388:

431:. The group accounted for 95% of French steel production. The Usinor-Sacilor group undertook an internal reorganization in 1987 into four specialized divisions: Sollac for thin flat products, Ugine for special flat and stainless steel products, Unimetal for long products and Ascometal for special long products. The new Sollac, the largest subsidiary of the group, included the flat products operations of the formerly competing Usinor and Sollac companies. In 1988 the company started to base profit sharing on productivity improvements, with the share calculated separately at each location.

375:. Great hopes were pinned in the Fos-sur-Mer project, but in 1971 Wendel-Sidélor did not have enough revenue to finance the project without assistance. In May 1972 Jacques Ferry of the CSSF helped the government persuade the head of Usinor to help bail out the project, despite his very poor relationship with the head of Wendel-Sidélor. In October 1972 it was agreed that Ferry would head Solmer, which would be jointly controlled by Usinor and Wendel-Sidélor. Solmer was 47.5% owned by Wendel-Sidélor, 47.5% by Usinor and 5% by

35:

400:

September 1978. The government converted part of the accumulated losses of about $ 8,000 million into state equite shareholding, and covered the remaining losses with loans and guarantees. In effect the companies had been nationalized. Usinor shares were devalued by 33% and

Sacilor's by 50%. The unions at once called for a 24-hour stoppage at the Sacilor-Sollac plants throughout Lorraine on 25 September 1978, but there was little they could do to prevent layoffs.

417:

280:

408:, Managing Director of Sacilor-Sollac, said that steel production in Europe would be limited for some time, so to keep production stable it would be necessary to cut worker numbers from year to year. Sacilor-Sollac bought SNAP, a specialty steel producer. The Thomas steel plant at Hagandange was closed, and Sollac obtained new oxygen furnaces and two continuous casters. Between 1985 and 1988 Sollac cut the costs of its inputs by 20%.

352:

131:, founded in 1849 and Nord-Est (Forges et Aciéries du Nord-Est). The main reason for the merger was to implement a continuous rolling mill to reduce costs and satisfy the expected growing market for automobiles and consumer goods. The company used technology from United Engineering and Westinghouse Electric International. In 1948 it was accepted that a second strip mill should be set up, also using American equipment.

368:

subsidiary to build and operate the new plant. Sollac was in turn a subsidiary of Wendel-Sidélor. At the same time, Usinor decided to increase the capacity of its

Dunkirk plant to 8 million tons per year. Taken with the 4 million tons from Fos-sur-Mer, the two companies would add almost 8 million tons or about 45% of total French output between 1968 and 1973.

311:, that he hoped the French iron-steel industry would soon be the first in Europe". In 1950 the company formed an association with Continental Foundry and Machines for manufacture of pilger rolls for continuous mills. The Sollac continuous strip mills at Serémange-Erzange opened in 1954. In September 1954

450:

Sollac

Mediterranee was later renamed ArcelorMittal Mediterranee SASU. In 2017 ArcelorMittal Atlantique et Lorraine included the main plant at Dunkirk with a capacity of 7 million tonnes of steel slab and 4.45 million tonnes of hot-rolled coils per year. It also supplied steel slabs to the second hot

438:

On 1 February 2000 Usinor was restructured geographically. Sollac-Atlantique, Sollac-Lorraine and Sollac-Méditerranée were now fully independent subsidiaries. Sollac-Méditerranée included the French plants at Fos-sur-Mer and Saint-Chély-d'Apcher, and also included plants in Spain, Italy, Turkey and

434:

In

January 1993 Sollac decided to increase its prices to offset declining volumes. As of 2000 the Sollac steel plant just outside Dunkirk was one of the largest and most efficient in Europe. It converted iron ore and coal into steel rolls in a continuous process, producing 6 million tonnes annually.

