2687:. The lower part of the press contains a V-shaped groove called the die. The upper part of the press contains a punch that presses the sheet metal down into the v-shaped die, causing it to bend. There are several techniques used, but the most common modern method is "air bending". Here, the die has a sharper angle than the required bend (typically 85 degrees for a 90 degree bend) and the upper tool is precisely controlled in its stroke to push the metal down the required amount to bend it through 90 degrees. Typically, a general purpose machine has an available bending force of around 25 tons per meter of length. The opening width of the lower die is typically 8 to 10 times the thickness of the metal to be bent (for example, 5 mm material could be bent in a 40 mm die). The inner radius of the bend formed in the metal is determined not by the radius of the upper tool, but by the lower die width. Typically, the inner radius is equal to 1/6 of the V-width used in the forming process.

217:" later as manufacturers of the period did not use the term. The popularity of both shingles and ceilings encouraged widespread production. With further advances of steel sheet metal production in the 1890s, the promise of being cheap, durable, easy to install, lightweight and fireproof gave the middle-class a significant appetite for sheet metal products. It was not until the 1930s and WWII that metals became scarce and the sheet metal industry began to collapse. However, some American companies, such as the W.F. Norman Corporation, were able to stay in business by making other products until

2486:

38:

20:

2672:

2881:, splicing, etc. to make the final product we want (such as computer chassis, washing machine shells, refrigerator door panels, etc.), we generally called sheet metal fabrication. The academic community currently has no uniform definition, but this process has a common feature of the process is that the material is generally a thin sheet, and will not change the thickness of most of the material of the part.

2752:

371:

208:

Hand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The process of flattening metal sheets required large rotating iron cylinders which pressed metal pieces into sheets. The metals

2852:

The process of using an

English wheel is called wheeling. It is basically a metal working or metal forming process. An English wheel is used by a craftsperson to form compound curves from a flat sheet of metal of aluminium or steel. It is costly, as highly skilled labour is required. It can produce

2709:

Punching is performed by placing the sheet of metal stock between a punch and a die mounted in a press. The punch and die are made of hardened steel and are the same shape. The punch is sized to be a very close fit in the die. The press pushes the punch against and into the die with enough force to

2455:

The curling process is used to form an edge on a ring. This process is used to remove sharp edges. It also increases the moment of inertia near the curled end. The flare/burr should be turned away from the die. It is used to curl a material of specific thickness. Tool steel is generally used due to

2721:

has a choice of up to 60 tools in a "turret" that can be rotated to bring any tool to the punching position. A simple shape (e.g. a square, circle, or hexagon) is cut directly from the sheet. A complex shape can be cut out by making many square or rounded cuts around the perimeter. A punch is less

2694:

to position depth of the bend along the workpiece. The backgauge can be computer controlled to allow the operator to make a series of bends in a component to a high degree of accuracy. Simple machines control only the backstop, more advanced machines control the position and angle of the stop, its

356:

For forming limit curves of materials aluminium, mild steel and brass. Theoretical analysis is carried out by deriving governing equations for determining of equivalent stress and equivalent strain based on the bulging to be spherical and Tresca's yield criterion with the associated flow rule. For

2523:

and then stretching the sheet open in accordion-like fashion. It is used in applications where air and water flow are desired as well as when light weight is desired at cost of a solid flat surface. A similar process is used in other materials such as paper to create a low cost packing paper with

1862:

process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the

Manufacturer's Standard Gauge, which has no inherent tolerances.

424:

Use of gauge numbers to designate sheet metal thickness is discouraged by numerous international standards organizations. For example, ASTM states in specification ASTM A480-10a: "The use of gauge number is discouraged as being an archaic term of limited usefulness not having general agreement on

2621:

CNC laser involves moving a lens assembly carrying a beam of laser light over the surface of the metal. Oxygen, nitrogen or air is fed through the same nozzle from which the laser beam exits. The metal is heated and burnt by the laser beam, cutting the metal sheet. The quality of the edge can be

2644:

Photochemical machining, also known as photo etching, is a tightly controlled corrosion process which is used to produce complex metal parts from sheet metal with very fine detail. The photo etching process involves photo sensitive polymer being applied to a raw metal sheet. Using CAD designed

428:

Manufacturers' Standard Gauge for Sheet Steel is based on an average density of 41.82 lb per square foot per inch thick, equivalent to 501.84 pounds per cubic foot (8,038.7 kg/m). Gauge is defined differently for ferrous (iron-based) and non-ferrous metals (e.g. aluminium and brass).

