128:) of all three basic pump types (gear, vane and piston pumps) These pumps create pressure through the meshing of the gear teeth, which forces fluid around the gears to pressurize the outlet side. Some gear pumps can be quite noisy, compared to other types, but modern gear pumps are highly reliable and much quieter than older models. This is in part due to designs incorporating split gears, helical gear teeth and higher precision/quality tooth profiles that mesh and unmesh more smoothly, reducing pressure ripple and related detrimental problems. Another positive attribute of the gear pump, is that catastrophic breakdown is a lot less common than in most other types of hydraulic pumps. This is because the gears gradually wear down the housing and/or main bushings, reducing the volumetric efficiency of the pump gradually until it is all but useless. This often happens long before wear and causes the unit to seize or break down. Hydraulic gear pumps are used in various applications where there are different requirements such as lifting, lowering, opening, closing, or rotating, and they are expected to be safe and long-lasting.

230:, axial piston pumps and motors using the bent axis principle, fixed or adjustable displacement, exists in two different basic designs. The Thoma-principle (engineer Hans Thoma, Germany, patent 1935) with max 25 degrees angle and the Wahlmark-principle (Gunnar Axel Wahlmark, patent 1960) with spherical-shaped pistons in one piece with the piston rod, piston rings, and maximum 40 degrees between the driveshaft centerline and pistons (Volvo Hydraulics Co.). These have the best efficiency of all pumps. Although in general, the largest displacements are approximately one litre per revolution, if necessary a two-liter swept volume pump can be built. Often variable-displacement pumps are used so that the oil flow can be adjusted carefully. These pumps can in general work with a working pressure of up to 350–420 bars in continuous work.

157:

vanes are pushed into contact with the pump housing, and how the vane tips are machined at this very point. Several type of "lip" designs are used, and the main objective is to provide a tight seal between the inside of the housing and the vane, and at the same time to minimize wear and metal-to-metal contact. Forcing the vane out of the rotating centre and towards the pump housing is accomplished using spring-loaded vanes, or more traditionally, vanes loaded hydrodynamically (via the pressurized system fluid).

20:

259:

149:

166:

132:

156:

A rotary vane pump is a positive-displacement pump that consists of vanes mounted to a rotor that rotates inside a cavity. In some cases these vanes can have variable length and/or be tensioned to maintain contact with the walls as the pump rotates. A critical element in vane pump design is how the

246:

By using different compensation techniques, the variable displacement type of these pumps can continuously alter fluid discharge per revolution and system pressure based on load requirements, maximum pressure cut-off settings, horsepower/ratio control, and even fully electro proportional systems,

39:

and can be hydrostatic or hydrodynamic. They generate flow with enough power to overcome pressure induced by a load at the pump outlet. When a hydraulic pump operates, it creates a vacuum at the pump inlet, which forces liquid from the reservoir into the inlet line to the pump and by mechanical

180:

that intermesh and are enclosed within the same chamber. These pumps are used for high flows at relatively low pressure (max 100 bars (10,000 kPa)). They were used on board ships where a constant pressure hydraulic system extended through the whole ship, especially to control

74:

239:

56:

247:

requiring no other input than electrical signals. This makes them potentially hugely power saving compared to other constant flow pumps in systems where prime mover/diesel/electric motor rotational speed is constant and required fluid flow is non-constant.

724:

513:

945:

48:, which have a more complicated construction that allows the displacement to be adjusted. Hydrodynamic pumps are more frequent in day-to-day life. Hydrostatic pumps of various types all work on the principle of

328:

1171:

653:

789:

441:

820:

595:

410:

1049:

758:

1095:

988:

622:

126:

266:

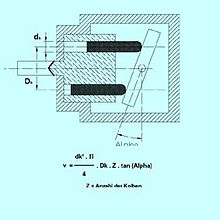

A radial piston pump is a form of hydraulic pump. The working pistons extend in a radial direction symmetrically around the drive shaft, in contrast to the axial piston pump.

564:

540:

379:

355:

185:

but also to help drive the steering gear and other systems. The advantage of the screw pumps is the low sound level of these pumps; however, the efficiency is not high.