330:

In 1954 there were more than 2,000 workers in the factories of Serémange alone. In 1955 half the 3,000 workers at Sollac were

Algerian, brought in by the company due to the shortage of French workers. Production of crude steel at Serémange reached 1,411,000 tons by 1959. Serémange had its own oxygen

367:

in the Rhone's

Mediterranean delta. Sollac would have preferred a site near Le Havre, since it would have been closer to large markets, but the government's regional development plans took priority. Solmer (Societé Lorraine et Méridionale de Laminage Continu) was formed in November 1970 as a Sollac

138:

promoted the creation of Sollac as a joint-venture flat steel manufacturer. Most of the funding came from the state. François Bloch-Lainé justified this in 1948 on the basis that Sollac would be in the state's interest. The Société Lorraine de

Laminage Continu (Sollac) was established in December

399:

became

Managing Director of Sollac in 1975. In 1979 he assumed the same position with Rhône-Poulenc. By early 1978 the French steel industry was in crisis, with excess capacity and low prices. After a delay due to the March 1978 elections, the cabinet released details of their rescue plan on 20

98:

company formed in

December 1948 as a cooperative to produce steel rolls in Lorraine from steel provided by several other companies. There were various changes of ownership during the years that followed. In 1970 the company, under pressure from the French government, began to develop a large new

338:

In 1951 PFFW and Wendel et Cie merged to form de Wendel SA. Pont-à-Mousson and Marine

Firminy formed Sidélor in 1951, holding their combined assets in Lorraine. In 1964 Sidélor and Wendel formed the Societé des aciéries de Lorraine. The consortium that was fully merged in January 1968 to form

257:

The Sollac project was submitted by France to the Organisation of European Economic Cooperation (OEEC) in April 1949, which had representatives of all the Marshall Plan countries. When the Belgians refused to approve the project, the Marshall Plan's Economic Cooperation Administration (ECA)

1424:

266:. Sollac became the largest single project funded by the Marshall Plan, with $ 49.4 million of direct funds and $ 83.7 million of counterpart funds. It was hoped by the Americans that with two strip mills a French monopoly was less likely to emerge.

435:

The plant had a dedicated port, railway and 55 kilometres (34 mi) road network. However, Sollac was struggling due to decline in demand from the automobile and construction industries in Europe, with prices falling and excess steel piling up.

143:, as well as a Thomas and Martin mill and two cold mills. The founding companies retained their autonomy. Each company supplied its share of cast iron or steel, which Sollac turned into sheet metal, charging cost price. The founders included:

443:. Sollac Atlantique was terminated on 22 January 2007. As of 2008 the subsidiaries were named Société Arcelor Atlantique et Lorraine and Sollac Méditerrannée. The companies were involved in a dispute with the French government over the

99:

continuous strip mill in the south of France. The French steel industry soon went into crisis, with excess capacity and declining demands from automobile manufacturers and the construction industry. Sollac became a subsidiary of

451:

rolling mill of the unit located in Sérémange in Lorraine. The unit also included plants at Florange, Base-Indre, Desvres, Mardyck, Montataire and Mouzon. In 2012 49% of the unit's output was delivered to the automobile sector.

362:

In the mid-1960s the French government set up a group under Sollac's director general, Louis Dherse, to look into building a second new French steel mill. The government pushed Sollac into building the plant at

403:

As of January 1981 Sollac's Moselle holdings were a cold rolling operation at Ebange-Florange in the Moselle Valley, and a coke works and continuous casting plant at Sérémange in the Fensch Valley. That year

1185:

339:

Wendel-Sidelor. It controlled both Sacilor and Sollac. Sacilor specialised in long product while Sollac produced flat products. In 1968 a new Sacilor plant was being built in the Moselle valley at

235:

371:

By 1971 Wendel-Sidélor was the largest steel producer in France, owning Sacilor, the majority of Sollac, and many smaller facilities. However, its productivity was 40% below that of

343:, expected to have a capacity of 1.6 million tons by 1970. In the late 1960s Saint-Gobain-Pont-à-Mousson, which owned half of Wendel-Sidélor, decided to withdraw from steelmaking.

1295:

Kipping, Matthias (Fall 1994), "Competing for Dollars and Technology: The United States and the Modernization of the French and German Steel Industries after World War II",

17:

331:

factory, which was expanded in 1959. This was the location where the pure oxygen Kaldo process was to be installed, with a planned capacity of 500,000 tons. A 160t

1096:(Proceedings of the Caen Preconference 18–20 September 1997, Workshop C 45 of Twelfth International Economic History Congress of Madrid), Presses Paris Sorbonne,

1548:

320:

439:

Portugal. In February 2002 Usinor was merged with Arbed (Luxembourg) and Aceralia (Spain) to form Arcelor. In 2006 Arcelor was merged with Mittal Steel to form

1538:

1553:

447:

allowance trading scheme, in which different treatment was being applied to the steel sector and to the chemical and non-ferrous metal sectors.