352:

In sheet hydroforming, variation in incoming sheet coil properties is a common problem for forming process, especially with materials for automotive applications. Even though incoming sheet coil may meet tensile test specifications, high rejection rate is often observed in production due to

2598:

Ironing is a sheet metal working or sheet metal forming process. It uniformly thins the workpiece in a specific area. This is a very useful process. It is used to produce a uniform wall thickness part with a high height-to-diameter ratio. It is used in making aluminium beverage cans.

432:

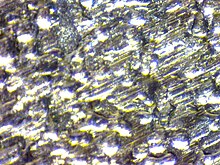

The gauge thicknesses shown in column 2 (U.S. standard sheet and plate iron and steel decimal inch (mm)) seem somewhat arbitrary. The progression of thicknesses is clear in column 3 (U.S. standard for sheet and plate iron and steel 64ths inch (delta)). The thicknesses vary first by

144:

process is adopted as needed to prevent it from rusting due to constant exposure to the outdoors. Sometimes a layer of color coating is applied to the surface of the cold-rolled sheet to obtain a decorative and protective metal sheet, generally called a color-coated metal sheet.

2695:

height and the position of the two reference pegs used to locate the material. The machine can also record the exact position and pressure required for each bending operation to allow the operator to achieve a perfect 90 degree bend across a variety of operations on the part.

85:) metals and nonferrous metals such as aluminum or copper. Copper thickness, for example, is measured in ounces, representing the weight of copper contained in an area of one square foot. Parts manufactured from sheet metal must maintain a uniform thickness for ideal results.

2617:

up to very large powered shears. With the advances in technology, sheet metal cutting has turned to computers for precise cutting. Many sheet metal cutting operations are based on computer numerically controlled (CNC) laser cutting or multi-tool CNC punch press.

2568:

to the workpiece or to a bladder that is in contact with the workpiece, rather than by the movable part of a die in a mechanical or hydraulic press. Unlike deep drawing, hydroforming usually does not involve draw reductions—the piece is formed in a single step.

2501:, etc. Deep drawing is generally done in multiple steps called draw reductions. The greater the depth, the more reductions are required. Deep drawing may also be accomplished with fewer reductions by heating the workpiece, for example in sink manufacture.

2583:

Incremental sheet forming or ISF forming process is basically sheet metal working or sheet metal forming process. In this case, sheet is formed into final shape by a series of processes in which small incremental deformation can be done in each series.

353:

inconsistent material behavior. Thus there is a strong need for a discriminating method for testing incoming sheet material formability. The hydraulic sheet bulge test emulates biaxial deformation conditions commonly seen in production operations.

2815:

Stamping includes a variety of operations such as punching, blanking, embossing, bending, flanging, and coining; simple or complex shapes can be formed at high production rates; tooling and equipment costs can be high, but labor costs are low.

386:. In particular, it does not explain the difference among the various gauge standards like Manufacturers' Standard Gauge, Standard Decimal Gauge, U.S. Standard Gauge, Birmingham Gage and British Standard Gauge and their appropriate application.

2714:, a coil of stock is fed into a long die/punch set with many stages. Multiple simple shaped holes may be produced in one stage, but complex holes are created in multiple stages. In the final stage, the part is punched free from the "web".

283:

is widely used in sheet metal form due to its flexibility, wide range of options, cost effectiveness, and other properties. The four most common aluminium grades available as sheet metal are 1100-H14, 3003-H14, 5052-H32, and 6061-T6.

2771:

Rolling is metal working or metal forming process. In this method, stock passes through one or more pair of rolls to reduce thickness. It is used to make thickness uniform. It is classified according to its temperature of rolling:

2622:

mirror smooth and a precision of around 0.1 mm (0.0039 in) can be obtained. Cutting speeds on thin 1.2 mm (0.047 in) sheet can be as high as 25 m (82 ft) per minute. Most laser cutting systems use a CO

2801:). Rollers or rigid tools press the stock against the form, stretching it until the stock takes the shape of the form. Spinning is used to make rocket motor casings, missile nose cones, satellite dishes and metal kitchen funnels.

