275:

467:

183:

597:

442:

428:

1069:

but the failures that do occur are more linked to surface stresses. By separating surface from the subsurface, mitigating mechanisms can more easily be identified. GBLM makes use of advanced tribology models to introduce a surface distress failure mode function, obtained from the evaluation of surface fatigue. For the subsurface fatigue, GBLM uses the classical

Hertzian rolling contact model. With all this, GBLM includes the effects of lubrication, contamination, and race surface properties, which together influence the stress distribution in the rolling contact.

516:

1193:(friction), which is defined, in ascending order, by a number 1–9. The third character is the radial clearance, which is normally defined by a number between 0 and 9 (inclusive), in ascending order, however for radial-thrust bearings it is defined by a number between 1 and 3, inclusive. The fourth character is the accuracy ratings, which normally are, in ascending order: 0 (normal), 6X, 6, 5, 4, T, and 2. Ratings 0 and 6 are the most common; ratings 5 and 4 are used in high-speed applications; and rating 2 is used in

530:

are used, for example, as the wheel bearings of most wheeled land vehicles. The downsides to this bearing is that due to manufacturing complexities, tapered roller bearings are usually more expensive than ball bearings; and additionally under heavy loads the tapered roller is like a wedge and bearing loads tend to try to eject the roller; the force from the collar which keeps the roller in the bearing adds to bearing friction compared to ball bearings.

490:

86:

569:, but can accommodate both angular misalignment and also axial displacement. Compared to a spherical roller bearing, their radius of curvature is longer than a spherical radius would be, making them an intermediate form between spherical and cylindrical rollers. Their limitation is that, like a cylindrical roller, they do not locate axially. CARB bearings are typically used in pairs with a locating bearing, such as a

539:

659:

1099:

small defect (irregularity) in the material is often responsible for bearing failure; one of the biggest improvements in the life of common bearings during the second half of the 20th century was the use of more homogeneous materials, rather than better materials or lubricants (though both were also significant). Lubricant properties vary with temperature and load, so the best lubricant varies with application.

723:

populations of bearings. All information with regard to load ratings is then based on the life that 90% of a sufficiently large group of apparently identical bearings can be expected to attain or exceed. This gives a clearer definition of the concept of bearing life, which is essential to calculate the correct bearing size. Life models can thus help to predict the performance of a bearing more realistically.

25:

719:) occurs on the race of the inner or outer ring, or on a rolling element. Calculating the endurance life of bearings is possible with the help of so-called life models. More specifically, life models are used to determine the bearing size – since this must be sufficient to ensure that the bearing is strong enough to deliver the required life under certain defined operating conditions.

1126:, requiring no further maintenance for the life of the mechanical assembly. Although seals are appealing, they increase friction, and in a permanently sealed bearing the lubricant may become contaminated by hard particles, such as steel chips from the race or bearing, sand, or grit that gets past the seal. Contamination in the lubricant is

1143:, to define all of the physical parameters. The main designation is a seven digit number with optional alphanumeric digits before or after to define additional parameters. Here the digits will be defined as: 7654321. Any zeros to the left of the last defined digit are not printed; e.g. a designation of 0007208 is printed 7208.

1147:

designations are used: 00 = 10 mm ID, 01 = 12 mm ID, 02 = 15 mm ID, and 03 = 17 mm ID. The third digit defines the "diameter series", which defines the outer diameter (OD). The diameter series, defined in ascending order, is: 0, 8, 9, 1, 7, 2, 3, 4, 5, 6. The fourth digit defines the type of bearing:

507:

herringbone or with the skew end faces to realize efficient rolling axial contact. The downside to this bearing is manufacturing complexity. Gear bearings could be used, for example, as efficient rotary suspension, kinematically simplified planetary gear mechanism in measuring instruments and watches.

1200:

There are five optional characters that can defined after the main designation: A, E, P, C, and T; these are tacked directly onto the end of the main designation. Unlike the prefix, not all of the designations must be defined. "A" indicates an increased dynamic load rating. "E" indicates the use of a

1130:

and greatly reduces the operating life of the bearing assembly. Another major cause of bearing failure is the presence of water in the lubrication oil. Online water-in-oil monitors have been introduced in recent years to monitor the effects of both particles and the presence of water in oil and their

702:

Although there are many other apparent causes of bearing failure, most can be reduced to these three. For example, a bearing which is run dry of lubricant fails not because it is "without lubricant", but because lack of lubrication leads to fatigue and welding, and the resulting wear debris can cause

240:

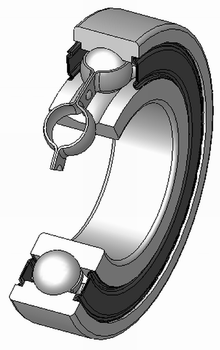

A rolling element rotary bearing uses a shaft in a much larger hole, and spheres or cylinders called "rollers" tightly fill the space between the shaft and hole. As the shaft turns, each roller acts as the logs in the above example. However, since the bearing is round, the rollers never fall out from

1072:

In 2019, the

Generalized Bearing Life Model was relaunched. The updated model offers life calculations also for hybrid bearings, i.e. bearings with steel rings and ceramic (silicon nitride) rolling elements. Even if the 2019 GBLM release was primarily developed to realistically determine the working

1068:

In 2015, the SKF Generalized

Bearing Life Model (GBLM) was introduced. In contrast to previous life models, GBLM explicitly separates surface and subsurface failure modes – making the model flexible to accommodate several different failure modes. Modern bearings and applications show fewer failures,

453:

type of rolling-element-bearing, dating back to at least 40 BC. Common roller bearings use cylinders of slightly greater length than diameter. Roller bearings typically have a higher radial load capacity than ball bearings, but a lower capacity and higher friction under axial loads. If the inner and

431:

Load distribution (normal force per roller) in a cylindrical roller bearing of type NU206. The inner ring and rollers of the bearing rotate counterclockwise; a static radial load of 3,000 N acts on the inner ring in the downward direction. The bearing has 13 rollers, 4 of which are under load at all