666:

44:

while hydrodynamic pumps can be fixed displacement pumps, in which the displacement (flow through the pump per rotation of the pump) cannot be adjusted, or

32:

454:

188:

The major problem of screw pumps is that the hydraulic reaction force is transmitted in a direction that's axially opposed to the direction of the flow.

227:

833:

281:

1123:

1202:

1197:

1229:

629:

765:

1415:

417:

796:

571:

386:

995:

734:

1420:

40:

action delivers this liquid to the pump outlet and forces it into the hydraulic system. Hydrostatic pumps are

1056:

955:

602:

95:

1298:

1288:

1425:

45:

41:

1113:

Parr, Andrew (2011). "Hydraulics and

Pneumatics a technician's and engineer's guide", p. 38. Elsevier.

1303:

1293:

547:

523:

362:

338:

1283:

1222:

1374:

84:(with external teeth) (fixed displacement) are simple and economical pumps. The swept volume or

1394:

1359:

36:

88:

of gear pumps for hydraulics will be between about 1 to 200 milliliters. They have the lowest

1339:

1318:

1267:

89:

719:{\displaystyle n_{\text{mech}}={T_{\text{theoretical}} \over T_{\text{actual}}}\cdot 100\%}

177:

8:

1451:

1334:

1215:

85:

1364:

1354:

1147:

198:

create a hydraulic balance by directing a hydraulic force to a piston under the rotor.

31:

is a mechanical source of power that converts mechanical power into hydraulic energy (

1349:

1308:

508:{\displaystyle P={n\cdot V_{\text{stroke}}\cdot \Delta p \over \eta _{\text{mech}}}}

1379:

1369:

1344:

1312:

1257:

49:

1446:

1399:

1440:

1389:

1262:

59:

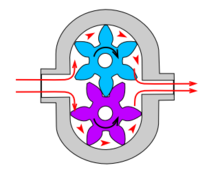

Gearpump with external teeth, note the rotational direction of the gears.

1252:

1238:

182:

173:

940:{\displaystyle n_{hydr}={Q_{actual} \over Q_{theoretical}}\cdot 100\%}

258:

19:

81:

148:

323:{\displaystyle Q=n\cdot V_{\text{stroke}}\cdot \eta _{\text{vol}}}

169:

Principle of screw pump (Saugseite = intake, Druckseite = outflow)

136:

1124:"4 Design Features That Determine Hydraulic Gear Pump Selection"

131:

73:

1207:

238:

165:

55:

1172:"AMPHIMAX HYDRAULICS PUMPS WHEEL MOTORS CONTROLS VALVES"

269:

1060:

999:

959:

800:

769:

738:

633:

606:

575:

551:

527:

421:

390:

366:

342:

1059:

998:

958:

836:

799:

768:

737:

669:

648:{\displaystyle \scriptstyle \eta _{\text{mech,hydr}}}

632:

605:

574:

550:

526:

457:

420:

389:

365:

341:

284:

98:

784:{\displaystyle \scriptstyle T_{\text{theoretical}}}

1089:

1043:

982:

939:

814:

783:

752:

718:

647:

616:

589:

558:

534:

507:

435:

404:

373:

349:

322:

120:

35:i.e. flow, pressure). Hydraulic pumps are used in

1438:

436:{\displaystyle \scriptstyle \eta _{\text{vol}}}

815:{\displaystyle \scriptstyle T_{\text{actual}}}

590:{\displaystyle \scriptstyle V_{\text{stroke}}}

405:{\displaystyle \scriptstyle V_{\text{stroke}}}

1223:

191:There are two ways to overcome this problem:

1044:{\displaystyle \scriptstyle Q_{theoretical}}

753:{\displaystyle \scriptstyle n_{\text{mech}}}

233:

1230:

1216:

63:

659:

257:

237:

195:put a thrust bearing beneath each rotor;

164:

147:

130:

72:

54:

18:

1148:"Hydraulic Pumps | Hydraulic Parts USA"

1090:{\displaystyle \scriptstyle Q_{actual}}

826:

242:Axial piston pump, swashplate principle

139:(image does not show intake or exhaust)

1439:

253:

1211:

983:{\displaystyle \scriptstyle n_{hydr}}

617:{\displaystyle \scriptstyle \Delta p}

270:Hydraulic pumps, calculation formulas

121:{\displaystyle \eta _{v}\approx 90\%}

760:, mechanical pump efficiency percent

624:, pressure difference over pump (Pa)

