988:

69:

286:

28:

145:

1939:

245:(E) of a polymer is influenced by the load and the response time. Time–temperature superposition implies that the response time function of the elastic modulus at a certain temperature resembles the shape of the same functions of adjacent temperatures. Curves of E vs. log(response time) at one temperature can be shifted to overlap with adjacent curves, as long as the data sets did not suffer from ageing effects during the test time (see

2299:

2073:

2022:

226:

transition from a hard “glassy” state to a soft “rubbery” state in which the modulus can be several orders of magnitude lower than it was in the glassy state. The transition from glassy to rubbery behavior is continuous and the transition zone is often referred to as the leathery zone. The onset temperature of the transition zone, moving from glassy to rubbery, is known as the

628:

832:

237:

In the 1940s

Andrews and Tobolsky showed that there was a simple relationship between temperature and time for the mechanical response of a polymer. Modulus measurements are made by stretching or compressing a sample at a prescribed rate of deformation. For polymers, changing the rate of deformation

1954:

The principle of time-temperature superposition requires the assumption of thermorheologically simple behavior (all curves have the same characteristic time variation law with temperature). From an initial spectral window and a series of isotherms in this window, we can calculate the master curves

276:

or viscosity can often be a strong indicator of the molecular structure and molecular mobility. Time–temperature superposition avoids the inefficiency of measuring a polymer's behavior over long periods of time at a specified temperature by utilizing the fact that at higher temperatures and shorter

225:

polymer against the temperature at which you measured it, you will get a curve which can be divided up into distinct regions of physical behavior. At very low temperatures, the polymer will behave like a glass and exhibit a high modulus. As you increase the temperature, the polymer will undergo a

264:

Consider a viscoelastic body that is subjected to dynamic loading. If the excitation frequency is low enough the viscous behavior is paramount and all polymer chains have the time to respond to the applied load within a time period. In contrast, at higher frequencies, the chains do not have the

205:

The translation factor is often computed using an empirical relation first established by

Malcolm L. Williams, Robert F. Landel and John D. Ferry (also called the Williams-Landel-Ferry or WLF model). An alternative model suggested by Arrhenius is also used. The WLF model is related to macroscopic

2359:

For the superposition principle to apply, the sample must be homogeneous, isotropic and amorphous. The material must be linear viscoelastic under the deformations of interest, i.e., the deformation must be expressed as a linear function of the stress by applying very small strains, e.g. 0.01%.

136:

as a function of time do not change shape as the temperature is changed but appear only to shift left or right. This implies that a master curve at a given temperature can be used as the reference to predict curves at various temperatures by applying a shift operation. The time-temperature

1897:

1679:

1441:

470:

265:

time to fully respond and the resulting artificial viscosity results in an increase in the macroscopic modulus. Moreover, at constant frequency, an increase in temperature results in a reduction of the modulus due to an increase in free volume and chain movement.

238:

will cause the curve described above to be shifted along the temperature axis. Increasing the rate of deformation will shift the curve to higher temperatures so that the transition from a glassy to a rubbery state will happen at higher temperatures.

2254:

651:

1930:≈ 50 K. Experimentally observed values deviate from the values in the table. These orders of magnitude are useful and are a good indicator of the quality of a relationship that has been computed from experimental data.

1169:

909:

1697:

1270:

623:{\displaystyle {\begin{aligned}&T>T_{0}\quad \implies \quad a_{\rm {T}}<1\\&T<T_{0}\quad \implies \quad a_{\rm {T}}>1\\&T=T_{0}\quad \implies \quad a_{\rm {T}}=1\,.\end{aligned}}}

452:

656:

475:

1497:

1212:

are positive constants that depend on the material and the reference temperature. This relationship holds only in the approximate temperature range . To determine the constants, the factor

2490:

Experiments that determine the mechanical properties of polymers often use periodic loading. For such situations, the loading rate is related to the frequency of the applied load.

2150:

827:{\displaystyle {\begin{aligned}G'(\omega ,T)&=G'\left(a_{\rm {T}}\,\omega ,T_{0}\right)\\G''(\omega ,T)&=G''\left(a_{\rm {T}}\,\omega ,T_{0}\right).\end{aligned}}}

339:. At constant strain, the stress relaxes faster at the higher temperature. The principle of time-temperature superposition states that the change in temperature from

192:

experimental determination of frequency-dependent curves of isothermal viscoelastic mechanical properties at several temperatures and for a small range of frequencies

1192:

2018:

The viscoelastic behavior is well modeled and allows extrapolation beyond the field of experimental frequencies which typically ranges from 0.01 to 100 Hz .

2525:

Andrews, R. D.; Tobolsky, A. V. (August 1951). "Elastoviscous properties of polyisobutylene. IV. Relaxation time spectrum and calculation of bulk viscosity".