1146:

Digits one and two together are used to define the inner diameter (ID), or bore diameter, of the bearing. For diameters between 20 and 495 mm, inclusive, the designation is multiplied by five to give the ID; e.g. designation 08 is a 40 mm ID. For inner diameters less than 20 the following

1081:

All parts of a bearing are subject to many design constraints. For example, the inner and outer races are often complex shapes, making them difficult to manufacture. Balls and rollers, though simpler in shape, are small; since they bend sharply where they run on the races, the bearings are prone to

1045:

constant now had values of 4 for ball and 5 for roller bearings. Provided that load limits were observed, the idea of a 'fatigue limit' entered bearing lifetime calculations. If the bearing was not loaded beyond this limit, its theoretical lifetime would be limited only by external factors, such as

1008:

This model was recognised to have become inaccurate for modern bearings. Particularly owing to improvements in the quality of bearing steels, the mechanisms for how failures develop in the 1924 model are no longer as significant. By the 1990s, real bearings were found to give service lives up to 14

253:

are used as widely as rolling-element bearings. Common mechanical components where they are widely used are – automotive, industrial, marine, and aerospace applications. They are products of great necessity for modern technology. The rolling element bearing was developed from a firm foundation that

1102:

Although bearings tend to wear out with use, designers can make tradeoffs of bearing size and cost versus lifetime. A bearing can last indefinitely—longer than the rest of the machine—if it is kept cool, clean, lubricated, is run within the rated load, and if the bearing materials are sufficiently

529:

Tapered roller bearings use conical rollers that run on conical races. Most roller bearings only take radial or axial loads, but tapered roller bearings support both radial and axial loads, and generally can carry higher loads than ball bearings due to greater contact area. Tapered roller bearings

480:

Spherical roller bearings have an outer race with an internal spherical shape. The rollers are thicker in the middle and thinner at the ends. Spherical roller bearings can thus accommodate both static and dynamic misalignment. However, spherical rollers are difficult to produce and thus expensive,

1184:

The fifth and sixth digit define structural modifications to the bearing. For example, on radial thrust bearings the digits define the contact angle, or the presence of seals on any bearing type. The seventh digit defines the "width series", or thickness, of the bearing. The width series, defined

552:

The needle roller bearing is a special type of roller bearing which uses long, thin cylindrical rollers resembling needles. Often the ends of the rollers taper to points, and these are used to keep the rollers captive, or they may be hemispherical and not captive but held by the shaft itself or a

506:

is roller bearing combining to epicyclical gear. Each element of it is represented by concentric alternation of rollers and gearwheels with equality of roller(s) diameter(s) to gearwheel(s) pitch diameter(s). The widths of conjugated rollers and gearwheels in pairs are the same. The engagement is

457:

As in all radial bearings, the outer load is continuously re-distributed among the rollers. Often fewer than half of the total number of rollers carry a significant portion of the load. The animation on the right shows how a static radial load is supported by the bearing rollers as the inner ring

413:

roll. Each race features a groove usually shaped so the ball fits slightly loose. Thus, in principle, the ball contacts each race across a very narrow area. However, a load on an infinitely small point would cause infinitely high contact pressure. In practice, the ball deforms (flattens) slightly

1098:

There are also many material issues: a harder material may be more durable against abrasion but more likely to suffer fatigue fracture, so the material varies with the application, and while steel is most common for rolling-element bearings, plastics, glass, and ceramics are all in common use. A

641:

Linear motion roller-element bearings are typically designed for either shafts or flat surfaces. Flat surface bearings often consist of rollers and are mounted in a cage, which is then placed between the two flat surfaces; a common example is drawer-support hardware. Roller-element bearing for a

418:

flattens where it contacts the road. The race also yields slightly where each ball presses against it. Thus, the contact between ball and race is of finite size and has finite pressure. The deformed ball and race do not roll entirely smoothly because different parts of the ball are moving at

351:

Bearings, especially rolling element bearings are designed in similar fashion across the board consisting of the outer and inner track, a central bore, a retainer to keep the rolling elements from clashing into one another or seizing the bearing movement, and the rolling elements themselves.

722:

Under controlled laboratory conditions, however, seemingly identical bearings operating under identical conditions can have different individual endurance lives. Thus, bearing life cannot be calculated based on specific bearings, but is instead related to in statistical terms, referring to

1188:

There are four optional prefix characters, here defined as A321-XXXXXXX (where the X's are the main designation), which are separated from the main designation with a dash. The first character, A, is the bearing class, which is defined, in ascending order: C, B, A. The class defines extra

674:

Rolling-element bearings often work well in non-ideal conditions, but sometimes minor problems cause bearings to fail quickly and mysteriously. For example, with a stationary (non-rotating) load, small vibrations can gradually press out the lubricant between the races and rollers or balls

626:

Rolling-element bearings are often used for axles due to their low rolling friction. For light loads, such as bicycles, ball bearings are often used. For heavy loads and where the loads can greatly change during cornering, such as cars and trucks, tapered rolling bearings are used.

1086:

rather than the applied load. Smaller rolling elements are lighter and thus have less momentum, but smaller elements also bend more sharply where they contact the race, causing them to fail more rapidly from fatigue. Maximum rolling-element bearing speeds are often specified in

1118:

being pumped. All lubricants reacted with the oxygen, leading to fires and other failures. The solution was to lubricate the bearing with the oxygen. Although liquid oxygen is a poor lubricant, it was adequate, since the service life of the pump was just a few hours.