1543:

1093:

Catching Up with America: Productivity Missions and the Diffusion of American Economic and Technological Influence After the Second World War

1048:

1533:

1469:

1385:

1280:

1215:

1153:

1127:

1101:

1075:

395:

In 1973 Wendel-Sidélor was renamed Sacilor Aciéries et Laminoires de Lorraine. In 1975 Sacilor merged with Marine Firminy.

1316:

1528:

1400:

Mioche, Philippe (April–June 1994), "La sidérurgie Française de 1973 à nos jours: Dégénérescence et transformation",

123:(1939–45) the United States wanted to ensure that the French steel industry could compete effectively with the Ruhr.

1013:

1168:

1187:

La sidérurgie française, 1945-1979. : L’histoire d’une faillite. Les solutions qui s’affrontent

1484:

444:

387:

1375:

1270:

1205:

1143:

1117:

1091:

927:

291:

The foundation stone for the Sollac mill was laid on 23 December 1949 in the small village of

1459:

1065:

1442:

1377:

The Politics of Steel: Western Europe and the Steel Industry in the Crisis Years (1974-1984)

246:

1502:

1230:

Godelier, Éric (Summer 2008), "La naissance d'un géant : Arcelor-Mittal (1948-2006)",

8:

567:

565:

1413:

1363:

1343:

1304:

1239:

303:

said at the groundbreaking ceremony, which was attended by the French Foreign Minister

562:

1465:

1381:

1276:

1211:

1149:

1123:

1097:

1071:

978:

300:

139:

1948. It was created under a cooperative model to build a wide-strip rolling mill in

1119:

American Firms in Europe: Strategy, Identity, Perception and Performance (1880-1980)

1405:

1334:

Martin, J. E. (July 1961), "DEVELOPMENTS IN THE LORRAINE IRON AND STEEL INDUSTRY",

167:

1423:

1297:

Papers presented at the fortieth annual meeting of the Business History Conference

933:

332:

405:

308:

304:

1251:

990:

1522:

440:

427:

In 1986 Usinor and Sacilor were combined under one holding company headed by

259:

108:

73:

34:

1030:

127:(Union Sidérurgique du Nord de la France) was formed in 1948 by a merger of

1501:

571:

396:

312:

128:

120:

316:

292:

135:

103:

in 1987, responsible for all flat products. In 2002 Usinor became part of

1354:

Martin, J. E. (November 1968), "New Trends in the Lorraine Iron Region",

1207:

Industry and Work in Contemporary Capitalism: Global Models, Local Lives?

1012:

984:

428:

420:

364:

355:

1367:

1347:

1308:

1243:

1417:

954:

376:

324:

944:

942:

340:

279:

1409:

416:

939:

258:

recommended that the project be funded anyway. A large part of the

140:

1047:

996:

966:

821:

819:

794:

792:

728:

726:

659:

657:

655:

351:

284:

104:

816:

789:

723:

652:

475:

372:

315:

was asked by Sollac to assume the post of president, replacing

296:

263:

124:

100:

1145:

Steel, State, and Labor: Mobilization and Adjustment in France

95:

1483:

960:

915:

535:

533:

531:

1303:, vol. 23, no. 1, Cambridge University Press,

674:

672:

628:

594:

592:

552:

550:

548:

465:

463:

1441:

948:

879:

855:

779:

777:

738:

701:

699:

577:

528:

335:

was installed in 1960 at Sollac's Florange steelworks.

321:

High Authority of the European Coal and Steel Community

1167:

1064:

Bamford, Colin Grahame; Munday, Stephen C. R. (2002),

972:

518:

516:

514:

669:

589:

545:

460:

262:

counterpart funds of 1949–51 were used by Sollac and

218:

Saar, Mar-Mich-Pont (soon to become part of Sidélor)

94:(Société Lorraine de Laminage Continu) was a French

1374:

Mény, Yves; Wright, Vincent; Rhodes, Martin (1987),

903:

891:

867:

843:

831:

774:

750:

711:

696:

684:

640:

616:

804:

511:

487:

1204:Goddard, Victoria; Narotzky, Susana (2015-01-30),

1015:ArcelorMittal Mediterranee SASU (Company Overview)