2470:

It is a metal working process of removing camber, the horizontal bend, from a strip shaped material. It may be done to a finite length section or coils. It resembles flattening of leveling process, but on a deformed edge.

340:

is a common heat-treated structural aluminium alloy. It is weldable, corrosion resistant, and stronger than 5052, but not as formable. It loses some of its strength when welded. It is used in modern aircraft structures.

2837:

A water jet cutter, also known as a waterjet, is a tool capable of a controlled erosion into metal or other materials using a jet of water at high velocity and pressure, or a mixture of water and an abrasive substance.

271:

Grade 430 is a popular grade, low-cost alternative to series 300's grades. This is used when high corrosion resistance is not a primary criterion. Common grade for appliance products, often with a brushed finish.

476:

Some steel tubes are manufactured by folding a single steel sheet into a square/circle and welding the seam together. Their wall thickness has a similar (but distinct) gauge to the thickness of steel sheets.

3167:

Baptiste, R., Clark, D.L. and Matin, P., 2017, June. Designing a Strain

Measurement System based on Circle Grid Analysis for Sheet Metal Forming Applications. In 2017 ASEE Annual Conference & Exposition.

2504:

In many cases, material is rolled at the mill in both directions to aid in deep drawing. This leads to a more uniform grain structure which limits tearing and is referred to as "draw quality" material.

77:

In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its

329:

Grade 5052-H32 is much stronger than 3003 while still maintaining good formability. It maintains high corrosion resistance and weldability. Common applications include electronic chassis, tanks, and

2659:

Perforating is a cutting process that punches multiple small holes close together in a flat workpiece. Perforated sheet metal is used to make a wide variety of surface cutting tools, such as the

2412:

213:." Sheet metals appeared in the United States in the 1870s, being used for shingle roofing, stamped ornamental ceilings, and exterior façades. Sheet metal ceilings were only popularly known as "

2722:

flexible than a laser for cutting compound shapes, but faster for repetitive shapes (for example, the grille of an air-conditioning unit). A CNC punch can achieve 600 strokes per minute.

349:

Brass is an alloy of copper, which is widely used as a sheet metal. It has more strength, corrosion resistance and formability when compared to copper while retaining its conductivity.

209:

suited for this were lead, copper, zinc, iron and later steel. Tin was often used to coat iron and steel sheets to prevent it from rusting. This tin-coated sheet metal was called "

2542:

Hemming is a process of folding the edge of sheet metal onto itself to reinforce that edge. Seaming is a process of folding two sheets of metal together to form a joint.

3386:"The influence of the laser and plasma traverse cutting speed process parameter on the cut-edge characteristics and durability of Yellow Goods vehicle applications"

2497:. In deep drawing the depth of the part being made is more than half its diameter. Deep drawing is used for making automotive fuel tanks, kitchen sinks, two-piece

2557:

81:. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Gauge differs between ferrous (

3347:

3551:

3649:

298:

Grade 3003-H14 is stronger than 1100, while maintaining the same formability and low cost. It is corrosion resistant and weldable. It is often used in

200:. Sheet metal workers are also known as "tin bashers" (or "tin knockers"), a name derived from the hammering of panel seams when installing tin roofs.

3179:"ASTM A480/A480M-13b Standard Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip"

3041:

3536:

3611:

2725:

A typical component (such as the side of a computer case) can be cut to high precision from a blank sheet in under 15 seconds by either a

2645:

photo-tools as stencils, the metal is exposed to UV light to leave a design pattern, which is developed and etched from the metal sheet.

2993:

3264:

3093:

70:

Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a

3642:

3520:

3024:

3570:

3152:

2359:

2955:

3304:

249:

Grade 316 possesses more corrosion resistance and strength at elevated temperatures than 304. It is commonly used for

172:

for buildings (architecture), and many other applications. Sheet metal of iron and other materials with high magnetic

3635:

3604:

3501:

3111:

2987:

2743:

A continuous bending operation for producing open profiles or welded tubes with long lengths or in large quantities.