693:

Pressure-induced welding can occur when two metal pieces are pressed together at very high pressure and they become one. Although balls, rollers and races may look smooth, they are microscopically rough. Thus, there are high-pressure spots which push away the bearing

689:

Fatigue results when a material becomes brittle after being repeatedly loaded and released. Where the ball or roller touches the race there is always some deformation, and hence a risk of fatigue. Smaller balls or rollers deform more sharply, and so tend to fatigue

244:

Rolling-element bearings have the advantage of a good trade-off between cost, size, weight, carrying capacity, durability, accuracy, friction, and so on. Other bearing designs are often better on one specific attribute, but worse in most other attributes, although

679:). Without lubricant the bearing fails, even though it is not rotating and thus is apparently not being used. For these sorts of reasons, much of bearing design is about failure analysis. Vibration based analysis can be used for fault identification of bearings.

300:

Beginning in 2600 BCE - The

Ancient Egyptians were the first to notably use the concept behind rolling bearings, they first did this by using logs under these stones with groups of builders on either side to push and pull the weight of the

379:

Needle - Varying in size, diameters, and materials these types of bearings are best suited for helping reduce weight as well as smaller cross sections application, typically higher load capacity than ball bearings and rigid shaft applications.

553:

similar arrangement. Since the rollers are thin, the outside diameter of the bearing is only slightly larger than the hole in the middle. However, the small-diameter rollers must bend sharply where they contact the races, and thus the bearing

698:. Sometimes, the resulting metal-to-metal contact welds a microscopic part of the ball or roller to the race. As the bearing continues to rotate, the weld is then torn apart, but it may leave race welded to bearing or bearing welded to race.

703:

abrasion. Similar events occur in false brinelling damage. In high speed applications, the oil flow also reduces the bearing metal temperature by convection. The oil becomes the heat sink for the friction losses generated by the bearing.

233:. As each log comes out the back, it is moved to the front where the block then rolls on to it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them. See "

304:

40 BC - In the remains of a sunken Roman Ship in Lake Nemi. This discovery shows the continual development of the principle. The remains of the ship do not show clear signs of an indication of what these bearings were used

618:, tapered roller thrust bearings or cylindrical roller thrust bearings. Also non-rolling-element bearings such as hydrostatic or magnetic bearings see some use where particularly heavy loads or low friction is needed.

714:

The life of a rolling bearing is expressed as the number of revolutions or the number of operating hours at a given speed that the bearing is capable of enduring before the first sign of metal fatigue (also known as

355:

The internal rolling components may differ in design due to their intended purpose of application of the bearing. The main five types of bearings are Ball, Cylindrical, Tapered, Barrel, and Needle.

1185:

from lightest to heaviest, is: 7, 8, 9, 0, 1 (extra light series), 2 (light series), 3 (medium series), 4 (heavy series). The third digit and the seventh digit define the "dimensional series" of the bearing.

956:

The major implication of this model is that bearing life is finite, and reduces by a cube power of the ratio between design load and applied load. This model was developed in 1924, 1947 and 1952 work by

362:

Cylindrical - For single axis movement for straight directional movement. The shape allows for more surface area to be in contact adding in moving more weight with less force at a greater distance.

229:

One of the earliest and best-known rolling-element bearings are sets of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little

370:

1828:

Morales-Espejel, Guillermo E.; Gabelli, Antonio (April 2016). "A model for rolling bearing life with surface and subsurface survival: Sporadic surface damage from deterministic indentations".

1208:

While manufacturers follow ISO 15 for part number designations on some of their products, it is common for them to implement proprietary part number systems that do not correlate to ISO 15.

1082:

fatigue. The loads within a bearing assembly are also affected by the speed of operation: rolling-element bearings may spin over 100,000 rpm, and the principal load in such a bearing may be

1025:, that avoided the internal inclusions that had previously acted as stress risers within the rolling elements, and also on smoother finishes to bearing tracks that avoided impact loads. The

359:

Ball - the simplest following the basic principles with minimal design intention. Important to note the ability for more seizures is likely due to the freedom of the track design.

1201:

plastic cage. "P" indicates that heat-resistant steel are used. "C" indicates the type of lubricant used (C1–C28). "T" indicates the degree to which the bearing components have been

588:

The configuration of the races determine the types of motions and loads that a bearing can best support. A given configuration can serve multiple of the following types of loading.

1189:

requirements for vibration, deviations in shape, the rolling surface tolerances, and other parameters that are not defined by a designation character. The second character is the

1756:

Morales-Espejel, Guillermo E.; Gabelli, Antonio; de Vries, Alexander J. C. (2015). "A Model for

Rolling Bearing Life with Surface and Subsurface Survival—Tribological Effects".

1859:

1122:

The operating environment and service needs are also important design considerations. Some bearing assemblies require routine addition of lubricants, while others are factory

1005:

values may be seen as both a longer lifetime for a correctly-used bearing below its design load, or also as the increased rate by which lifetime is shortened when overloaded.

787:

481:

and the bearings have higher friction than an ideal cylindrical or tapered roller bearing since there will be a certain amount of sliding between rolling elements and races.

2046:

366:

1616:

1432:

1830:

951:

916:

819:

1857:

Morales-Espejel, Guillermo E; Gabelli, Antonio (2019). "Application of a rolling bearing life model with surface and subsurface survival to hybrid bearing cases".

1793:

1043:

1003:

983:

885:

863:

841:

1018:

1612:

1407:

1190:

821:

is the 'basic life' (usually quoted in millions of revolutions) for a reliability of 90%, i.e. no more than 10% of bearings are expected to have failed

1494:

1319:

274:

1675:

1242: – in machining, the contact area between two objects – often used for the area of a screw head that directly connects to the attached part.

419:

different speeds as it rolls. Thus, there are opposing forces and sliding motions at each ball/race contact. Overall, these cause bearing drag.

1791:

Morales-Espejel, Guillermo E.; Brizmer, Victor (2011). "Micropitting

Modelling in Rolling–Sliding Contacts: Application to Rolling Bearings".

573:. This non-locating bearing can be an advantage, as it can be used to allow a shaft and a housing to undergo thermal expansion independently.

