665:

membranes can be a flat sheet or tubular or a combination of both and can incorporate an online backwash system which reduces membrane surface fouling by pumping membrane permeate back through the membrane. In systems where the membranes are in a separate tank from the bioreactor, individual trains of membranes can be isolated to undertake cleaning regimes incorporating membrane soaks, however, the biomass must be continuously pumped back to the main reactor to limit mixed liquor suspended solids concentration increases. Additional aeration is also required to provide air scouring to reduce fouling. Where the membranes are installed in the main reactor, membrane modules are removed from the vessel and transferred to an offline cleaning tank. Usually, the internal/submerged configuration is used for larger-scale lower strength applications. To optimize the reactor volume and minimize the production of sludge, submerged membrane bioreactor systems typically operate with mixed liquor suspended solids concentrations comprised between 12000 mg/L and 20000 mg/L, hence they offer good flexibility in the selection of the design Sludge retention time. It is mandatory to take into account that an excessively high content of mixed liquor suspended solids may render the aeration system less effective; the classical solution to this optimization problem is to ensure a concentration of mixed liquor suspended solids which approaches 10.000 mg/L to guarantee a good mass transfer of oxygen with a good permeation flux. This type of solution is widely accepted in larger-scale units, where the internal/submerged configuration is typically used, because of the higher relative cost of the membrane compared to the additional tank volume required.

713:

generally tracked via the variation of transmembrane pressure with time. In recent reviews covering membrane applications to bioreactors, it has been shown that, as with other membrane separation processes, membrane fouling is the most serious problem affecting system performance. Fouling leads to a significant increase in hydraulic resistance, manifested as permeate flux declines or transmembrane pressure increases when the process is operated under constant-transmembrane-pressure or constant-flux conditions respectively. In systems where flux is maintained by increasing transmembrane pressure, the energy required to achieve filtration increases. Frequent membrane cleaning is an alternative that significantly increases operating costs as a result of added cleaning agent costs, added production downtime, and more frequent membrane replacement.

653:

809:

reaction rate (diffusion-controlled). Hydrodynamic stress in membrane bioreactors reduces floc size (to 3.5 μm in side stream configurations) and thereby increases the effective reaction rate. Like in the conventional activated sludge process, sludge yield is decreased at higher solids retention times or biomass concentrations. Little or no sludge is produced at sludge loading rates of 0.01 kgCOD/(kgMLSS d). Because of the imposed biomass concentration limit, such low loading rates would result in enormous tank sizes or long hydrodynamic residence times in conventional activated sludge processes.

615:

decrease in the membrane cost led to an exponential increase in membrane bioreactor plant installations from the mid-1990s. Since then, further improvements in membrane bioreactor design and operation have been introduced and incorporated into larger plants. While earlier devices were operated at solid retention times as high as 100 days with mixed liquor suspended solids up to 30 g/L, the recent trend is to apply lower solid retention times (around 10–20 days), resulting in more manageable suspended solids levels (10 to 15 g/L). Thanks to these new operating conditions, the

628:

717:

composition and varies with feed water composition and reactor operating conditions. Thus, though many investigations of membrane fouling have been published, the diverse range of operating conditions and feedwater matrices employed, the different analytical methods used, and the limited information reported in most studies on the suspended biomass composition, have made it difficult to establish any generic behavior pertaining to membrane fouling in membrane bioreactors specifically.

687:

the maintenance of the unit. As in other membrane processes, a shear over the membrane surface is needed to prevent or limit fouling; the external/side stream configuration provides this shear using a pumping system, while the internal/submerged configuration provides the shear through aeration in the bioreactor, and there is an energy requirement to promote the shear by pumping. In this configuration fouling is more consistent due to the higher fluxes involved.

2735:

934:

721:

636:

membrane replacement can be undertaken without specialized lifting equipment. As a result, research and development has continued to improve the side stream configurations, and this has culminated in recent years with the development of low energy systems which incorporate more sophisticated control of the operating parameters coupled with periodic backwashes, which enable sustainable operation at energy usage as low as 0.3 kWh/m3 of product.

854:

521:

25:

598:

initial design focus was on the attainment of high fluxes, and it was, therefore, necessary to pump the mixed liquor and its suspended solids at high cross-flow velocity at significant energy demand (of the order 10 kWh/m product) to reduce fouling. Because of the poor economics of the first-generation devices, they only found applications in niche areas with special needs such as isolated trailer parks or ski resorts.

499:

66:

549:

778:

113:

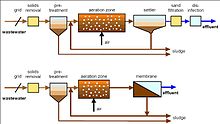

211:. The two basic membrane bioreactor configurations are the submerged membrane bioreactor and the side stream membrane bioreactor. In the submerged configuration, the membrane is located inside the biological reactor and submerged in the wastewater, while in a side stream membrane bioreactor, the membrane is located outside the reactor as an additional step after biological treatment.

949:(e.g. inlet/outlet/recycle flow rates, baffle/mixer position etc.). However, some factors are peculiar to membrane bioreactors and these include the filtration tank design (e.g. membrane type, multiple outlets attributed to membranes, membrane packing density, membrane orientation, etc.) and its operation (e.g. membrane relaxation, membrane backflush, etc.).

837:(P), are responsible for the excessive growth of photosynthetic organisms like algae. All these factors make its reduction focus on wastewater treatment. In wastewater, nitrogen can be present in multiple forms. Like in the conventional activated sludge process, currently, the most widely applied technology for N-removal from municipal wastewater is

533:

their consistently rising numbers and capacity. The current membrane bioreactor market was estimated to be worth around US $ 216 million in 2006 and US$ 838.2 million in 2011, grounding projections that the market for membrane bioreactors was growing at an average rate of 22.4% and would reach a market size of US $ 3.44 billion in 2018.

877:, no nutrients removal). In contrast, membrane-based technologies enable advanced treatment (disinfection), but at a high energy cost. Therefore, the combination of both can only be economically viable if a compact process for energy recovery is desired, or when disinfection is required after anaerobic treatment (cases of

804:) removal is found to increase with mixed liquor suspended solids concentration. Above 15 g/L, COD removal becomes almost independent of biomass concentration at >96 percent. Arbitrary high suspended solids concentrations are not employed, however, lest oxygen transfer be impeded due to higher viscosity and

884:

Recently, anaerobic membrane bioreactors have seen successful full-scale application to the treatment of some types of industrial wastewaters—typically high-strength wastes. Example applications include the treatment of alcohol stillage wastewater in Japan and the treatment of salad dressing/barbecue

849:

can be implemented which requires an additional anaerobic process step. Some characteristics for membrane bioreactor technology render enhanced biological phosphorus removal in combination with post-denitrification an attractive alternative that achieves very low nutrient effluent concentrations. For

700:

Membrane bioreactor filtration performance inevitably decreases with filtration time due to the deposition of soluble and particulate materials onto and into the membrane, attributable to the interactions between activated sludge components and the membrane. This major drawback and process limitation

969:

at the membrane surface to residence time distribution analysis for a complete membrane bioreactor. Cui et al. (2003) investigated the movement of Taylor bubbles through tubular membranes. Khosravi, M. (2007) examined an entire membrane filtration vessel using CFD and velocity measurements. Brannock

795:

Simply due to the high number of microorganisms in membrane bioreactors, pollutant uptake rates can be increased. This leads to better degradation in a given time span or to smaller required reactor volumes. In comparison to conventional activated sludge process treatments which typically achieve 95

686:

Usually, the external/side stream configuration is used for smaller scale and higher strength applications; the main advantage that the external/side stream configuration shows is the possibility to design and size the tank and the membrane separately, with practical advantages for the operation and

532:

Recent technical innovation and significant membrane cost reduction have enabled membrane bioreactors to become an established process option to treat wastewater. Membrane bioreactors have become an attractive option for the treatment and reuse of industrial and municipal wastewater, as evidenced by

743:

Air backwashing, where pressurized air in the membrane's permeate side builds up and releases a significant pressure within a very short period of time. Membrane modules, therefore, need to be in a pressurized vessel coupled to a vent system. Air usually does not go through the membrane. If it did,

712:

Membrane fouling can be accommodated either by allowing a decrease in permeation flux while holding transmembrane pressure constant or by increasing transmembrane pressure to maintain constant flux. Most wastewater treatment plants are operated in constant flux mode, and hence fouling phenomena are

677:

In side stream membrane bioreactor technology, the filtration modules are outside the aerobic tank, hence the name side-stream configuration. Like the immersed or submerged configuration, the aeration system is also used to clean and supply oxygen to the bacteria that degrade the organic compounds.