176:(fixed displacement) consist of two

143:

23:Fluid flow in an external gear pump

13:

934:

713:

607:

486:

222:

115:

14:

1463:

1191:

655:, mechanical/hydraulic efficiency

1237:

1203:Internal gear pump description

1198:External gear pump description

1164:

1140:

1116:

1107:

1051:, theoretical flow rate output

559:{\displaystyle \scriptstyle n}

535:{\displaystyle \scriptstyle P}

374:{\displaystyle \scriptstyle n}

350:{\displaystyle \scriptstyle Q}

160:

1:

1101:

791:, theoretical torque to drive

68:

152:Fixed displacement vane pump

77:Gearpump with internal teeth

7:

990:, hydraulic pump efficiency

46:variable displacement pumps

42:positive displacement pumps

10:

1468:

1408:

1327:

1304:Hydrological optimization

1294:Groundwater flow equation

1276:

1245:

1176:www.bluebird-electric.net

1097:, actual flow rate output

234:Inline axial piston pumps

822:, actual torque to drive

447:

1299:Hazen–Williams equation

1289:Darcy–Weisbach equation

566:, stroke frequency (Hz)

443:, volumetric efficiency

381:, stroke frequency (Hz)

274:

64:Types of hydraulic pump

37:hydraulic drive systems

16:Mechanical power source

1091:

1045:

984:

941:

816:

785:

754:

720:

649:

618:

591:

560:

536:

509:

437:

406:

375:

351:

324:

263:

243:

202:Types of screw pumps:

170:

153:

140:

122:

78:

60:

24:

1319:Pipe network analysis

1284:Bernoulli's principle

1268:Hydraulic engineering

1152:hydraulicpartsusa.com

1092:

1046:

985:

942:

817:

786:

755:

721:

660:Mechanical efficiency

650:

619:

592:

561:

537:

510:

438:

407:

376:

352:

325:

261:

241:

168:

151:

134:

123:

90:volumetric efficiency

76:

58:

22:

1057:

996:

956:

834:

827:Hydraulic efficiency

797:

766:

735:

667:

630:

603:

597:, stroked volume (m)

572:

548:

524:

455:

418:

412:, stroked volume (m)

387:

363:

339:

282:

218:multi rotor untimed.

96:

254:Radial piston pumps

1128:www.blueascend.com

1087:

1086:

1041:

1040:

980:

979:

937:

812:

811:

781:

780:

750:

749:

716:

645:

644:

614:

613:

587:

586:

556:

555:

532:

531:

505:

433:

432:

402:

401:

371:

370:

347:

346:

320:

264:

262:Radial piston pump

244:

178:Archimedes' screws

171:

154:

141:

118:

79:

61:

33:hydrostatic energy

25:

1434:

1433:

1309:Open-channel flow

926:

808:

777:

746:

705:

702:

692:

677:

641:

583:

503:

500:

480:

429:

398:

317:

304:

215:multi rotor timed

144:Rotary vane pumps

1459:

1232:

1225:

1218:

1209:

1208:

1186:

1185:

1183:

1182:

1168:

1162:

1161:

1159:

1158:

1144:

1138:

1137:

1135:

1134:

1120:

1114:

1111:

1096:

1094:

1093:

1088:

1085:

1084:

1050:

1048:

1047:

1042:

1039:

1038:

989:

987:

986:

981:

978:

977:

946:

944:

943:

938:

927:

925:

924:

885:

884:

860:

855:

854:

821:

819:

818:

813:

810:

809:

806:

790:

788:

787:

782:

779:

778:

775:

759:

757:

756:

751:

748:

747:

744:

725:

723:

722:

717:

706:

704:

703:

700:

694:

693:

690:

684:

679:

678:

675:

654:

652:

651:

646:

643:

642:

639:

623:

621:

620:

615:

596:

594:

593:

588:

585:

584:

581:

565:

563:

562:

557:

541:

539:

538:

533:

514:

512:

511:

506:

504:

502:

501:

498:

492:

482:

481:

478:

465:

442:

440:

439:

434:

431:

430:

427:

411:

409:

408:

403:

400:

399:

396:

380:

378:

377:

372:

356:

354:

353:

348:

329:

327:

326:

321:

319:

318:

315:

306:

305:

302:

127:

125:

124:

119:

108:

107:

1467:

1466:

1462:

1461:

1460:

1458:

1457:

1456:

1437:

1436:

1435:

1430:

1409:Public networks

1404:

1323:

1313:Manning formula

1272:

1258:Hydraulic fluid

1241:

1236:

1194:

1189:

1180:

1178:

1170:

1169:

1165:

1156:

1154:

1146:

1145:

1141:

1132:

1130:

1122:

1121:

1117:

1112:

1108:

1104:

1065:

1061:

1058:

1055:

1054:

1004:

1000:

997:

994:

993:

964:

960:

957:

954:

953:

890:

886:

865:

861:

859:

841:

837:

835:

832:

831:

829:

805:

801:

798:

795:

794:

774:

770:

767:

764:

763:

743:

739:

736:

733:

732:

699:

695:

689:

685:

683:

674:

670:

668:

665:

664:

662:

638:

634:

631:

628:

627:

604:

601:

600:

580:

576:

573:

570:

569:

549:

546:

545:

525:

522:

521:

497:

493:

477:

473:

466:

464:

456:

453:

452:

450:

426:

422:

419:

416:

415:

395:

391:

388:

385:

384:

364:

361:

360:

340:

337:

336:

314:

310:

301:

297:

283:

280:

279:

277:

272:

256:

250:

236:

228:Bent axis pumps

225:

223:Bent axis pumps

163:

146:

103:

99:

97:

94:

93:

71:

66:

17:

12:

11:

5:

1465:

1455:

1454:

1449:

1432:

1431:

1429:

1428:

1423:

1418:

1412:

1410:

1406:

1405:

1403:

1402:

1397:

1392:

1387:

1382:

1377:

1372:

1367:

1362:

1357:

1352:

1347:

1342:

1337:

1331:

1329:

1325:

1324:

1322:

1321:

1316:

1306:

1301:

1296:

1291:

1286:

1280:

1278:

1274:

1273:

1271:

1270:

1265:

1260:

1255:

1249:

1247:

1243:

1242:

1235:

1234:

1227:

1220:

1212:

1206:

1205:

1200:

1193:

1192:External links

1190:

1188:

1187:

1163:

1139:

1115:

1105:

1103:

1100:

1099:

1098:

1083:

1080:

1077:

1074:

1071:

1068:

1064:

1052:

1037:

1034:

1031:

1028:

1025:

1022:

1019:

1016:

1013:

1010:

1007:

1003:

991:

976:

973:

970:

967:

963:

936:

933:

930:

923:

920:

917:

914:

911:

908:

905:

902:

899:

896:

893:

889:

883:

880:

877:

874:

871:

868:

864:

858:

853:

850:

847:

844:

840:

828:

825:

824:

823:

804:

792:

773:

761:

742:

715:

712:

709:

698:

688:

682:

673:

661:

658:

657:

656:

637:

625:

612:

609:

598:

579:

567:

554:

543:

530:

496:

491:

488:

485:

476:

472:

469:

463:

460:

449:

446:

445:

444:

425:

413:

394:

382:

369:

358:

345:

313:

309:

300:

296:

293:

290:

287:

276:

273:

271:

268:

255:

252:

235:

232:

224:

221:

220:

219:

216:

213:

210:

207:

200:

199:

196:

162:

159:

145:

142:

117:

114:

111:

106:

102:

70:

67:

65:

62:

29:hydraulic pump

15:

9:

6:

4:

3:

2:

1464:

1453:

1450:

1448:

1445:

1444:

1442:

1427:

1424:

1422:

1419:

1417:

1414:

1413:

1411:

1407:

1401:

1398:

1396:

1393:

1391:

1388:

1386:

1383:

1381:

1378:

1376:

1375:Power network

1373:

1371:

1368:

1366:

1363:

1361:

1358:

1356:

1353:

1351:

1348:

1346:

1343:

1341:

1338:

1336:

1333:

1332:

1330:

1326:

1320:

1317:

1314:

1310:

1307:

1305:

1302:

1300:

1297:

1295:

1292:

1290:

1287:

1285:

1282:

1281:

1279:

1275:

1269:

1266:

1264:

1261:

1259:

1256:

1254:

1251:

1250:

1248:

1244:

1240:

1233:

1228:

1226:

1221:

1219:

1214:

1213:

1210:

1204:

1201:

1199:

1196:

1195:

1177:

1173:

1167:

1153:

1149:

1143:

1129:

1125:

1119:

1110:

1106:

1081:

1078:

1075:

1072:

1069:

1066:

1062:

1053:

1035:

1032:

1029:

1026:

1023:

1020:

1017:

1014:

1011:

1008:

1005:

1001:

992:

974:

971:

968:

965:

961:

952:

951:

950:

947:

931:

928:

921:

918:

915:

912:

909:

906:

903:

900:

897:

894:

891:

887:

881:

878:

875:

872:

869:

866:

862:

856:

851:

848:

845:

842:

838:

802:

793:

771:

762:

740:

731:

730:

729:

726:

710:

707:

696:

686:

680:

671:

635:

626:

610:

599:

577:

568:

552:

544:

528:

520:

519:

518:

515:

494:

489:

483:

474:

470:

467:

461:

458:

423:

414:

392:

383:

367:

359:

343:

335:

334:

333:

330:

311:

307:

298:

294:

291:

288:

285:

267:

260:

251:

248:

240:

231:

229:

217:

214:

211:

208:

205:

204:

203:

197:

194:

193:

192:

189:

186:

184:

179:

175:

167:

158:

150:

138:

133:

129:

112:

109:

104:

100:

91:

87:

83:

75:

57:

53:

51:

47:

43:

38:

34:

30:

21:

1395:Rescue tools

1384:

1360:Drive system

1328:Technologies

1179:. Retrieved

1175:

1166:

1155:. Retrieved

1151:

1142:

1131:. Retrieved

1127:

1118:

1109:

948:

830:

727:

663:

516:

451:

357:, flow (m/s)

331:

278:

265:

249:

245:

226:

212:single rotor

201:

190:

187:

172:

155:

86:displacement

80:

50:Pascal's law

28:

26:

1340:Accumulator

1263:Fluid power

776:theoretical

691:theoretical

542:, power (W)

183:ball valves

174:Screw pumps

161:Screw pumps

1452:Hydraulics

1441:Categories

1426:Manchester

1253:Hydraulics

1239:Hydraulics

1181:2024-05-31

1157:2024-05-31

1133:2023-07-21

1102:References

209:double end

206:single end

82:Gear pumps

69:Gear pumps

1416:Liverpool

1335:Machinery

935:%

929:⋅

714:%

708:⋅

640:mech,hydr

636:η

608:Δ

495:η

487:Δ

484:⋅

471:⋅

424:η

312:η

308:⋅

295:⋅

116:%

110:≈

101:η

1365:Manifold

1355:Cylinder

1277:Modeling

1246:Concepts

1350:Circuit

137:gerotor

1421:London

949:where

807:actual

728:where

701:actual

582:stroke

517:where

479:stroke

397:stroke

332:where

303:stroke

1447:Pumps

1380:Press

1370:Motor

1345:Brake

448:Power

1400:Seal

1385:Pump

745:mech

676:mech

499:mech

275:Flow

1390:Ram

932:100

711:100

428:vol

316:vol

1443::

1174:.

1150:.

1126:.

135:A

113:90

52:.

27:A

1315:)

1311:(

1231:e

1224:t

1217:v

1184:.

1160:.

1136:.

1082:l

1079:a

1076:u

1073:t

1070:c

1067:a

1063:Q

1036:l

1033:a

1030:c

1027:i

1024:t

1021:e

1018:r

1015:o

1012:e

1009:h

1006:t

1002:Q

975:r

972:d

969:y

966:h

962:n

922:l

919:a

916:c

913:i

910:t

907:e

904:r

901:o

898:e

895:h

892:t

888:Q

882:l

879:a

876:u

873:t

870:c

867:a

863:Q

857:=

852:r

849:d

846:y

843:h

839:n

803:T

772:T

741:n

697:T

687:T

681:=

672:n

611:p

578:V

553:n

529:P

490:p

475:V

468:n

462:=

459:P

393:V

368:n

344:Q

299:V

292:n

289:=

286:Q

105:v

92:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.