934:Modernisation en vue pour Sollac – L'UsineNouvelle

762:

1520:

1404:(in French) (42), Sciences Po University Press,

1373:

825:

798:

732:

663:

604:

411:

1203:

572:Une Ville ... Une histoire .. Serémange-Erzange

499:

481:

382:

1549:Manufacturing companies disestablished in 2007

1461:Industrial Policies in the European Community

1063:

985:ArcelorMittal Mediterranee SASU ... Bloomberg

921:

274:

1539:Manufacturing companies established in 1948

1317:"Jean Gandois, un PDG sans langue de bois"

1183:

634:

539:

33:

1115:

583:

1252:"IN MEMORIAM 21 mars 1887 - 28 mai 1966"

1229:

885:

861:

744:

415:

386:

350:

278:

163:PFFW (Petits-Fils de François De Wendel)

1554:French companies disestablished in 2007

1507:(in French), Ville de Serémange-Erzange

1294:

556:

469:

14:

1521:

1399:

1353:

1333:

1232:French Politics, Culture & Society

1116:Bonin, Hubert; Goey, Ferry de (2009),

1089:

997:Atlantique et Lorraine – ArcelorMittal

909:

873:

678:

598:

493:

319:, who had been called to serve in the

193:J.-J. Carnaud et Forges de Basse-Indre

1458:Price, Victoria Curzon (1981-11-26),

1457:

1314:

1268:

1141:

897:

849:

837:

810:

783:

768:

756:

717:

705:

690:

646:

622:

522:

1544:French companies established in 1948

1249:

1028:

610:

505:

18:Société Lorraine de Laminage Continu

346:

24:

1425:"Modernisation en vue pour Sollac"

1402:Vingtième Siècle. Revue d'histoire

25:

1565:

1148:, University of Pittsburgh Pre,

107:, which in turn was merged into

1362:(4), Geographical Association,

1342:(3), Geographical Association,

961:Sollac Atlantique – Societe SAS

1315:Lhaik, Corinne (23 May 1996),

1250:J.M. (August–September 1966),

826:Mény, Wright & Rhodes 1987

799:Mény, Wright & Rhodes 1987

733:Mény, Wright & Rhodes 1987

664:Mény, Wright & Rhodes 1987

182:Forges et Aciéries de Gueugnon

13:

1:

1301:Business and Economic History

1142:Daley, Anthony (1996-02-15),

1029:Aron, Aexis (February 1960),

412:Usinor subsidiary (1986–2002)

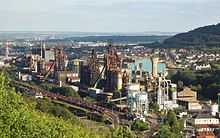

391:Sérémange steel works in 2012

215:Forges et Aciéries de Dilling

1534:Companies based in Grand Est

1275:, Harvard University Press,

383:Industry in crisis (1972–86)

251:Soon part of LorraineEscaut

114:

7:

1184:Freyssenet, Michel (1979),

949:Our History – ArcelorMittal

482:Goddard & Narotzky 2015

10:

1570:

1504:Une Ville ... Une histoire

1170:EUR-Lex - 62007CA0127 - EN

1090:Barjot, Dominique (2002),

1053:(in French), ArcelorMittal

1005:

973:EUR-Lex - 62007CA0127 - EN

269:

39:Hot Rolling Mill, Florange

1529:Steel companies of France

1464:, Palgrave Macmillan UK,

922:Bamford & Munday 2002

307:and Minister of Industry

283:Patural blast furnace at

275:Early expansion (1949–69)

165:

159:

79:

68:

60:

52:

44:

32:

454:

423:, head of the new Usinor

287:and Sérémange steelworks

207:Lorraine, Mar-Mich-Pont

445:greenhouse gas emission

299:river. U.S. Ambassador

1269:James, Harold (2006),

1050:Atlantique et Lorraine

424:

392:

359:

288:

236:Marine & Homécourt

1380:, Walter de Gruyter,

1238:(2), Berghahn Books,

584:Bonin & Goey 2009

419:

390:

354:

282:

174:De Wendel & Cie.