635:

Despite the more favorable energy usage of submerged membranes, there continued to be a market for the side stream configuration, particularly in smaller flow industrial applications. For ease of maintenance, side stream configurations can be installed on a lower level in a plant building, and thus

619:

transfer and the pumping cost in the reactors have tended to decrease and the overall maintenance has been simplified. There is now a range of membrane bioreactor systems available commercially, most of which use submerged membranes although some side stream modules are available; these side stream

606:

to produce mixing and limit fouling. The energy demand of the submerged system can be up to 2 orders of magnitude lower than that of the side stream systems and submerged systems operate at a lower flux, demanding more membrane area. In submerged configurations, aeration is considered as one of the

808:

viscosity effects. Kinetics may also differ due to easier substrate access. In typical activated sludge process treatment, flocs may reach several 100 μm in size. This means that the substrate can reach the active sites only by diffusion which causes an additional resistance and limits the overall

1021:

The membrane bioreactors market in the EMEA region has witnessed stable growth. Countries such as Saudi Arabia, the UAE, Kuwait, Algeria, Turkey, and Spain are major contributors to that growth rate. Scarcity of clean and fresh water is the key driver for the increasing demand for efficient water

961:

modeling, on the other hand, does not rely on broad assumptions about the mixing characteristics and instead attempts to predict the hydrodynamics from a fundamental level. It is applicable to all scales of fluid flow and can reveal much information about the mixing in a process, ranging from the

668:

Immersed MBR has been the preferred configuration due to its low energy consumption level, high biodegradation efficiency, and low fouling rate compared to side stream membrane bioreactors. In addition, iMBR systems can handle higher suspended solids concentrations, while traditional systems work

614:

The next key steps in membrane bioreactor development were the acceptance of modest fluxes (25 percent or less of those in the first generation) and the idea to use two-phase (bubbly) flow to control fouling. The lower operating cost obtained with the submerged configuration along with the steady

708:

Membrane fouling can cause severe flux drops and affects the quality of the water produced. Severe fouling may require intense chemical cleaning or membrane replacement. This increases the operating costs of a treatment plant. Membrane fouling has traditionally been thought to occur through four

669:

only with suspended solids concentrations between 2.5-3.5, iMBR can handle concentrations between 4-12 g/L, an increase in range of 300%. This type of configuration is adopted in industrial sectors including textile, food & beverage, oil & gas, mining, power generation, pulp & paper.

544:

However, high initial investments and operational expenditure may hamper the global membrane bioreactor market. In addition, technological limitations, particularly the recurrent costs of membrane fouling, are likely to hinder production adoption. Ongoing research and development progress toward

249:

is a material that allows the selective flow of certain substances. In the case of water purification or regeneration, the aim is to allow the water to flow through the membrane whilst retaining undesirable particles on the originating side. By varying the type of membrane, it is possible to get

728:

Air-induced cross flow in submerged membrane bioreactors can efficiently remove or at least reduce the fouling layer on the membrane surface. A recent review reports the latest findings on applications of aeration in submerged membrane configuration and describes the performance benefits of gas

597:

of the conventional activated sludge process was attractive, it was difficult to justify the use of such a process because of the high cost of membranes, the low economic value of the product (tertiary effluent) and sometimes rapid losses of performance due to membrane fouling. As a result, the

1025:

Ultimately, the

Americas region has been witnessing major demand from countries including the US, Canada, Antigua, Argentina, Brazil, and Chile. The membrane bioreactor market has grown on account of stringent regulatory enforcement towards the safe discharge of wastewater. The demand for this

765:

Intensive cleaning may also be carried out when further filtration cannot be sustained because of an elevated transmembrane pressure. Each of the four membrane bioreactor suppliers Kubota, Evoqua, Mitsubishi and GE Water have their own chemical cleaning recipes; these differ mainly in terms of

664:

In the immersed

Membrane Bioreactor (iMBR) configuration, the filtration element is installed in either the main bioreactor vessel or in a separate tank. The modules are positioned above the aeration system, fulfilling two functions, the supply of oxygen and the cleaning of the membranes. The

716:

Membrane fouling results from the interaction between a membrane material and the components of the activated sludge liquor, which include biological flocs formed by a large range of living or dead microorganisms along with soluble and colloidal compounds. The suspended biomass has no fixed

601:

The next breakthrough for the membrane bioreactor came in 1989 with the introduction of submerged membrane bioreactor configurations. Until then, membrane bioreactors were designed with a separation device located external to the reactor (side stream membrane bioreactors) and relied on high

1017:

APAC has the largest membrane bioreactors market. Developing economies such as India, China, Indonesia, and the

Philippines are major contributors to growth in this market region. APAC is considered one of the most disaster-prone regions in the world: in 2013, thousands of people died from

678:

The biomass is either pumped directly through several membrane modules in series and back to the bioreactor or the biomass is pumped to a bank of modules, from which a second pump circulates the biomass through the modules in series. Cleaning and soaking of the membranes can be undertaken

929:

of the system. The mixing within the system can also influence the production of possible foulants. For example, vessels not completely mixed (i.e. plug flow reactors) are more susceptible to the effects of shock loads which may cause cell lysis and release of soluble microbial products.

736:

Intermittent permeation or relaxation, where the filtration is stopped at regular time intervals before being resumed. Particles deposited on the membrane surface tend to diffuse back to the reactor; this phenomenon will be increased by the continuous aeration applied during this resting

536:

The global membrane bioreactor market is expected to grow in the near future due to various driving forces, for instance increasing scarcity of water worldwide which makes wastewater reclamation more profitable; this will likely be further aggravated by continuing climate change. Growing

709:

mechanisms: 1) complete pore blocking, 2) standard blocking, 3) intermediate blocking, and 4) cake layer formation. There are various types of foulants: biological (bacteria, fungi), colloidal (clays, flocs), scaling (mineral precipitates), and organic (oils, polyelectrolytes, (humics).

510:, membrane bioreactor processes can produce effluent of high enough quality for discharge into the oceans, surfaces, brackish bodies, or urban irrigation waterways. Other advantages of membrane bioreactors over conventional processes include reduced footprints and simpler retrofitting.

1018:

water-related disasters in the region, accounting for nine-tenth of the water-related deaths, globally. In addition to this, the public water supply system in the region is not as developed when compared to other countries such as the US, Canada, the countries in Europe, etc.

704:

Fouling is the process by which the particles (colloidal particles, solute macromolecules) are deposited or adsorbed onto the membrane surface or pores by physical and chemical interactions or mechanical action. This produces a reduction in size or blockage of membrane pores.

897:(or mixing) within a membrane bioreactor plays an important role in determining the pollutant removal and fouling control within the system. It has a substantial effect on energy usage and size requirements, and therefore the whole life cost of a membrane bioreactor is high.

