206:

465:

58:

471:

201:

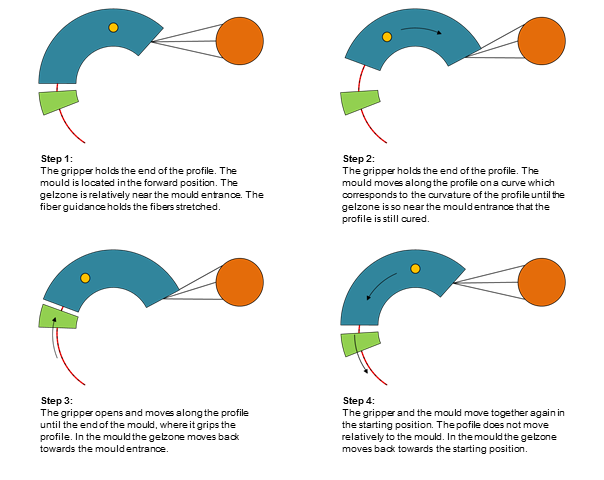

In a recently developed modification of the process, developed and patented by Thomas GmbH + Co. Technik + Innovation KG, the die is no longer stationary but moving back and forth along the profile to be manufactured. This modified process, known as "Radius-Pultrusion" allows also to manufacture two-

228:

For the radius pultrusion process the layout of the machines has two moving stages similar to the hand over hand pulling unit, but as the process is intermittent with only one puller and the mould mounted on the stage of other one. Whether the stages are moving linear or circular depends on the type

144:(PET) either by powder impregnation of the glass fiber or by surrounding it with sheet material of the thermoplastic matrix, which is then heated. Engineered Composites Ltd in the UK has led the improvements in the process over the last 38 years working with major production houses and universities.

37:

A very early pultrusions type patent was filed by J.H. Watson in 1944. This was followed by M.J. Meek's filing of 1950. The first commercial pultrusions were provided by

Glastic Company of Cleveland, Ohio under the patent filed in 1952 by Rodger B. White. The patent issued to W. B. Goldsworthy in

151:

appear to be forcible arguments in favor of reinforced thermoplastics. For these reasons the industrial output and use of the given materials in highly industrialized countries have increased by 8–10% per year in recent decades. New developments (see process modifications) which enable the

179:

in electrical power engineering for manufacturing of dielectric structures, fiberglass rods used in composite insulators and as supporting structures for elements of signaling blocks, and fiberglass profiles used in manufacturing of transformers and electric

48:

Invention, development and the issuance of patents continue in the pultrusion field through today. A later innovation in this field has been developed and patented by Thomas GmbH + Co. Technik + Innovation KG in

Germany 2008 and is described below.

215:

166:

In the agriculture and chemical industries for manufacturing of chemically resistant to aggressive media slatted floors with enhanced strength characteristics used in the construction of livestock facilities, chemical plants,

158:

Economic and environmental factors favor use of a thermoplastic matrix but due to the high viscosity of melts it is difficult to achieve high productivity and high quality of fiberfills impregnation with this type of matrix.

106:. The impregnation is either done by pulling the reinforcement through a bath or by injecting the resin into an injection chamber which typically is connected to the die. Many resin types may be used in pultrusion including

202:

and three-dimensional curved profiles. It also is beneficiary for a number of tasks in the linear process especially if quite complex textile reinforcements with a low rate of distortion are needed.

122:. Resin provides the resistance to the environment, (i.e., the corrosion resistance, the UV resistance, the impact resistance, etc.) and the glass provides strength, in addition to safety from fire.

183:

in commercial production, using grains of long-fiber molding material (LLM) as a raw material for subsequent manufacturing of structures and products with enhanced strength and chemical properties;

229:

of profiles to be manufactured. The minimum radius for a linear machine with rotating stages is approx. 2 m. For smaller radii a circular movement of the mould and gripper stage is necessary.

1072:

147:

Ecological cleanness of manufactured products, in contrast to composites on thermosetting resins base, as well as practically unlimited possibilities of recycling (processing) after the

176:

in the sports and tourism industries for manufacturing of equipment exhibiting enhanced strength properties: skis, ski poles, golf course flagsticks, tent and hovel constructions, etc.;

45:

Parallel to the work of

Goldsworthy, who concentrated his work on unsaturated polyester resins, Ernst Kühne in Germany developed a quite similar process in 1954 based on epoxy resin.

39:

189:

and in many other industries and plants, using mechanisms, structures and materials, which meet high standards of chemical, dielectric and strength stability.

796:

152:

manufacturing not only of straight but also curved profiles are actually pushing the demand for this technology, especially in the automotive sector.