1256:La Jaune et la Rouge

1193:(in French), Savelli

1035:La Jaune et la Rouge

1485:"Sollac Atlantique"

226:UCPMI de Hagondange

29:

1122:, Librairie Droz,

425:

393:

360:

289:

247:Aciéries de Longwy

204:Aciéries de Rombas

27:

1471:978-1-349-16640-4

1387:978-3-11-010517-9

1282:978-0-674-02181-5

1272:FAMILY CAPITALISM

1217:978-1-317-74521-1

1155:978-0-8229-7485-7

1129:978-2-600-01259-1

1103:978-2-84050-240-1

1077:978-0-435-33223-5

301:David K. E. Bruce

255:

254:

89:

88:

16:(Redirected from

1561:

1514:

1513:

1512:

1498:

1497:

1496:

1480:

1479:

1478:

1454:

1453:

1452:

1438:

1437:

1436:

1420:

1396:

1395:

1394:

1370:

1350:

1330:

1329:

1328:

1311:

1291:

1290:

1289:

1265:

1264:

1263:

1246:

1226:

1225:

1224:

1200:

1199:

1198:

1192:

1180:

1179:

1178:

1164:

1163:

1162:

1138:

1137:

1136:

1112:

1111:

1110:

1086:

1085:

1084:

1060:

1059:

1058:

1044:

1043:

1042:

1025:

1024:

1023:

1000:

994:

988:

982:

976:

970:

964:

958:

952:

946:

937:

931:

925:

919:

913:

907:

901:

895:

889:

883:

877:

871:

865:

859:

853:

847:

841:

835:

829:

823:

814:

808:

802:

796:

787:

781:

772:

766:

760:

754:

748:

742:

736:

730:

721:

715:

709:

703:

694:

688:

682:

676:

667:

661:

650:

644:

638:

632:

626:

620:

614:

608:

602:

596:

587:

581:

575:

569:

560:

554:

543:

537:

526:

520:

509:

503:

497:

491:

485:

479:

473:

467:

347:Solmer (1970–72)

295:on the banks of

166:Lorraine based,

146:

145:

37:

30:

26:

21:

1569:

1568:

1564:

1563:

1562:

1560:

1559:

1558:

1519:

1518:

1517:

1510:

1508:

1494:

1492:

1476:

1474:

1472:

1450:

1448:

1447:, ArcelorMittal

1434:

1432:

1429:L'UsineNouvelle

1410:10.2307/3771210

1392:

1390:

1388:

1326:

1324:

1287:

1285:

1283:

1261:

1259:

1222:

1220:

1218:

1196:

1194:

1190:

1176:

1174:

1160:

1158:

1156:

1134:

1132:

1130:

1108:

1106:

1104:

1082:

1080:

1078:

1056:

1054:

1040:

1038:

1021:

1019:

1008:

1003:

995:

991:

983:

979:

971:

967:

959:

955:

947:

940:

932:

928:

920:

916:

908:

904:

896:

892:

884:

880:

872:

868:

860:

856:

848:

844:

836:

832:

824:

817:

809:

805:

797:

790:

782:

775:

767:

763:

755:

751:

743:

739:

731:

724:

716:

712:

704:

697:

689:

685:

677:

670:

662:

653:

645:

641:

635:Freyssenet 1979

633:

629:

621:

617:

609:

605:

597:

590:

582:

578:

570:

563:

555:

546:

540:Freyssenet 1979

538:

529:

521:

512:

504:

500:

492:

488:

480:

476:

468:

461:

457:

414:

385:

358:industrial zone

349:

277:

272:

117:

85:

40:

23:

22:

15:

12:

11:

5:

1567:

1557:

1556:

1551:

1546:

1541:

1536:

1531:

1516:

1515:

1499:

1481:

1470:

1455:

1439:

1421:

1397:

1386:

1371:

1351:

1331:

1312:

1292:

1281:

1266:

1247:

1227:

1216:

1201:

1181:

1165:

1154:

1139:

1128:

1113:

1102:

1087:

1076:

1061:

1045:

1031:"Jules AUBRUN"

1026:

1009:

1007:

1004:

1002:

1001:

989:

977:

965:

953:

938:

926:

914:

902:

900:, p. 165.

890:

888:, p. 127.

878:

866:

864:, p. 126.

854:

852:, p. 258.

842:

840:, p. 127.

830:

828:, p. 537.

815:

803:

801:, p. 601.

788:

786:, p. 126.

773:

761:

759:, p. 104.

749:

747:, p. 122.

