223:

70:

31:

298:

141:

82:

219:

plant, it accounts for about 40% of the total energy consumption. Industrial distillation is typically performed in large, vertical cylindrical columns (as shown in Figure 2) known as "distillation towers" or "distillation columns" with diameters ranging from about 65 centimeters to 6 meters and heights ranging from about 6 meters to 60 meters or more.

258:

Inside the column, the downflowing reflux liquid provides cooling and condensation of upflowing vapors thereby increasing the efficacy of the distillation tower. The more reflux and/or more trays provided, the better is the tower's separation of lower boiling materials from higher boiling materials.

250:

Figure 3 depicts an industrial fractionating column separating a feed stream into one distillate fraction and one bottoms fraction. However, many industrial fractionating columns have outlets at intervals up the column so that multiple products having different boiling ranges may be withdrawn from a

218:

Distillation is one of the most common and energy-intensive separation processes. Effectiveness of separation is dependent upon the height and diameter of the column, the ratio of the column's height to diameter, and the material that comprises the distillation column itself. In a typical chemical

246:

and with the feed must equal the amount heat removed by the overhead condenser and with the products. The heat entering a distillation column is a crucial operating parameter, addition of excess or insufficient heat to the column can lead to foaming, weeping, entrainment, or flooding.

274:

Bubble-cap "trays" or "plates" are one of the types of physical devices, which are used to provide good contact between the upflowing vapor and the downflowing liquid inside an industrial fractionating column. Such trays are shown in

Figures 4 and 5.

254:

Industrial fractionating columns use external reflux to achieve better separation of products. Reflux refers to the portion of the condensed overhead liquid product that returns to the upper part of the fractionating column as shown in Figure 3.

238:

Industrial distillation towers are usually operated at a continuous steady state. Unless disturbed by changes in feed, heat, ambient temperature, or condensing, the amount of feed being added normally equals the amount of product being removed.

199:. In such refineries, the crude oil feedstock is a complex, multicomponent mixture that must be separated. Yields of pure chemical compounds are generally not expected, however, yields of groups of compounds within a relatively small range of

251:

column distilling a multi-component feed stream. The "lightest" products with the lowest boiling points exit from the top of the columns and the "heaviest" products with the highest boiling points exit from the bottom.

262:

The design and operation of a fractionating column depends on the composition of the feed as well as the composition of the desired products. Given a simple, binary component feed, analytical methods such as the

109:-vaporization cycle, the vapors are enriched in a certain component. A larger surface area allows more cycles, improving separation. This is the rationale for a Vigreux column or a packed fractionating column.

116:

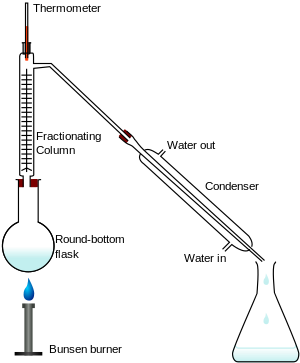

In a typical fractional distillation, a liquid mixture is heated in the distilling flask, and the resulting vapor rises up the fractionating column (see Figure 1). The vapor condenses on glass spurs (known as

231:

629:

290:

137:, which cools the vapor until it condenses into a liquid distillate. The separation may be enhanced by the addition of more trays (to a practical limitation of heat, flow, etc.).

113:

achieves the same outcome by using a rotating band within the column to force the rising vapors and descending condensate into close contact, achieving equilibrium more quickly.

89:

A laboratory fractionating column is a piece of glassware used to separate vaporized mixtures of liquid compounds with close volatility. Most commonly used is either a

325:

takes place. Differently shaped packings have different surface areas and void space between packings. Both of these factors affect packing performance.

164:. Fractionating columns are widely used in chemical process industries where large quantities of liquids have to be distilled. Such industries are

639:

507:

309:

is used in the column instead of trays, especially when low pressure drops across the column are required, as when operating under

532:

645:

571:

654:

61:. Fractionating columns are used in small-scale laboratory distillations as well as large-scale industrial distillations.

282:. Hence, a fractionating column almost always needs more actual, physical plates than the required number of theoretical

17:

669:

611:

516:

482:

457:

427:

402:

133:. Only the most volatile of the vapors stays in gas form all the way to the top, where it may then proceed through a

125:

the rising distillate vapor. The hottest tray is at the bottom of the column and the coolest tray is at the top. At

634:

271:

can be used. For a multi-component feed, simulation models are used both for design, operation, and construction.