1994:. Conversely, lowering the temperature corresponds to the exploration of the part of the curve corresponding to high frequencies. For a reference temperature

268:

Time–temperature superposition is a procedure that has become important in the field of polymers to observe the dependence upon temperature on the change of

2320:

2094:

1916:

for a given polymer system be collected in a table. These constants are approximately the same for a large number of polymers and can be written

1058:

2388:

requires extensive dynamic testing at a number of scanning frequencies and temperature, which represents at least a hundred measurement points.

17:

1892:{\displaystyle C_{1}^{0}={\frac {C_{1}^{g}\,C_{2}^{g}}{C_{2}^{g}+(T_{0}-T_{g})}}\qquad {\rm {and}}\qquad C_{2}^{0}=C_{2}^{g}+(T_{0}-T_{g})\,.}

1436:{\displaystyle \log a_{\rm {T}}=-{\frac {C_{1}^{g}(T-T_{g})}{C_{2}^{g}+(T-T_{g})}}=\log \left({\frac {\eta _{\rm {T}}}{\eta _{T_{g}}}}\right)}

851:

201:

application of the translation factor to determine temperature-dependent moduli over the whole range of frequencies in the master curve.

2632:

374:

2589:

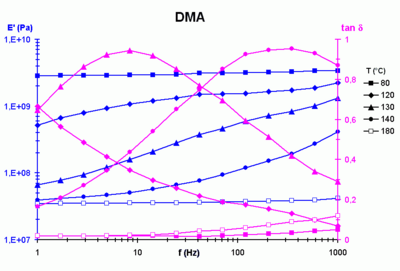

Curve has been generated with data from a dynamic test with a double scanning frequency / temperature on a viscoelastic polymer.

1684:

In particular, to transform the constants from those obtained at the glass transition temperature to a reference temperature

987:

2430:

Li, Rongzhi (February 2000). "Time-temperature superposition method for glass transition temperature of plastic materials".

1674:{\displaystyle C'_{1}={\frac {C_{1}\,C_{2}}{C_{2}+(T'_{0}-T_{0})}}\qquad {\rm {and}}\qquad C'_{2}=C_{2}+(T'_{0}-T_{0})\,.}

2414:

1017:, combined with the principle of time-temperature superposition, can account for variations in the intrinsic viscosity

2561:

2346:

2120:

2328:

2281:. This Arrhenius law, under this glass transition temperature, applies to secondary transitions (relaxation) called

2102:

845:

For a polymer in solution or "molten" state the following relationship can be used to determine the shift factor:

2576:

For the superposition principle to apply, the excitation frequency should be well above the characteristic time

2637:

2608:

2509:

2324:

2098:

2021:

246:

148:

Moduli measured using a dynamic viscoelastic modulus analyzer. The plots show the variation of elastic modulus

1962:

is taken as a reference for setting the frequency scale (the curve at that temperature undergoes no shift).

198:

experimental determination of a master curve showing the effect of frequency for a wide range of frequencies

2363:

To apply the WLF relationship, such a sample should be sought in the approximate temperature range , where

1024:

of amorphous polymers as a function of temperature, for temperatures near the glass transition temperature

227:

1460:

are the coefficients of the WLF model when the reference temperature is the glass transition temperature.

1980:) decreases. This amounts to explore a part of the master curve corresponding to frequencies lower than

195:

computation of a translation factor to correlate these properties for the temperature and frequency range

2249:{\displaystyle \log(a_{\rm {T}})=-{\frac {E_{a}}{2.303R}}\left({\frac {1}{T}}-{\frac {1}{T_{0}}}\right)}

124:

This superposition principle is used to determine temperature-dependent mechanical properties of linear

2662:

2458:

837:

A decrease in temperature increases the time characteristics while frequency characteristics decrease.

128:

materials from known properties at a reference temperature. The elastic moduli of typical amorphous

285:

2652:

2309:

2083:

68:

2313:

2087:

206:

motion of the bulk material, while the

Arrhenius model considers local motion of polymer chains.

2657:

27:

1177:

144:

118:

1233:*. A good correlation between the two shift factors gives the values of the coefficients

960:

versus the reciprocal of temperature (in K), the slope of the curve can be interpreted as

132:

increase with loading rate but decrease when the temperature is increased. Curves of the

8:

464:

is called the horizontal translation factor or the shift factor and has the properties:

976:

2443:

2604:

2557:

2505:

2410:

1955:

of a material which extends over a broader frequency range. An arbitrary temperature

1195:

943:

1031:. The WLF model also expresses the change with the temperature of the shift factor.

2580:(also called relaxation time) which depends on the molecular weight of the polymer.

2534:

2439:

1477:

depend on the reference temperature. If the reference temperature is changed from

2627:

2044:

is the frequency. The shift factor is computed from data in the frequency range

242:

218:

138:

133:

114:

73:

1950:

as a function of frequency. The data have been fit to a polynomial of degree 7.