737:

735:, p. 509.

722:

720:, p. 103.

710:

708:, p. 311.

695:

693:, p. 249.

683:

681:, p. 375.

668:

666:, p. 536.

651:

649:, p. 306.

639:

627:

625:, p. 308.

615:

603:

601:, p. 245.

588:

586:, p. 556.

576:

561:

559:, p. 233.

544:

527:

525:, p. 305.

510:

498:

486:

474:

472:, p. 232.

458:

456:

453:

413:

410:

406:Jacques Mayoux

384:

381:

348:

345:

309:Robert Lacoste

305:Robert Schuman

276:

273:

271:

268:

253:

252:

249:

244:

241:

240:

238:

233:

230:

229:

227:

224:

220:

219:

216:

213:

209:

208:

205:

202:

198:

197:

194:

191:

187:

186:

183:

180:

176:

175:

171:

170:

164:

161:

157:

156:

153:

150:

116:

113:

87:

86:

83:

81:

77:

76:

70:

66:

65:

62:

58:

57:

54:

50:

49:

46:

42:

41:

38:

9:

6:

4:

3:

2:

1566:

1555:

1552:

1550:

1547:

1545:

1542:

1540:

1537:

1535:

1532:

1530:

1527:

1526:

1524:

1506:

1505:

1500:

1490:

1486:

1482:

1473:

1467:

1463:

1462:

1456:

1446:

1445:

1440:

1430:

1426:

1422:

1419:

1415:

1411:

1407:

1403:

1398:

1389:

1383:

1379:

1378:

1372:

1369:

1365:

1361:

1357:

1352:

1349:

1345:

1341:

1337:

1332:

1322:

1318:

1313:

1310:

1306:

1302:

1298:

1293:

1284:

1278:

1274:

1273:

1267:

1257:

1253:

1248:

1245:

1241:

1237:

1234:(in French),

1233:

1228:

1219:

1213:

1210:, Routledge,

1209:

1208:

1202:

1189:

1188:

1182:

1172:

1171:

1166:

1157:

1151:

1147:

1146:

1140:

1131:

1125:

1121:

1120:

1114:

1105:

1099:

1095:

1094:

1088:

1079:

1073:

1070:, Heinemann,

1069:

1068:

1062:

1052:

1051:

1046:

1036:

1032:

1027:

1017:

1016:

1011:

1010:

998:

993:

986:

981:

974:

969:

962:

957:

950:

945:

943:

935:

930:

924:, p. 59.

923:

918:

912:, p. 23.

911:

906:

899:

894:

887:

886:Godelier 2008

882:

876:, p. 22.

875:

870:

863:

862:Godelier 2008

858:

851:

846:

839:

834:

827:

822:

820:

813:, p. 96.

812:

807:

800:

795:

793:

785:

780:

778:

770:

765:

758:

753:

746:

745:Godelier 2008

741:

734:

729:

727:

719:

714:

707:

702:

700:

692:

687:

680:

675:

673:

665:

660:

658:

656:

648:

643:

637:, p. 81.

636:

631:

624:

619:

612:

607:

600:

595:

593:

585:

580:

573:

568:

566:

558:

553:

551:

549:

542:, p. 24.

541:

536:

534:

532:

524:

519:

517:

515:

507:

502:

496:, p. 34.

495:

490:

483:

478:

471:

466:

464:

459:

452:

448:

446:

442:

441:ArcelorMittal

436:

432:

430:

422:

418:

409:

407:

401:

398:

389:

380:

378:

374:

369:

366:

357:

353:

344:

342:

336:

334:

333:Kaldo furnace

328:

326:

322:

318:

314:

310:

306:

302:

298:

294:

286:

281:

267:

265:

261:

260:Marshall Plan

250:

248:

245:

243:

242:

239:

237:

234:

232:

231:

228:

225:

222:

221:

217:

214:

211:

210:

206:

203:

200:

199:

195:

192:

189:

188:

184:

181:

178:

177:

173:

172:

169:

162:

158:

154:

151:

148:

147:

144:

142:

137:

132:

130:

126:

122:

112:

110:

109:ArcelorMittal

106:

102:

97:

93:

82:

78:

75:

74:ArcelorMittal

71:

67:

63:

59:

56:December 1948

55:

51:

47:

43:

36:

31:

19:

1509:, retrieved

1503:

1493:, retrieved

1488:

1475:, retrieved

1460:

1449:, retrieved

1443:

1433:, retrieved

1428:

1401:

1391:, retrieved

1376:

1359:

1355:

1339:

1335:

1325:, retrieved

1320:

1300:

1296:

1286:, retrieved

1271:

1260:, retrieved

1255:

1235:

1231:

1221:, retrieved

1206:

1195:, retrieved

1186:

1175:, retrieved

1169:

1159:, retrieved

1144:

1133:, retrieved

1118:

1107:, retrieved

1092:

1081:, retrieved

1066:

1055:, retrieved

1049:

1039:, retrieved

1034:

1020:, retrieved

1014:

992:

980:

968:

956:

929:

917:

905:

893:

881:

869:

857:

845:

833:

806:

764:

752:

740:

713:

686:

642:

630:

618:

606:

579:

557:Kipping 1994

501:

489:

477:

470:Kipping 1994

449:

437:

433:

426:

402:

397:Jean Gandois

394:

370:

361:

337:

329:

313:Jules Aubrun

290:

256:

133:

129:Denain-Anzin

121:World War II

118:

91:

90:

80:Headquarters

72:Merged into

1491:(in French)

1489:Societe SAS

1444:Our History

1431:(in French)

1323:(in French)

1258:(in French)

1037:(in French)

1018:, Bloomberg

910:Mioche 1994

874:Mioche 1994

679:Martin 1968

599:Martin 1961

494:Barjot 2002

429:Francis Mer

421:Francis Mer

365:Fos-sur-Mer

356:Fos-sur-Mer

196:de Wendell

185:de Wendell

1523:Categories

1511:2017-10-20

1495:2017-10-20

1477:2017-10-20

1451:2017-10-19

1435:2017-10-20

1393:2017-10-19

1327:2017-10-02

1288:2017-07-17

1262:2017-07-10

1223:2017-10-20

1197:2017-10-19

1177:2017-10-20

1161:2017-10-19

1135:2017-07-17

1109:2017-10-20

1083:2017-10-20

1057:2017-10-20

1041:2017-07-10

1022:2017-10-20

898:Daley 1996

850:Daley 1996

838:Daley 1996

811:Price 1981

784:Daley 1996

769:Lhaik 1996

757:Daley 1996

718:Daley 1996

706:James 2006

691:Daley 1996

647:James 2006

623:James 2006

523:James 2006

325:Luxembourg

1356:Geography

1336:Geography

1321:L'Express

1173:, EUR-Lex

611:Aron 1960

506:J.M. 1966

341:Gandrange

317:Léon Daum

293:Serémange

168:de Wendel

136:Léon Daum

115:Formation

111:in 2006.

1368:40566963

1348:40565267

1309:23702848

1244:42843551

484:, PT149.

141:Florange

134:In 1948

45:Industry

1418:3771210

1067:Markets

1006:Sources

377:Thyssen

285:Hayange

270:History

152:Company

105:Arcelor

61:Defunct

53:Founded

1468:

1416:

1384:

1366:

1346:

1307:

1279:

1242:

1214:

1152:

1126:

1100:

1074:

373:Usinor

297:Fensch

264:Usinor

155:Notes

125:Usinor

119:After

101:Usinor

92:Sollac

84:France

28:Sollac

1414:JSTOR

1364:JSTOR

1344:JSTOR

1305:JSTOR

1240:JSTOR

1191:(PDF)

455:Notes

201:14.5%

160:47.5%

149:Share

96:steel

48:Steel

1466:ISBN

1382:ISBN

1277:ISBN

1212:ISBN

1150:ISBN

1124:ISBN

1098:ISBN

1072:ISBN

323:in

223:3.5%

190:3.5%

179:3.5%

69:Fate

64:2007

1406:doi

212:21%

1525::

1487:,

1427:,

1412:,

1360:53

1358:,

1340:46

1338:,

1319:,

1299:,

1254:,

1236:26

1033:,

941:^

818:^

791:^

776:^

725:^

698:^

671:^

654:^

591:^

564:^

547:^

530:^

513:^

462:^

379:.

327:.

1408::

999:.

987:.

975:.

963:.

951:.

936:.

771:.

613:.

574:.

508:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.