375:-6, the P&ID is used for the identification of measurements within the process. The identifications consist of up to 5 letters. The first identification letter is for the measured value, the second is a modifier, 3rd indicates passive/readout function, 4th - active/output function, and the 5th is the function modifier. This is followed by loop number, which is unique to that loop. For instance FIC045 means it is the Flow Indicating Controller in control loop 045. This is also known as the "tag" identifier of the field device, which is normally given to the location and function of the instrument. The same loop may have FT045 - which is the flow transmitter in the same loop.

1618:

22:

1277:

1291:

1123:

1303:

1135:

1265:

1207:

1022:

1630:

1398:

1221:

1149:

117:

125:

966:

1249:

1556:

1468:

1111:

994:

1317:

1686:

1512:

1498:

1329:

1596:

940:

1442:

1386:

1235:

1191:

980:

954:

1484:

1456:

1542:

1163:

1580:

1526:

1428:

1372:

1066:

1341:

1096:

1054:

1608:

1177:

1355:

133:

1412:

1080:

1008:

926:

1568:

1042:

310:

P&IDs are originally drawn up at the design stage from a combination of process flow sheet data, the mechanical process equipment design, and the instrumentation engineering design. During the design stage, the diagram also provides the basis for the development of system control schemes,

318:

P&IDs also play a significant role in the maintenance and modification of the process after initial build. Modifications are red-penned onto the diagrams and are vital records of the current plant design.

894:

1682:(CAD) in the late 1980s, P&IDs were drawn by hand. The drawing template shown below, actual size 225.mm by 111 mm, is typical of those used to draw P&IDs.

1789:. Prentice Hall international series in the physical and chemical engineering sciences (4th ed.). Upper Saddle River, N.J. Munich: Prentice Hall.

148:

A diagram which shows the interconnection of process equipment and the instrumentation used to control the process. In the process industry, a

1760:

1736:

315:(HAZOP). To do this, it is critical to demonstrate the physical sequence of equipment and systems, as well as how these systems connect.

1753:

108:(PFD) which indicates the more general flow of plant processes and the relationship between major equipment of a plant facility.

1794:

1617:

880:

Industrial systems, installations and equipment and industrial products — Structuring principles and reference designations

153:

65:

43:

36:

149:

1785:

Turton, Richard; Bailie, Richard C.; Whiting, Wallace B.; Shaeiwitz, Joseph A.; Bhattacharyya, Debangsu (2012).

1831:

152:

is used to prepare drawings of processes. The instrument symbols used in these drawings are generally based on

1709:

1284:

368:

128:

Piping and instrumentation diagram of pump with storage tank. Symbols according to EN ISO 10628 and EN 62424.

905:

Below are listed some symbols of chemical apparatus and equipment normally used in a P&ID, according to

1816:

312:

352:

344:

274:

Process control instrumentation and designation (names, numbers, unique tag identifiers), including:

120:

Example of a single industrial control loop; showing continuously modulated control of process flow.

1764:

1623:

340:

30:

1629:

47:

1748:

1679:

1256:

1087:

105:

8:

1665:

1405:

1184:

947:

190:

1276:

1826:

1790:

1658:

1228:

94:

1595:

1821:

1519:

1505:

1103:

1073:

987:

198:

174:

160:

98:

1692:

Piping and instrumentation diagram manual drawing template (1980s). Symbol key:

1290:

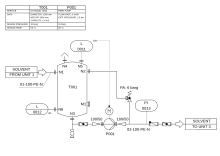

1122:

277:

Valves and their types and identifications (e.g. isolation, shutoff, relief and

1717:

1302:

1214:

1001:

232:

228:

186:

1134:

874:

For reference designation of any equipment in industrial systems the standard

1810:

1651:

1449:

1264:

1198:

1156:

206:

202:

1206:

1021:

1644:

1635:

1491:

1170:

278:

267:

216:

1685:

1397:

1220:

1148:

116:

101:

and control devices. It is also called as mechanical flow diagram (MFD).