277:

time the polymer will behave the same, provided there are no phase transitions.

2538:

253:

840:

2646:

1014:

1938:

1164:{\displaystyle \log a_{\rm {T}}=-{\frac {C_{1}(T-T_{0})}{C_{2}+(T-T_{0})}}}

982:

217:

properties on the temperature at which they are measured. If you plot the

214:

125:

32:

222:

188:

The application of the principle typically involves the following steps:

942:

The time–temperature shift factor can also be described in terms of the

921:

is the viscosity (non-Newtonian) during continuous flow at temperature

904:{\displaystyle a_{\rm {T}}={\frac {\eta _{\rm {T}}}{\eta _{\rm {T0}}}}}

76:

of a viscoelastic material under periodic excitation. The frequency is

979:= 8.64x10 eV/K and the activation energy is expressed in terms of eV.

269:

256:

is closely related to the concept of time-temperature superposition.

2298:

2072:

1034:

Williams, Landel and Ferry proposed the following relationship for

273:

129:

2133:

The shift factor (which depends on the nature of the transition)

350:

is equivalent to multiplying the time scale by a constant factor

210:

2367:-transitions are observed (relaxation). The study to determine

2278:

633:

The superposition principle for complex dynamic moduli (G* = G

2015:

is described by an homographic function of the temperature.

1965:

In the frequency range , if the temperature increases from

1902:

These same authors have proposed the "universal constants"

841:

Relationship between shift factor and intrinsic viscosities

447:{\displaystyle E(t,T)=E({\frac {t}{a_{\rm {T}}}},T_{0})\,.}

31:

Temperature dependence of elastic relaxation modulus of a

2554:

Physical aging in amorphous polymers and other materials

2409:(2nd ed.). Taylor & Francis. pp. 486–491.

983:

Shift factor using the

Williams-Landel-Ferry (WLF) model

289:

Schematic of the evolution of the instantaneous modulus

2001:, shifts of the modulus curves have the amplitude log(

2459:"Time-temperature superposition for polymeric blends"

2153:

1700:

1500:

1273:

1180:

1061:

854:

654:

473:

377:

2062:

2248:

1891:

1673:

1435:

1186:

1163:

903:

826:

622:

446:

357:which is only a function of the two temperatures

280:

2644:

2025:Principle of construction of a master curve for

1933:

2524:

2456:

1013:The empirical relationship of Williams-Landel-

176:is the phase angle as a function of frequency

2457:van Gurp, Marnix; Palmen, Jo (January 1998).

2405:Hiemenz, Paul C.; Lodge, Timothy P. (2007).

2404:

1942:Master curves for the instantaneous modulus

2499:

2327:. Unsourced material may be challenged and

2101:. Unsourced material may be challenged and

213:in particular, show a strong dependence of

2633:Temperature dependence of liquid viscosity

2556:. Amsterdam: Elsevier Scientific Pub. Co.

2502:Theory of viscoelasticity: an introduction

592:

588:

546:

542:

500:

496:

241:It has been shown experimentally that the

2347:Learn how and when to remove this message

2121:Learn how and when to remove this message

1885:

1737:

1667:

1530:

795:

714:

612:

440:

2504:. New York: Academic Press. p. 92.

2020:

1937:

986:

284:

143:

111:time–temperature superposition principle

67:

26:

14:

2645:

2551:

2598:

2008:). In the area of glass transition,

1987:while maintaining the temperature at

259:

2570:

2484:

2432:Materials Science and Engineering: A

2325:adding citations to reliable sources

2292:

2099:adding citations to reliable sources

2066:

1491:, the new coefficients are given by

2601:Viscoelastic properties of polymers

2270:is the universal gas constant, and

141:is based on the above observation.

24:

2429:

2169:

1814:

1811:

1808:

1600:

1597:

1594:

1404:

1286:

1074:

890:

878:

861:

789:

708:

600:

554:

508:

416:

137:superposition principle of linear

25:

2674:

1219:is calculated for each component

2603:(3d ed.). New York: Wiley.

2500:Christensen, Richard M. (1971).

2297:

2071:

2063:Shift factor using Arrhenius law

1247:that characterize the material.

1229:of the complex measured modulus

953:). By plotting the shift factor

935:is the viscosity at temperature

313:Consider the relaxation modulus

2592:

1819:

1805:

1605:

1591:

593:

587:

547:

541:

501:

495:

301:) in a static relaxation test.

