520:

310:. Another important investor from Akron was Colonel Arthur Latham Conger, who was the company's first president. Conger was a Civil War veteran who invested in companies in Ohio and Indiana (including in Kokomo). He was also elected president of the Hartford City Land Company in 1893. Hartford City's Sydney W. Cantwell was secretary of the Hartford City Glass Company during its early years. He was also president of the state organization of window glass manufacturers. Cantwell was an attorney involved with the Blackford County Bank, Akron Oil Company, and Hartford City Land Company. Another Hartford City investor, Henry "H. B." Smith, was president of Hartford City's Citizen's Bank.

279:

353:

362:

623:

accounting for over half of the nation's window glass manufacturing capacity. In 1913, the company continued to close many of its smaller plants, while the large plants were equipped with the glass blowing machines. Plant number 3 was the third largest window glass factory in the United States, and the largest west of

Pennsylvania. The Belgian portion of Hartford City's glassmaking workforce was dramatically reduced because of two factors: the glass-blowing machine replaced human glass blowers; and Belgians had difficulty returning from summer vacations in their European homeland after the start of World War I.

601:

Glass successfully changed energy sources from natural gas to gas made from coal. The company also had a technological advantage. Instead of using a glass blower, American Window Glass plants extracted molten glass with a machine. The machine, which was not immediately utilized at all

American Window Glass plants, was known as the Lubbers blowing machine. Refinements to the machine and glass-making process were made at the Hartford City works by plant manager Harry G. Slingluff. Production records for the entire company were set at the Hartford City plant in 1905 and 1907—using the Lubbers machines.

200:

579:

619:

capacity of the plants to be consolidated, then

Hartford City would have "become the greatest window glass town in the world." The plant would have employed nearly 1000 people, equaling the largest window glass plant in the world in capacity. That plant in combination with Hartford City's two other window glass factories, not even considering the flint glass plants or bottle plants, would make the city's window glass capacity the highest in the world. The rumor had some truth—smaller plants were eventually closed. However, Hartford City's large southside plant was not expanded.

330:. He was also involved in banking and had been president of the Bank of Akron. John R. Johnston began working at the Hartford City plant in 1890 as a bookkeeper. He was elected secretary after 4 years. Johnston lived in Hartford City and helped Heagany run the business. Heagany submitted his resignation at the August 1899 board meeting, retiring after 42 years in the glass business. Johnston became plant manager at that time. Johnston resigned a short time later, effective April 1900. He formed Hartford City's Johnston Glass Company in September of the same year.

450:

661:—who hired Colburn to continue work on the machine. Owens was the creator of the Owens Bottling Machine that revolutionized the glass bottle industry. Working with Colburn, Owens improved the window glass machine enough that it began being used for production in 1921. By 1926, Libbey-Owens had gained a window glass market share of 29 percent, while American Window Glass's share was 59 percent. During the 1920s, Pittsburgh Plate Glass also developed a new process for making window glass, creating even more competition in the window glass industry.

570:

636:

479:

the efficiency in manufacturing and shipping. The new buildings were made fire-resistant by using stone, brick, and iron for construction materials. They were also well ventilated, which made the work environment more comfortable for the glass workers. The expansion increased total capacity to about 90 pots. This made the works the second-largest glass factory in the United States. Expenditures necessary to finance the expansion were $ 100,000 (over $ 2.5 million in 2012 dollars).

298:, and opened the first window glass plant in the region to use natural gas as a fuel source. Heagany's Kokomo plant lasted three years before it was destroyed by fire. Instead of rebuilding in Kokomo, he moved to Hartford City and organized the Hartford City Glass Company. The company was organized in 1890 with the financial assistance of several capitalists. Production began in early 1891 after the plant was constructed. Heagany was the plant manager until his retirement in 1899.

339:

largest industry in the county, it was thought to be the second-largest plant of any industry located in the

Indiana Gas Belt. To help meet the housing needs for the factory's many employees, 184 houses were built nearby. In 1896, 443 workers at the plant lived in Hartford City, especially on the south side. Assuming each local worker had a family of five, over one-third of the city's population (2,235 of "an estimated 6,000") was financially dependent upon Hartford City Glass.

687:

Company, and Sneath Glass

Company. An eighth plant, the Sans-Pariel Bottle Company, is listed in a 1901 state inspection report. The count of eight factories excludes predecessor companies. The Hurrle Glass Company factory, also listed in the 1901 report, became the Clelland Glass Company. Hartford City Glass Company and Jones Glass Company, both listed in a state inspection report for 1898, became American Window Glass Company factories 3 and 32, respectively.

270:

3668:

665:

reorganization in 1929. Dividends on its preferred stock were lowered. Although a few plants were re-equipped, the

Hartford City plant was not. Hartford City's natural gas supply was depleted, and the type of sand used to produce glass was in better supply near other American Window Glass plants in Pennsylvania. Thus, American Window Glass Company plant number 3, the former Hartford City Glass Company, was closed in 1929.

556:. The Hartford City Glass Company became known as Plant Number 3 of the American Window Glass Company. J. R. Johnston, already manager for Hartford City Glass Company, was named manager of the American Window Glass version of the same plant in December. A second window glass factory from Hartford City, Jones Glass Company, was also acquired—and became plant No. 32. Eventually, the company acquired 41 glass factories.

3656:

483:

adequate fire protection and housing for the workers. Community leaders did not respond soon enough, and the expansion was postponed. However, it is no coincidence that

Hartford City's waterworks began operations in 1894, and the plant was built on the city's south side. The city also acquired a chemical fire engine from the Chicago Fire Extinguisher Company, which was delivered in February 1894.

610:

percent of the glass blower wage. The machine was also five times more productive than the human blowers. It could make windows four times as large because a larger cylinder was extracted from the tank of molten glass. Thus, the highest–paid skilled workers in the United States were considered obsolete. In the case of

Hartford City, machines replaced most of the human glass blowers by 1908.

757:) to produce window glass. His process was adopted during the 1930s by a group of companies in the United States called Furco Glass. Market share for American Window Glass fell to 20 percent in the United States. The remainder of the market was dominated by three other manufacturers: Libbey-Owens with 30 percent, Pittsburgh Plate Glass with 25 percent, and Furco with 25 percent.

441:, was built one block north of the courthouse in 1894—and features large stained glass windows imported from Belgium. For over 50 years, the bigger of two huge windows was considered the largest single-frame window in the state of Indiana. These stained-glass windows, plus at least four smaller ones, were installed by the local (and mostly Catholic) Belgian glass workers.

252:, relocated from Tiffin, Ohio, in 1894. During 1901, Indiana state inspectors visited 15 manufacturing facilities in Hartford City. These manufacturers employed 1,077 people, and the American Window Glass plant (the former Hartford City Glass Company) plus the Sneath Glass works accounted for over half of the manufacturing employees. By 1902, Hartford City was the home of

319:

immediately expressed his unhappiness with the election by selling his company stock and leaving town. Conger's stock was purchased by Kokomo banker John A. Jay. Officers of

Hartford City Glass in 1896 were George T. Perkins, President; John A. Jay, Vice President; H.B. Smith, Treasurer; Richard Heagany, General Manager; and John Rodgers Johnston, Secretary.

462:

continuously or by the batch. The

Hartford City plant used the tank system, and it was originally the "largest tank window glass factory in the world". The tank had a capacity equivalent to 30 pots, giving the Hartford City plant more than double the capacity of some of the window glass plants built a few years earlier in Ohio.

170:, at the time the world’s leading manufacturer of window glass. The Belgian workers and their families accounted for over one-third of Hartford City's population during the 1890s, and lived on the city's south side. Because of the importance of the French-speaking Belgians, one of the local newspapers featured articles in French.