411:

3182:

2710:

cut a hole in the stock. In some cases the punch and die "nest" together to create a depression in the stock. In

173:

291:

and weldable, but has low strength. It is commonly used in chemical processing equipment, light reflectors, and

287:

Grade 1100-H14 is commercially pure aluminium, highly chemical and weather resistant. It is ductile enough for

3340:

3555:

2797:

Spinning is used to make tubular (axis-symmetric) parts by fixing a piece of sheet stock to a rotating form (

3962:

3663:

3597:

2519:

Expanding is a process of cutting or stamping slits in alternating pattern much like the stretcher bond in

2556:

Hydroforming is a process that is analogous to deep drawing, in that the part is formed by stretching the

63:, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of

234:

Grade 304 is the most common of the three grades. It offers good corrosion resistance while maintaining

2915:

264:

stainless steel, but it has a lower corrosion resistance than the other grades. It is commonly used in

169:

3584:

2578:

2426:

3879:

3720:

389:

3931:

3750:

3725:

3715:

3488:

2847:

2810:

2639:

299:

2820:

132:). These metal sheets are processed through different processing technologies, mainly including

3957:

3775:

3770:

3710:

3705:

3659:

2862:

2760:

2680:

2593:

2450:

2349:

1859:

307:

157:

3208:

2853:

different panels by the same method. A stamping press is used for high numbers in production.

2977:

2926:

218:

141:

3760:

3260:

2910:

2711:

2683:

used to produce long, thin sheet metal parts. The machine that bends the metal is called a

2565:

2514:

337:

8:

2561:

2533:

2494:

381:

315:

3097:

2630:; some more recent systems use a YAG based laser with a wavelength of around 1 μm.

2485:

3530:

2537:

257:, chemical equipment, and marine applications. Available finishes are #2B, #3, and #4.

165:

2766:

177:

3906:

3901:

3836:

3730:

3679:

3516:

3497:

3405:

3020:

2983:

2898:

2782:

Warm rolling: In this temperature is used is in between Hot rolling and cold rolling.

78:

30:

25:

3493:

3397:

2890:

2874:

2832:

393:

323:

185:

64:

3385:

37:

3811:

3755:

3401:

3308:

3156:

3149:

330:

153:

3513:

Building

Victory: Aircraft Manufacturing in the Los Angeles Area in World War II

2861:

The use of sheet metal, through a comprehensive cold working process, including

3859:

3780:

2792:

303:

3235:

2564:. The force required is generated by the direct application of extremely high

3951:

3854:

3849:

3409:

2921:

2870:

2726:

2608:

357:

experimentation circular grid analysis is one of the most effective methods.

261:

243:

71:

3042:"Historic Decorative Metal Ceilings and Walls: Use, Repair, and Replacement"

2493:

Drawing is a forming process in which the metal is stretched over a form or

2437:

are the length and thickness of the sheet metal, respectively. The variable

3790:

3745:

3620:

2738:

2718:

2551:

2498:

2480:

319:

288:

214:

149:

133:

88:

There are many different metals that can be made into sheet metal, such as

56:

19:

3178:

2936:

2931:

2779:

Cold rolling: In this temperature is below recrystallisation temperature.

2684:

2654:

2465:

239:

235:

189:

181:

137:

55:

Thicknesses can vary significantly; extremely thin sheets are considered

2776:

Hot rolling: in this temperature is above recrystallisation temperature.

3926:

3921:

3684:

2691:

2421:

is a factor taking into account several parameters including friction.

311:

197:

196:, and sheet metal continues to have many decorative uses, including in

60:

3017:

Cheap, Quick, & Easy: Imitative

Architectural Materials, 1870-1930

3916:

3911:

3844:

3821:

3735:

2614:

2520:

280:

89:

2979:

Wobblies, pile butts, and other heroes : laborlore explorations

2671:

3765:

2866:

2704:

210:

161:

129:

125:

113:

3936:

3896:

3874:

3869:

3826:

3806:

3785:

3740:

2798:

2660:

292:

265:

193:

52:

formed into thin, flat pieces, usually by an industrial process.

3864:

3589:

2613:

Sheet metal can be cut in various ways, from hand tools called

443:

inch in higher thicknesses and then step down to increments of

246:

are #2B, #3, and #4. Grade 303 is not available in sheet form.