2638:Williams-Landel-Ferry equation

2583:

2545:

2518:

2493:

2450:

2423:

2398:

2288:

2277:is a reference temperature in

2175:

2160:

1882:

1856:

1799:

1773:

1664:

1635:

1585:

1556:

1377:

1358:

1335:

1316:

1155:

1136:

1118:

1099:

760:

748:

679:

667:

589:

543:

497:

437:

402:

393:

381:

281:Time-temperature superposition

247:Williams-Landel-Ferry equation

18:Time-temperature superposition

13:

1:

2444:10.1016/S0921-5093(99)00602-4

2391:

1934:Construction of master curves

2029:for a reference temperature

1002:for a reference temperature

228:glass transition temperature

84:is the elastic modulus, and

7:

2621:

160:) and the loss factor, tan

10:

2679:

2539:10.1002/pol.1951.120070210

2527:Journal of Polymer Science

2266:is the activation energy,

991:Curve of the variation of

72:Temperature dependence of

2552:Struik, L. C. E. (1978).

2144:using an Arrhenius law:

2599:Ferry, John D. (1980).

1946:and the loss factor tan

645:is obtained similarly:

641:) at a fixed frequency

2250:

2135:can be defined, below

2059:

1972:, the complex modulus

1951:

1893:

1675:

1437:

1188:

1165:

1010:

905:

828:

624:

448:

310:

272:of a polymeric fluid.

221:of a noncrystallizing

185:

117:and in the physics of

106:

65:

2374:and the coefficients

2251:

2024:

1941:

1894:

1676:

1438:

1189:

1187:{\displaystyle \log }

1166:

990:

906:

829:

625:

449:

288:

147:

134:instantaneous modulus

119:glass-forming liquids

71:

30:

2321:improve this section

2151:

2095:improve this section

1698:

1498:

1271:

1178:

1059:

852:

652:

471:

375:

317:at two temperatures

43:is the modulus, and

1852:

1834:

1769:

1752:

1736:

1715:

1650:

1618:

1571:

1513:

1354:

1315:

368:. In other words,

309:is the temperature.

2246:

2060:

1952:

1889:

1838:

1820:

1755:

1738:

1722:

1701:

1671:

1638:

1606:

1559:

1501:

1433:

1340:

1301:

1184:

1161:

1011:

977:Boltzmann constant

901:

824:

822:

620:

618:

444:

311:

260:Physical principle

186:

107:

66:

2663:Rubber properties

2466:Rheology Bulletin

2407:Polymer chemistry

2357:

2356:

2349:

2239:

2219:

2204:

2131:

2130:

2123:

1803:

1589:

1463:The coefficients

1427:

1381:

1196:decadic logarithm

1159:

998:as a function of

944:activation energy

899:

422:

16:(Redirected from

2670:

2615:

2614:

2596:

2590:

2587:

2581:

2574:

2568:

2567:

2549:

2543:

2542:

2522:

2516:

2515:

2497:

2491:

2488:

2482:

2481:

2479:

2477:

2463:

2454:

2448:

2447:

2427:

2421:

2420:

2402:

2352:

2345:

2341:

2338:

2332:

2301:

2293:

2255:

2253:

2252:

2247:

2245:

2241:

2240:

2238:

2237:

2225:

2220:

2212:

2205:

2203:

2195:

2194:

2185:

2174:

2173:

2172:

2143:

2126:

2119:

2115:

2112:

2106:

2075:

2067:

1898:

1896:

1895:

1890:

1881:

1880:

1868:

1867:

1851:

1846:

1833:

1828:

1818:

1817:

1804:

1802:

1798:

1797:

1785:

1784:

1768:

1763:

1753:

1751:

1746:

1735:

1730:

1720:

1714:

1709:

1680:

1678:

1677:

1672:

1663:

1662:

1646:

1631:

1630:

1614:

1604:

1603:

1590:

1588:

1584:

1583:

1567:

1552:

1551:

1541:

1540:

1539:

1529:

1528:

1518:

1509:

1442:

1440:

1439:

1434:

1432:

1428:

1426:

1425:

1424:

1423:

1409:

1408:

1407:

1397:

1382:

1380:

1376:

1375:

1353:

1348:

1338:

1334:

1333:

1314:

1309:

1299:

1291:

1290:

1289:

1193:

1191:

1190:

1185:

1170:

1168:

1167:

1162:

1160:

1158:

1154:

1153:

1132:

1131:

1121:

1117:

1116:

1098:

1097:

1087:

1079:

1078:

1077:

910:

908:

907:

902:

900:

898:

897:

896:

883:

882:

881:

871:

866:

865:

864:

833:

831:

830:

825:

823:

816:

812:

811:

810:

794:

793:

792:

777:

747:

735:

731:

730:

729:

713:

712:

711:

696:

666:

629:

627:

626:

621:

619:

605:

604:

603:

586:

585:

569:

559:

558:

557:

540:

539:

523:

513:

512:

511:

494:

493:

477:

453:

451:

450:

445:

436:

435:

423:

421:

420:

419:

406:

305:is the time and

209:Some materials,

180:and temperature

113:is a concept in

35:material. Here

21:

2678:

2677:

2673:

2672:

2671:

2669:

2668:

2667:

2653:Polymer physics

2643:

2642:

2628:Viscoelasticity

2624:

2619:

2618:

2611:

2597:

2593:

2588:

2584:

2575:

2571:

2564:

2550:

2546:

2533:(23): 221–242.