491:

ornamental glass used for interiors of office buildings and with furniture. At that time, the plant was the second-largest window glass producer in the country, although it became the third-largest later in the year. Its grounds had grown to cover 25 acres (10.1 ha), and included a railroad spur off of the

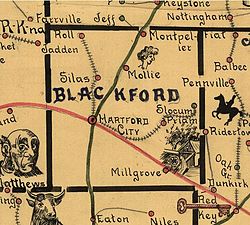

219:. Manufacturers were lured to the region to take advantage of the low cost fuel. Blackford County, a small rural county located close to Eaton, had only 181 people working in manufacturing in 1880. By 1901, the county had over 1,100 people employed at manufacturing plants in small communities such as

2515:

Fifty years and over of Akron and Summit County : embellished by nearly six hundred engravings--portraits of pioneer settlers, prominent citizens, business, official and professional--ancient and modern views, etc.; nine-tenth's of a century of solid local history--pioneer incidents, interesting

461:

In the United States, two systems were used during the 1890s to create molten glass. The older system used a pot furnace, where ceramic pots were heated inside the furnace to melt the batch of ingredients needed to make the molten glass. The newer system used a large brick tank that could be operated

531:

called American Window Glass Company. The company was formed from the American Glass Company, but did not incorporate until 1899. The trust planned to acquire 70 glass plants, "some of which it will close to bring the production down to the demand." The prices offered for the glass plants were very

510:

Plans for the addition of another tank began again in late 1896. A third tank would make the Hartford City plant the largest in the country. As part of the conditions for expansion, the plant owners requested housing for its potential new workers. Although the houses were built, the company was not

724:

When constructed, the Hartford City Glass Company plant was considered the largest window glass works in the world. For many years, it was one of the three largest window glass plants in the United States—competing with two plants in Pennsylvania. In congressional hearings, the plant was listed as

664:

Because of the improved technology and processes utilized by competitors, many of the American Window Glass patents, and much of its machinery, became obsolete. By the late 1920s, American Window Glass was forced to begin re-equipping its plants with new machinery. The company underwent a financial

647:

During the beginning of the 20th century, competitors of the American Window Glass trust used a different approach to gain a technological advantage. The machines used by American Window Glass replaced glass blowers, but still used the same blowing and cutting process used in the 1880s—although the

600:

After the acquisition, the Hartford City Glass works became known as plant number 3 of the American Window Glass Company. The plant employed 450 people in 1901. As natural gas supplies in Indiana became depleted, many manufacturers moved or did not survive. The major plants of the American Window

486:

Although the third tank was not added in 1893, a new ware room was built. The room was 60 feet (18.3 m) long by 120 feet (36.6 m) wide, and could hold 20,000 boxes. The roof and walls were covered in iron. By September (without the capacity expansion), the plant had a payroll of $ 45,000

389:

melting a batch of ingredients that included sand, soda, and lime. At newer plants such as the Hartford City works, tanks were used instead of pots. The tanks were essentially huge brick pots with multiple workstations. A tank furnace is more efficient than a pot furnace, but more costly to build.

388:

and glass cutter—who were both highly skilled and well paid. The glass blower led a small production crew that included skilled and unskilled workers. At older plants, the glass blower's workstation was adjacent to a ceramic pot located inside the furnace. Each pot contained molten glass created by

173:

In 1899, Hartford City Glass was acquired by the American Window Glass Company, which controlled 85 percent of the American window glass manufacturing capacity. During the next decade, the company began replacing its skilled and well–paid Belgian glass blowers with machines and less-skilled machine

743:

Testimony before the United States House Committee on Ways and Means in 1913 listed the Hartford City Glass Company as having two tanks in 1898—not three. In 1913, when the plant was owned by American Window Glass Company, it was still described as having two tanks: a large tank "equipped with 10

535:

The trust was incorporated effective August 2, 1899. James A. Chambers continued as president, and Hartford City’s H.B. Smith was one of the directors of the newly incorporated company. Initial acquisitions included over 20 major window glass plants, including Hartford City Glass Company. Most of

478:

In 1892, management decided to expand the factory's capacity by adding a second tank. The new tank would add approximately 50 pots of capacity. In early April, construction of the facilities for the new tank began. "Modern and improved methods in all departments of the works" were used, improving

457:

Construction of Hartford City's new glass works was completed in early January 1891, and production started shortly thereafter. The glass works was located on Hartford City's south side, and originally occupied 12 acres (4.9 ha). Natural gas was the plant's original fuel source for both the

425:

The city's influx of French-speaking Belgians affected the town. The south side (south of Lick Creek) became known as Belgium Town. Most Belgians were Catholic, and they built the city's Catholic church near their homes on the city's south side. The church's Father Dhe was a native of France and

408:

inside a long oven. The newly made glass gradually moved from the hot end of the lehr to its opposite end, which was at room temperature. The glass would then be cut into the desired window glass size, placed in a box, and moved to inventory. It is not known if (or when) the lehrs at the Hartford

686:

A 1902 Hartford City directory lists 7 glass factories in Hartford City: American Window Glass Company factory number 3, American Window Glass Company factory number 32, Blackford Glass Company, Clelland Glass Company, Diamond Flint Glass Company, Johnston Glass Company, Hartford City Flint Glass

318:

Top management changed during 1895 after the company's annual shareholders' meeting. Colonel A. L. Conger, who had been president since the company's beginning, lost his position to another colonel from Akron, George T. Perkins. Conger had fallen into disfavor with many of the local citizens. He

150:

was among the top three window glass manufacturers in the United States between 1890 and 1899, and continued to be one of the nation's largest after its acquisition. It was also the country's largest manufacturer of chipped glass, with capacity double that of its nearest competitor. The company's

626:

American Window Glass made record profits in 1920. All of the company's small plants had been sold or closed by that time. The glass-blowing machines were still being used to extract molten glass. The company was described as having "six large and well-equipped plants located near the Pittsburgh

392:

In the first step of the glass-making process, molten glass was extracted from the pot or tank. The glass blower and his helper used a blowpipe, which was typically 4 feet (1.2 m) to 5 feet (1.5 m) long, to create a bubble of molten glass. The glass blower manipulated the bubble into a

618:

During the spring of 1900, rumors circulated that American Window Glass planned to move production from smaller plants in nearby Dunkirk and Redkey (factories 17, 30, 34, and 41) to the large southside Hartford City plant. If the Hartford City plant would have its capacity expanded equal to the

609:

The glass blowing machine used by American Window Glass factories was created by Pittsburgh resident John H. Lubbers, and he continued to contribute improvements to the machine over the next decade. By using the Lubbers machine, human glass blowers were replaced with a machine operator paid 30

243:

Like many Indiana communities during the gas boom, Hartford City’s leaders sought to take advantage of their newfound energy resource. The Hartford City Land Company was formed in 1891 as part of the effort to attract manufacturers. The company offered "free sites, free gas, excellent switching

622:

In 1905 American Window Glass sold some of its smaller plants, including Hartford City's plant number 32. Plant number 3 still continued operations. It employed 500 people in 1910. Before the start of World War I, American Window Glass Company was still the dominant window glass manufacturer,

482:

During 1893, the company considered adding a third tank, which would add another 60 pots of capacity. The expansion cost estimate was $ 150,000 (over $ 3.8 million in 2012 dollars), and was said to "give employment to 350 men." Two major concerns voiced by management to community leaders were

338:

During its peak years, Hartford City Glass Company employed 500 to 600 people. In 1894, it employed 100 glass blowers as part of a total workforce of 540 people. The wages for that workforce were said to be equivalent to "about 1500 men in any other industry." Not only was the glass works the

469:

Initial production at the Hartford City plant continued until June, when the works was shut down to decrease inventories. Summer shutdowns were normal in the glass industry at that time. The heat from the furnaces combined with summer weather made extremely uncomfortable working conditions,

490:

In 1896, the plant employed 550 people, and produced about 2 million square feet of window glass per month. In addition to window glass, the company was the nation’s largest producer of chipped glass, with capacity double that of the second-largest manufacturer. Chipped glass was a popular

247:

Hartford City's success in attracting manufacturers can be indirectly measured by its population growth. The city's population was 2,287 in 1890, but grew to 5,912 by 1900. In 1890, the city convinced glassmaker Richard Heagany to relocate from Kokomo, Indiana. An additional glass maker,

421:

was the largest exporter of window glass to the United States, and plant manager Heagany previously used the skills of glass blowers from that country in his Kokomo glass works. In Hartford City, Heagany again relied upon Belgian workers for the skilled positions in his glass works.

244:

facilities, and reasonable cash subsidies" as enticements for manufacturers to locate in the boom town. Manufacturers that used high quantities of energy were especially attracted to no-cost or low-cost natural gas sites, and glassmaking was one of those energy-consuming industries.