1022:

642:

shaft use bearing balls in a groove designed to recirculate them from one end to the other as the bearing moves; as such, they are called

454:

outer races are misaligned, the bearing capacity often drops quickly compared to either a ball bearing or a spherical roller bearing.

150:

249:

can sometimes simultaneously outperform on carrying capacity, durability, accuracy, friction, rotation rate and sometimes cost. Only

376:

Barrel - Provides assistance to high radial socks loads that cause misalignment and uses its shape and size for compensation.

122:

1140:

329:

receives the first patent for a radial ball bearing, his design was used by James Moore to win the first 80 mile bicycle race from

103:

49:

2085:

Damping and

Stiffness Characteristics of Rolling Element Bearings - Theory and Experiment (PhD thesis, Paul Dietl, TU Vienna, 1997

129:

2002:

1975:

1948:

682:

There are three usual limits to the lifetime or load capacity of a bearing: abrasion, fatigue and pressure-induced welding.

1627:

136:

738:

2099:

2030:

1912:

169:

67:

118:

1197:. For tapered bearings, the values are, in ascending order: 0, N, and X, where 0 is 0, N is "normal", and X is 6X.

1017:, then the Lundberg-Palmgren mechanism for failure by fatigue would simply never occur. This relied on homogeneous

670:

due to wet conditions, improper lubrication, improper pre-load adjustment, and fatigue from frequent shock loading.

918:

is the life that 90% of bearings can be expected to reach or exceed. The median or average life, sometimes called

1459:

615:

2104:

1103:

free of microscopic defects. Cooling, lubrication, and sealing are thus important parts of the bearing design.

107:

2077:- Movies and photos of hundreds of working mechanical-systems models at Cornell University. Also includes an

1106:

The needed bearing lifetime also varies with the application. For example, Tedric A. Harris reports in his

1057:

as the

Ioannides-Harris model. ISO 281:2000 first incorporated this model and ISO 281:2007 is based on it.

1091:', which is the product of the mean diameter (in mm) and the maximum RPM. For angular contact bearings nD

1686:

1383:

1358:

919:

143:

40:

1742:

466:

206:

which carries a load by placing rolling elements (such as balls or rollers) between two concentric,

182:

1264:

570:

566:

475:

450:

1333:

686:

Abrasion occurs when the surface is eroded by hard contaminants scraping at the bearing materials.

596:

441:

733:

The traditional life prediction model for rolling-element bearings uses the basic life equation:

96:

1060:

The concept of fatigue limit, and thus ISO 281:2007, remains controversial, at least in the US.

1202:

524:

427:

373:

and how it does this is by using a conical structure enabling the elements to roll diagonally.

191:

1965:

1938:

1992:

1729:

1724:

Ioannides, Stathis; Harris, Ted (1985). "A New

Fatigue Life Model for Rolling Bearings". SKF.

1593:

1313:

1095:

s over 2.1 million have been found to be reliable in high performance rocketry applications.

636:

610:

Thrust bearings are used to support axial loads, such as vertical shafts. Common designs are

547:

1685:. Society of Tribologists and Lubrication Engineers (STLE): 34–43. July 2010. Archived from

1073:

life of hybrid bearings, the concept can also be used for other products and failure modes.

929:

894:

797:

2020:

1233:

234:

207:

203:

1552:

1236: – Mechanism to constrain relative movement to the desired motion and reduce friction

8:

1648:

611:

887:

is a constant: 3 for ball bearings, 4 for pure line contact and 3.33 for roller bearings

2109:

1876:

1810:

1773:

1572:

1028:

988:

968:

870:

848:

826:

580:

as "CARB bearings". The inventor behind the bearing was the engineer Magnus

Kellström.

554:

322:, Wales. This is the first design seen with a spherical object moving through a groove.

311:

1740 - John Harrison invented the first caged roller bearing for H3 marine timekeeping.

219:

1512:

2026:

1998:

1971:

1944:

1908:

1880:

1814:

1777:

1123:

958:

282:

263:

35:

1893:

Design of liquid propellant rocket engines -Dieter K. Huzel and David H.Huang pg.209

1576:

922:(MTBF), is about five times the calculated basic rating life. Several factors, the '

515:

1868:

1843:

1839:

1802:

1765:

1564:

1050:

1014:

676:

663:

230:

223:

16:

Bearing which carries a load with rolling elements placed between two grooved rings

1769:

2084:

1806:

1626:. Society of Tribologists and Lubrication Engineers (STLE): 30–40. Archived from

1553:"Typical bearing-fault rating using force measurements: application to real data"

1301:

1239:

2078:

308:

17th century - Galileo describes the functionality of a caged bearing

254:

was built over thousands of years. The concept emerged in its primitive form in

2069:

605:

410:

405:

315:

211:

2074:

1706:

953:

life depending upon the desired reliability, lubrication, contamination, etc.

45:

Parts of the article are poorly written/formatted, making for awkward reading.

2093:

1872:

1568:

1460:"The CARB bearing – a better solution for the front side of drying cylinders"

1408:"Today in Transportation History – 1869: A Big Little Invention for Bicycles"

1258:

1139:

Metric rolling-element bearings have alphanumerical designations, defined by

1115:

1111:

326:

258:; after a long inactive period in the Middle Ages, it was revived during the

250:

246:

1537:

1253:

1227:

1010:

1009:

times longer than those predicted. An explanation was put forward based on

503:

498:

400:

394:

255:

2021:

Johannes Brändlein; Paul Eschmann; Ludwig Hasbargen; Karl Weigand (1999).

2060:

2051:

706:

ISO has categorised bearing failures into a document Numbered ISO 15243.

259:

1248:

319:

1466:

1194:

843:

is the dynamic load rating of the bearing, quoted by the manufacturer

695:

489:

85:

1617:"In search of a fatigue limit: A critique of ISO standard 281:2007"

1267: – Rolling-element bearing that tolerates angular misalignment

1127:

1083:

716:

266:, developed steadily in the seventeenth and eighteenth centuries.