117:

109:

97:

3816:

2894:

2878:

2751:

254:

101:

93:

49:

2823:

have low tooling and equipment costs, but high labor costs.

2627:

250:

121:

116:. For decorative uses, some important sheet metals include

82:

2354:

The equation for estimating the maximum bending force is,

2889:

Fasteners that are commonly used on sheet metal include:

105:

3019:. Knoxville: University of Tennessee Press. p. 31.

463:

inch, with the final increments at decimal fractions of

3657:

2626:

based laser source with a wavelength of around 10

188:. Historically, an important use of sheet metal was in

221:

projects aided the revival of ornamental sheet metal.

2362:

2982:. Urbana u.a.: Univ. of Illinois Press. p. 20.

2524:

better supportive properties than flat paper alone.

2407:{\displaystyle F_{\text{max}}=k{\frac {TLt^{2}}{W}}}

2406:

3314:Standard gauge for sheet and plate iron and steel

3949:

3263:. University of North Carolina at Chapel Hill.

3580:. Sachiya Steel International. September 2023.

41:Microscopic close-up of mild steel sheet metal

3643:

3605:

3323:

3321:

2572:

2441:is the open width of a V-die or wiping die.

392:. There might be a discussion about this on

128:(platinum sheet metal is also utilized as a

3284:

3282:

3650:

3636:

3612:

3598:

3535:: CS1 maint: location missing publisher (

3112:"Sustainability of Aluminium in Buildings"

2856:

2633:

3318:

3096:. precisionsheetmetal.com. Archived from

412:Learn how and when to remove this message

3585:Milestones in the History of Sheet Metal

3486:Oberg, Erik; Jones, Franklin D. (2004).

3279:

3137:Central Steel & Wire Company Catalog

2750:

2670:

2484:

36:

18:

3258:

3014:

2956:"Design Guide: Sheet Metal Fabrication"

2203:Stainless steel sheet metal tolerances

3950:

3552:"Manufacturers Standard Gauge History"

3383:

3341:"ASTM-AISI Thickness Tolerance Ranges"

3088:

3086:

2918:, also known as Corrugated Sheet Metal

2819:Alternatively, the related techniques

2666:

2527:

2456:the amount of wear done by operation.

3631:

3593:

3554:. Steel Market Update. Archived from

3299:

3297:

3230:

3228:

3084:

3082:

3080:

3078:

3076:

3074:

3072:

3070:

3068:

3066:

3039:

2975:

268:. The only available finish is dull.

3571:"Sheet Steel Gauges and Thicknesses"

2826:

2338:

364:

2690:The press usually has some sort of

150:automobile and truck (lorry) bodies

16:Metal formed into thin, flat pieces

13:

3390:Journal of Manufacturing Processes

3353:from the original on 5 August 2012

3294:

3225:

3063:

2767:Tinplate § Strip mill process

229:

14:

3974:

3544:

3384:Thomas, Daniel J. (August 2011).

3267:from the original on 19 July 2013

3139:(2006–2008 ed.), p. 151

2996:from the original on 14 July 2015

2045:Aluminium sheet metal tolerances

3619:

3185:from the original on 2014-02-22.

3150:All Metal Construction Made Easy

3117:. European Aluminium Association

2755:Bending sheet metal with rollers

2602:

369:

3479:

3464:

3452:

3440:

3428:

3416:

3377:

3365:

3333:

3252:

3201:

3189:

3171:

2732:

2545:

2474:

3261:"Sheet Metal Thickness Gauges"

3259:Rowlett, Ross (26 July 2002).

3161:

3143:

3129:

3104:

3033:

3008:

2969:

2948:

2648:

2459:

1:

2942:

2675:Forming metal on a pressbrake

2201:

2043:

1867:Steel sheet metal tolerances

1865:

1853:

3402:10.1016/j.jmapro.2011.02.002

2884:

2508:

1846:

1843:

1840:

1837:

1834:

1817:

1814:

1811:

1808:

1805:

1788:

1785:

1782:

1779:

1776:

1759:

1756:

1753:

1750:

1747:

1730:

1727:

1724:

1721:

1718:

1701:

1698:

1695:

1692:

1689:

1672:

1669:

1666:

1663:

1660:

1643:

1637:

1614:

1608:

1585:

1579:

1556:

1550:

1527:

1521:

1498:

1492:

1469:

1463:

935:

909:

906:

886:

880:

877:

857:

851:

848:

828:

822:

819:

802:

799:

793:

790:

787:

773:

770:

764:

761:

758:

744:

741:

735:

732:

729:

715:

712:

706:

703:

700:

686:

683:

680:

677:

674:

671:

657:

654:

651:

648:

645:

642:

628:

625:

622:

619:

616:

613:

599:

596:

593:

590:

587:

584:

570:

567:

564:

561:

558:

555:

481:Standard sheet metal gauges

275:

224:

7:

3510:

3492:(27th ed.). New York:

3470:

3458:

3446:

3434:

3422:

3371:

3209:"How Is Steel Tubing Made?"

3015:Simpson, Pamela H. (1999).

2904:

2841:

2804:

2786:

2698:

1067:

1038:

1009:

10:

3979:

3485:

3327:

3288:

3240:Tech Steel & Materials

3195:

2916:Corrugated galvanised iron

2845:

2830:

2808:

2790:

2764:

2758:

2746:

2736:

2702:

2652:

2637:

2606:

2591:

2587:

2576:

2549:

2531:

2512:

2489:Example of deep drawn part

2478:

2463:

2448:

2444:

2347:

2343:

980:

951:

922:

893:

203:

29:stainless steel cover the

3892:

3835:

3799:

3698:

3672:

3627:

2579:Incremental sheet forming

2573:Incremental sheet forming

2427:ultimate tensile strength

2211:

2207:

2053:

2049:

3721:Electrohydraulic forming

3473:, pp. 17, 22, 29–30, 117

2729:or a laser CNC machine.

360:

344:

3726:Electromagnetic forming

2857:Sheet metal fabrication

2640:Photochemical machining

2634:Photochemical machining

2238:0.031–0.041 (0.79–1.04)

2227:0.017–0.030 (0.43–0.76)

2091:0.037–0.045 (0.94–1.14)

2080:0.029–0.036 (0.74–0.91)

2069:0.018–0.028 (0.46–0.71)

148:Sheet metal is used in

3711:Casting (metalworking)

3181:. ASTM International.

3094:"Sheet metal material"

2976:Green, Archie (1993).

2756:

2676:

2490:

2408:

180:, has applications in

42:

34:

3932:Tools and terminology

3040:Staveteig, Kaaren R.

2927:Forming limit diagram

2754:

2674:

2488:

2409:

2326:0.147–0.187 (3.7–4.7)

2315:0.132–0.146 (3.4–3.7)

2304:0.116–0.131 (2.9–3.3)

2293:0.100–0.115 (2.5–2.9)

2282:0.085–0.099 (2.2–2.5)

2271:0.074–0.084 (1.9–2.1)

2260:0.060–0.073 (1.5–1.9)

2249:0.042–0.059 (1.1–1.5)

2190:0.204–0.249 (5.2–6.3)

2179:0.173–0.203 (4.4–5.2)

2168:0.141–0.172 (3.6–4.4)

2157:0.126–0.140 (3.2–3.6)

2146:0.109–0.125 (2.8–3.2)

2135:0.097–0.108 (2.5–2.7)

2124:0.077–0.096 (2.0–2.4)

2113:0.069–0.076 (1.8–1.9)

2102:0.046–0.068 (1.2–1.7)

219:Historic preservation

178:laminated steel cores

40:

22:

3761:Progressive stamping

3489:Machinery's Handbook

2911:Circle grid analysis

2821:repoussé and chasing

2712:progressive stamping

2566:hydrostatic pressure

2515:Expanded sheet metal

2360:

382:confusing or unclear

3963:Fabrication (metal)

3837:Finishing processes

3346:. CoyoteSteel.com.