2523:

2519:

2512:

2498:

2494:

2489:

2485:

2475:

2473:

2461:

2455:

2451:

2428:

2424:

2417:

2403:

2399:

2394:

2387:

2380:

2373:

2353:

2342:

2336:

2333:

2318:

2302:

2291:

2276:

2265:

2233:

2229:

2224:

2211:

2210:

2206:

2196:

2190:

2186:

2184:

2168:

2167:

2163:

2152:

2149:

2148:

2141:

2134:

2127:

2116:

2110:

2107:

2092:

2076:

2065:

2057:

2050:

2035:

2014:

2007:

2000:

1993:

1986:

1971:

1961:

1936:

1929:

1922:

1915:

1908:

1876:

1872:

1863:

1859:

1847:

1842:

1829:

1824:

1807:

1806:

1793:

1789:

1780:

1776:

1764:

1759:

1754:

1747:

1742:

1731:

1726:

1721:

1719:

1710:

1705:

1699:

1696:

1695:

1690:

1658:

1654:

1642:

1626:

1622:

1610:

1593:

1592:

1579:

1575:

1563:

1547:

1543:

1542:

1535:

1531:

1524:

1520:

1519:

1517:

1505:

1499:

1496:

1495:

1490:

1487:

1483:

1476:

1469:

1459:

1452:

1419:

1415:

1414:

1410:

1403:

1402:

1398:

1396:

1392:

1371:

1367:

1349:

1344:

1339:

1329:

1325:

1310:

1305:

1300:

1298:

1285:

1284:

1280:

1272:

1269:

1268:

1263:

1256:

1246:

1239:

1228:

1218:

1211:

1204:

1179:

1176:

1175:

1149:

1145:

1127:

1123:

1122:

1112:

1108:

1093:

1089:

1088:

1086:

1073:

1072:

1068:

1060:

1057:

1056:

1051:

1040:

1030:

1023:

1008:

997:

985:

966:

959:

952:

934:

927:

920:

889:

888:

884:

877:

876:

872:

870:

860:

859:

855:

853:

850:

849:

843:

821:

820:

806:

802:

788:

787:

783:

782:

778:

770:

763:

740:

737:

736:

725:

721:

707:

706:

702:

701:

697:

689:

682:

659:

655:

653:

650:

649:

617:

616:

599:

598:

594:

581:

577:

567:

566:

553:

552:

548:

535:

531:

521:

520:

507:

506:

502:

489:

485:

474:

472:

469:

468:

463:

431:

427:

415:

414:

410:

405:

376:

373:

372:

367:

356:

349:

338:

327:

283:

262:

243:elastic modulus

233:

219:elastic modulus

139:viscoelasticity

115:polymer physics

104:

97:

90:

74:elastic modulus

63:

56:

49:

23:

22:

15:

12:

11:

5:

2676:

2666:

2665:

2660:

2655:

2641:

2640:

2635:

2630:

2623:

2620:

2617:

2616:

2609:

2591:

2582:

2569:

2562:

2544:

2517:

2510:

2492:

2483:

2449:

2438:(1–2): 36–45.

2422:

2416:978-1574447798

2415:

2396:

2395:

2393:

2390:

2385:

2378:

2371:

2355:

2354:

2305:

2303:

2296:

2290:

2287:

2285:-transitions.

2274:

2263:

2257:

2256:

2244:

2236:

2232:

2228:

2223:

2218:

2215:

2209:

2202:

2199:

2193:

2189:

2183:

2180:

2177:

2171:

2166:

2162:

2159:

2156:

2139:

2129:

2128:

2079:

2077:

2070:

2064:

2061:

2055:

2048:

2033:

2012:

2005:

1998:

1991:

1984:

1969:

1959:

1935:

1932:

1927:

1920:

1913:

1906:

1900:

1899:

1888:

1884:

1879:

1875:

1871:

1866:

1862:

1858:

1855:

1850:

1845:

1841:

1837:

1832:

1827:

1823:

1816:

1813:

1810:

1801:

1796:

1792:

1788:

1783:

1779:

1775:

1772:

1767:

1762:

1758:

1750:

1745:

1741:

1734:

1729:

1725:

1718:

1713:

1708:

1704:

1688:

1682:

1681:

1670:

1666:

1661:

1657:

1653:

1649:

1645:

1641:

1637:

1634:

1629:

1625:

1621:

1617:

1613:

1609:

1602:

1599:

1596:

1587:

1582:

1578:

1574:

1570:

1566:

1562:

1558:

1555:

1550:

1546:

1538:

1534:

1527:

1523:

1516:

1512:

1508:

1504:

1488:

1485:

1481:

1474:

1467:

1457:

1450:

1444:

1443:

1431:

1422:

1418:

1413:

1406:

1401:

1395:

1391:

1388:

1385:

1379:

1374:

1370:

1366:

1363:

1360:

1357:

1352:

1347:

1343:

1337:

1332:

1328:

1324:

1321:

1318:

1313:

1308:

1304:

1297:

1294:

1288:

1283:

1279:

1276:

1261:

1254:

1244:

1237:

1224:

1216:

1209:

1202:

1183:

1172:

1171:

1157:

1152:

1148:

1144:

1141:

1138:

1135:

1130:

1126:

1120:

1115:

1111:

1107:

1104:

1101:

1096:

1092:

1085:

1082:

1076:

1071:

1067:

1064:

1049:

1038:

1028:

1021:

1006:

995:

984:

981:

964:

957:

950:

932:

925:

918:

912:

911:

895:

892:

887:

880:

875:

869:

863:

858:

842:

839:

835:

834:

819:

815:

809:

805:

801:

798:

791:

786:

781:

776:

773:

769:

766:

764:

762:

759:

756:

753:

750:

746:

743:

739:

738:

734:

728:

724:

720:

717:

710:

705:

700:

695:

692:

688:

685:

683:

681:

678:

675:

672:

669:

665:

662:

658:

657:

631:

630:

615:

611:

608:

602:

597:

591:

584:

580:

576:

573:

570:

568:

565:

562:

556:

551:

545:

538:

534:

530:

527:

524:

522:

519:

516:

510:

505:

499:

492:

488:

484:

481:

478:

476:

461:

455:

454:

443:

439:

434:

430:

426:

418:

413:

409:

404:

401:

398:

395:

392:

389:

386:

383:

380:

365:

354:

347:

336:

325:

282:

279:

261:

258:

254:Deborah number

231:

203:

202:

199:

196:

193:

102:

95:

88:

61:

54:

47:

9:

6:

4:

3:

2:

2675:

2664:

2661:

2659:

2658:Glass physics

2656:

2654:

2651:

2650:

2648:

2639:

2636:

2634:

2631:

2629:

2626:

2625:

2612:

2606:

2602:

2595:

2586:

2579:

2573:

2565:

2563:9780444416551

2559:

2555:

2548:

2540:

2536:

2532:

2528:

2521:

2513:

2507:

2503:

2496:

2487:

2471:

2467:

2460:

2453:

2445:

2441:

2437:

2433:

2426:

2418:

2412:

2408:

2401:

2397:

2389:

2384:

2377:

2370:

2366:

2361:

2351:

2348:

2340:

2337:December 2021

2330:

2326:

2322:

2316:

2315:

2311:

2306:This section

2304:

2300:

2295:

2294:

2286:

2284:

2280:

2273:

2269:

2262:

2242:

2234:

2230:

2226:

2221:

2216:

2213:

2207:

2200:

2197:

2191:

2187:

2181:

2178:

2164:

2157:

2154:

2147:

2146:

2145:

2138:

2125:

2122:

2114:

2111:December 2021

2104:

2100:

2096:

2090:

2089:

2085:

2080:This section

2078:

2074:

2069:

2068:

2054:

2047:

2043:

2039:

2032:

2028:

2023:

2019:

2016:

2011:

2004:

1997:

1990:

1983:

1979:

1975:

1968:

1963:

1958:

1949:

1945:

1940:

1931:

1926:

1919:

1912:

1905:

1886:

1877:

1873:

1869:

1864:

1860:

1853:

1848:

1843:

1839:

1835:

1830:

1825:

1821:

1794:

1790:

1786:

1781:

1777:

1770:

1765:

1760:

1756:

1748:

1743:

1739:

1732:

1727:

1723:

1716:

1711:

1706:

1702:

1694:

1693:

1692:

1687:

1668:

1659:

1655:

1651:

1647:

1643:

1639:

1632:

1627:

1623:

1619:

1615:

1611:

1607:

1580:

1576:

1572:

1568:

1564:

1560:

1553:

1548:

1544:

1536:

1532:

1525:

1521:

1514:

1510:

1506:

1502:

1494:

1493:

1492:

1480:

1473:

1466:

1461:

1456:

1449:

1429:

1420:

1416:

1411:

1399:

1393:

1389:

1386:

1383:

1372:

1368:

1364:

1361:

1355:

1350:

1345:

1341:

1330:

1326:

1322:

1319:

1311:

1306:

1302:

1295:

1292:

1281:

1277:

1274:

1267:

1266:

1265:

1260:

1253:

1248:

1243:

1236:

1232:

1227:

1222:

1215:

1208:

1201:

1197:

1181:

1150:

1146:

1142:

1139:

1133:

1128:

1124:

1113:

1109:

1105:

1102:

1094:

1090:

1083:

1080:

1069:

1065:

1062:

1055:

1054:

1053:

1048:

1044:

1041:in terms of (

1037:

1032:

1027:

1020:

1016:

1005:

1001:

994:

989:

980:

978:

974:

970:

963:

956:

949:

945:

940:

938:

931:

924:

917:

893:

885:

873:

867:

856:

848:

847:

846:

838:

817:

813:

807:

803:

799:

796:

784:

779:

774:

771:

767:

765:

757:

754:

751:

744:

741:

732:

726:

722:

718:

715:

703:

698:

693:

690:

686:

684:

676:

673:

670:

663:

660:

648:

647:

646:

644:

640:

636:

613:

609:

606:

595:

582:

578:

574:

571:

563:

560:

549:

536:

532:

528:

525:

517:

514:

503:

490:

486:

482:

479:

467:

466:

465:

460:

457:The quantity

441:

432:

428:

424:

411:

407:

399:

396:

390:

387:

384:

378:

371:

370:

369:

364:

360:

353:

346:

342:

335:

331:

324:

320:

316:

308:

304:

300:

296:

292:

287:

278:

275:

271:

266:

257:

255:

250:

248:

244:

239:

235:

229:

224:

220:

216:

212:

207:

200:

197:

194:

191:

190:

189:

183:

179:

175:

171:

167:

163:

159:

155:

151:

146:

142:

140:

135:

131:

127:

122:

120:

116:

112:

101:

94:

87:

83:

79:

75:

70:

60:

53:

46:

42:

39:is the time,

38:

34:

29:

19:

2600:

2594:

2585:

2577:

2572:

2553:

2547:

2530:

2526:

2520:

2501:

2495:

2486:

2474:. Retrieved

2469:

2465:

2452:

2435:

2431:

2425:

2406:

2400:

2382:

2375:

2368:

2364:

2362:

2358:

2343:

2334:

2319:Please help

2307:

2282:

2271:

2267:

2260:

2258:

2136:

2132:

2117:

2108:

2093:Please help

2081:

2052:

2045:

2041:

2037:

2030:

2026:

2017:

2009:

2002:

1995:

1988:

1981:

1977:

1973:

1966:

1964:

1956:

1953:

1947:

1943:

1924:

1917:

1910:

1903:

1901:

1685:

1683:

1478:

1471:

1464:

1462:

1454:

1447:

1445:

1258:

1251:

1249:

1241:

1234:

1230:

1225:

1220:

1213:

1206:

1199:

1173:

1046:

1042:

1035:

1033:

1025:

1018:

1012:

1003:

999:

992:

972:

968:

961:

954:

947:

941:

936:

929:

922:

915:

913:

844:

836:

642:

638:

634:

632:

458:

456:

362:

358:

351:

344:

340:

333:

329:

322:

318:

314:

312:

306:

302:

298:

294:

290:

267:

263:

251:

240:

236:

215:viscoelastic

208:

204:

187:

181:

177:

173:

169:

165:

161:

157:

153:

149:

126:viscoelastic

123:

110:

108:

99:

92:

85:

81:

77:

58:

51:

44:

40:

36:

33:viscoelastic

2289:Limitations

2051:= 1 Hz and

223:crosslinked

2647:Categories

2610:0471048941

2511:0121742504

2476:7 December

2392:References

2058:= 1000 Hz.

328:such that

2308:does not

2222:−

2182:−

2158:

2082:does not

1923:≈ 15 and

1870:−

1787:−

1652:−

1573:−

1412:η

1400:η

1390:

1365:−

1323:−

1296:−

1278:

1143:−

1106:−

1084:−

1066:

1052:) :

886:η

874:η

797:ω

752:ω

716:ω

671:ω

590:⟹

544:⟹

498:⟹

270:viscosity

172:), where

2622:See also

2472:(1): 5–8

1648:′

1616:′

1569:′

1511:′

971:, where

775:″

745:″

694:′

664:′

274:Rheology

211:polymers

130:polymers

2329:removed

2314:sources

2279:kelvins

2103:removed

2088:sources

1194:is the

975:is the

2607:

2560:

2508:

2413:

2259:where

1446:where

1174:where

914:where

230:, or T

2462:(PDF)

2198:2.303

1015:Ferry

637:+ i G

332:>

98:<

91:<

57:<

50:<

2605:ISBN

2558:ISBN

2506:ISBN

2478:2021

2411:ISBN

2381:and

2312:any

2310:cite

2086:any

2084:cite

1909:and

1470:and

1453:and

1240:and

1223:and

1205:and

1198:and

928:and

561:>

529:<

515:<

483:>

361:and

321:and

252:The

109:The

2535:doi

2440:doi

2436:278

2323:by

2155:log

2097:by

2036:.

1691:,

1484:to

1387:log

1275:log

1250:If

1182:log

1063:log

639:''

343:to

249:).