186:

in the automotive industry for the production of structural and complex parts of the vehicles with enhanced stiffness, rigidity and lightness;

198:

As the materials are pulled through a die in the standard pultrusion process the process is only suited to manufacture straight profiles.

125:

A surface veil can also be added to protect against erosion or “fiber bloom” and provide corrosion resistance and ultraviolet resistance.

170:

in the construction industry for the production of glass-fiber reinforcement, profiles, carcasses, stiffening bars for PVC-windows, etc.;

155:

Pultrusion technology of manufacturing of fiber composites with polymer matrix appears to be energy-efficient and resource-saving.

789:

225:

The design of pultrusion machines varies. Two often used types are reciprocating (hand-over-hand) and continuous (cat-track).

672:

1131:

1082:

1051:

214:

782:

289:

245:

774:

314:

1067:

1046:

943:

697:

1178:

1121:

1041:

1114:

1036:

852:

449:

1183:

379:

354:

141:

137:

1154:

888:

687:

512:

329:

319:

1173:

958:

948:

810:

497:

444:

334:

23:

548:

439:

424:

404:

963:

841:

596:

324:

282:

1143:

847:

492:

129:

98:, possibly followed by a separate preforming system, and pulled through a heated stationary

863:

858:

831:

749:

8:

993:

754:

677:

591:

543:

162:

Products manufactured under this technology are widely used in the following industries:

99:

257:

1008:

926:

667:

641:

611:

571:

553:

502:

454:

434:

148:

34:". As opposed to extrusion, which pushes the material, pultrusion pulls the material.

1138:

1104:

1024:

836:

658:

576:

275:

1029:

724:

626:

601:

533:

399:

394:

339:

804:

893:

879:

744:

631:

621:

389:

173:

in the aerospace industry for manufacturing of structure components of aircraft;

922:

734:

636:

507:

258:"Pultrusion Process | Pultrusion Manufacturing | Liberty Pultrusions"

133:

103:

38:

1959 helped initiate the promotion and knowledge spread within the industry.

1167:

1109:

916:

702:

692:

682:

586:

487:

409:

359:

205:

16:

Process to manufacture fibre-reinforced plastics with constant cross-sections

729:

719:

581:

528:

429:

374:

349:

111:

975:

464:

912:

884:

819:

739:

538:

419:

414:

27:

57:

988:

606:

115:

1077:

983:

953:

823:

384:

369:

344:

107:

31:

90:

In the standard pultrusion process the reinforcement materials like

998:

470:

1126:

1003:

904:

806:

298:

119:

95:

91:

132:. More recently, pultrusion has been successfully used with

364:

267:

65:

Continuous roll of reinforced fibers/woven fiber mat

42:is widely regarded as the inventor of pultrusion.

94:or woven or braided strands are impregnated with

1165:

790:

283:

26:with constant cross-section. The term is a

22:is a continuous process for manufacture of

797:

783:

290:

276:

246:"Brandt Goldsworthy: Composites Visionary"

83:Finished hardened fiber reinforced polymer

204:

193:

56:

1166:

380:Polyethylene terephthalate (PET, PETE)

778:

320:Cross-linked polyethylene (PEX, XLPE)

315:Acrylonitrile butadiene styrene (ABS)

271:

1132:List of environmental health hazards

1052:List of environmental health hazards

61:Diagram of the pultrusion process.

13:

937:Miscellaneous additives incl. PHCs

14:

1195:

128:The technology is not limited to

469:

463:

355:Polybutylene terephthalate (PBT)

330:Poly(methyl methacrylate) (PMMA)

213:

335:Poly(ethyl methacrylate) (PEMA)

698:Category:Plastics applications

445:Styrene maleic anhydride (SMA)

440:Polyvinylidene chloride (PVDC)

425:Polytetrafluoroethylene (PTFE)

250:

239:

1:

405:Poly(p-phenylene oxide) (PPO)

232:

209:Flexible pultruded 3D-profile

1122:Persistent organic pollutant

1083:Toxic Substances Control Act

1042:Persistent organic pollutant

325:Ethylene vinyl acetate (EVA)

297:

220:

30:word, combining "pull" and "

7:

1115:Great Pacific garbage patch

1037:Great Pacific garbage patch

450:Styrene-acrylonitrile (SAN)

365:Polyetheretherketone (PEEK)

10:

1200:

1078:Japan Toxic Substances Law

873:Miscellaneous plasticizers

142:polyethylene terephthalate

138:polybutylene terephthalate

102:where the resin undergoes

52:

1152:

1097:

1073:European REACH regulation

1068:California Proposition 65

1060:

1017:

974:

936:

903:

872:

818:

811:polyhalogenated compounds

767:

712:

688:High-performance plastics

657:

650:

562:

521:

513:High-performance plastics

478:

461:

305:

24:fibre-reinforced plastics

498:Fibre-reinforced plastic

435:Polyvinyl chloride (PVC)

549:Biodegradable additives

964:Perfluorooctanoic acid

400:Polyphenyl ether (PPE)

395:Polyoxymethylene (POM)

340:Polyacrylic acid (PAA)

210:

130:thermosetting polymers

87:

1144:Biodegradable plastic

493:Thermosetting polymer

390:Polylactic acid (PLA)

208:

194:Process modifications

60:

40:W. Brandt Goldsworthy

1155:Identification codes

755:Foam food containers

678:Engineering plastics

1179:Composite materials

994:Endocrine disruptor

592:Compression molding

544:Polymer stabilizers

77:Die and heat source

1009:Polymer fume fever

668:Commodity plastics

642:Rotational molding

612:Fiberglass molding

572:Injection moulding

554:Filler (materials)

503:Corrugated plastic

455:Tritan copolyester

410:Polypropylene (PP)

360:Polycarbonate (PC)

211:

149:resource depletion

88:

74:Resin soaked fiber

1184:Plastics industry

1161:

1160:

1139:Plastic recycling

1105:Plastic pollution

1091:

1090:

1025:Plastic pollution

805:Health issues of

763:

762:

659:Plastics industry

577:Plastic extrusion

430:Polyurethane (PU)

420:Polysulfone (PES)

375:Polyethylene (PE)

350:Polybutylene (PB)

136:matrices such as

71:Resin impregnator

1191:

1030:Rubber pollution

880:Organophosphates

799:

792:

785:

776:

775:

655:

654:

627:Filament winding

602:Transfer molding

529:Polymer additive

473:

467:

415:Polystyrene (PS)

292:

285:

278:

269:

268:

262:

261:

254:

248:

243:

217:

1199:

1198:

1194:

1193:

1192:

1190:

1189:

1188:

1174:Unit operations

1164:

1163:

1162:

1157:

1148:

1093:

1092:

1087:

1056:

1013:

970:

932:

899:

868:

814:

803:

769:

759:

708:

646:

632:Solvent bonding

622:Plastic welding

564:

558:

517:

480:

474:

468:

459:

370:Polyester (PEs)

307:

301:

296:

266:

265:

256:

255:

251:

244:

240:

235:

223:

196:

86:

55:

17:

12:

11:

5:

1197:

1187:

1186:

1181:

1176:

1159:

1158:

1153:

1150:

1149:

1147:

1146:

1141:

1136:

1135:

1134:

1129:

1124:

1119:

1118:

1117:

1101:

1099:

1095:

1094:

1089:

1088:

1086:

1085:

1080:

1075:

1070:

1064:

1062:

1058:

1057:

1055:

1054:

1049:

1044:

1039:

1034:

1033:

1032:

1021:

1019:

1015:

1014:

1012:

1011:

1006:

1001:

996:

991:

986:

980:

978:

972:

971:

969:

968:

967:

966:

956:

951:

946:

940:

938:

934:

933:

931:

930:

923:Vinyl chloride

920:

917:Polycarbonates

909:

907:

901:

900:

898:

897:

891:

882:

876:

874:

870:

869:

867:

866:

861:

856:

850:

845:

839:

834:

828:

826:

816:

815:

802:

801:

794:

787:

779:

773:

771:

765:

764:

761:

760:

758:

757:

752:

747:

742:

737:

732:

730:Packaging film

727:

722:

716:

714:

713:Specific goods

710:

709:

707:

706:

700:

695:

690:

685:

680:

675:

670:

664:

662:

652:

648:

647:

645:

644:

639:

637:Vacuum forming

634:

629:

624:

619:

614:

609:

604:

599:

594:

589:

584:

579:

574:

568:

566:

560:

559:

557:

556:

551:

546:

541:

536:

531:

525:

523:

519:

518:

516:

515:

510:

508:Polymeric foam

505:

500:

495:

490:

484:

482:

476:

475:

462:

460:

458:

457:

452:

447:

442:

437:

432:

427:

422:

417:

412:

407:

402:

397:

392:

387:

385:Polyimide (PI)

382:

377:

372:

367:

362:

357:

352:

347:

345:Polyamide (PA)

342:

337:

332:

327:

322:

317:

311:

309:

303:

302:

295:

294:

287:

280:

272:

264:

263:

249:

237:

236:

234:

231:

222:

219:

195:

192:

191:

190:

187:

184:

181:

177:

174:

171:

168:

104:polymerization

85:

84:

81:

80:Pull mechanism

78:

75:

72:

69:

68:Tension roller

66:

62:

54:

51:

15:

9:

6:

4:

3:

2:

1196:

1185:

1182:

1180:

1177:

1175:

1172:

1171:

1169:

1156:

1151:

1145:

1142:

1140:

1137:

1133:

1130:

1128:

1125:

1123:

1120:

1116:

1113:

1112:

1111:

1110:Garbage patch

1108:

1107:

1106:

1103:

1102:

1100:

1096:

1084:

1081:

1079:

1076:

1074:

1071:

1069:

1066:

1065:

1063:

1059:

1053:

1050:

1048:

1045:

1043:

1040:

1038:

1035:

1031:

1028:

1027:

1026:

1023:

1022:

1020:

1016:

1010:

1007:

1005:

1002:

1000:

997:

995:

992:

990:

987:

985:

982:

981:

979:

977:

976:Health issues

973:

965:

962:

961:

960:

957:

955:

952:

950:

947:

945:

942:

941:

939:

935:

928:

924:

921:

918:

914:

911:

910:

908:

906:

902:

895:

892:

890:

886:

883:

881:

878:

877:

875:

871:

865:

862:

860:

857:

854:

851:

849:

846:

843:

840:

838:

835:

833:

830:

829:

827:

825:

821:

817:

812:

808:

800:

795:

793:

788:

786:

781:

780:

777:

772:

766:

756:

753:

751:

750:Shopping bags

748:

746:

743:

741:

738:

736:

733:

731:

728:

726:

723:

721:

718:

717:

715:

711:

705:(Agriculture)

704:

703:Plasticulture

701:

699:

696:

694:

691:

689:

686:

684:

683:Geosynthetics

681:

679:

676:

674:

671:

669:

666:

665:

663:

660:

656:

653:

649:

643:

640:

638:

635:

633:

630:

628:

625:

623:

620:

618:

615:

613:

610:

608:

605:

603:

600:

598:

595:

593:

590:

588:

587:Thermoforming

585:

583:

580:

578:

575:

573:

570:

569:

567:

561:

555:

552:

550:

547:

545:

542:

540:

537:

535:

532:

530:

527:

526:

524:

520:

514:

511:

509:

506:

504:

501:

499:

496:

494:

491:

489:

488:Thermoplastic

486:

485:

483:

477:

472:

466:

456:

453:

451:

448:

446:

443:

441:

438:

436:

433:

431:

428:

426:

423:

421:

418:

416:

413:

411:

408:

406:

403:

401:

398:

396:

393:

391:

388:

386:

383:

381:

378:

376:

373:

371:

368:

366:

363:

361:

358:

356:

353:

351:

348:

346:

343:

341:

338:

336:

333:

331:

328:

326:

323:

321:

318:

316:

313:

312:

310:

304:

300:

293:

288:

286:

281:

279:

274:

273:

270:

259:

253:

247:

242:

238:

230:

226:

218:

216:

207:

203:

199:

188:

185:

182:

178:

175:

172:

169:

165:

164:

163:

160:

156:

153:

150:

145:

143:

139:

135:

134:thermoplastic

131:

126:

123:

121:

117:

113:

109:

105:

101:

97:

93:

82:

79:

76:

73:

70:

67:

64:

63:

59:

50:

46:

43:

41:

35:

33:

29:

25:

21:

820:Plasticizers

768:Environment

720:Blister pack

673:Construction

616:

582:Blow molding

252:

241:

227:

224:

212:

200:

197:

161:

157:

154:

146:

127:

124:

112:polyurethane

89:

47:

44:

36:

19:

18:

1061:Regulations

913:Bisphenol A

597:Calendering

539:Plasticizer

479:Mechanical

28:portmanteau

1168:Categories

989:Carcinogen

954:Organotins

824:Phthalates

770:and health

617:Pultrusion

607:Laminating

565:processing

233:References

116:vinylester

20:Pultrusion

1018:Pollution

984:Teratogen

915:(BPA, in

563:Plastics

534:Colorants

522:Additives

306:Chemical

221:Equipment

108:polyester

32:extrusion

999:Diabetes

905:Monomers

885:Adipates

807:plastics

661:segments

651:Products

299:Plastics

1127:Dioxins

1047:Dioxins

1004:Obesity

745:Cutlery

735:Bottles

180:motors;

140:(PBT),

53:Process

844:(BBzP)

813:(PHCs)

725:Chairs

693:Nurdle

92:fibers

1098:Waste

944:PBDEs

855:(DOP)

481:types

308:types

167:etc.;

120:epoxy

96:resin

959:PFCs

949:PCBs

925:(in

889:DEHA

864:DINP

859:DIDP

853:DEHP

848:DIHP

832:DIBP

809:and

740:Bags

118:and

927:PVC

894:DOA

842:BBP

837:DBP

100:die

1170::

822::

114:,

110:,

929:)

919:)

896:)

887:(

798:e

791:t

784:v

291:e

284:t

277:v

260:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.