704:

Glass Company, has written at least 3 glass–related books. Window glassmaking at the Hartford City Glass Company plant is discussed, by a former glassworker whose father worked at the Hartford City plant, in a book produced by the Blackford County Historical

465:

With its size, newest technology, and newly built facilities, the plant was "said to be the largest and best arranged window glass works in the world." During its existence, the plant was always one of the largest window glass works in the United States.

2743:

Hartford City illustrated : a publication devoted to the city's best interests and containing half tone engravings of prominent factories, business blocks, residences, and a selection of representative commercial and professional men and

470:

justifying the summer months as the best time to shut down for maintenance (or for manipulation of inventories). In the case of the first year's shutdown for the Hartford City Glass works, production was restarted in October.

652:

began working on a machine that produced window glass using a different process. Colburn patented his work during the first decade of the 20th century. Although he filed for bankruptcy in 1912, his patents were purchased by

539:

Many of the Indiana glass works acquired by the trust were from the East Central Indiana Gas Belt. Among those plants were the Hartford City Glass Company; and the nearby Muncie plants of Maring, Hart, and Company and

714:

The first window glass plant built in Fostoria, Ohio, (Mambourg Glass Company built in 1887) had a capacity of 13 pots. In Toledo, Ohio, the Toledo Window Glass Company plant was built with a 10 pot capacity in

536:

the original acquisitions were from Indiana and Pennsylvania. Those glass plants were important enough to enable American Window Glass to control 85 percent of the window glass production in the United States.

293:

In 1878, glassmaker Richard Heagany organized a window glass plant in New York and was the factory's superintendent. That plant became the largest window glass plant in the state. In 1886, he moved to

438:

27:

1362:

The Hartford City glass works have just been completed and are said to be the largest and best arranged window glass works in the world. The weekly pay roll will amount to over $ 3,000.

393:

cylinder, and removed it from the pot or tank. The cylinders were 12 inches (30.5 cm) to 16 inches (40.6 cm) in diameter, and 4 feet (1.2 m) or 5 feet (1.5 m) long.

507:. The tank in one of the melting rooms was 18 feet (5.5 m) long, 18 feet (5.5 m) wide, and 6 feet (1.8 m) deep. One tank required 4 flattening ovens and a cutting room.

177:

During the 1920s, competitors developed new window glass production processes that eclipsed the American Window Glass technology, and the company lost its advantage. By the time the

430:

claimed to be the "only newspaper in State that prints French and circulates among the window glass and iron workers, the highest paid skilled mechanics in the world."

532:

generous. Owners of the glass plants could sell their plant for either cash or a combination of cash and stock in the new company. Many owners chose to receive stock.

3723:

2468:"Annual Report of the Department of Inspection of manufacturing and mercantile establishments, laundries, bakeries, quarries, printing offices and public buildings"

3703:

2044:

National Newspaper Directory and Gazetteer. Containing a Complete Classified Directory of the Newspapers and Periodicals Published in the United States ..

3688:

734:

Capacity "expansion" was difficult to measure precisely. The pot-equivalency of a tank varied, depending on the tank size and way the tank was equipped.

3713:

2217:

434:

2936:

2545:

Merriam, William Rush; Hunt, William C.; King, William Alexander; Powers, Le Grand; North, Simon Newton Dexter; United States Census Office (1901).

725:

third-largest in the United States (behind the two Pennsylvania plants) in 1898. The same hearings show the Hartford City plant as largest in 1913.

2576:

2104:

2061:

A History of Blackford County, Indiana : with historical accounts of the county, 1838–1986 histories of families who have lived in the county

3718:

2767:

2488:

2661:

2192:

2716:

3209:

2544:

1551:

2546:

2631:

174:

operators. The company used the Hartford City plant to test and refine the new technology. Most of the Belgian glass workers left town.

2378:

396:

Next, the glass–cutter cut the cylinder, and the glass was flattened. It was necessary to gradually cool the glass, a process known as

2467:

2348:

306:

One of the principal stockholders of the new company was multi-millionaire A. M. Barber. Barber was involved in grain and banking in

253:

152:

3708:

2411:

2165:

3693:

2445:

Indiana Department of Factory Inspection (1899). "Exhibit A.—Factories Inspected—Continued – Hartford City, Blackford County".

2281:

3332:

2929:

2291:

2175:

1894:"Human Blowers Thing of the Past – Machines Replacing Skilled Trades and Obsolete Methods of Manufacture of Window Glass".

3214:

2672:

Tariff schedule, no. 3-4. Hearings before the committee on Schedule B - earths, earthenware, and glassware, January, 1913

2113:

2909:

American Window Glass Made High Record Earnings in the Year Ended August Last – Largest Company of the Kind in the World

3698:

2670:

2595:

2421:

2262:

2227:

2123:

511:

satisfied, as the expansion was never consummated. Without the third tank, the workforce still grew to 600 by 1898.

194:

3254:

2922:

1137:"Annual Meetings. Manufacturers Directors of the Hartford City Glass Company and Hartford City Land Company Meet".

1995:

2016:"Belle Vernon and Arnold Plant Method of Window Glass Manufacture Success Certain But Business Is Still Dull".

2077:

3119:

2254:

Population of states and counties of the United States: 1790 to 1990 from the twenty-one decennial censuses

3234:

2629:

1392:

1224:

1212:

648:

company was constantly working to make the process more efficient. Competitors such as American inventor

2076:

Castelo, Sinuard; Clamme, Louise; Dodds, Dealie; Clamme, David; Marshall, Mary Lou; Storms, Ron (2012).

519:

3646:

3463:

2167:

Directory of Hartford City, Indiana, Together with a Complete Gazetteer of Blackford County Land Owners

2042:

Blackford County Gazette (advertisement) (1903). "The Blackford County Gazette (near bottom of page)".

377:

224:

541:

3591:

3099:

3054:

2075:

1638:

1200:

1163:

228:

2817:

1312:

3363:

3348:

923:

649:

361:

278:

199:

2257:. United States Department of Commerce, Bureau of the Census, Population Division. p. 225.

352:

3418:

3229:

2792:

2322:

220:

156:

103:

2867:

1627:

1462:

1125:

3428:

3269:

3164:

2252:

830:

492:

232:

2842:

3403:

3314:

3064:

2999:

2979:

2359:

2349:"National Register of Historic Places Nomination: Hartford City Courthouse Square District"

658:

327:

249:

216:

3179:

2520:

2499:(Statistical Year Ending December 31, 1906). Indianapolis: Indiana State Board of Health.

404:

or annealing oven was used to anneal the product. A typical 20th-century lehr was a large

8:

3481:

3408:

3274:

3194:

3129:

3084:

2668:

1707:

1473:

1458:

777:

3601:

3491:

3353:

3174:

3114:

3089:

3034:

2989:

2984:

2655:

2570:

2098:

553:

401:

323:

163:. It became the city's largest manufacturer and employer, peaking with 600 employees.

578:

3621:

3448:

3438:

3433:

3294:

3284:

3189:

2900:

2879:

2854:

2829:

2804:

2779:

2748:

2741:

2728:

2703:

2676:

2637:

2618:

2601:

2591:

2552:

2524:

2500:

2475:

2454:

2427:

2417:

2398:

2326:

2316:

2297:

2287:

2268:

2258:

2233:

2223:

2198:

2171:

2152:

2129:

2119:

2082:. Hartford City, IN: Blackford County Historical Society. p. 127. Archived from

2064:

2047:

754:

545:

397:

2516:

events--industrial, commercial, financial and educational progress, biographies, etc

449:

376:

The window glass manufacturing process used by Hartford City Glass was known as the

3660:

3373:

3358:

3109:

3094:

2390:

549:

528:

190:

178:

160:

26:

2891:

Windsor, John T. (January 8, 1921). "Prosperity in Glass Manufacturing Industry".

2633:

The Glass Industry. Report on the cost of production of glass in the United States

2630:

United States Bureau of foreign and domestic commerce (Dept. of Commerce) (1917).