82:G'

2649::

2529:.

2470:67

2468:.

2464:.

2434:.

2027:E′

1974:E′

1944:E′

1486:T′

1264::

1257:=

1221:M′

939:.

919:T0

635:'

234:.

168:,

156:,

150:E′

121:.

80:,

2613:.

2578:τ

2566:.

2541:.

2537::

2531:7

2514:.

2480:.

2446:.

2442::

2419:.

2386:2

2383:C

2379:1

2376:C

2372:T

2369:a

2365:α

2350:)

2344:(

2339:)

2335:(

2331:.

2317:.

2283:β

2275:0

2272:T

2268:R

2264:a

2261:E

2243:)

2235:0

2231:T

2227:1

2217:T

2214:1

2208:(

2201:R

2192:a

2188:E

2179:=

2176:)

2170:T

2165:a

2161:(

2142:,

2140:g

2137:T

2124:)

2118:(

2113:)

2109:(

2105:.

2091:.

2056:2

2053:ω

2049:1

2046:ω

2042:ω

2040:=

2038:f

2034:0

2031:T

2013:T

2010:a

2006:T

2003:a

1999:0

1996:T

1992:0

1989:T

1985:1

1982:ω

1978:ω

1976:(

1970:0

1967:T

1960:0

1957:T

1948:δ

1928:2

1925:C

1921:1

1918:C

1914:2

1911:C

1907:1

1904:C

1887:.

1883:)

1878:g

1874:T

1865:0

1861:T

1857:(

1854:+

1849:g

1844:2

1840:C

1836:=

1831:0

1826:2

1822:C

1815:d

1812:n

1809:a

1800:)

1795:g

1791:T

1782:0

1778:T

1774:(

1771:+

1766:g

1761:2

1757:C

1749:g

1744:2

1740:C

1733:g

1728:1

1724:C

1717:=

1712:0

1707:1

1703:C

1689:0

1686:T

1669:.

1665:)

1660:0

1656:T

1644:0

1640:T

1636:(

1633:+

1628:2

1624:C

1620:=

1612:2

1608:C

1601:d

1598:n

1595:a

1586:)

1581:0

1577:T

1565:0

1561:T

1557:(

1554:+

1549:2

1545:C

1537:2

1533:C

1526:1

1522:C

1515:=

1507:1

1503:C

1489:0

1482:0

1479:T

1475:2

1472:C

1468:1

1465:C

1458:2

1455:C

1451:1

1448:C

1430:)

1421:g

1417:T

1405:T

1394:(

1384:=

1378:)

1373:g

1369:T

1362:T

1359:(

1356:+

1351:g

1346:2

1342:C

1336:)

1331:g

1327:T

1320:T

1317:(

1312:g

1307:1

1303:C

1293:=

1287:T

1282:a

1262:g

1259:T

1255:0

1252:T

1245:2

1242:C

1238:1

1235:C

1231:M

1226:M

1217:T

1214:a

1210:2

1207:C

1203:1

1200:C

1156:)

1151:0

1147:T

1140:T

1137:(

1134:+

1129:2

1125:C

1119:)

1114:0

1110:T

1103:T

1100:(

1095:1

1091:C

1081:=

1075:T

1070:a

1050:0

1047:T

1045:-

1043:T

1039:T

1036:a

1029:g

1026:T

1022:0

1019:η

1009:.

1007:0

1004:T

1000:T

996:T

993:a

973:k

969:k

967:/

965:a

962:E

958:T

955:a

951:a

948:E

946:(

937:T

933:T

930:η

926:0

923:T

916:η

894:0

891:T

879:T

868:=

862:T

857:a

818:.

814:)

808:0

804:T

800:,

790:T

785:a

780:(

772:G

768:=

761:)

758:T

755:,

749:(

742:G

733:)

727:0

723:T

719:,

709:T

704:a

699:(

691:G

687:=

680:)

677:T

674:,

668:(

661:G

643:ω

614:.

610:1

607:=

601:T

596:a

583:0

579:T

575:=

572:T

564:1

555:T

550:a

537:0

533:T

526:T

518:1

509:T

504:a

491:0

487:T

480:T

462:T

459:a

442:.

438:)

433:0

429:T

425:,

417:T

412:a

408:t

403:(

400:E

397:=

394:)

391:T

388:,

385:t

382:(

379:E

366:0

363:T

359:T

355:T

352:a

348:0

345:T

341:T

337:0

334:T

330:T

326:0

323:T

319:T

315:E

307:T

303:t

299:T

297:,

295:t

293:(

291:E

232:g

184:.

182:T

178:f

174:δ

170:T

166:f

164:(

162:δ

158:T

154:f

152:(

105:.

103:2

100:T

96:1

93:T

89:0

86:T

78:ω

64:.

62:2

59:T

55:1

52:T

48:0

45:T

41:G

37:t

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.