850:

this, a membrane bioreactor improves the retention of solids, which provides a better biotreatment, supporting the development of slower-growing microorganisms, especially nitrifying ones, so that it makes them especially effective in the elimination of N (nitrification).

2081:

924:

The control of fouling, as previously mentioned, is primarily achieved via coarse bubble aeration. The distribution of bubbles around the membranes, the shear at the membrane surface for cake removal and the size of the bubble are greatly influenced by the

1013:

In this line, in 2016, some studies and reports showed that the APAC region took the lead in terms of market share, owning 41.90%. On the other hand, the EMEA region's market share is approximately 31.34% and the

Americas constitute 26.67% of the market.

556:

Membrane bioreactors can be used to reduce the footprint of an activated sludge sewage treatment system by removing some of the liquid components of the mixed liquor. This leaves a concentrated waste product that is then treated using the

537:

environmental concerns over industrial wastewater disposal along with declining freshwater resources across developing economies also account for increasing demand for membrane bioreactor technology. Population growth, urbanization, and

257:

There are two main types of membrane materials available on the market: organic-based polymeric membranes and ceramic membranes. Polymeric membranes are the most commonly used materials in water and wastewater treatment. In particular,

956:

technique which will only derive the residence time distribution of a process (e.g. the reactor) or a process unit (e.g. the membrane filtration vessel) and which relies on broad assumptions of the mixing properties of each sub-unit.

250:

better pollutant retention of different kinds. Some of the required characteristics in a membrane for wastewater treatment are chemical and mechanical resistance for five years of operation and capacity to operate stably over a wide

729:

bubbling. The choice of aeration rate is a key parameter in submerged membrane bioreactor design, as there is generally an optimal air flow rate beyond which further increases in aeration have no benefits for preventing fouling.

1009:

The market for membrane bioreactors is segmented based on end-user type, such as municipal and industrial users, and end-user geography, for instance Europe, Middle East and Africa (EMEA), Asia-Pacific (APAC), and the

Americas.

985:

Independent control of solids retention time and hydraulic retention time: As all the biological solids are contained in the bioreactor, the solids retention time can be controlled independently from the hydrodynamic retention

682:

with the use of an installed cleaning tank, pump, and pipework. The quality of the final product is such that it can be reused in process applications due to the filtration capacity of the micro- and ultrafiltration membranes.

912:

of mixing in the system and it is determined by the design of the reactor (e.g. size, inlet/recycle flow rates, wall/baffle/mixer/aerator positioning, mixing energy input). An example of the effect of mixing is that a

2143:

Brannock, M.W.D., Kuechle, B., Wang, Y. and Leslie, G. (2007) Evaluation of membrane bioreactor performance via residence time distribution analysis: effects of membrane configuration in full-scale MBRs, IWA Berlin,

592:

bioreactor with a cross-flow membrane filtration loop. The flat sheet membranes used in this process were polymeric and featured pore sizes ranging from 0.003 to 0.01 μm. Although the idea of replacing the

1718:

Meng, Fangang; Yang, Fenglin; Shi, Baoqiang; Zhang, Hanmin (February 2008). "A comprehensive study on membrane fouling in submerged membrane bioreactors operated under different aeration intensities".

1860:

Grant, Shannon; Page, Ian; Moro, Masashi; Yamamoto, Tetsuya (2008). "Full-Scale

Applications of the Anaerobic Membrane Bioreactor Process for Treatment of Stillage from Alcohol Production in Japan".

607:

major parameters in process performance both hydraulic and biological. Aeration maintains solids in suspension, scours the membrane surface, and provides oxygen to the biomass, leading to better

952:

The mixing modeling and design techniques applied to membrane bioreactors are very similar to those used for conventional activated sludge systems. They include the relatively quick and easy

1438:

Wang, Z.; Wu, Z.; Yin, X.; Tian, L. (2008). "Membrane fouling in a submerged membrane bioreactor (MBR) under sub-critical flux operation: Membrane foulant and gel layer characterization".

774:. It is common for membrane bioreactor suppliers to adapt specific protocols for chemical cleanings (i.e. chemical concentrations and cleaning frequencies) for individual facilities.

242:, membrane processes stand out for their capacity to retain solids and salts and even to disinfect water, producing water suitable for reuse in irrigation and other applications.

937:

Example of computational fluid dynamic (CFD) modelling results (streamlines) for a full-scale MBR (Adapted from the

Project AMEDEUS – Australian Node Newsletter August 2007).

869:(sometimes abbreviated AnMBR) were introduced in the 1980s in South Africa. However, anaerobic processes are normally used when a low-cost treatment is required that enables

1332:

Pervez, Md Nahid; Balakrishnan, Malini; Hasan, Shadi Wajih; Choo, Kwang-Ho; Zhao, Yaping; Cai, Yingjie; Zarra, Tiziano; Belgiorno, Vincenzo; Naddeo, Vincenzo (2020-11-05).

740:

Membrane backwashing, where permeate water is pumped back to the membrane and flows through the pores to the feed channel, dislodging internal and external foulants.

1150:

Zhen, Guangyin; Pan, Yang; Lu, Xueqin; Li, Yu-You; Zhang, Zhongyi; Niu, Chengxin; Kumar, Gopalakrishnan; Kobayashi, Takuro; Zhao, Youcai; Xu, Kaiqin (2019-11-01).

87:

1939:"The motion of Taylor bubbles in vertical tubes. I. A numerical simulation for the shape and rise velocity of Taylor bubbles in stagnant and flowing liquid"

611:

and cell synthesis. Submerged membrane bioreactor systems became preferred to side stream configurations, especially for domestic wastewater treatment.

829:(N) is a pollutant present in wastewater that must be eliminated for multiple reasons: it reduces dissolved oxygen in surface waters, is toxic to the

2187:

881:

with nutrients). If maximal energy recovery is desired, a single anaerobic process will always be superior to a combination with a membrane process.

1318:

1152:"Anaerobic membrane bioreactor towards biowaste biorefinery and chemical energy harvest: Recent progress, membrane fouling and future perspectives"

2318:

1749:

941:

Many factors affect the hydrodynamics of wastewater processes and hence membrane bioreactors. These range from physical properties (e.g. mixture

701:

has been under investigation since the earliest membrane bioreactors and remains one of the most challenging issues facing further development.

585:

517:

concentrations compared to conventional settlement separation systems, thus reducing the reactor volume to achieve the same loading rate.

2258:

1920:

962:

residence time distribution to the shear profile on a membrane surface. A visualization of such modeling results is shown in the image.

781:

Intensive chemical cleaning protocols for four MBR suppliers (the exact protocol for chemical cleaning can vary from a plant to another)

620:

systems also use two-phase flow for fouling control. Typical hydraulic retention times range between 3 and 10 hours. For the most part,

1035:

1809:

A. Drews; H. Evenblij; S. Rosenberger (2005). "Potential and drawbacks of microbiology-membrane interaction in membrane bioreactors".

1022:

treatment technologies. In this regard, increased awareness about water treatment and safe drinking water is also driving the growth.

74:

2624:

1092:

Goswami, Lalit; Vinoth Kumar, R.; Borah, Siddhartha

Narayan; Arul Manikandan, N.; Pakshirajan, Kannan; Pugazhenthi, G. (2018-12-01).

1072:

S. Judd, The MBR book (2006) Principles and applications of membrane bioreactors in water and wastewater treatment, Elsevier, Oxford

1419:

1889:"The First Two Years of Full-Scale Anaerobic Membrane Bioreactor (AnMBR) Operation Treating High-Strength Industrial Wastewater"

900:

The removal of pollutants is greatly influenced by the length of time fluid elements spend in the membrane bioreactor (i.e. the

744:

the air would dry the membrane and a re-wet step would be necessary, accomplished by pressurizing the feed side of the membrane.