2034:

Amstutz, Reverend A. Allison; Historical Committee (1943), "The First 100 Years",

370:

Two large stained-glass windows installed by Hartford City's Belgian glass workers

166:

Many of the skilled workers employed at the Hartford City Glass Company were from

3626:

3586:

3581:

3516:

3458:

3443:

3239:

3019:

2974:

381:

295:

3289:

487:(over $ 1.1 million in 2012 dollars) per month, and employed 500 glass workers.

3672:

3486:

3299:

3244:

3224:

3149:

3134:

3009:

2994:

2959:

2513:

701:

212:

3059:

2548:

Census reports ... Twelfth census of the United States, taken in the year 1900

1393:

United States Bureau of foreign and domestic commerce (Dept. of Commerce) 1917

1225:

United States Bureau of foreign and domestic commerce (Dept. of Commerce) 1917

1213:

United States Bureau of foreign and domestic commerce (Dept. of Commerce) 1917

640:

569:

3682:

3596:

3566:

3546:

3531:

3496:

3393:

3388:

3383:

3368:

3304:

3204:

3159:

3144:

3039:

2808:

2783:

2622:

2458:

2431:

2237:

2156:

2133:

654:

592:

588:

405:

2752:

2680:

2605:

2528:

2504:

2479:

2301:

2272:

2219:

Glass Towns: Industry, Labor and Political Economy in Appalachia, 1890-1930s

2068:

2051:

3571:

3561:

3541:

3501:

3453:

3398:

3378:

3249:

3169:

3024:

2969:

2964:

2904:

2883:

2858:

2833:

2732:

2707:

2641:

2402:

2330:

2202:

2197:. New York and Chicago: The American Historical Society, Inc. p. 349.

635:

433:

The Belgian workforce also affected the city's north side. Hartford City's

385:

2914:

2556:

2058:

1326:

1284:

1272:

877:

287:

Richard Heagany, founder of Hartford City Glass Company, and advertisement

3526:

3511:

3423:

3413:

3309:

3069:

2694:

Unlisted (Glass & Pottery World) (1896). "Chipped and Ground Glass".

307:

208:

2444:

2413:

Glasshouses and Glass Manufacturers of the Pittsburgh Region 1795 – 1910

2394:

2041:

2036:

Centennial Brochure, First Presbyterian Church of Hartford City, Indiana

1308:

919:

696:

For more detail on 1880s glassmaking, see Appendix A in Jack Paquette's

458:

furnace used to make the glass and the ovens used to gradually cool it.

426:

was also involved with glass making. During the early 1900s, the local

3556:

3219:

3124:

2083:

753:

In Europe, Belgian Emil Fourcault developed his own mechanized method (

500:

223:. Between 1880 and 1900, populations doubled in area counties such as

3611:

3536:

3521:

3279:

3264:

3184:

3104:

3079:

3029:

2840:

2815:

2714:

1783:

996:

972:

504:

496:

2739:

2693:

1680:

1380:

1109:

1062:

1050:

853:

417:

During the late 19th century, glass blowers were difficult to find.

527:

In 1898, a group of men led by James A. Chambers organized a glass

2588:

Blowpipes, Northwest Ohio Glassmaking in the Gas Boom of the 1880s

2190:

1151:

269:

3631:

3606:

3506:

3139:

3049:

3044:

3014:

2669:

United States Congress House Committee on Ways and Means (1913).

902:"Company is Organized To Operate the Late Hurrle Glass Factory".

418:

167:

107:

2790:

2765:

2465:

2453:(1898). Indianapolis: Indiana Department of Factory Inspection.

1864:

1719:

814:

3259:

3154:

2063:. Hartford City, Indiana: Blackford County Historical Society.

2191:

Fleming, George Thornton; American Historical Society (1922).

3616:

3576:

3551:

3199:

3074:

3004:

2486:

1708:

United States Congress House Committee on Ways and Means 1913

1623:

1474:

United States Congress House Committee on Ways and Means 1913

1459:

United States Congress House Committee on Ways and Means 1913

744:

machines" and a "smaller tank, with a six-machine equipment".

45:

2115:

Scale and scope : the dynamics of industrial capitalism

1835:"American Window Glass is to Continue the Use of Coal Gas".

1796:"(untitled second column from right, near bottom of page)".

2033:

1338:

235:. The region became Indiana’s major manufacturing center.

203:

Eaton, Hartford City, and Blackford County, Indiana in 1887

2315:

Graham, Albert Adams; Perrin, William Henry, eds. (1881).

2286:. Image of America. Charleston, SC: Arcadia. p. 128.

1747:"The Glass Trust. Manufacturers Believe It Is a Sure Go".

2347:

Hamilton, Kristi; Abraham, Kent; Lankford, Susan (2005).

2222:. Urbana, IL: University of Illinois Press. p. 236.

2474:(1901). Indianapolis: Indiana Department of Inspection.

2318:

History of Summit County, with an outline sketch of Ohio

453:

Drawing of the Hartford City Glass Company plant in 1896

2489:"Annual Report of the State Board of Health of Indiana"

2346:

1732:"The Big Trust. The New Window Glass Combine Certain".

865:

1507:

The Hartford City glass works have resumed operations.

627:

district, and one large plant at Hartford City, Ind."

3644:

2447:

Annual Report of the Department of Factory Inspection

1356:"(Untitled column on far left near bottom of page)".

2828:(15). Chicago: D. Van Ness Publishing Company: 13.

2389:(1). Easton, PA: American Chemical Society: 80–81.

2383:

The Journal of Industrial and Engineering Chemistry

2059:Blackford County Historical Society (Ind.) (1986).

2872:The Manual of Statistics: Stock Exchange Handbook

2379:"The Present Status of the Window Glass Industry"

1966:

1964:

1962:

1907:

1905:

1674:

915:

913:

184:

3724:Defunct manufacturing companies based in Indiana

3680:

2866:Wallace, Henry E.; Goodsell, Charles M. (1901).

1532:

1530:

1467:

1452:

1196:

1194:

1192:

1190:

1174:

1172:

966:

953:

951:

949:

933:

931:

2865:

2617:. Gretna, LA: Pelican Publishing. p. 320.

1850:"Indiana Company Has New Glass Making Record".

1843:

1766:

1440:

1351:

1349:

1347:

1327:Blackford County Historical Society (Ind.) 1986

1285:Blackford County Historical Society (Ind.) 1986

1273:Blackford County Historical Society (Ind.) 1986

958:"Factory Owner of Natural Gas Days Here Dies".

878:Blackford County Historical Society (Ind.) 1986

780:. The American Oil & Gas Historical Society

523:Advertisement for American Window Glass in 1913

495:. The grounds contained two melting rooms, two

78:1899 (facility continued to operate until 1929)

2841:Unlisted (Paint, Oil and Drug Review) (1907).

2816:Unlisted (Paint, Oil and Drug Review) (1899).

2715:Unlisted (Glass & Pottery World) (1896b).

1959:

1902:

1858:

1762:

1760:

1758:

1713:

1572:

1242:

1152:Fleming & American Historical Society 1922

990:

910:

259:

2930:

2740:Unlisted (Hartford City Illustrated) (1896).

2472:Annual Report of the Department of Inspection

2151:. Bloomington, IN: AuthorHouse. p. 196.

2146:

2118:. Cambridge, MA: Belknap Press. p. 765.

1935:

1828:

1789:

1779:

1777:

1775:

1740:

1725:

1686:

1644:

1602:

1587:

1557:

1527:

1479:

1413:

1398:

1309:Blackford County Gazette (advertisement) 1903

1296:

1260:

1187:

1169:

1130:

1083:

1068:

1029:

946:

928:

920:Indiana Department of Factory Inspection 1899

895:

810:

808:

806:

2575:: CS1 maint: multiple names: authors list (

2519:. Akron, OH: Beacon Job Department. p.

2314:

2279:

2103:: CS1 maint: multiple names: authors list (

2046:. Boston and New York: Pettingill & Co.

1996:"The Fabulous Monster: Owens Bottle Machine"

1947:

1920:

1896:Daily Times Gazette (Hartford City, Indiana)

1822:

1701:

1659:

1617:

1512:

1494:

1376:

1374:

1372:

1370:

1344:

1014:

984:

841:

797:

181:struck, the Hartford City plant had closed.