214:. The relative motion of the races causes the rolling elements to

1218:

667:

538:

215:

730:/American Bearing Manufacturers Association Standards 9 and 11.

658:

1299:

726:

The prediction of bearing life is described in ISO 281 and the

1860:

Proceedings of the Institution of Mechanical Engineers, Part C

1755:

399:

A particularly common kind of rolling-element bearing is the

334:

330:

365:

Tapered - Primarily focused on the ability to take on

923:

727:

415:

291:

287:

1594:"Rolling bearings -- Dynamic load ratings and rating life"

1550:

1261: – Simplest type of bearing, with no rolling elements

565:

CARB bearings are toroidal roller bearings and similar to

1676:"ISO 281:2007 bearing life standard – and the answer is?"

1498:

1054:

577:

2023:

Ball and Roller Bearings: Theory, Design and Application

1063:

965:. The model dates from 1924, the values of the constant

1223:

Pages displaying short descriptions of redirect targets

314:

1794 - The first patent for the ball race was given to

2081:

of classic texts on mechanical design and engineering.

1943:. Vol. 10. New York: Springer. pp. 465–467.

1856:

1827:

1790:

926:

five factor model', can be used to further adjust the

237:" for more on the historical development of bearings.

1646:

1031:

991:

971:

932:

897:

873:

865:

is the equivalent dynamic load applied to the bearing

851:

829:

800:

741:

2075:

Kinematic Models for Design Digital Library (KMODDL)

1244:

Pages displaying wikidata descriptions as a fallback

576:

Toroidal roller bearings were introduced in 1995 by

1994:

Hands on Water and Wastewater Equipment Maintenance

1701:

1699:

1642:

1640:

1551:Slavic, J; Brkovic, A; Boltezar M (December 2011).

110:. Unsourced material may be challenged and removed.

1037:

997:

977:

945:

910:

879:

857:

835:

813:

781:

1937:Grote, Karl-Heinrich; Antonsson, Erik K. (2009).

1902:

1611:

1607:

1605:

1603:

2091:

1964:Brumbach, Michael E.; Clade, Jeffrey A. (2003),

1717:

1696:

1637:

1300:Hamrock, B. J.; Anderson, W. J. (June 1, 1983).

1114:which could not be adequately isolated from the

1013:; if the bearing was loaded to never exceed the

560:

2047:Technical publication about bearing lubrication

1723:

1670:

1668:

1666:

1664:

1662:

1049:A new model of bearing life was put forward by

269:

1936:

1600:

1588:

1586:

1221: – Parts list of railroad trucks (bogies)

1164:Roller needle or with long cylindrical rollers

662:A prematurely failed rear bearing cone from a

1963:

1076:

1990:

1659:

1318:: CS1 maint: multiple names: authors list (

1158:Roller radial with short cylindrical rollers

1940:Springer handbook of mechanical engineering

1583:

1489:

1487:

1046:contamination or a failure of lubrication.

1707:"ISO Adopts SKF Bearing Life Calculations"

709:

170:Learn how and when to remove this message

68:Learn how and when to remove this message

1957:

1932:

1930:

1928:

1926:

1924:

1484:

657:

595:

537:

514:

488:

465:

440:

426:

383:

273:

181:

1647:Daniel R. Snyder, SKF (12 April 2007).

1381:

1230: – Type of rolling-element bearing

2092:

1970:, Cengage Learning, pp. 112–113,

1683:Tribology & Lubrication Technology

1624:Tribology & Lubrication Technology

1110:on an oxygen pump bearing in the U.S.

414:where it contacts each race much as a

1991:Renner, Don; Renner, Barbara (1998).

1921:

1064:Generalized Bearing Life Model (GBLM)

436:

1907:(4th ed.). Wiley-Interscience.

1454:

1452:

1295:

1293:

1283:

1281:

963:Dynamic Capacity of Rolling Bearings

108:adding citations to reliable sources

79:

18:

961:and Gustaf Lundberg in their paper

461:

13:

2014:

1388:Auburn Bearing & Manufacturing

1161:Roller radial spherical double-row

653:

621:

591:

422:

403:. The bearing has inner and outer

14:

2121:

2070:How rolling-element bearings work

2040:

1449:

1290:

1278:

1167:Roller radial with spiral rollers

583:

510:

341:

186:A sealed deep groove ball bearing

1557:Journal of Vibration and Control

1513:"CARB - a revolutionary concept"

1384:"A Brief History of the Bearing"

1359:"Galileo and history of bearing"

1155:Ball radial spherical double-row

985:from the post-war works. Higher

782:{\displaystyle L_{10}=(C/P)^{p}}

630:

616:spherical roller thrust bearings

533:

84:

23:

2063:Lubrication of Machine Elements

1984:

1896:

1887:

1850:

1821:

1784:

1749:

1544:

1530:

1505:

1495:"CARB toroidal roller bearings"

1176:Ball thrust, ball thrust-radial

484:

388:

95:needs additional citations for

1844:10.1016/j.triboint.2015.12.036

1425:

1400:

1375:

1351:

1326:

1179:Roller thrust or thrust-radial

1134:

770:

755:

1:

1770:10.1080/10402004.2015.1025932

1649:"The meaning of bearing life"

1306:NASA Technical Reports Server

1272:

1170:Ball radial-thrust single-row

666:, caused by a combination of

561:CARB toroidal roller bearings

1807:10.1080/10402004.2011.587633

1382:Wiseman, Mike (2022-03-04).

1334:"The History of the Bearing"

445:A cylindrical roller bearing

270:History of Bearings Timeline

7:

1211:

43:. The specific problem is:

10:

2126:

1903:Harris, Tedric A. (2000).

1302:"Rolling-Element Bearings"

1077:Constraints and trade-offs

634:

603:

545:

522:

496:

473:

470:A spherical roller bearing

392:

1997:. CRC Press. p. 28.

1596:. ISO. 2007. ISO281:2007.