2338:

846:

2082:"Taylor bubble rising in a vertical pipe against laminar or turbulent downward flow: symmetric to asymmetric shape transition"

1619:

2333:

1689:

1593:

1518:

796:

percent removal, removal can be increased to 96 to 99 percent in membrane bioreactors (see table,). Chemical oxygen demand (

2230:

38:

131:

123:

2765:

2619:

1843:

T. Stephenson, S. Judd, B. Jefferson, K. Brindle, Membrane bioreactors for wastewater treatment, IWA Publishing (2000)

1026:

emerging technology comes mainly from the pharmaceuticals, food & beverages, automotive, and chemicals industries.

965:

Investigations of membrane bioreactor hydrodynamics have occurred at many different scales ranging from examination of

989:

Small footprint: thanks to the membrane filtration, there is a high biomass concentration contained in a small volume.

2489:

2134:

Khosravi, M. and Kraume, M. (2007) Prediction of the circulation velocity in a membrane bioreactor, IWA Harrogate, UK

1482:

1094:"Membrane bioreactor and integrated membrane bioreactor systems for micropollutant removal from wastewater: A review"

845:, carried out by bacteria nitrifying and the involvement of facultative organisms. Besides phosphorus precipitation,

167:

149:

52:

2579:

2549:

2519:

914:

732:

Many other antifouling strategies can be applied in membrane bioreactor applications. They include, for example:

208:

2293:

751:

In addition, different types and intensities of chemical cleaning may also be recommended on typical schedules:

1848:

1498:

1077:

995:

Compact process: compared to the conventional activated sludge process, membrane bioreactors are more compact.

2569:

2393:

2353:

982:

High quality effluent: given the small size of the membrane's pores, the effluent is clear and pathogen free.

866:

514:

2775:

992:

Robust to load variations: membrane bioreactors can be operated with a broad range of operation conditions.

958:

766:

concentration and methods (see Table 1). Under normal conditions, the prevalent cleaning agents are NaOCl (

1771:; U. Bracklow; M. Vocks; A. Drews (2005). "Nutrients removal in MBRs for municipal wastewater treatment".

2494:

1669:

905:

901:

1392:

P. Le-Clech; V. Chen; A.G. Fane (2006). "Fouling in membrane bioreactors used in wastewater treatment".

652:

2634:

2401:

1745:

262:(PVDF) is the most prevalent material due to its long lifetime and chemical and mechanical resistance.

1985:

1668:

Liu, Lingling; Luo, Xu-Biao; Ding, Lin; Luo, Sheng-Lian (2019-01-01), Luo, Xubiao; Deng, Fang (eds.),

1151:

1093:

2406:

801:

568:

for the realization of more efficient and sustainable membrane bioreactors for wastewater treatment.

2780:

2323:

2223:

44:

2594:

2534:

2461:

2303:

953:

603:

259:

79:

2451:

2446:

2411:

1641:

Z.F. Cui; S. Chang; A.G. Fane (2003). "The use of gas bubbling to enhance membrane processes".

1040:

797:

602:

trans-membrane pressure to maintain filtration. The submerged configuration takes advantage of

246:

1917:

1312:

1050:

970:

et al. (2007) examined an entire MBR system using tracer study experiments and RTD analysis.

657:

621:

2770:

2660:

2471:

2093:

2044:

1997:

1950:

1818:

1345:

1334:"A critical review on nanomaterials membrane bioreactor (NMs-MBR) for wastewater treatment"

1282:

1163:

1105:

818:

747:

Proprietary antifouling products, such as Nalco's

Membrane Performance Enhancer Technology.

545:

increasing output and minimizing sludge formation are anticipated to fuel industry growth.

196:

2154:

8:

2574:

2514:

2313:

2216:

946:

805:

767:

627:

624:

and flat sheet membrane configurations are utilized in membrane bioreactor applications.

184:

2097:

2048:

2001:

1954:

1822:

1349:

1286:

1167:

1109:

2700:

2665:

2609:

2529:

2504:

2273:

2253:

2117:

1695:

1681:

1524:

1510:

1371:

1300:

1187:

1129:

576:

Membrane bioreactors were introduced in the late 1960s, shortly after commercial-scale

222:

has prompted efforts to reuse waste water once it has been properly treated, known as "

1938:

1654:

1218:

2760:

2739:

2524:

2421:

2268:

2109:

2062:

2013:

1966:

1962:

1844:

1788:

1699:

1685:

1599:

1589:

1558:

1514:

1478:

1375:

1363:

1304:

1191:

1179:

1133:

1121:

1073:

830:

538:

2121:

1528:

1235:"WaterWorld. (2012). Membrane multiplier: MBR set for global growth e water world".

2655:

2614:

2599:

2499:

2479:

2101:

2052:

2005:

1958:

1900:

1888:

1869:

1826:

1780:

1727:

1677:

1650:

1616:

1581:

1550:

1506:

1470:

1447:

1401:

1353:

1290:

1214:

1171:

1113:

1045:

608:

589:

558:

525:

204:

200:

1887:

Christian, Scott; Shannon Grant; Peter McCarthy; Dwain Wilson; Dale Mills (2011).

2690:

2564:

2278:

1924:

1768:

1753:

1731:

1623:

1451:

1405:

870:

842:

581:

577:

223:

192:

188:

1886:

2715:

2695:

2685:

2680:

2670:

2650:

2589:

2484:

2416:

2358:

2343:

2288:

1873:

1358:

1333:

1175:

1117:

874:

822:

219:

2009:

1585:

1554:

1295:

1270:

1205:

S. Atkinson (2006). "Research studies predict strong growth for MBR markets".

2754:

2373:

2298:

2113:

2066:

2017:

1970:

1603:

1562:

1367:

1183:

1125:

926:

909:

894:

838:

594:

565:

1859:

1670:"4 - Application of Nanotechnology in the Removal of Heavy Metal From Water"

2720:

2604:

2554:

2426:

2383:

1792:

1474:

966:

917:

will not have as high pollutant conversion per unit volume of reactor as a

1784:

2710:

2705:

2629:

2584:

2544:

2441:

2348:

2105:

2057:

2032:

1904:

933:

878:

771:

978:

Some of the advantages provided by membrane bioreactors are as follows.

720:

2675:

2539:

2239:

1091:

834:

239:

1674:

Nanomaterials for the

Removal of Pollutants and Resource Reutilization

1541:"2018 oleochemicals market size, share & trends analysis report".

853:

2509:

2456:

2308:

1984:

Salman, Wael; Gavriilidis, Asterios; Angeli, Panagiota (2006-10-01).

1830:

1268:

918:

528:

process (top) and external (side stream) membrane bioreactor (bottom)

520:

1767:

1746:

http://www.nalco.com/ASP/applications/membrane_tech/products/mpe.asp

584:

membranes became available. The original designs were introduced by

2436:

2328:

2263:

942:

826:

2188:"Membrane Bioreactors Market - Segments and Forecast by Technavio"

790:

513:

It is possible to operate membrane bioreactor processes at higher

2363:

1808:

758:

Maintenance cleaning with higher chemical concentration (weekly);

498:

65:

2378:

2368:

777:

616:

507:

2283:

2208:

1469:, Wiley-VCH Verlag GmbH & Co. KGaA, pp. 1–14, 2002,

1271:"The challenges of water, waste and climate change in cities"

548:

1421:

MBR-The reliable solution for difficult to treat Wastewaters

857:

Nutrients removal in MBRs for municipal wastewater treatment

552:

Simplified illustrations of a submerged and side-stream MBR.