94:Plant No. 3 of American Window Glass Company

3704:Manufacturing companies established in 1890

2944:

2551:. Washington: United States Census Office.

2009:

1755:

1428:

1302:

1290:

1254:

1036:"Within Our Borders - Will Make No Glass".

700:book. Paquette, a former Vice President of

3689:Glassmaking companies of the United States

2937:

2923:

2727:(8). Chicago: Trade Magazine Association.

2702:(2). Chicago: Trade Magazine Association.

2675:. Washington: Government Printing Office.

2660:: CS1 maint: location missing publisher (

2215:

1941:

1784:Unlisted (Paint, Oil and Drug Review) 1907

1772:

1693:"Indiana News - Enlarging a Glass Plant".

1666:"From Hoosierdom - Glass Works to Start".

1386:

1322:

1320:

1218:

1206:

997:Unlisted (Paint, Oil and Drug Review) 1899

973:Unlisted (Glass & Pottery World) 1896b

803:

3714:American companies disestablished in 1899

3210:Pauly & C. - Compagnia Venezia Murano

2791:Unlisted (National Glass Budget) (1917).

2766:Unlisted (National Glass Budget) (1913).

2466:Indiana Department of Inspection (1902).

2147:Clamme, Louise; Castelo, Sinuard (2011).

1804:

1681:Unlisted (Glass & Pottery World) 1896

1632:

1381:Unlisted (Hartford City Illustrated) 1896

1367:

1266:

1157:

1145:

1110:Unlisted (Hartford City Illustrated) 1896

1063:Unlisted (Hartford City Illustrated) 1896

1056:

1051:Unlisted (Hartford City Illustrated) 1896

1044:

978:

883:

854:Unlisted (Hartford City Illustrated) 1896

2585:

2321:. Chicago: Baskin & Battey. p.

2280:Glass, James A.; Kohrman, David (2005).

2250:

2111:

1976:

1970:

1545:

1446:

1434:

1332:

1248:

1105:

1103:

1101:

859:

826:

634:

559:

518:

448:

207:During the late 1880s, the discovery of

198:

2899:. New York: Ticker Publishing Company.

2890:

2612:

2409:

2358:. National Park Service. Archived from

1982:

1953:

1877:

1875:

1873:

1816:

1810:

1339:Amstutz & Historical Committee 1943

1317:

1278:

1236:

1230:

1115:

1002:

847:

820:

668:

3719:American companies established in 1890

3681:

2487:Indiana State Board of Health (1907).

1609:"(untitled third column from right)".

1486:"State News - Glass Works Shut Down".

871:

791:

439:National Register of Historical Places

3333:List of defunct glassmaking companies

2918:

2376:

1881:

1865:Unlisted (National Glass Budget) 1917

1720:Unlisted (National Glass Budget) 1913

1651:"(untitled third column from left)".

1420:"(untitled third column from left)".

1098:

866:Hamilton, Abraham & Lankford 2005

835:

815:Indiana Department of Inspection 1902

2615:Michael Owens and the Glass Industry

2511:

2356:National Register of Historic Places

2283:The Gas Boom of East Central Indiana

2163:

1870:

1121:

1008:

889:

313:

16:American glass manufacturing company

2747:. Daulton & Scott. p. 47.

2493:Report of the State Board of Health

215:started an economic boom period in

13:

2251:Forstall, Richard L., ed. (1996).

2194:History of Pittsburgh and environs

1624:Indiana State Board of Health 1907

604:

400:, to prevent it from breaking. A

14:

3735:

2843:"Machine Window Glass Production"

1564:"Glass Works for Hartford City".

444:

384:, and required the services of a

322:Colonel George Tod Perkins was a

195:History of Hartford City, Indiana

3666:

3654:

2112:Chandler, Alfred Dupont (1999).

1594:"Meeting of the Glass Company".

613:

577:

568:

360:

351:

277:

268:

238:

25:

2878:. New York: Charles H. Nicoll.

1988:

1887:

747:

737:

728:

718:

708:

690:

680:

544:. Other plants were located in

412:

120:Richard Heagany, J. R. Johnston

3709:1890 establishments in Indiana

2768:"Successful Start at Hartford"

2170:. Troy, Ohio: George R. Dale.

2027:

1927:"Offers Old Plants for Sale".

770:

643:"Means for Making Sheet Glass"

514:

342:

301:

185:Manufacturers drawn to Indiana

1:

3694:Defunct glassmaking companies

3270:Sterlite Optical Technologies

3120:Kokomo Opalescent Glass Works

2590:. Xlibris Corp. p. 559.

2512:Lane, Samuel Alanson (1892).

764:

326:veteran and president of the

151:works was the first of eight

2613:Skrabec, Quentin R. (2007).

2539:A. L. Conger glass Hartford.

1581:Shoals Martin County Tribune

778:"Indiana's Natural Gas Boom"

473:

333:

7:

2893:The Magazine of Wall Street

2853:(1). Chicago: D. Van Ness.

2818:"(untitled column on left)"

2636:. Washington. p. 430.

1767:Wallace & Goodsell 1901

1695:Connersville Daily Examiner

1566:Connersville Daily Examiner

1075:"Dont Bet on the Colonel".

437:, which is now part of the

260:Organization and management

148:Hartford City Glass Company

128:window glass, chipped glass

20:Hartford City Glass Company

10:

3740:

2868:"American Window Glass Co"

2847:Paint, Oil and Drug Review

2822:Paint, Oil and Drug Review

2793:"The Window Glass Machine"

2586:Paquette, Jack K. (2002).

1852:Fort Wayne Journal Gazette

630:

409:City plant had conveyors.

188:

3699:Blackford County, Indiana

3472:

3341:

3323:

2950:

2721:Glass & Pottery World

2696:Glass & Pottery World

2341:A. M. Barber grain Akron.

1998:. Corning Museum of Glass

1854:. 1905-04-09. p. 18.

1505:. 1891-10-07. p. 3.

1360:. 1891-01-02. p. 1.

1297:Clamme & Castelo 2011

1261:Clamme & Castelo 2011

1092:Fort Wayne Weekly Gazette

153:glass plants that existed

132:

124:

114:

98:

90:

82:

74:

66:

51:

41:

33:

24:

3060:Firozabad glass industry

3055:Fenton Art Glass Company

2410:Hawkins, Jay W. (2009).

2216:Fones-Wolf, Ken (2007).

2164:Dale, George R. (1902).

2020:. 1930-02-20. p. 1.

1931:. 1905-06-15. p. 7.

1916:. 1900-05-22. p. 1.

1914:Portland Semi Weekly Sun

1912:"We'll Lead the World".

1898:. 1908-04-13. p. 1.

1839:. 1895-09-27. p. 1.

1823:Glass & Kohrman 2005

1800:. 1899-12-13. p. 1.

1751:. 1899-07-12. p. 1.

1736:. 1899-05-17. p. 1.

1697:. 1896-12-28. p. 1.

1670:. 1893-09-20. p. 1.

1655:. 1893-04-06. p. 1.

1613:. 1893-06-01. p. 1.

1598:. 1893-04-20. p. 1.

1583:. 1893-03-24. p. 2.

1568:. 1892-03-31. p. 1.

1541:. 1892-04-07. p. 1.

1523:. 1892-04-07. p. 6.

1490:. 1891-06-03. p. 5.

1424:. 1893-03-02. p. 1.

1409:. 1891-04-27. p. 2.

1183:. 1894-12-05. p. 1.

1141:. 1899-08-30. p. 1.

1094:. 1895-09-05. p. 2.

1079:. 1894-12-12. p. 1.

1040:. 1891-09-01. p. 3.

1025:. 1893-09-08. p. 7.

985:Graham & Perrin 1881

962:. 1925-09-10. p. 1.

942:. 1899-09-27. p. 1.

906:. 1895-01-04. p. 1.

842:Glass & Kohrman 2005

798:Glass & Kohrman 2005

673:

428:Blackford County Gazette

3364:Irving Wightman Colburn

2945:Glass makers and brands

2416:. New York: iUniverse.

1837:Hartford City Telegram

1798:Hartford City Telegram

1749:Hartford City Telegram

1734:Hartford City Telegram

1653:Hartford City Telegram

1611:Hartford City Telegram

1596:Hartford City Telegram

1579:"State News Summary".