920:Mean Time Between Failure

567:spherical roller bearings

119:"Rolling-element bearing"

2100:Rolling-element bearings

2061:NASA technical handbook

2052:NASA technical handbook

1905:Rolling Bearing Analysis

1873:10.1177/0954406219848470

1569:10.1177/1077546311399949

1433:"Barrel roller bearings"

1265:Spherical roller bearing

1108:Rolling Bearing Analysis

571:spherical roller bearing

519:A tapered roller bearing

476:Spherical roller bearing

449:Roller bearings are the

2054:Rolling-Element Bearing

2025:(3rd ed.). Wiley.

1831:Tribology International

1150:

710:Life calculation models

600:A thrust roller bearing

542:A needle roller bearing

196:rolling-element bearing

1967:Industrial Maintenance

1794:Tribology Transactions

1758:Tribology Transactions

1737:Cite journal requires

1412:Transportation History

1152:Ball radial single-row

1039:

999:

979:

947:

946:{\displaystyle L_{10}}

912:

911:{\displaystyle L_{10}}

881:

859:

837:

815:

814:{\displaystyle L_{10}}

783:

671:

648:recirculating bearings

601:

543:

525:Tapered roller bearing

520:

494:

471:

446:

433:

296:

192:mechanical engineering

187:

2105:Bearings (mechanical)

1465:. SKF. Archived from

1040:

1000:

980:

948:

913:

882:

860:

838:

816:

784:

661:

637:Linear-motion bearing

599:

548:Needle roller bearing

541:

518:

492:

469:

444:

430:

384:Specific Design Types

279:Study of ball bearing

277:

185:

1234:Bearing (mechanical)

1029:

1019:vacuum-melted steels

989:

969:

930:

895:

871:

849:

827:

798:

739:

644:linear ball bearings

612:Thrust ball bearings

557:relatively quickly.

104:improve this article

50:improve this article

39:to meet Knowledge's

1338:www.acorn-ind.co.uk

1472:on 3 December 2013

1035:

995:

975:

943:

908:

877:

855:

833:

811:

779:

672:

602:

544:

521:

495:

472:

447:

437:Cylindrical roller

434:

347:Design description

297:

220:rolling resistance

198:, also known as a

188:

2004:978-1-56676-428-5

1977:978-0-7668-2695-3

1950:978-3-540-49131-6

1867:(15): 5491–5498.

1613:Erwin V. Zaretsky

1563:(14): 2164–2174.

1437:www.schaeffler.us

1191:frictional moment

1131:combined effect.

1053:and developed by

1038:{\displaystyle p}

998:{\displaystyle p}

978:{\displaystyle p}

880:{\displaystyle p}

858:{\displaystyle P}

836:{\displaystyle C}

283:Leonardo da Vinci

264:Leonardo da Vinci

218:with very little

180:

179:

172:

154:

78:

77:

70:

41:quality standards

32:This article may

2117:

2036:

2009:

2008:

1988:

1982:

1981:

1961:

1955:

1954:

1934:

1919:

1918:

1900:

1894:

1891:

1885:

1884:

1854:

1848:

1847:

1825:

1819:

1818:

1788:

1782:

1781:

1753:

1747:

1746:

1740:

1735:

1733:

1725:

1721:

1715:

1714:

1703:

1694:

1693:

1691:

1680:

1672:

1657:

1656:

1644:

1635:

1634:

1632:

1621:

1609:

1598:

1597:

1590:

1581:

1580:

1548:

1542:

1541:

1534:

1528:

1527:

1525:

1523:

1517:

1509:

1503:

1502:

1491:

1482:

1481:

1479:

1477:

1471:

1464:

1456:

1447:

1446:

1444:

1443:

1429:

1423:

1422:

1420:

1419:

1404:

1398:

1397:

1395:

1394:

1379:

1373:

1372:

1370:

1369:

1363:www.linkedin.com

1355:

1349:

1348:

1346:

1345:

1330:

1324:

1323:

1317:

1309:

1297:

1288:

1285:

1245:

1224:

1044:

1042:

1041:

1036:

1015:fatigue strength

1004:

1002:

1001:

996:

984:

982:

981:

976:

952:

950:

949:

944:

942:

941:

917:

915:

914:

909:

907:

906:

886:

884:

883:

878:

864:

862:

861:

856:

842:

840:

839:

834:

820:

818:

817:

812:

810:

809:

788:

786:

785:

780:

778:

777:

765:

751:

750:

677:false brinelling

664:mountain bicycle

462:Spherical roller

241:under the load.

231:sliding friction

222:and with little

175:

168:

164:

161:

155:

153:

112:

88:

80:

73:

66:

62:

59:

53:

27:

26:

19:

2125:

2124:

2120:

2119:

2118:

2116:

2115:

2114:

2090:

2089:

2043:

2033:

2017:

2015:Further reading

2012:

2005:

1989:

1985:

1978:

1962:

1958:

1951:

1935:

1922:

1915:

1901:

1897:

1892:

1888:

1855:

1851:

1826:

1822:

1789:

1785:

1754:

1750:

1738:

1736:

1727:

1726:

1722:

1718:

1713:. 28 June 2006.

1705:

1704:

1697:

1689:

1678:

1674:

1673:

1660:

1645:

1638:

1630:

1619:

1615:(August 2010).