57:

of liquid mixtures to separate the mixture into its component parts, or fractions, based on their differences in

283:

130:

313:. This packing material can either be random dumped packing (1–3 in or 2.5–7.6 cm wide) such as

689:

321:. Liquids tend to wet the surface of the packing, and the vapors pass across this wetted surface, where

293:

Figure 5: Section of fractionating tower of Figure 4 showing detail of a pair of trays with bubble caps

110:

134:

264:

642:

by Ivar J. Halvorsen and Sigurd

Skogestad, Norwegian University of Science and Technology, Norway

374:

349:

344:

334:

153:

694:

278:

The efficiency of a tray or plate is typically lower than that of a theoretical 100% efficient

173:

58:

234:

Figure 4: Chemical engineering schematic of typical bubble-cap trays in a fractionating column

684:

222:

354:

161:

97:. Fractionating columns help to separate the mixture by allowing the mixed vapors to cool,

8:

448:

369:

69:

359:

339:

318:

607:

567:

512:

478:

453:

423:

398:

364:

279:

118:

39:

35:

30:

540:

74:

658:

268:

157:

102:

651:

200:

90:

297:

678:

322:

226:

Figure 3: Chemical engineering schematic of a continuous fractionating column

169:

587:

Beychok, Milton (May 1951). "Algebraic

Solution of McCabe-Thiele Diagram".

314:

196:

126:

106:

98:

94:

54:

230:

189:

140:

306:

185:

165:

93:

or a straight column packed with glass beads or metal pieces such as

81:

195:

production. Fractional distillation finds its widest application in

289:

243:

192:

177:

181:

310:

122:

601:

504:

670:

121:) inside the column, and returns to the distilling flask,

664:

397:(5th ed.). Hoboken, New Jersey: Wiley-Interscience.

418:

Smith, Julian; McCabe, Warren; Harriott, Peter (2004).

207:, are expected. This process is the origin of the name

129:

conditions, the vapor and liquid on each tray reach an

561:

635:

More drawings of glassware including

Vigreux columns

73:

Figure 1: Fractional distillation apparatus using a

417:

148:

64:

144:Figure 2: Typical industrial fractionating columns

676:

445:

392:

242:The amount of heat entering the column from the

395:Kirk-Othmer Encyclopedia of Chemical Technology

301:Figure 6: Entire view of a Distillation Column

393:Kroschwitz, Jacqueline; Seidel, Arza (2004).

27:Equipment to separate liquids by distillation

630:Use of distillation columns in Oil & Gas

595:

564:Elementary Principles of Chemical Processes

472:

602:Seader, J. D.; Henley, Ernest J. (1998).

505:Perry, Robert H.; Green, Don W. (1984).

441:

439:

296:

288:

229:

221:

139:

101:, and vaporize again in accordance with

80:

68:

29:

586:

500:

498:

496:

494:

420:Unit Operations of Chemical Engineering

119:theoretical trays or theoretical plates

14:

677:

648:by Ming Tham, Newcastle University, UK

580:

436:

508:Perry's Chemical Engineers' Handbook

491:

85:Vigreux column in a laboratory setup

24:

25:

706:

623:

665:Distillation simulation software

562:Felder, R.; Roussea, W. (2005).

305:In industrial uses, sometimes a

149:Industrial fractionating columns

65:Laboratory fractionating columns

661:by the Distillation Group, USA

555:

525:

466:

411:

386:

34:Giant fractionating column of

13:

1:

646:Distillation, An Introduction

604:Separation Process Principles

589:Chemical Engineering Progress

511:(6th ed.). McGraw-Hill.

477:(2nd ed.). McGraw Hill.

452:(1st ed.). McGraw-Hill.

422:(7th ed.). McGraw Hill.

380:

7:

328:

10:

711:

111:Spinning band distillation

446:Kister, Henry Z. (1992).

53:is equipment used in the

284:vapor–liquid equilibrium

566:(3rd ed.). Wiley.

375:Fractional distillation

350:Extractive distillation

345:Continuous distillation

335:Azeotropic distillation

209:fractional distillation

154:Fractional distillation

40:Machine Sazi Arak (MSA)

533:"Distillation Columns"

319:structured sheet metal

302:

294:

235:

227:

174:natural gas processing

145:

86:

78:

42:

300:

292:

233:

225:

143:

84:

72:

33:

543:on 23 September 2015

475:Separation Processes

355:Laboratory glassware

265:McCabe–Thiele method

197:petroleum refineries

162:chemical engineering

47:fractionating column

640:Distillation Theory

606:. New York: Wiley.

