DINP

2211:DIDP

2205:DEHP

2200:DIHP

2184:DIBP

2161:and

2092:Bags

1599:ISBN

1561:ISSN

1526:ISSN

1495:help

1469:ISBN

1303:help

1257:ISBN

1209:ISBN

1171:ISBN

1145:2015

1093:ISBN

1003:and

1001:talc

991:and

871:the

785:wear

783:The

756:talc

754:and

715:The

612:4.5

609:5.6

595:2.5

575:5.2

541:2.4

470:2-3

453:5.5

433:2.6

402:4.5

399:2.9

368:3-4

365:2.7

324:sand

202:wear

167:Talc

130:CaCO

79:talc

2279:PVC

2246:DOA

2194:BBP

2189:DBP

1591:doi

1553:doi

1518:doi

1461:doi

1330:doi

1249:doi

1085:doi

671:+cΦ

663:= σ

238:or

81:to

2522::

2174::

1597:,

1585:,

1573:^

1559:.

1549:67

1547:.

1524:.

1514:63

1512:.

1487::

1485:}}

1481:{{

1467:.

1413:^

1397:.

1372:.

1338:.

1326:28

1324:.

1320:.

1295::

1293:}}

1289:{{

1255:,

1243:,

1223:^

1185:^

1153:^

1115:.

1091:.

923:/E

846:,

842:,

629:6

436:2

385:1

65:,

61:,

57:,

45:,

41:,

2281:)

2271:)

2248:)

2239:(

2150:e

2143:t

2136:v

1643:e

1636:t

1629:v

1593::

1567:.

1555::

1532:.

1520::

1497:)

1477:.

1463::

1407:.

1383:.

1346:.

1332::

1305:)

1285:.

1251::

1217:.

1179:.

1147:.

1125:.

1101:.

1087::

957:c

955:E

950:m

948:E

943:m

941:ε

936:c

934:ε

925:c

921:m

917:m

913:c

911:ε

828:s

826:I

803:)

801:s

797:s

795:W

789:s

741:0

739:E

729:0

719:(

700:f

698:Φ

693:p

691:σ

686:c

684:σ

675:)

673:f

669:f

665:p

661:c

659:σ

537:2

517:3

185:)

183:3

132:3

124:3

118:)

116:3

107:3

23:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.