1610:

1601:

1592:

1591:

1584:

1549:

1545:

1538:"McMaster-Carr"

1536:

1535:

1531:

1521:

1519:

1515:

1511:

1510:

1506:

1493:

1492:

1485:

1475:

1473:

1469:

1462:

1458:

1457:

1450:

1441:

1439:

1431:

1430:

1426:

1417:

1415:

1406:

1405:

1401:

1392:

1390:

1380:

1376:

1367:

1365:

1357:

1356:

1352:

1343:

1341:

1332:

1331:

1327:

1311:

1310:

1298:

1291:

1286:

1279:

1275:

1270:

1243:

1240:Bearing surface

1222:

1214:

1182:

1137:

1094:

1090:

1079:

1066:

1030:

1027:

1026:

990:

987:

986:

970:

967:

966:

937:

933:

931:

928:

927:

902:

898:

896:

893:

892:

872:

869:

868:

850:

847:

846:

828:

825:

824:

805:

801:

799:

796:

795:

773:

769:

761:

746:

742:

740:

737:

736:

712:

656:

654:Bearing failure

639:

633:

624:

622:Radial loadings

608:

594:

592:Thrust loadings

586:

563:

550:

536:

527:

513:

501:

487:

478:

464:

439:

425:

423:Roller bearings

397:

391:

386:

344:

272:

200:rolling bearing

176:

165:

159:

156:

113:

111:

101:

89:

74:

63:

57:

54:

47:

28:

24:

17:

12:

11:

5:

2123:

2113:

2112:

2107:

2102:

2088:

2087:

2082:

2079:e-book library

2072:

2067:

2065:(NASA-RP-1126)

2058:

2056:(NASA-RP-1105)

2049:

2042:

2041:External links

2039:

2038:

2037:

2031:

2016:

2013:

2011:

2010:

2003:

1983:

1976:

1956:

1949:

1920:

1913:

1895:

1886:

1849:

1820:

1801:(4): 625–643.

1783:

1764:(5): 894–906.

1748:

1739:|journal=

1716:

1695:

1692:on 2013-10-24.

1658:

1653:Machine Design

1636:

1633:on 2015-05-18.

1599:

1582:

1543:

1529:

1504:

1483:

1448:

1424:

1399:

1374:

1350:

1325:

1289:

1276:

1274:

1271:

1269:

1268:

1262:

1256:

1251:

1246:

1237:

1231:

1225:

1215:

1213:

1210:

1181:

1180:

1177:

1174:

1173:Roller tapered

1171:

1168:

1165:

1162:

1159:

1156:

1153:

1149:

1136:

1133:

1092:

1088:

1078:

1075:

1065:

1062:

1034:

994:

974:

959:Arvid Palmgren

940:

936:

905:

901:

891:Basic life or

889:

888:

876:

866:

854:

844:

832:

822:

808:

804:

776:

772:

768:

764:

760:

757:

754:

749:

745:

711:

708:

700:

699:

691:

687:

655:

652:

635:Main article:

632:

629:

623:

620:

606:Thrust bearing

604:Main article:

593:

590:

585:

584:Configurations

582:

562:

559:

546:Main article:

535:

532:

523:Main article:

512:

511:Tapered roller

509:

497:Main article:

493:A gear bearing

486:

483:

474:Main article:

463:

460:

451:earliest known

438:

435:

424:

421:

409:between which

393:Main article:

390:

387:

385:

382:

371:radial loading

343:

342:Overall Design

340:

339:

338:

323:

316:Phillip Vaughn

312:

309:

306:

302:

271:

268:

251:plain bearings

247:fluid bearings

178:

177:

92:

90:

83:

76:

75:

31:

29:

22:

15:

9:

6:

4:

3:

2:

2122:

2111:

2108:

2106:

2103:

2101:

2098:

2097:

2095:

2086:

2083:

2080:

2076:

2073:

2071:

2068:

2066:

2064:

2059:

2057:

2055:

2050:

2048:

2045:

2044:

2034:

2032:0-471-98452-3

2028:

2024:

2019:

2018:

2006:

2000:

1996:

1995:

1987:

1979:

1973:

1969:

1968:

1960:

1952:

1946:

1942:

1941:

1933:

1931:

1929:

1927:

1925:

1916:

1914:0-471-35457-0

1910:

1906:

1899:

1890:

1882:

1878:

1874:

1870:

1866:

1862:

1861:

1853:

1845:

1841:

1837:

1833:

1832:

1824:

1816:

1812:

1808:

1804:

1800:

1796:

1795:

1787:

1779:

1775:

1771:

1767:

1763:

1759:

1752:

1744:

1731:

1720:

1712:

1711:eBearing News

1708:

1702:

1700:

1688:

1684:

1677:

1671:

1669:

1667:

1665:

1663:

1654:

1650:

1643:

1641:

1629:

1625:

1618:

1614:

1608:

1606:

1604:

1595:

1589:

1587:

1578:

1574:

1570:

1566:

1562:

1558:

1554:

1547:

1539:

1533:

1514:

1508:

1500:

1496:

1490:

1488:

1468:

1461:

1455:

1453:

1438:

1434:

1428:

1413:

1409:

1403:

1389:

1385:

1378:

1364:

1360:

1354:

1339:

1335:

1329:

1321:

1315:

1307:

1303:

1296:

1294:

1284:

1282:

1277:

1266:

1263:

1260:

1259:Plain bearing

1257:

1255:

1252:

1250:

1247:

1241:

1238:

1235:

1232:

1229:

1226:

1220:

1217:

1216:

1209:

1206:

1204:

1198:

1196:

1192:

1186:

1178:

1175:

1172:

1169:

1166:

1163:

1160:

1157:

1154:

1151:

1148:

1144:

1142:

1132:

1129:

1125:

1120:

1117:

1116:liquid oxygen

1113:

1112:Space Shuttle

1109:

1104:

1100:

1096:

1085:

1074:

1070:

1061:

1058:

1056:

1052:

1047:

1032:

1024:

1020:

1016:

1012:

1006:

992:

972:

964:

960:

954:

938:

934:

925:

921:

903:

899:

874:

867:

852:

845:

830:

823:

806:

802:

794:

793:

792:

789:

774:

766:

762:

758:

752:

747:

743:

734:

731:

729:

724:

720:

718:

707:

704:

697:

692:

688:

685:

684:

683:

680:

678:

669:

665:

660:

651:

649:

645:

638:

631:Linear motion

628:

619:

617:

613:

607:

598:

589:

581:

579:

574:

572:

568:

558:

556:

549:

540:

534:Needle roller

531:

526:

517:

508:

505:

500:

491:

482:

477:

468:

459:

455:

452:

443:

429:

420:

417:

412:

408:

407:

402:

396:

381:

377:

374:

372:

368:

367:axial loading

363:

360:

357:

353:

349:

348:

336:

332:

328:

327:Jules Suriray

324:

321:

317:

313:

310:

307:

303:

299:

298:

294:

293:

289:

284:

280:

276:

267:

265:

261:

257:

252:

248:

242:

238:

236:

232:

227:

225:

221:

217:

213:

210:rings called

209:

205:

201:

197:

193:

184:

174:

171:

163:

160:December 2019

152:

149:

145:

142:

138:

135:

131:

128:

124:

121: –

120:

116:

115:Find sources:

109:

105:

99:

98:

93:This article

91:

87:

82:

81:

72:

69:

61:

58:February 2024

51:

46:

42:

38:

37:

30:

21:

20:

2062:

2053:

2022:

1993:

1986:

1966:

1959:

1939:

1904:

1898:

1889:

1864:

1858:

1852:

1835:

1829:

1823:

1798:

1792:

1786:

1761:

1757:

1751:

1730:cite journal

1719:

1710:

1687:the original

1682:

1652:

1628:the original

1623:

1560:

1556:

1546:

1532:

1520:. Retrieved

1507:

1474:. Retrieved

1467:the original

1440:. Retrieved

1436:

1427:

1416:. Retrieved

1414:. 2017-08-03

1411:

1402:

1391:. Retrieved

1387:

1377:

1366:. Retrieved

1362:

1353:

1342:. Retrieved

1340:. 2022-03-28

1337:

1328:

1314:cite journal

1305:

1254:Gear bearing

1228:Ball bearing

1207:

1199:

1187:

1183:

1145:

1138:

1121:

1107:

1105:

1101:

1097:

1080:

1071:

1067:

1059:

1048:

1011:fatigue life

1007:

962:

955:

890:

790:

735:

732:

725:

721:

713:

705:

701:

681:

673:

647:

643:

640:

625:

609:

587:

575:

564:

551:

528:

504:Gear bearing

502:

499:Gear bearing

485:Gear bearing

479:

456:

448:

404:

401:ball bearing

398:

395:Ball bearing

389:Ball bearing

378:

375:

364:

361:

358:

354:

350:

346:

345:

286:

278:

243:

239:

228:

199:

195:

189:

166:

157:

147:

140:

133:

126:

114:

102:Please help

97:verification

94:

64:

55:

48:Please help

44:

33:

1838:: 279–288.

1135:Designation

260:Renaissance

256:Roman times

52:if you can.

2094:Categories

1522:2 December

1476:2 December

1442:2024-02-26

1418:2024-02-26

1393:2024-02-26

1368:2024-02-26

1344:2024-02-26

1273:References

1249:Brinelling

1195:gyroscopes

1023:AISI 52100

1021:, such as

320:Carmarthen

130:newspapers

2110:Tribology

1881:164456996

1815:137662003

1778:137670935

1205:(T1–T5).

696:lubricant

458:rotates.

1577:53959482

1212:See also

1203:tempered

1128:abrasive

1084:momentum

717:spalling

555:fatigues

235:bearings

34:require

1219:Axlebox

791:Where:

690:faster.

668:pitting

301:stones.

224:sliding

208:grooved

204:bearing

202:, is a

144:scholar

36:cleanup

2029:

2001:

1974:

1947:

1911:

1879:

1813:

1776:

1575:

1287:ISO 15

1141:ISO 15

1124:sealed

325:1869 -

146:

139:

132:

125:

117:

1877:S2CID

1811:S2CID

1774:S2CID

1690:(PDF)

1679:(PDF)

1631:(PDF)

1620:(PDF)

1573:S2CID

1518:. SKF

1516:(PDF)

1470:(PDF)

1463:(PDF)

432:time.

411:balls

406:races

335:Rouen

331:Paris

212:races

151:JSTOR

137:books

2027:ISBN

1999:ISBN

1972:ISBN

1945:ISBN

1909:ISBN

1743:help

1524:2013

1478:2013

1320:link

924:ASME

728:ANSI

416:tire

369:and

305:for.

292:1519

288:1452

216:roll

194:, a

123:news

1869:doi

1865:233

1840:doi

1803:doi

1766:doi

1565:doi

1499:SKF

1087:'nD

1055:SKF

1051:FAG

646:or

578:SKF

333:to

318:of

281:by

262:by

190:In

106:by

2096::

1923:^

1875:.

1863:.

1836:96

1834:.

1809:.

1799:54

1797:.

1772:.

1762:58

1760:.

1734::

1732:}}

1728:{{

1709:.

1698:^

1681:.

1661:^

1651:.

1639:^

1622:.

1602:^

1585:^

1571:.

1561:17

1559:.

1555:.

1497:.

1486:^

1451:^

1435:.

1410:.

1386:.

1361:.

1336:.

1316:}}

1312:{{

1304:.

1292:^

1280:^

939:10

904:10

807:10

748:10

650:.

614:,

226:.

2035:.

2007:.

1980:.

1953:.

1917:.

1883:.

1871::

1846:.

1842::

1817:.

1805::

1780:.

1768::

1745:)

1741:(

1655:.

1579:.

1567::

1540:.

1526:.

1501:.

1480:.

1445:.

1421:.

1396:.

1371:.

1347:.

1322:)

1308:.

1093:m

1089:m

1033:p

993:p

973:p

935:L

900:L

875:p

853:P

831:C

803:L

775:p

771:)

767:P

763:/

759:C

756:(

753:=

744:L

675:(

337:.

295:)

290:–

285:(

173:)

167:(

162:)

158:(

148:·

141:·

134:·

127:·

100:.

71:)

65:(

60:)

56:(

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.