473:King, C.J. (1980).

449:Distillation Design

370:Vacuum distillation

18:Distillation column

690:Chemical equipment

657:2014-07-13 at the

360:Steam distillation

340:Batch distillation

303:

295:

236:

228:

146:

87:

79:

43:

573:978-0-471-68757-3

365:Theoretical plate

280:equilibrium stage

51:fractional column

36:Arak Oil Refinery

16:(Redirected from

702:

618:

617:

599:

593:

592:

584:

578:

577:

559:

553:

552:

550:

548:

539:. Archived from

529:

523:

522:

502:

489:

488:

470:

464:

463:

443:

434:

433:

415:

409:

408:

390:

307:packing material

188:separation, and

75:Liebig condenser

38:manufactured by

21:

710:

709:

705:

704:

703:

701:

700:

699:

675:

674:

659:Wayback Machine

626:

621:

614:

600:

596:

585:

581:

574:

560:

556:

546:

544:

531:

530:

526:

519:

503:

492:

485:

471:

467:

460:

444:

437:

430:

416:

412:

405:

391:

387:

383:

331:

269:Fenske equation

158:unit operations

151:

67:

28:

23:

22:

15:

12:

11:

5:

708:

698:

697:

692:

687:

673:

672:

667:

662:

649:

643:

637:

632:

625:

624:External links

622:

620:

619:

612:

594:

579:

572:

554:

524:

517:

490:

483:

465:

458:

435:

428:

410:

403:

384:

382:

379:

378:

377:

372:

367:

362:

357:

352:

347:

342:

337:

330:

327:

203:, also called

201:boiling points

156:is one of the

150:

147:

91:Vigreux column

66:

63:

26:

9:

6:

4:

3:

2:

707:

696:

695:Fractionation

693:

691:

688:

686:

683:

682:

680:

671:

668:

666:

663:

660:

656:

653:

650:

647:

644:

641:

638:

636:

633:

631:

628:

627:

615:

613:0-471-58626-9

609:

605:

598:

590:

583:

575:

569:

565:

558:

542:

538:

534:

528:

520:

518:0-07-049479-7

514:

510:

509:

501:

499:

497:

495:

486:

484:0-07-034612-7

480:

476:

469:

461:

459:0-07-034909-6

455:

451:

450:

442:

440:

431:

429:0-07-284823-5

425:

421:

414:

406:

404:0-471-48810-0

400:

396:

389:

385:

376:

373:

371:

368:

366:

363:

361:

358:

356:

353:

351:

348:

346:

343:

341:

338:

336:

333:

332:

326:

324:

323:mass transfer

320:

316:

315:Raschig rings

312:

308:

299:

291:

287:

285:

281:

276:

272:

270:

266:

260:

256:

252:

248:

245:

240:

232:

224:

220:

216:

214:

213:fractionation

210:

206:

202:

198:

194:

191:

187:

186:liquefied air

183:

179:

175:

171:

170:petrochemical

167:

163:

159:

155:

142:

138:

136:

132:

128:

124:

120:

114:

112:

108:

104:

100:

96:

95:Raschig rings

92:

83:

76:

71:

62:

60:

56:

52:

48:

41:

37:

32:

19:

685:Distillation

652:Distillation

603:

597:

588:

582:

563:

557:

545:. Retrieved

541:the original

536:

527:

506:

474:

468:

447:

419:

413:

394:

388:

304:

277:

273:

261:

257:

253:

249:

241:

237:

217:

212:

208:

204:

180:processing,

172:production,

168:processing,

152:

127:steady-state

115:

107:condensation

105:. With each

103:Raoult's law

88:

55:distillation

50:

46:

44:

190:hydrocarbon

131:equilibrium

679:Categories

381:References

59:volatility

205:fractions

166:petroleum

135:condenser

123:refluxing

655:Archived

547:4 August

537:Brewhaus

329:See also

286:stages.

244:reboiler

193:solvents

178:coal tar

99:condense

267:or the

182:brewing

610:

570:

515:

481:

456:

426:

401:

311:vacuum

608:ISBN

568:ISBN

549:2015

513:ISBN

479:ISBN

454:ISBN

424:ISBN

399:ISBN

317:or

211:or

160:of

49:or

681::

535:.

493:^

438:^

215:.

184:,

176:,

45:A

616:.

591:.

576:.

551:.

521:.

487:.

462:.

432:.

407:.

77:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.