2080:

Fabre, Jean; Figueroa-Espinoza, Bernardo (September 2014).

1391:

1331:

1676:, Micro and Nano Technologies, Elsevier, pp. 83–147,

1640:

571:

238:). Among the treatment technologies available to reclaim

2431:

1983:

817:

Nutrient removal is one of the main concerns in modern

251:

2079:

1427:. OWEA NE Industrial Waste Seminar. 20 February 2014.

1252:

Advances in Membrane Technologies for Water Treatment

2031:

Zhou, Guangzhao; Prosperetti, Andrea (August 2021).

1986:"On the formation of Taylor bubbles in small tubes"

833:, poses a risk to public health, and together with

785:

761:

Intensive chemical cleaning (once or twice a year).

724:Factors influencing fouling (interactions in red)

2752:

1864:. WEFTEC 2008: Session 101 through Session 115.

1717:

2030:

1862:Proceedings of the Water Environment Federation

791:Chemical oxygen demand removal and sludge yield

16:Combination technology for wastewater treatment

1269:Koop, S. H., & van Leeuwen, C. J. (2017).

695:

644:

541:will further complicate the business outlook.

2224:

1667:

1576:Hrubec, Jiri, ed. (1995). "Water Pollution".

1437:

873:but does not achieve advanced treatment (low

821:, especially, in areas that are sensitive to

203:. These technologies are now widely used for

1317:: CS1 maint: multiple names: authors list (

1250:"Membrane bioreactors for water treatment".

945:and gas/liquid/solid density etc.) to fluid

1496:

1387:

1385:

1275:Environment, Development and Sustainability

1204:

1149:

888:

564:Recent studies show the opportunity to use

502:Simple schematic describing the MBR process

53:Learn how and when to remove these messages

2231:

2217:

1036:List of waste-water treatment technologies

407:Comparison: Polymeric vs Ceramic Membranes

2056:

1937:Mao, Zai-Sha; Dukler, A. E (1990-11-01).

1936:

1763:

1761:

1467:Catalytic Membranes and Membrane Reactors

1357:

1294:

168:Learn how and when to remove this message

150:Learn how and when to remove this message

1804:

1802:

1382:

1156:Renewable and Sustainable Energy Reviews

932:

852:

776:

719:

651:

626:

547:

519:

497:

90:of all important aspects of the article.

1578:The Handbook of Environmental Chemistry

885:sauce wastewater in the United States.

690:

672:

2753:

1758:

1720:Separation and Purification Technology

1636:

1634:

1632:

1575:

1068:

1066:

847:enhanced biological phosphorus removal

572:History and basic operating parameters

86:Please consider expanding the lead to

2212:

2182:

2180:

2178:

2176:

2174:

1799:

755:Chemically enhanced backwash (daily);

631:UF membrane side stream configuration

1711:

1230:

1228:

1145:

1143:

1098:Journal of Water Process Engineering

1087:

1085:

1004:

438:Bundles of hundreds of hollow fibers

106:

59:

18:

1629:

1063:

999:

812:

13:

2620:Ultraviolet germicidal irradiation

2171:

1682:10.1016/b978-0-12-814837-2.00004-4

1511:10.1016/b978-0-444-53199-5.00096-8

122:tone or style may not reflect the

14:

2792:

2490:Agricultural wastewater treatment

1243:

1225:

1140:

1082:

861:

639:

34:This article has multiple issues.

2734:

2733:

1943:Journal of Computational Physics

1497:Hai, F.I.; Yamamoto, K. (2011),

893:Like in any other reactors, the

800:) and biological oxygen demand (

786:Biological performances/kinetics

132:guide to writing better articles

111:

64:

23:

2550:Industrial wastewater treatment

2520:Decentralized wastewater system

2147:

2137:

2128:

2073:

2024:

1977:

1930:

1911:

1893:Water Practice & Technology

1880:

1853:

1837:

1738:

1661:

1610:

1569:

1534:

1490:

1458:

1431:

1412:

915:continuous stirred-tank reactor

486:Majority of commercial products

462:Lower cost in terms of capacity

209:industrial wastewater treatment

78:may be too short to adequately

42:or discuss these issues on the

2238:

1505:, Elsevier, pp. 571–613,

1499:"Membrane Biological Reactors"

1325:

1262:

1198:

867:Anaerobic membrane bioreactors

88:provide an accessible overview

1:

2570:Rotating biological contactor

1655:10.1016/S0376-7388(03)00246-1

1219:10.1016/S0958-2118(06)70635-8

1056:

973:

515:mixed liquor suspended solids

479:Little operational experience

1990:Chemical Engineering Science

1963:10.1016/0021-9991(90)90008-O

1773:Water Science and Technology

1732:10.1016/j.seppur.2007.05.040

1452:10.1016/j.memsci.2008.07.035

1406:10.1016/j.memsci.2006.08.019

959:Computational fluid dynamics

426:Subject to mechanical damage

395:Zirconium dioxide / Zirconia

271:Polymeric Membrane Materials

7:

1643:Journal of Membrane Science

1440:Journal of Membrane Science

1394:Journal of Membrane Science

1029:

906:residence time distribution

902:residence time distribution

696:Fouling and fouling control

588:and combined the use of an

295:(High density) polyethylene

214:

10:

2797:

2635:Wastewater treatment plant

2402:Adsorbable organic halides

2086:Journal of Fluid Mechanics

2037:Journal of Fluid Mechanics

1874:10.2175/193864708790894179

1359:10.1038/s41545-020-00090-2

1176:10.1016/j.rser.2019.109392

1118:10.1016/j.jwpe.2018.10.024

524:Schematic of conventional

431:Higher mechanical strength

390:Titanium dioxide / Titania

354:Ceramic Membrane Materials

2766:Environmental engineering

2729:

2643:

2470:

2407:Biochemical oxygen demand

2392:

2246:

2010:10.1016/j.ces.2006.05.036

1586:10.1007/978-3-540-48468-4

1555:10.1016/j.fos.2019.01.003

1503:Treatise on Water Science

1296:10.1007/s10668-016-9760-4

405:

352:

343:Polyvinylidine difluoride

269:

260:polyvinylidene difluoride

908:is a description of the

889:Mixing and hydrodynamics

455:Good chemical resistance

381:Aluminum oxide / Alumina

201:activated sludge process

2595:Sewage sludge treatment

2535:Fecal sludge management

2495:API oil–water separator

2462:Wastewater surveillance

2033:"Faster Taylor bubbles"

954:compartmental modelling

450:Vulnerable to chemicals

443:One "piece" per element

331:Polytetrafluoroethylene

2452:Total suspended solids

2447:Total dissolved solids

2412:Chemical oxygen demand

1811:Environmental Progress

1626:. membrane.unsw.edu.au

1549:(1): 2. January 2019.