1539:Hartford City Telegram

1537:"WINDOW GLASS NOTES".

1519:"Indiana State News".

1422:Hartford City Telegram

1407:Oskaloosa Daily Herald

1405:"In the Gas Fields.".

1181:Hartford City Telegram

1139:Hartford City Telegram

1090:"Col. Conger Beaten".

1077:Hartford City Telegram

1021:"Indiana State News".

940:Hartford City Telegram

904:Hartford City Telegram

868:, p. 13 section 8

655:Edward Drummond Libbey

644:

524:

454:

328:B. F. Goodrich Company

221:Hartford City, Indiana

204:

157:Hartford City, Indiana

3429:Henry William Stiegel

3160:Mats Jonasson Målerås

3100:Holmegaard Glassworks

2797:National Glass Budget

2772:National Glass Budget

2377:Hamor, W. A. (1913).

2079:Dusty Bits and Pieces

638:

560:American Window Glass

522:

493:Pennsylvania Railroad

452:

202:

3404:Michael Joseph Owens

2980:Aurora Glass Foundry

960:Kokomo Daily Tribune

938:"Injunction Suits".

669:Notes and references

250:Sneath Glass Company

217:East Central Indiana

3492:Bomex/Duran/Endural

3409:Alastair Pilkington

3085:Guardian Industries

2990:Barovier & Toso

2395:10.1021/ie50049a053

2018:Charleroi (PA) Mail

1929:Logansport Reporter

1668:Logansport Reporter

1639:Castelo et al. 2012

1552:Merriam et al. 1901

1201:Castelo et al. 2012

1164:Castelo et al. 2012

435:Presbyterian Church

380:. The process was

134:Number of employees

46:Glass manufacturing

21:

3354:Richard M. Atwater

3175:Nippon Sheet Glass

3115:Kingdom of Crystal

3035:Dartington Crystal

2803:(49). Chicago: 1.

2778:(28). Chicago: 7.

2149:Strangers Among Us

1973:, pp. 115–116

1503:Logansport Journal

1501:"Over the State".

1476:, pp. 412–413

1449:, pp. 333–334

1251:, pp. 469–475

1179:"A Big Industry".

892:, pp. 121–122

645:

641:M. J. Owens patent

639:Drawing from 1920

554:Fairmount, Indiana

525:

455:

205:

19:

3640:

3639:

3449:Tomasz Urbanowicz

3439:Lino Tagliapietra

3434:S. Donald Stookey

3285:Val Saint Lambert

3180:Nižbor glassworks

3095:Hardman & Co.

2293:978-0-7385-3963-8

2177:978-1-153-46853-4

1488:Goshen Daily News

1358:Rochester Tribune

1038:Goshen Daily News

755:Fourcault process

650:Irving W. Colburn

314:Management change

254:8 glass factories

145:

144:

141:

3731:

3671:

3670:

3669:

3659:

3658:

3657:

3650:

3389:Edward D. Libbey

3359:Frederick Carder

2939:

2932:

2925:

2916:

2915:

2911:

2887:

2862:

2837:

2812:

2787:

2762:

2760:

2759:

2736:

2711:

2690:

2688:

2687:

2665:

2659:

2651:

2649:

2648:

2626:

2609:

2580:

2574:

2566:

2564:

2563:

2541:

2536:

2535:

2508:

2483:

2462:

2441:

2439:

2438:

2406:

2373:

2371:

2370:

2364:

2353:

2343:

2338:

2337:

2311:

2309:

2308:

2276:

2247:

2245:

2244:

2212:

2210:

2209:

2187:

2185:

2184:

2160:

2143:

2141:

2140:

2108:

2102:

2094:

2092:

2091:

2072:

2055:

2038:

2022:

2021:

2013:

2007:

2006:

2004:

2003:

1992:

1986:

1980:

1974:

1968:

1957:

1951:

1945:

1939:

1933:

1932:

1924:

1918:

1917:

1909:

1900:

1899:

1891:

1885:

1879:

1868:

1862:

1856:

1855:

1847:

1841:

1840:

1832:

1826:

1820:

1814:

1808:

1802:

1801:

1793:

1787:

1781:

1770:

1764:

1753:

1752:

1744:

1738:

1737:

1729:

1723:

1717:

1711:

1705:

1699:

1698:

1690:

1684:

1678:

1672:

1671:

1663:

1657:

1656:

1648:

1642:

1636:

1630:

1621:

1615:

1614:

1606:

1600:

1599:

1591:

1585:

1584:

1576:

1570:

1569:

1561:

1555:

1549:

1543:

1542:

1534:

1525:

1524:

1521:Spencer Democrat

1516:

1510:

1509:

1498:

1492:

1491:

1483:

1477:

1471:

1465:

1456:

1450:

1444:

1438:

1432:

1426:

1425:

1417:

1411:

1410:

1402:

1396:

1390:

1384:

1378:

1365:

1364:

1353:

1342:

1336:

1330:

1324:

1315:

1306:

1300:

1294:

1288:

1282:

1276:

1275:, pp. 48–49

1270:

1264:

1258:

1252:

1246:

1240:

1234:

1228:

1222:

1216:

1210:

1204:

1203:, pp. 16–17

1198:

1185:

1184:

1176:

1167:

1161:

1155:

1149:

1143:

1142:

1134:

1128:

1119:

1113:

1107:

1096:

1095:

1087:

1081:

1080:

1072:

1066:

1060:

1054:

1048:

1042:

1041:

1033:

1027:

1026:

1018:

1012:

1006:

1000:

994:

988:

982:

976:

970:

964:

963:

955:

944:

943:

935:

926:

917:

908:

907:

899:

893:

887:

881:

875:

869:

863:

857:

851:

845:

839:

833:

824:

818:

812:

801:

795:

789:

788:

786:

785:

774:

758:

751:

745:

741:

735:

732:

726:

722:

716:

712:

706:

694:

688:

684:

659:Michael J. Owens

581:

572:

364:

355:

281:

272:

191:Indiana Gas Boom

179:Great Depression

161:Indiana Gas Boom

139:

62:

60:

29:

22:

18:

3739:

3738:

3734:

3733:

3732:

3730:

3729:

3728:

3679:

3678:

3677:

3667:

3665:

3655:

3653:

3645:

3641:

3636:

3474:

3468:

3459:John M. Whitall

3444:W. E. S. Turner

3337:

3325:

3319:

3300:Watts & Co.

3020:Caithness Glass

2952:

2946:

2943:

2757:

2755:

2685:

2683:

2653:

2652:

2646:

2644:

2598:

2568:

2567:

2561:

2559:

2533:

2531:

2436:

2434:

2424:

2368:

2366:

2362:

2351:

2335:

2333:

2306:

2304:

2294:

2265:

2242:

2240:

2230:

2207:

2205:

2182:

2180:

2178:

2138:

2136:

2126:

2096:

2095:

2089:

2087:

2030:

2025:

2015:

2014:

2010:

2001:

1999:

1994:

1993:

1989:

1981:

1977:

1969:

1960:

1952:

1948:

1942:Fones-Wolf 2007

1940:

1936:

1926:

1925:

1921:

1911:

1910:

1903:

1893:

1892:

1888:

1880:

1871:

1863:

1859:

1849:

1848:

1844:

1834:

1833:

1829:

1821:

1817:

1809:

1805:

1795:

1794:

1790:

1782:

1773:

1765:

1756:

1746:

1745:

1741:

1731:

1730:

1726:

1718:

1714:

1706:

1702:

1692:

1691:

1687:

1679:

1675:

1665:

1664:

1660:

1650:

1649:

1645:

1637:

1633:

1622:

1618:

1608:

1607:

1603:

1593:

1592:

1588:

1578:

1577:

1573:

1563:

1562:

1558:

1550:

1546:

1536:

1535:

1528:

1518:

1517:

1513:

1500:

1499:

1495:

1485:

1484:

1480:

1472:

1468:

1457:

1453:

1445:

1441:

1433:

1429:

1419:

1418:

1414:

1404:

1403:

1399:

1391:

1387:

1379:

1368:

1355:

1354:

1345:

1337:

1333:

1325:

1318:

1307:

1303:

1295:

1291:

1283:

1279:

1271:

1267:

1259:

1255:

1247:

1243:

1235:

1231:

1223:

1219:

1211:

1207:

1199:

1188:

1178:

1177:

1170:

1162:

1158:

1150:

1146:

1136:

1135:

1131:

1120:

1116:

1108:

1099:

1089:

1088:

1084:

1074:

1073:

1069:

1061:

1057:

1049:

1045:

1035:

1034:

1030:

1020:

1019:

1015:

1007:

1003:

995:

991:

983:

979:

971:

967:

957:

956:

947:

937:

936:

929:

918:

911:

901:

900:

896:

888:

884:

876:

872:

864:

860:

852:

848:

840:

836:

825:

821:

813:

804:

796:

792:

783:

781:

776:

775:

771:

767:

762:

761:

752:

748:

742:

738:

733:

729:

723:

719:

713:

709:

695:

691:

685:

681:

676:

671:

633:

616:

607:

605:Lubbers machine

598:

597:

596:

595:

589:H. G. Slingluff

584:

583:

582:

574:

573:

562:

517:

476:

447:

415:

382:labor-intensive

378:Cylinder Method

374:

373:

372:

371:

367:

366:

365:

357:

356:

345:

336:

316:

304:

296:Kokomo, Indiana

291:

290:

289:

288:

284:

283:

282:

274:

273:

262:

241:

197:

187:

135:

117:

110:

70:Richard Heagany

58:

56:

17:

12:

11:

5:

3737:

3727:

3726:

3721:

3716:

3711:

3706:

3701:

3696:

3691:

3676:

3675:

3663:

3638:

3637:

3635:

3634:

3629:

3624:

3619:

3614:

3609:

3604:

3599:

3594:

3592:Satsuma Kiriko

3589:

3584:

3579:

3574:

3569:

3564:

3559:

3554:

3549:

3544:

3539:

3534:

3529:

3524:

3519:

3514:

3509:

3504:

3499:

3494:

3489:

3484:

3478:

3476:

3470:

3469:

3467:

3466:

3461:

3456:

3451:

3446:

3441:

3436:

3431:

3426:

3421:

3416:

3411:

3406:

3401:

3396:

3391:

3386:

3381:

3376:

3371:

3366:

3361:

3356:

3351:

3345:

3343:

3339:

3338:

3336:

3335:

3329:

3327:

3321:

3320:

3318:

3317:

3312:

3307:

3302:

3297:

3292:

3287:

3282:

3277:

3272:

3267:

3262:

3257:

3252:

3247:

3245:Royal Brierley

3242:

3237:

3232:

3227:

3225:PPG Industries

3222:

3217:

3212:

3207:

3202:

3197:

3192:

3187:

3182:

3177:

3172:

3167:

3162:

3157:

3152:

3150:Johns Manville

3147:

3142:

3137:

3135:Liuli Gongfang

3132:

3127:

3122:

3117:

3112:

3107:

3102:

3097:

3092:

3087:

3082:

3077:

3072:

3067:

3062:

3057:

3052:

3047:

3042:

3037:

3032:

3027:

3022:

3017:

3012:

3010:Bormioli Rocco

3007:

3002:

2997:

2995:Berengo Studio

2992:

2987:

2982:

2977:

2972:

2967:

2962:

2960:Anchor Hocking

2956:

2954:

2948:

2947:

2942:

2941:

2934:

2927:

2919:

2913:

2912:

2888:

2863:

2838:

2813:

2788:

2763:

2737:

2712:

2691:

2666:

2627:

2610:

2596:

2582:

2581:

2542:

2509:

2484:

2463:

2442:

2422:

2407:

2374:

2344:

2312:

2292:

2277:

2263:

2248:

2228:

2213:

2188:

2176:

2161:

2144:

2124:

2109:

2073:

2056:

2039:

2029:

2026:

2024:

2023:

2008:

1987:

1975:

1958:

1946:

1934:

1919:

1901:

1886:

1869:

1857:

1842:

1827:

1815:

1803:

1788:

1771:

1754:

1739:

1724:

1712:

1700:

1685:

1673:

1658:

1643:

1631:

1616:

1601:

1586:

1571:

1556:

1544:

1526:

1511:

1493:

1478:

1466:

1451:

1439:

1427:

1412:

1397:

1385:

1366:

1343:

1331:

1316:

1301:

1289:

1277:

1265:

1253:

1241:

1229:

1217:

1205:

1186:

1168:

1156:

1144:

1129:

1114:

1097:

1082:

1067:

1055:

1043:

1028:

1013:

1001:

989:

977:

965:

945:

927:

909:

894:

882:

870:

858:

846:

834:

819:

802:

790:

768:

766:

763:

760:

759:

746:

736:

727:

717:

707:

702:Owens-Illinois

689:

678:

677:

675:

672:

670:

667:

632:

629:

615:

612:

606:

603:

586:

585:

576:

575:

567:

566:

565:

564:

563:

561:

558:

516:

513:

475:

472:

446:

445:Infrastructure

443:

414:

411:

369:

368:

359:

358:

350:

349:

348:

347:

346:

344:

341:

335:

332:

315:

312:

303:

300:

286:

285:

276:

275:

267:

266:

265:

264:

263:

261:

258:

240:

237:

213:Eaton, Indiana

186:

183:

143:

142:

136:

133:

130:

129:

126:

122:

121:

118:

115:

112:

111:

102:

100:

96:

95:

92:

88:

87:

84:

80:

79:

76:

72:

71:

68:

64:

63:

53:

49:

48:

43:

39:

38:

35:

31:

30:

15:

9:

6:

4:

3:

2:

3736:

3725:

3722:

3720:

3717:

3715:

3712:

3710:

3707:

3705:

3702:

3700:

3697:

3695:

3692:

3690:

3687:

3686:

3684:

3674:

3664:

3662:

3652:

3651:

3648:

3643:

3633:

3630:

3628:

3625:

3623:

3620:

3618:

3615:

3613:

3610:

3608:

3605:

3603:

3600:

3598:

3595:

3593:

3590:

3588:

3585:

3583:

3580:

3578:

3575:

3573:

3570:

3568:

3565:

3563:

3560:

3558:

3555:

3553:

3550:

3548:

3545:

3543:

3540:

3538:

3535:

3533:

3530:

3528:

3525:

3523:

3520:

3518:

3515:

3513:

3510:

3508:

3505:

3503:

3500:

3498:

3495:

3493:

3490:

3488:

3485:

3483:

3480:

3479:

3477:

3471:

3465:

3464:Caspar Wistar

3462:

3460:

3457:

3455:

3452:

3450:

3447:

3445:

3442:

3440:

3437:

3435:

3432:

3430:

3427:

3425:

3422:

3420:

3417:

3415:

3412:

3410:

3407:

3405:

3402:

3400:

3397:

3395:

3394:Dante Marioni

3392:

3390:

3387:

3385:

3384:Deming Jarves

3382:

3380:

3377:

3375:

3372:

3370:

3369:Henry Crimmel

3367:

3365:

3362:

3360:

3357:

3355:

3352:

3350:

3347:

3346:

3344:

3340:

3334:

3331:

3330:

3328:

3322:

3316:

3313:

3311:

3308:

3306:

3305:World Kitchen

3303:

3301:

3298:

3296:

3293:

3291:

3288:

3286:

3283:

3281:

3278:

3276:

3273:

3271:

3268:

3266:

3263:

3261:

3258:

3256:

3253:

3251:

3248:

3246:

3243:

3241:

3238:

3236:

3233:

3231:

3228:

3226:

3223:

3221:

3218:

3216:

3213:

3211:

3208:

3206:

3205:Owens Corning

3203:

3201:

3198:

3196:

3193:

3191:

3188:

3186:

3183:

3181:

3178:

3176:

3173:

3171:

3168:

3166:

3163:

3161:

3158:

3156:

3153:

3151:

3148:

3146:

3143:

3141:

3138:

3136:

3133:

3131:

3128:

3126:

3123:

3121:

3118:

3116:

3113:

3111:

3108:

3106:

3103:

3101:

3098:

3096:

3093:

3091:

3088:

3086:

3083:

3081:

3078:

3076:

3073:

3071:

3068:

3066:

3063:

3061:

3058:

3056:

3053:

3051:

3048:

3046:

3043:

3041:

3038:

3036:

3033:

3031:

3028:

3026:

3023:

3021:

3018:

3016:

3013:

3011:

3008:

3006:

3003:

3001:

2998:

2996:

2993:

2991:

2988:

2986:

2983:

2981:

2978:

2976:

2973:

2971:

2968:

2966:

2963:

2961:

2958:

2957:

2955:

2949:

2940:

2935:

2933:

2928:

2926:

2921:

2920:

2917:

2910:

2906:

2902:

2898:

2894:

2889:

2885:

2881:

2877:

2873:

2869:

2864:

2860:

2856:

2852:

2848:

2844:

2839:

2835:

2831:

2827:

2823:

2819:

2814:

2810:

2806:

2802:

2798:

2794:

2789:

2785:

2781:

2777:

2773:

2769:

2764:

2754:

2750:

2746:

2745:

2738:

2734:

2730:

2726:

2722:

2718:

2713:

2709:

2705:

2701:

2697:

2692:

2682:

2678:

2674:

2673:

2667:

2663:

2657:

2643:

2639:

2635:

2634:

2628:

2624:

2620:

2616:

2611:

2607:

2603:

2599:

2597:1-4010-4790-4

2593:

2589:

2584:

2583:

2578:

2572:

2558:

2554:

2550:

2549:

2543:

2540:

2530:

2526:

2522:

2518:

2517:

2510:

2506:

2502:

2498:

2494:

2490:

2485:

2481:

2477:

2473:

2469:

2464:

2460:

2456:

2452:

2448:

2443:

2433:

2429:

2425:

2423:9781440114946

2419:

2415:

2414:

2408:

2404:

2400:

2396:

2392:

2388:

2384:

2380:

2375:

2365:on 2012-10-10

2361:

2357:

2350:

2345:

2342:

2332:

2328:

2324:

2320:

2319:

2313:

2303:

2299:

2295:

2289:

2285:

2284:

2278:

2274:

2270:

2266:

2264:0-934213-48-8

2260:

2256:

2255:

2249:

2239:

2235:

2231:

2229:9780252073717

2225:

2221:

2220:

2214:

2204:

2200:

2196:

2195:

2189:

2179:

2173:

2169:

2168:

2162:

2158:

2154:

2150:

2145:

2135:

2131:

2127:

2125:9780674789951

2121:

2117:

2116:

2110:

2106:

2100:

2086:on 2013-08-12

2085:

2081:

2080:

2074:

2070:

2066:

2062:

2057:

2053:

2049:

2045:

2040:

2037:

2032:

2031:

2019:

2012:

1997:

1991:

1985:, p. 124

1984:

1979:

1972:

1971:Chandler 1999

1967:

1965:

1963:

1956:, p. 318

1955:

1950:

1944:, p. 138

1943:

1938:

1930:

1923:

1915:

1908:

1906:

1897:

1890:

1883:

1878:

1876:

1874:

1866:

1861:

1853:

1846:

1838:

1831:

1824:

1819:

1812:

1807:

1799:

1792:

1785:

1780:

1778:

1776:

1769:, p. 315

1768:

1763:

1761:

1759:

1750:

1743:

1735:

1728:

1721:

1716:

1710:, p. 406

1709:

1704:

1696:

1689:

1682:

1677:

1669:

1662:

1654:

1647:

1640:

1635:

1629:

1625:

1620:

1612:

1605:

1597:

1590:

1582:

1575:

1567:

1560:

1554:, p. 390

1553:

1548:

1540:

1533:

1531:

1522:

1515:

1508:

1504:

1497:

1489:

1482:

1475:

1470:

1464:

1460:

1455:

1448:

1447:Paquette 2002

1443:

1437:, p. 176

1436:

1435:Paquette 2002

1431:

1423:

1416:

1408:

1401:

1394:

1389:

1382:

1377:

1375:

1373:

1371:

1363:

1359:

1352:

1350:

1348:

1340:

1335:

1328:

1323:

1321:

1314:

1310:

1305:

1298:

1293:

1286:

1281:

1274:

1269:

1262:

1257:

1250:

1249:Paquette 2002

1245:

1238:

1233:

1226:

1221:

1214:

1209:

1202:

1197:

1195:

1193:

1191:

1182:

1175:

1173:

1165:

1160:

1153:

1148:

1140:

1133:

1127:

1123:

1118:

1111:

1106:

1104:

1102:

1093:

1086:

1078:

1071:

1064:

1059:

1052:

1047:

1039:

1032:

1024:

1017:

1011:, p. 470

1010:

1005:

998:

993:

987:, p. 684

986:

981:

974:

969:

961:

954:

952:

950:

941:

934:

932:

925:

921:

916:

914:

905:

898:

891:

886:

879:

874:

867:

862:

855:

850:

843:

838:

832:

828:

827:Forstall 1996

823:

816:

811:

809:

807:

799:

794:

779:

773:

769:

756:

750:

740:

731:

721:

711:

703:

699:

693:

683:

679:

666:

662:

660:

656:

651:

642:

637:

628:

624:

620:

614:Consolidation

611:

602:

594:

593:J. H. Lubbers

590:

580:

571:

557:

555:

551:

547:

543:

537:

533:

530:

521:

512:

508:

506:

502:

498:

494:

488:

484:

480:

471:

467:

463:

459:

451:

442:

440:

436:

431:

429:

423:

420:

410:

407:

403:

399:

394:

390:

387:

383:

379:

363:

354:

340:

331:

329:

325:

320:

311:

309:

299:

297:

280:

271:

257:

255:

251:

245:

239:Hartford City

236:

234:

230:

226:

222:

218:

214:

210:

201:

196:

192:

182:

180:

175:

171:

169:

164:

162:

158:

154:

149:

137:

131:

127:

123:

119:

113:

109:

105:

104:Hartford City

101:

97:

93:

89:

85:

81:

77:

73:

69:

65:

54:

50:

47:

44:

40:

36:

32:

28:

23:

3642:

3502:Chevron bead

3454:Paolo Venini

3399:Antonio Neri

3379:A. H. Heisey

3290:Vallérysthal

3250:Saint-Gobain

3170:Mosser Glass

3000:Blenko Glass

2970:Ardagh Group

2965:Arc Holdings

2908:

2896:

2892:

2875:

2871:

2850:

2846:

2825:

2821:

2800:

2796:

2775:

2771:

2756:. Retrieved

2742:

2724:

2720:

2699:

2695:

2684:. Retrieved

2671:

2645:. Retrieved

2632:

2614:

2587:

2560:. Retrieved

2547:

2538:

2532:. Retrieved

2514:

2496:

2492:

2471:

2450:

2446:

2435:. Retrieved

2412:

2386:

2382:

2367:. Retrieved

2360:the original

2355:

2340:

2334:. Retrieved

2317:

2305:. Retrieved

2282:

2253:

2241:. Retrieved

2218:

2206:. Retrieved

2193:

2181:. Retrieved

2166:

2148:

2137:. Retrieved

2114:

2088:. Retrieved

2084:the original

2078:

2060:

2043:

2035:

2017:

2011:

2000:. Retrieved

1990:

1983:Skrabec 2007

1978:

1954:Windsor 1921

1949:

1937:

1928:

1922:

1913:

1895:

1889:

1884:, p. 81

1860:

1851:

1845:

1836:

1830:

1825:, p. 91

1818:

1813:, p. 23

1811:Hawkins 2009

1806:

1797:

1791:

1748:

1742:

1733:

1727:

1715:

1703:

1694:

1688:

1683:, p. 23

1676:

1667:

1661:

1652:

1646:

1641:, p. 23

1634:

1619:

1610:

1604:

1595:

1589:

1580:

1574:

1565:

1559:

1547:

1538:

1520:

1514:

1506:

1502:

1496:

1487:

1481:

1469:

1454:

1442:

1430:

1421:

1415:

1406:

1400:

1395:, p. 41

1388:

1383:, p. 16

1361:

1357:

1334:

1329:, p. 67

1304:

1299:, p. 23

1292:

1287:, p. 68

1280:

1268:

1263:, p. 11