1601:

1549:

1475:

1029:

224:

1607:

965:

890:

is used, followed by the above listed letter for the measured variable.

124:

1587:

1533:

1435:

1379:

1348:

1248:

1033:

220:

182:

144:

A piping and instrumentation diagram (P&ID) is defined as follows:

311:

allowing for further safety and operational investigations, such as a

910:

906:

875:

372:

1555:

1467:

1110:

993:

1316:

236:

194:

1511:

1497:

1328:

893:

For reference designation of any equipment in a power station the

339:

P&IDs form the basis for the live mimic diagrams displayed on

1363:

939:

210:

1441:

1385:

1234:

1190:

979:

953:

1483:

1455:

1242:

933:

306:

Identification of components and subsystems delivered by others

292:

285:

1541:

1162:

900:

1579:

1525:

1427:

1419:

1371:

1065:

348:

1784:

1340:

1095:

1053:

1015:

364:

358:

178:

1754:

1176:

1354:

132:

1411:

1079:

1007:

925:

295:, special fittings, sampling lines, reducers and swages

1749:

Learn How to Read P&ID Drawings – A Complete Guide

1567:

1041:

866:

Actuator, driver or unclassified final control element

1787:

Analysis, synthesis, and design of chemical processes

245:

Process piping, sizes and identification, including:

159:

The primary schematic drawing used for laying out a

1808:

322:They are also vital in enabling development of;

167:They usually contain the following information:

97:which shows process equipment together with the

219:, restriction orifices, strainers and filters,

1761:Commons:Category:Chemical engineering symbols

1700:Motor driven pump or compressor and baseplate

1737:Instrumentation in petrochemical industries

918:Symbols of chemical apparatus and equipment

901:Symbols of chemical apparatus and equipment

820:User's choice (usually on-off valve as XV)

257:Permanent start-up, flush and bypass lines

66:Learn how and when to remove this message

1684:

359:Identification and reference designation

131:

123:

115:

111:

78:Detailed diagram in the process industry

29:This article includes a list of general

1809:

520:User's choice (usually gaging/gauging)

895:KKS Power Plant Classification System

104:Superordinate to the P&ID is the

882:) can be applied. For the function

861:Z-axis or Safety Instrumented System

450:User's choice (usually conductivity)

248:Pipe classes and piping line numbers

15:

1722:Machine driven pump or other device

1285:Fixed straight tubes heat exchanger

154:International Society of Automation

13:

1624:Piston or reciprocating compressor

1578:

1566:

1554:

1540:

1524:

1510:

1496:

1482:

1466:

1454:

1440:

1426:

1410:

1396:

1384:

1370:

1353:

1339:

1327:

1315:

1301:

1289:

1275:

1263:

1247:

1233:

1219:

1205:

1189:

1175:

1161:

1147:

1133:

1121:

1109:

1094:

1078:

1064:

1052:

1040:

1020:

1006:

992:

978:

964:

952:

938:

924:

329:Safety and regulatory requirements

83:Piping and Instrumentation Diagram

35:it lacks sufficient corresponding

14:

1843:

1742:

1673:

171:Mechanical equipment, including:

1763:- A list of P&ID symbols in

1628:

1616:

1606:

1594:

1257:Plate & frame heat exchanger

20:

826:Accessory devices, unclassified

468:User's choice (usually density)

291:Miscellaneous - vents, drains,

288:and final elements, interlocks)

227:, silencers, flares and vents,

93:) is a detailed diagram in the

1778:

1298:U-shaped tubes heat exchanger

1130:Pressurized horizontal vessel

786:Vibration, mechanical analysis

642:User's choice (usually torque)

1:

1771:

1710:Shell and tube heat exchanger

1142:Pressurized vertical vessel

326:Control and shutdown schemes

313:Hazard and operability study

300:Interfaces for class changes

284:Control inputs and outputs (

136:A more complex example of a

7:

1730:

1272:Double pipe heat exchanger

396:(Readout/passive function)

353:distributed control systems

263:Blinds and spectacle blinds

254:Interconnections references

10:

1848:

345:industrial control systems

335:Operational understanding.