1475:10.1002/3527601988.ch1

1041:Activated sludge model

938:

858:

782:

725:

661:

656:A reinforced immersed

632:

604:coarse bubble aeration

553:

529:

503:

247:semipermeable membrane

2319:Industrial wastewater

1785:10.2166/wst.2005.0661

1752:June 7, 2008, at the

1051:Hollow fiber membrane

936:

856:

780:

723:

658:hollow fiber membrane

655:

630:

551:

523:

501:

2661:Groundwater recharge

2192:www.businesswire.com

2106:10.1017/jfm.2014.429

2058:10.1017/jfm.2021.432

1905:10.2166/wpt.2011.032

1617:Membrane Bioreactors

1543:Focus on Surfactants

819:wastewater treatment

691:Major considerations

673:External/side stream

197:wastewater treatment

183:are combinations of

181:Membrane bioreactors

2776:Membrane technology

2575:Secondary treatment

2560:Membrane bioreactor

2515:Constructed wetland

2314:Infiltration/Inflow

2098:2014JFM...755..485F

2049:2021JFM...920R...2Z

2002:2006ChEnS..61.6653S

1955:1990JCoPh..91..132M

1823:2005EnvPr..24..426D

1350:2020npjCW...3...43P

1287:2017EDSus..19..385K

1207:Membrane Technology

1168:2019RSERv.11509392Z

1110:2018JWPE...26..314G

947:boundary conditions

768:sodium hypochlorite

645:Internal/submerged/

508:domestic wastewater

474:Very common product

266:

2740:Category: Sewerage

2701:Septic drain field

2666:Infiltration basin

2610:Stabilization pond

2530:Facultative lagoon

2394:Quality indicators

2274:Blackwater (waste)

2254:Acid mine drainage

2155:"MBR Introduction"

1923:2008-04-25 at the

1622:2008-03-08 at the

939:

859:

783:

726:

662:

633:

554:

530:

504:

467:High capital costs

265:

195:with a biological

185:membrane processes

2748:

2747:

2525:Extended aeration

2472:Treatment options

2422:Oxygen saturation

2269:Blackwater (coal)

2247:Sources and types

1996:(20): 6653–6666.

1691:978-0-12-814837-2

1595:978-3-662-14504-3

1520:978-0-444-53199-5

1005:Regional insights

831:aquatic ecosystem

539:industrialization

496:

495:

401:

400:

348:

347:

307:Polyethylsulphone

283:Polyacrylonitrile

224:water reclamation

178:

177:

170:

160:

159:

152:

126:used on Knowledge

124:encyclopedic tone

105:

104:

57:

2788:

2737:

2736:

2656:Evaporation pond

2644:Disposal options

2615:Trickling filter

2600:Sewage treatment

2500:Carbon filtering

2480:Activated sludge

2233:

2226:

2219:

2210:

2209:

2203:

2202:

2200:

2199:

2184:

2169:

2168:

2166:

2165:

2159:www.lenntech.com

2151:

2145:

2141:

2135:

2132:

2126:

2125:

2077:

2071:

2070:

2060:

2028:

2022:

2021:

1981:

1975:

1974:

1934:

1928:

1927:. mbr-network.eu

1915:

1909:

1908:

1884:

1878:

1877:

1868:(7): 7556–7570.

1857:

1851:

1841:

1835:

1834:

1831:10.1002/ep.10113

1806:

1797:

1796:

1779:(6–7): 391–402.

1765:

1756:

1742:

1736:

1735:

1715:

1709:

1708:

1707:

1706:

1665:

1659:

1658:

1638:

1627:

1614:

1608:

1607:

1573:

1567:

1566:

1538:

1532:

1531:

1494:

1488:

1487:

1465:"Introduction",

1462:

1456:

1455:

1435:

1429:

1428:

1426:

1416:

1410:

1409:

1389:

1380:

1379:

1361:

1329:

1323:

1322:

1316:

1308:

1298:

1266:

1260:

1259:

1247:

1241:

1240:

1232:

1223:

1222:

1202:

1196:

1195:

1147:

1138:

1137:

1089:

1080:

1070:

1046:Membrane fouling

1000:Market framework

813:Nutrient removal

609:biodegradability

590:activated sludge

586:Dorr-Oliver Inc.

559:activated sludge

526:activated sludge

491:Few applications

403:

402:

350:

349:

267:

264:

228:wastewater reuse

173:

166:

155:

148:

144:

141:

135:

134:for suggestions.

130:See Knowledge's

115:

114:

107:

100:

97:

91:

68:

60:

49:

27:

26:

19:

2796:

2795:

2791:

2790:

2789:

2787:

2786:

2785:

2781:Water treatment

2751:

2750:

2749:

2744:

2725:

2691:Reclaimed water

2639:

2565:Reverse osmosis

2466:

2388:

2354:Reverse osmosis

2279:Boiler blowdown

2242:

2237:

2207:

2206:

2197:

2195:

2186:

2185:

2172:

2163:

2161:

2153:

2152:

2148:

2142:

2138:

2133:

2129:

2078:

2074:

2029:

2025:

1982:

1978:

1935:

1931:

1925:Wayback Machine

1916:

1912:

1885:

1881:

1858:

1854:

1842:

1838:

1807:

1800:

1766:

1759:

1754:Wayback Machine

1743:

1739:

1716:

1712:

1704:

1702:

1692:

1666:

1662:

1639:

1630:

1624:Wayback Machine

1615:

1611:

1596:

1574:

1570:

1540:

1539:

1535:

1521:

1495:

1491:

1485:

1464:

1463:

1459:

1436:

1432:

1424:

1418:

1417:

1413:

1390:

1383:

1338:npj Clean Water

1330:

1326:

1310:

1309:

1267:

1263:

1249:

1248:

1244:

1234:

1233:

1226:

1203:

1199:

1148:

1141:

1090:

1083:

1071:

1064:

1059:

1032:

1007:

1002:

976:

891:

871:energy recovery

864:

843:denitrification

815:

793:

788:

698:

693:

675:

650:

642:

582:microfiltration

578:ultrafiltration

574:

506:When used with

385:Silicon carbide

236:water recycling

226:" (also called

217:

193:ultrafiltration

189:microfiltration

174:

163:

162:

161:

156:

145:

139:

136:

129:

120:This article's

116:

112:

101:

95:

92:

85:

73:This article's

69:

28:

24:

17:

12:

11:

5:

2794:

2784:

2783:

2778:

2773:

2768:

2763:

2746:

2745:

2743:

2742:

2730:

2727:

2726:

2724:

2723:

2718:

2716:Surface runoff

2713:

2708:

2703:

2698:

2696:Sanitary sewer

2693:

2688:

2686:Marine outfall

2683:

2681:Marine dumping

2678:

2673:

2671:Injection well

2668:

2663:

2658:

2653:

2651:Combined sewer

2647:

2645:

2641:

2640:

2638:

2637:

2632:

2627:

2622:

2617:

2612:

2607:

2602:

2597:

2592:

2590:Settling basin

2587:

2582:

2577:

2572:

2567:

2562:

2557:

2552:

2547:

2542:

2537:

2532:

2527:

2522:

2517:

2512:

2507:

2502:

2497:

2492:

2487:

2485:Aerated lagoon

2482:

2476:

2474:

2468:

2467:

2465:

2464:

2459:

2454:

2449:

2444:

2439:

2434:

2429:

2424:

2419:

2417:Coliform index

2414:

2409:

2404:

2398:

2396:

2390:

2389:

2387:

2386:

2381:

2376:

2371:

2366:

2361:

2359:Sanitary sewer

2356:

2351:

2346:

2344:Produced water

2341:

2336:

2331:

2326:

2321:

2316:

2311:

2306:

2301:

2296:

2291:

2289:Combined sewer

2286:

2281:

2276:

2271:

2266:

2261:

2256:

2250:

2248:

2244:

2243:

2236:

2235:

2228:

2221:

2213:

2205:

2204:

2170:

2146:

2136:

2127:

2072:

2023:

1976:

1949:(1): 132–160.

1929:

1910:

1879:

1852:

1836:

1817:(4): 426–433.

1798:

1757:

1737:

1710:

1690:

1660:

1628:

1609:

1594:

1568:

1533:

1519:

1489:

1483:

1457:

1446:(1): 238–244.

1430:

1411:

1400:(1–2): 17–53.