886:the reference designator

401:(Output/active function)

341:graphical user interfaces

1706:Valve diaphragm actuator

1118:Half pipe mixing vessel

948:Thermally insulated pipe

1678:Prior to the advent of

1406:Pressure reducing valve

735:Safety (Non SIS (S5.1))

303:Computer control system

260:Pipelines and flowlines

150:standard set of symbols

50:more precise citations.

1714:Flexible hose, bellows

1689:

1583:

1571:

1559:

1545:

1529:

1515:

1501:

1487:

1471:

1459:

1445:

1431:

1415:

1401:

1389:

1375:

1358:

1344:

1332:

1320:

1310:Spiral heat exchanger

1306:

1294:

1280:

1268:

1252:

1238:

1224:

1210:

1194:

1180:

1166:

1152:

1138:

1126:

1114:

1104:Jacketed mixing vessel

1099:

1083:

1069:

1057:

1045:

1025:

1011:

997:

983:

973:Cooled or heated pipe

969:

957:

943:

929:

840:Event, state, presence

634:Middle / intermediate

141:

129:

121:

1832:Industrial automation

1688:

1680:computer-aided design

1582:

1570:

1558:

1544:

1528:

1514:

1500:

1486:

1470:

1458:

1444:

1430:

1414:

1400:

1388:

1374:

1357:

1343:

1331:

1319:

1305:

1293:

1279:

1267:

1251:

1237:

1223:

1209:

1193:

1179:

1165:

1151:

1137:

1125:

1113:

1098:

1082:

1068:

1056:

1044:

1024:

1010:

996:

982:

968:

956:

942:

928:

684:Point/test connection

213:(see 'symbols' below)

135:

127:

119:

112:Contents and function

406:(Function modifier)

106:process flow diagram

1817:Process engineering

1666:Reciprocating pump

1229:Coil heat exchanger

988:Flexible connection

920:

858:Position, dimension

592:Time rate of change

589:Time, time schedule

526:Glass/gauge/viewing

281:, valve interlocks)

156:(ISA) Standard S5.1

1690:

1584:

1572:

1563:Back draft damper

1560:

1546:

1530:

1516:

1502:

1488:

1472:

1460:

1446:

1432:

1416:

1402:

1390:

1376:

1359:

1345:

1333:

1321:

1307:

1295:

1281:

1269:

1253:

1239:

1225:

1211:

1195:

1181:

1167:

1153:

1139:

1127:

1115:

1100:

1084:

1070:

1058:

1046:

1026:

1012:

998:

984:

970:

958:

944:

930:

916:

702:Totalize/integrate

699:Totalize/integrate

431:Burner, combustion

363:Based on STANDARD

332:Start-up sequences

223:, moisture traps,

177:, columns, tanks,

142:

130:

122:

1796:978-0-13-261812-0

1697:Vessel dished end

1671:

1670:

1324:Covered gas vent

872:

871:

848:Auxiliary devices

386:(Measured value)

76:

75:

68:

1839:

1801:

1800:

1782:

1659:Centrifugal pump

1632:

1620:

1610:

1598:

1336:Curved gas vent

921:

915:

897:can be applied.