1381:

1324:

1281:(2): 385–418.

1261:

1242:

1224:

1197:

1139:

1081:

1061:

1060:

1058:

1055:

1054:

1053:

1048:

1043:

1038:

1031:

1028:

1006:

1003:

1001:

998:

997:

996:

993:

990:

987:

983:

975:

972:

890:

887:

875:carbon removal

863:

862:Anaerobic MBRs

860:

841:combined with

823:eutrophication

814:

811:

792:

789:

787:

784:

763:

762:

759:

756:

749:

748:

745:

741:

738:

697:

694:

692:

689:

674:

671:

649:

643:

641:

640:Configurations

638:

573:

570:

494:

493:

488:

482:

481:

476:

470:

469:

464:

458:

457:

452:

446:

445:

440:

434:

433:

428:

422:

421:

416:

410:

409:

399:

398:

378:

357:

356:

346:

345:

340:

334:

333:

328:

322:

321:

316:

310:

309:

304:

298:

297:

292:

286:

285:

280:

274:

273:

220:Water scarcity

216:

213:

176:

175:

158:

157:

119:

117:

110:

103:

102:

82:the key points

72:

70:

63:

58:

32:

31:

29:

22:

15:

9:

6:

4:

3:

2:

2793:

2782:

2779:

2777:

2774:

2772:

2769:

2767:

2764:

2762:

2759:

2758:

2756:

2741:

2732:

2731:

2728:

2722:

2719:

2717:

2714:

2712:

2709:

2707:

2704:

2702:

2699:

2697:

2694:

2692:

2689:

2687:

2684:

2682:

2679:

2677:

2674:

2672:

2669:

2667:

2664:

2662:

2659:

2657:

2654:

2652:

2649:

2648:

2646:

2642:

2636:

2633:

2631:

2628:

2626:

2623:

2621:

2618:

2616:

2613:

2611:

2608:

2606:

2603:

2601:

2598:

2596:

2593:

2591:

2588:

2586:

2583:

2581:

2580:Sedimentation

2578:

2576:

2573:

2571:

2568:

2566:

2563:

2561:

2558:

2556:

2553:

2551:

2548:

2546:

2543:

2541:

2538:

2536:

2533:

2531:

2528:

2526:

2523:

2521:

2518:

2516:

2513:

2511:

2508:

2506:

2503:

2501:

2498:

2496:

2493:

2491:

2488:

2486:

2483:

2481:

2478:

2477:

2475:

2473:

2469:

2463:

2460:

2458:

2455:

2453:

2450:

2448:

2445:

2443:

2440:

2438:

2435:

2433:

2430:

2428:

2425:

2423:

2420:

2418:

2415:

2413:

2410:

2408:

2405:

2403:

2400:

2399:

2397:

2395:

2391:

2385:

2382:

2380:

2377:

2375:

2374:Sewage sludge

2372:

2370:

2367:

2365:

2362:

2360:

2357:

2355:

2352:

2350:

2347:

2345:

2342:

2340:

2337:

2335:

2332:

2330:

2327:

2325:

2322:

2320:

2317:

2315:

2312:

2310:

2307:

2305:

2302:

2300:

2299:Cooling water

2297:

2295:

2294:Cooling tower

2292:

2290:

2287:

2285:

2282:

2280:

2277:

2275:

2272:

2270:

2267:

2265:

2262:

2260:

2259:Ballast water

2257:

2255:

2252:

2251:

2249:

2245:

2241:

2234:

2229:

2227:

2222:

2220:

2215:

2214:

2211:

2193:

2189:

2183:

2181:

2179:

2177:

2175:

2160:

2156:

2150:

2140:

2131:

2123:

2119:

2115:

2111:

2107:

2103:

2099:

2095:

2091:

2087:

2083:

2076:

2068:

2064:

2059:

2054:

2050:

2046:

2042:

2038:

2034:

2027:

2019:

2015:

2011:

2007:

2003:

1999:

1995:

1991:

1987:

1980:

1972:

1968:

1964:

1960:

1956:

1952:

1948:

1944:

1940:

1933:

1926:

1922:

1919:

1914:

1906:

1902:

1898:

1894:

1890:

1883:

1875:

1871:

1867:

1863:

1856:

1850:

1846:

1840:

1832:

1828:

1824:

1820:

1816:

1812:

1805:

1803:

1794:

1790:

1786:

1782:

1778:

1774:

1770:

1764:

1762:

1755:

1751:

1747:

1741:

1733:

1729:

1726:(1): 91–100.

1725:

1721:

1714:

1701:

1697:

1693:

1687:

1683:

1679:

1675:

1671:

1664:

1656:

1652:

1649:(1–2): 1–35.

1648:

1644:

1637:

1635:

1633:

1625:

1621:

1618:

1613:

1605:

1601:

1597:

1591:

1587:

1583:

1579:

1572:

1564:

1560:

1556:

1552:

1548:

1544:

1537:

1530:

1526:

1522:

1516:

1512:

1508:

1504:

1500:

1493:

1486:

1484:3-527-30277-8

1480:

1476:

1472:

1468:

1461:

1453:

1449:

1445:

1441:

1434:

1423:

1422:

1415:

1407:

1403:

1399:

1395:

1388:

1386:

1377:

1373:

1369:

1365:

1360:

1355:

1351:

1347:

1343:

1339:

1335:

1328:

1320:

1314:

1306:

1302:

1297:

1292:

1288:

1284:

1280:

1276:

1272:

1265:

1257:

1253:

1246:

1238:

1231:

1229:

1220:

1216:

1212:

1208:

1201:

1193:

1189:

1185:

1181:

1177:

1173:

1169:

1165:

1161:

1157:

1153:

1146:

1144:

1135:

1131:

1127:

1123:

1119:

1115:

1111:

1107:

1103:

1099:

1095:

1088:

1086:

1079:

1075:

1069:

1067:

1062:

1052:

1049:

1047:

1044:

1042:

1039:

1037:

1034:

1033:

1027:

1023:

1019:

1015:

1011:

994:

991:

988:

984:

981:

980:

979:

971:

968:

963:

960:

955:

950:

948:

944:

935:

931:

928:

927:hydrodynamics

922:

920:

916:

911:

910:hydrodynamics

907:

903:

898:

896:

895:hydrodynamics

886:

882:

880:

876:

872:

868:

855:

851:

848:

844:

840:

839:nitrification

836:

832:

828:

824:

820:

810:

807:

806:non-Newtonian

803:

799:

779:

775:

773:

769:

760:

757:

754:

753:

752:

746:

742:

739:

735:

734:

733:

730:

722:

718:

714:

710:

706:

702:

688:

684:

681:

670:

666:

659:

654:

648:

637:

629:

625:

623:

618:

612:

610:

605:

599:

596:

595:settling tank

591:

587:

583:

579:

569:

567:

566:nanomaterials

562:

560:

550:

546:

542:

540:

534:

527:

522:

518:

516:

511:

509:

500:

492:

489:

487:

484:

483:

480:

477:

475:

472:

471:

468:

465:

463:

460:

459:

456:

453:

451:

448:

447:

444:

441:

439:

436:

435:

432:

429:

427:

424:

423:

420:

417:

415:

412:

411:

408:

404:

397:

396:

392:

391:

387:

386:

382:

379:

377:

376:

372:

371:

367:

366:

362:

359:

358:

355:

351:

344:

341:

339:

336:

335:

332:

329:

327:

324:

323:

320:

317:

315:

312:

311:

308:

305:

303:

300:

299:

296:

293:

291:

288:

287:

284:

281:

279:

276:

275:

272:

268:

263:

261:

255:

253:

248:

243:

241:

237:

233:

229:

225:

221:

212:

210:

206:

202:

199:process, the

198:

194:

190:

186:

182:

172:

169:

154:

151:

143:

140:February 2022

133:

127:

125:

118:

109:

108:

99:

96:February 2022

89:

83:

81:

76:

71:

67:

62:

61:

56:

54:

47:

46:

41:

40:

35:

30:

21:

20:

2721:Vacuum sewer

2605:Sewer mining

2559:

2555:Ion exchange

2505:Chlorination

2427:Heavy metals

2384:Urban runoff

2324:Ion exchange

2304:Fecal sludge

2196:. Retrieved

2194:. 2017-09-07

2191:

2162:. Retrieved

2158:

2149:

2139:

2130:

2089:

2085:

2075:

2040:

2036:

2026:

1993:

1989:

1979:

1946:

1942:

1932:

1913:

1896:

1892:

1882:

1865:

1861:

1855:

1839:

1814:

1810:

1776:

1772:

1740:

1723:

1719:

1713:

1703:, retrieved

1673:

1663:

1646:

1642:

1612:

1577:

1571:

1546:

1542:

1536:

1502:

1492:

1466:

1460:

1443:

1439:

1433:

1420:

1414:

1397:

1393:

1341:

1337:

1327:

1313:cite journal

1278:

1274:

1264:

1255:

1251:

1245:

1236:

1210:

1206:

1200:

1159:

1155:

1101:

1097:

1024:

1020:

1016:

1012:

1008:

977:

967:shear stress

964:

951:

940:

923:

899:

892:

883:

865:

816:

794:

764:

750:

731:

727:

715:

711:

707:

703:

699:

685:

679:

676:

667:

663:

646:

634:

622:hollow fiber

613:

600:

575:

563:

555:

543:

535:

531:

512:

505:

490:

485:

478:

473:

466:

461:

454:

449:

442:

437:

430:

425:

418:

413:

406:

394:

393:

389:

388:

384:

383:

380:

374:

373:

369:

368:

364:

363:

360:

353:

342:

337:

330:

325:

319:Polysulphone

318:

313:

306:

301:

294:

289:

282:

277:

270:

256:

244:

235:

232:water reuse,

231:

227:

218:

180:

179:

164:

146:

137:

121:

93:

77:

75:lead section

50:

43:

37:

36:Please help

33:

2771:Bioreactors

2711:Storm drain

2706:Sewage farm

2630:Vermifilter

2585:Septic tank

2545:Imhoff tank

2442:Temperature

2349:Return flow

2339:Papermaking

2092:: 485–502.

1918:MBR-Network

1213:(2): 8–10.

1104:: 314–328.

879:water reuse

772:citric acid

2755:Categories

2676:Irrigation

2540:Filtration

2240:Wastewater

2198:2020-05-27

2164:2023-01-13

1849:1900222078

1705:2022-06-02

1580:. 5 / 5B.

1258:: 155–184.

1237:WaterWorld

1162:: 109392.

1078:1856174816

1057:References

974:Advantages

835:phosphorus

240:wastewater

39:improve it

2510:Clarifier

2457:Turbidity

2309:Greywater

2114:0022-1120

2067:0022-1120

2018:0009-2509

1971:0021-9991

1769:M. Kraume

1700:139850140

1604:1867-979X

1563:1351-4210

1376:226248577

1368:2059-7037

1344:(1): 43.

1305:148564435

1192:203995165

1184:1364-0321

1134:134769916

1126:2214-7144

921:reactor.

919:plug flow

561:process.

414:Polymeric

205:municipal

80:summarize

45:talk page

2761:Sewerage

2437:Salinity

2329:Leachate

2264:Bathroom

2122:31959380

1921:Archived

1793:16004001

1750:Archived

1620:Archived

1529:32232685

1030:See also

943:rheology

827:Nitrogen

660:cassette

647:immersed

215:Overview

2364:Septage

2144:Germany

2094:Bibcode

2045:Bibcode

1998:Bibcode

1951:Bibcode

1819:Bibcode

1744:Nalco.

1346:Bibcode

1283:Bibcode

1164:Bibcode

1106:Bibcode

904:). The

737:period.

680:in situ

419:Ceramic

254:range.

2738:

2379:Toilet

2369:Sewage

2334:Manure

2120:

2112:

2065:

2016:

1969:

1847:

1791:

1698:

1688:

1602:

1592:

1561:

1527:

1517:

1481:

1374:

1366:

1303:

1190:

1182:

1132:

1124:

1076:

770:) and

617:oxygen

290:(HD)PE

2284:Brine

2118:S2CID

1899:(2).

1696:S2CID

1525:S2CID

1425:(PDF)

1372:S2CID

1301:S2CID

1188:S2CID

1130:S2CID

986:time.

375:ZrO2

370:TiO2

361:Al2O3

187:like

2625:UASB

2110:ISSN

2063:ISSN

2014:ISSN

1967:ISSN

1866:2008

1845:ISBN

1789:PMID

1686:ISBN

1600:ISSN

1590:ISBN

1559:ISSN

1547:2019

1515:ISBN

1479:ISBN

1364:ISSN

1319:link

1211:2006

1180:ISSN

1122:ISSN

1074:ISBN

802:BOD5

580:and

338:PVDF

326:PTFE

207:and

2102:doi

2090:755

2053:doi

2041:920

2006:doi

1959:doi

1901:doi

1870:doi

1827:doi

1781:doi

1728:doi

1678:doi

1651:doi

1647:221

1582:doi

1551:doi

1507:doi

1471:doi

1448:doi

1444:325

1402:doi

1398:284

1354:doi

1291:doi

1215:doi

1172:doi

1160:115

1114:doi

798:COD

365:SiC

302:PES

278:PAN

234:or

191:or

2757::

2432:pH

2190:.

2173:^

2157:.

2116:.

2108:.

2100:.

2088:.

2084:.

2061:.

2051:.

2043:.

2039:.

2035:.

2012:.

2004:.

1994:61

1992:.

1988:.

1965:.

1957:.

1947:91

1945:.

1941:.

1895:.

1891:.

1825:.

1815:24

1813:.

1801:^

1787:.

1777:51

1775:.

1760:^

1748:.

1724:59

1722:.

1694:,

1684:,

1672:,

1645:.

1631:^

1598:.

1588:.

1557:.

1545:.

1523:,

1513:,

1501:,

1477:,

1442:.

1396:.

1384:^

1370:.

1362:.

1352:.

1340:.

1336:.

1315:}}

1311:{{

1299:.

1289:.

1279:19

1277:.

1273:.

1254:.

1227:^

1209:.

1186:.

1178:.

1170:.

1158:.

1154:.

1142:^

1128:.

1120:.

1112:.

1102:26

1100:.

1096:.

1084:^

1065:^

825:.

314:PS

252:pH

245:A

230:,

48:.

2232:e

2225:t

2218:v

2201:.

2167:.

2124:.

2104::

2096::

2069:.

2055::

2047::

2020:.

2008::

2000::

1973:.

1961::

1953::

1907:.

1903::

1897:6

1876:.

1872::

1833:.

1829::

1821::

1795:.

1783::

1734:.

1730::

1680::

1657:.

1653::

1606:.

1584::

1565:.

1553::

1509::

1473::

1454:.

1450::

1408:.

1404::

1378:.

1356::

1348::

1342:3

1321:)

1307:.

1293::

1285::

1256:2

1239:.

1221:.

1217::

1194:.

1174::

1166::

1136:.

1116::

1108::

171:)

165:(

153:)

147:(

142:)

138:(

128:.

98:)

94:(

84:.

55:)

51:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.