732:Speed, frequency

378:

377:

175:Pressure vessels

95:process industry

71:

64:

60:

57:

51:

46:this article by

37:inline citations

24:

23:

16:

1847:

1846:

1842:

1841:

1840:

1838:

1837:

1836:

1807:

1806:

1805:

1804:

1797:

1783:

1779:

1774:

1745:

1733:

1728:

1676:

1520:Diaphragm valve

1506:Butterfly valve

903:

793:Valve or damper

597:Control station

405:

400:

395:

390:

385:

361:

266:Insulation and

251:Flow directions

233:vortex breakers

229:flame arrestors

207:turbo-expanders

187:heat exchangers

161:process control

114:

99:instrumentation

79:

72:

61:

55:

52:

42:Please help to

41:

25:

21:

12:

11:

5:

1845:

1835:

1834:

1829:

1824:

1819:

1803:

1802:

1795:

1776:

1775:

1773:

1770:

1769:

1768:

1757:

1756:

1751:

1744:

1743:External links

1741:

1740:

1739:

1732:

1729:

1727:

1726:

1723:

1720:

1715:

1712:

1707:

1704:

1701:

1698:

1694:

1675:

1674:Historical use

1672:

1669:

1668:

1663:

1661:

1656:

1654:

1649:

1647:

1642:

1639:

1638:

1633:

1626:

1621:

1614:

1611:

1604:

1599:

1591:

1590:

1585:

1576:

1573:

1564:

1561:

1552:

1547:

1537:

1536:

1531:

1522:

1517:

1508:

1503:

1494:

1489:

1479:

1478:

1473:

1464:

1461:

1452:

1447:

1438:

1433:

1423:

1422:

1417:

1408:

1403:

1394:

1393:Viewing glass

1391:

1382:

1377:

1367:

1366:

1360:

1351:

1346:

1337:

1334:

1325:

1322:

1312:

1311:

1308:

1299:

1296:

1287:

1282:

1273:

1270:

1260:

1259:

1254:

1245:

1240:

1231:

1226:

1217:

1215:Heat exchanger

1212:

1202:

1201:

1196:

1187:

1182:

1173:

1168:

1159:

1154:

1144:

1143:

1140:

1131:

1128:

1119:

1116:

1107:

1101:

1091:

1090:

1085:

1076:

1071:

1062:

1059:

1050:

1047:

1037:

1036:

1027:

1018:

1013:

1004:

1002:Hydraulic pump

999:

990:

985:

975:

974:

971:

962:

961:Jacketed pipe

959:

950:

945:

936:

931:

902:

899:

870:

869:

867:

864:

862:

859:

856:

852:

851:

849:

846:

844:

841:

838:

834:

833:

830:

827:

824:

821:

818:

814:

813:

811:

809:

806:

804:

801:

797:

796:

794:

791:

789:

787:

784:

780:

779:

777:

774:

771:

769:

766:

762:

761:

759:

756:

754:

752:

749:

745:

744:

741:

738:

736:

733:

730:

726:

725:

722:

720:

717:

715:

712:

708:

707:

705:

703:

700:

697:

694:

690:

689:

687:

685:

682:

680:

677:

673:

672:

669:

667:

664:

662:

659:

655:

654:

651:

648:

645:

643:

640:

636:

635:

632:

630:

628:

626:

623:

619:

618:

615:

613:

610:

608:

605:

601:

600:

598:

595:

593:

590:

587:

583:

582:

580:

578:

576:

573:

570:

566:

565:

563:

561:

558:

556:

553:

549:

548:

545:

543:

541:

539:

536:

532:

531:

529:

527:

524:

521:

518:

514:

513:

511:

509:

507:

504:

501:

497:

496:

494:

492:

489:

487:

484:

480:

479:

476:

474:

472:

469:

466:

462:

461:

458:

455:

453:

451:

448:

444:

443:

440:

437:

434:

432:

429:

425:

424:

422:

420:

417:

415:

412:

408:

407:

402:

397:

392:

387:

382:

360:

357:

337:

336:

333:

330:

327:

308:

307:

304:

301:

298:

297:

296:

289:

282:

272:

271:

270:

264:

261:

258:

255:

252:

249:

242:

241:

240:

239:

217:Bursting discs

214:

203:cooling towers

165:

164:

157:

113:

110:

77:

74:

73:

28:

26:

19:

9:

6:

4:

3:

2:

1844:

1833:

1830:

1828:

1825:

1823:

1820:

1818:

1815:

1814:

1812:

1798:

1792:

1788:

1781:

1777:

1766:

1762:

1759:

1758:

1755:

1752:

1750:

1747:

1746:

1738:

1735:

1734:

1724:

1721:

1719:

1716:

1713:

1711:

1708:

1705:

1702:

1699:

1696:

1695:

1693:

1687:

1683:

1681:

1667:

1664:

1662:

1660:

1657:

1655:

1653:

1652:Turboexpander

1650:

1648:

1646:

1643:

1641:

1640:

1637:

1634:

1631:

1627:

1625:

1622:

1619:

1615:

1612:

1609:

1605:

1603:

1600:

1597:

1593:

1592:

1589:

1586:

1581:

1577:

1574:

1569:

1565:

1562:

1557:

1553:

1551:

1548:

1543:

1539:

1538:

1535:

1532:

1527:

1523:

1521:

1518:

1513:

1509:

1507:

1504:

1499:

1495:

1493:

1490:

1485:

1481:

1480:

1477:

1474:

1469:

1465:

1463:Manual valve

1462:

1457:

1453:

1451:

1450:Control valve

1448:

1443:

1439:

1437:

1434:

1429:

1425:

1424:

1421:

1418:

1413:

1409:

1407:

1404:

1399:

1395:

1392:

1387:

1383:

1381:

1378:

1373:

1369:

1368:

1365:

1361:

1356:

1352:

1350:

1347:

1342:

1338:

1335:

1330:

1326:

1323:

1318:

1314:

1313:

1309:

1304:

1300:

1297:

1292:

1288:

1286:

1283:

1278:

1274:

1271:

1266:

1262:

1261:

1258:

1255:

1250:

1246:

1244:

1241:

1236:

1232:

1230:

1227:

1222:

1218:

1216:

1213:

1208:

1204:

1203:

1200:

1199:Cooling tower

1197:

1192:

1188:

1186:

1183:

1178:

1174:

1172:

1169:

1164:

1160:

1158:

1157:Packed column

1155:

1150:

1146:

1145:

1141:

1136:

1132:

1129:

1124:

1120:

1117:

1112:

1108:

1105:

1102:

1097:

1093:

1092:

1089:

1086:

1081:

1077:

1075:

1072:

1067:

1063:

1060:

1055:

1051:

1048:

1043:

1039:

1038:

1035:

1031:

1028:

1023:

1019:

1017:

1014:

1009:

1005:

1003:

1000:

995:

991:

989:

986:

981:

977:

976:

972:

967:

963:

960:

955:

951:

949:

946:

941:

937:

935:

932:

927:

923:

922:

919:

914:

912:

908:

898:

896:

891:

889:

885:

881:

877:

868:

865:

863:

860:

857:

854:

853:

850:

847:

845:

842:

839:

836:

835:

832:Unclassified

831:

828:

825:

822:

819:

816:

815:

812:

810:

808:Well or probe

807:

805:

803:Weight, force

802:

799:

798:

795:

792:

790:

788:

785:

782:

781:

778:

776:Multifunction

775:

773:Multifunction

772:

770:

768:Multivariable

767:

764:

763:

760:

757:

755:

753:

750:

747:

746:

742:

739:

737:

734:

731:

728:

727:

723:

721:

718:

716:

713:

710:

709:

706:

704:

701:

698:

695:

692:

691:

688:

686:

683:

681:

678:

675:

674:

670:

668:

665:

663:

661:User's choice

660:

657:

656:

652:

649:

646:

644:

641:

638:

637:

633:

631:

629:

627:

625:User's choice

624:

621:

620:

616:

614:

611:

609:

606:

603:

602:

599:

596:

594:

591:

588:

585:

584:

581:

579:

577:

574:

571:

568:

567:

564:

562:

559:

557:

554:

551:

550:

546:

544:

542:

540:

537:

534:

533:

530:

528:

525:

522:

519:

516:

515:

512:

510:

508:

505:

502:

499:

498:

495:

493:

490:

488:

485:

482:

481:

477:

475:

473:

470:

467:

464:

463:

459:

456:

454:

452:

449:

446:

445:

441:

438:

435:

433:

430:

427:

426:

423:

421:

418:

416:

413:

410:

409:

403:

398:

393:

388:

383:

380:

379:

376:

374:

370:

366:

356:

354:

350:

346:

342:

334:

331:

328:

325:

324:

323:

320:

316:

314:

305:

302:

299:

294:

290:

287:

283:

280:

279:safety valves

276:

275:

273:

269:

265:

262:

259:

256:

253:

250:

247:

246:

244:

243:

238:

234:

230:

226:

225:sight-glasses

222:

218:

215:

212:

208:

204:

200:

196:

192:

188:

184:

180:

176:

173:

172:

170:

169:

168:

163:installation.

162:

158:

155:

151:

147:

146:

145:

139:

134:

126:

118:

109:

107:

102:

100:

96:

92:

88:

84:

70:

67:

59:

56:November 2021

49:

45:

39:

38:

32:

27:

18:

17:

1786:

1780:

1691:

1677:

1645:Rupture disc

1636:Relief valve

1613:3-way valve

1492:Needle valve

1171:Plate column

1106:(autoclave)

917:

904:

892:

887:

883:

879:

873:

829:Unclassified

653:User choice

442:User choice

362:

338:

321:

317:

309:

268:heat tracing

166:

143:

137:

103:

90:

86:

82:

80:

62:

53:

34:

1602:Globe valve

1550:Check valve

1476:Check valve

1030:Vacuum pump

884:Measurement

751:Temperature

650:User choice

647:User choice

439:User choice

436:User choice

391:(Modifier)

221:steam traps

183:compressors

48:introducing

1811:Categories

1772:References

1588:Gas bottle

1534:Ball valve

1436:Gate valve

1380:Steam trap

1362:Funnel or

1349:Air filter

1074:Radial fan

1061:Axial fan

1034:compressor

478:Deviation

471:Difference

31:references

911:ISO 14617

907:ISO 10628

876:IEC 61346

714:Radiation

503:Flow rate

404:Column 5

399:Column 4

394:Column 3

389:Column 2

384:Column 1

373:ISO 14617

371:S5.1 and

343:of large

211:pig traps

195:wellheads

1827:Diagrams

1731:See also

1725:Reducers

758:Transmit

696:Quantity

679:Pressure

560:Indicate

414:Analysis

347:such as

237:eductors

191:furnaces

138:P&ID

87:P&ID

1718:Ejector

1364:tundish

1185:Furnace

666:Orifice

555:Current

486:Voltage

457:Control

381:Letter

293:flanges

286:sensors

44:improve

1822:Piping

1793:

1767:format

1703:Valves

1243:Cooler

843:Y-axis

823:X-axis

740:Switch

719:Record

491:Sensor

460:Close

33:, but

1420:Valve

1088:Dryer

743:Stop

671:Open

612:Light

607:Level

572:Power

547:High

506:Ratio

419:Alarm

349:SCADA

179:pumps

1791:ISBN

1575:Bag

1049:Fan

1016:Pump

934:Pipe

909:and

724:Run

617:Low

575:Scan

538:Hand

365:ANSI

351:and

199:fans

1765:SVG

1032:or

523:Gas

369:ISA

91:PID

89:or

1813::

913:.

355:.

235:,

231:,

209:,

205:,

201:,

197:,

193:,

189:,

185:,

181:,

81:A

1799:.

888:B

878:(

855:Z

837:Y

817:X

800:W

783:V

765:U

748:T

729:S

711:R

693:Q

676:P

658:O

639:N

622:M

604:L

586:K

569:J

552:I

535:H

517:G

500:F

483:E

465:D

447:C

428:B

411:A

367:/

140:.

85:(

69:)

63:(

58:)

54:(

40:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.