3236:"Tube Sizing Chart"

3049:Preservation Briefs

2667:Press brake forming

2534:Hemming and seaming

2528:Hemming and seaming

2204:

2046:

1868:

504:64ths inch (delta)

500:for sheet and plate

491:for sheet and plate

482:

390:clarify the article

158:fuselages and wings

142:hot-dip galvanizing

3155:2012-02-18 at the

2899:sheet metal screws

2757:

2679:This is a form of

2677:

2560:over a stationary

2538:Automotive Hemming

2491:

2404:

2202:

2044:

1866:

495:decimal inch (mm)

480:

43:

35:

3945:

3944:

3888:

3887:

3800:Joining processes

3731:Explosive forming

3699:Forming processes

3578:Sheet Steel Facts

3522:978-0-9897906-0-4

3026:978-1-62190-157-0

2875:water jet cutting

2833:Water jet cutting

2827:Water jet cutting

2402:

2370:

2339:Forming processes

2336:

2335:

2200:

2199:

2042:

2041:

1851:

1850:

422:

421:

414:

186:electric machines

31:Chrysler Building

3970:

3667:

3652:

3645:

3638:

3629:

3628:

3614:

3607:

3600:

3591:

3590:

3581:

3575:

3566:

3564:

3563:

3540:

3534:

3526:

3507:

3494:Industrial Press

3474:

3468:

3462:

3456:

3450:

3444:

3438:

3432:

3426:

3420:

3414:

3413:

3381:

3375:

3369:

3363:

3362:

3360:

3358:

3352:

3345:

3337:

3331:

3325:

3316:

3311:

3301:

3292:

3286:

3277:

3276:

3274:

3272:

3256:

3250:

3249:

3247:

3246:

3232:

3223:

3222:

3220:

3219:

3205:

3199:

3193:

3187:

3186:

3175:

3169:

3165:

3159:

3147:

3141:

3140:

3133:

3127:

3126:

3124:

3122:

3116:

3108:

3102:

3101:

3090:

3061:

3060:

3058:

3056:

3046:

3037:

3031:

3030:

3012:

3006:

3005:

3003:

3001:

2973:

2967:

2966:

2960:

2952:

2413:

2411:

2410:

2405:

2403:

2398:

2397:

2396:

2380:

2372:

2371:

2368:

2205:

2047:

1869:

516:Galvanized steel

483:

479:

472:

471:

467:

462:

461:

457:

452:

451:

447:

442:

441:

437:

417:

410:

406:

403:

397:

373:

372:

365:

331:pressure vessels

176:, also known as

154:major appliances

65:structural steel

3978:

3977:

3973:

3972:

3971:

3969:

3968:

3967:

3948:

3947:

3946:

3941:

3884:

3831:

3795:

3756:Press hardening

3694:

3668:

3666:, and finishing

3658:

3656:

3623:

3618:

3573:

3569:

3561:

3559:

3550:

3547:

3528:

3527:

3523:

3515:. Cypress, CA.

3511:Parker (2013).

3504:

3482:

3477:

3469:

3465:

3457:

3453:

3445:

3441:

3433:

3429:

3421:

3417:

3382:

3378:

3370:

3366:

3356:

3354:

3350:

3343:

3339:

3338:

3334:

3326:

3319:

3303:

3302:

3295:

3287:

3280:

3270:

3268:

3257:

3253:

3244:

3242:

3234:

3233:

3226:

3217:

3215:

3207:

3206:

3202:

3194:

3190:

3177:

3176:

3172:

3166:

3162:

3157:Wayback Machine

3148:

3144:

3135:

3134:

3130:

3120:

3118:

3114:

3110:

3109:

3105:

3092:

3091:

3064:

3054:

3052:

3044:

3038:

3034:

3027:

3013:

3009:

2999:

2997:

2990:

2974:

2970:

2958:

2954:

2953:

2949:

2945:

2907:

2887:

2859:

2850:

2844:

2835:

2829:

2813:

2807:

2795:

2789:

2769:

2763:

2749:

2741:

2735:

2707:

2701:

2669:

2657:

2651:

2642:

2636:

2625:

2611:

2605:

2596:

2590:

2581:

2575:

2554:

2548:

2540:

2532:Main articles:

2530:

2517:

2511:

2483:

2477:

2468:

2462:

2453:

2447:

2392:

2388:

2381:

2379:

2367:

2363:

2361:

2358:

2357:

2352:

2346:

2341:

2222:

2218:

2209:

2086:0.0025 (0.064)

2075:0.0025 (0.064)

2064:

2060:

2051:

1884:

1880:

1876:

1856:

637:0.4063 (10.32)

608:0.4375 (11.11)

579:0.4688 (11.91)

550:0.5000 (12.70)

541:

536:

531:

529:

527:

522:

521:Stainless steel

517:

512:

511:for Sheet Steel

510:

509:Standard Gauge

508:

507:Manufacturers'

503:

502:iron and steel

501:

499:

494:

492:

490:

469:

465:

464:

459:

455:

454:

449:

445:

444:

439:

435:

434:

418:

407:

401:

398:

387:

374:

370:

363:

347:

278:

260:Grade 410 is a

232:

230:Stainless steel

227:

206:

17:

12:

11:

5:

3976:

3966:

3965:

3960:

3943:

3942:

3940:

3939:

3934:

3929:

3924:

3919:

3914:

3909:

3904:

3899:

3893:

3890:

3889:

3886:

3885:

3883:

3882:

3877:

3872:

3867:

3862:

3860:Mass finishing

3857:

3852:

3847:

3841:

3839:

3833:

3832:

3830:

3829:

3824:

3819:

3814:

3809:

3803:

3801:

3797:

3796:

3794:

3793:

3788:

3783:

3778:

3773:

3768:

3763:

3758:

3753:

3748:

3743:

3738:

3733:

3728:

3723:

3718:

3713:

3708:

3702:

3700:

3696:

3695:

3693:

3692:

3687:

3682:

3676:

3674:

3670:

3669:

3655:

3654:

3647:

3640:

3632:

3625:

3624:

3617:

3616:

3609:

3602:

3594:

3588:

3587:

3582:

3567:

3546:

3545:External links

3543:

3542:

3541:

3521:

3508:

3502:

3481:

3478:

3476:

3475:

3463:

3451:

3439:

3427:

3415:

3396:(2): 120–132.

3376:

3364:

3332:

3317:

3293:

3278:

3251:

3224:

3200:

3188:

3170:

3160:

3142:

3128:

3103:

3100:on 2009-06-15.

3062:

3032:

3025:

3007:

2988:

2968:

2946:

2944:

2941:

2940:

2939:

2934:

2929:

2924:

2919:

2913:

2906:

2903:

2886:

2883:

2858:

2855:

2846:Main article:

2843:

2840:

2831:Main article:

2828:

2825:

2809:Main article:

2806:

2803:

2793:Metal spinning

2791:Main article:

2788:

2785:

2784:

2783:

2780:

2777:

2759:Main article:

2748:

2745:

2737:Main article:

2734:

2731:

2717:A typical CNC

2703:Main article:

2700:

2697:

2668:

2665:

2653:Main article:

2650:

2647:

2638:Main article:

2635:

2632:

2623:

2607:Main article:

2604:

2601:

2592:Main article:

2589:

2586:

2577:Main article:

2574:

2571:

2550:Main article:

2547:

2544:

2529:

2526:

2513:Main article:

2510:

2507:

2479:Main article:

2476:

2473:

2464:Main article:

2461:

2458:

2449:Main article:

2446:

2443:

2429:of the metal.

2401:

2395:

2391:

2387:

2384:

2378:

2375:

2366:

2348:Main article:

2345:

2342:

2340:

2337:

2334:

2333:

2332:0.0105 (0.27)

2330:

2327:

2323:

2322:

2319:

2316:

2312:

2311:

2310:0.0075 (0.19)

2308:

2305:

2301:

2300:

2297:

2294:

2290:

2289:

2286:

2283:

2279:

2278:

2277:0.0055 (0.14)

2275:

2272:

2268:

2267:

2266:0.0045 (0.11)

2264:

2261:

2257:

2256:

2253:

2250:

2246:

2245:

2244:0.003 (0.076)

2242:

2239:

2235:

2234:

2233:0.002 (0.051)

2231:

2230:0.0015 (0.038)

2228:

2224:

2223:

2219:

2214:

2213:

2210:

2198:

2197:

2194:

2191:

2187:

2186:

2183:

2180:

2176:

2175:

2172:

2169:

2165:

2164:

2161:

2158:

2154:

2153:

2150:

2147:

2143:

2142:

2139:

2136:

2132:

2131:

2128:

2127:0.0035 (0.089)

2125:

2121:

2120:

2117:

2114:

2110:

2109:

2106:

2103:

2099:

2098:

2097:0.003 (0.076)

2095:

2094:0.0025 (0.064)

2092:

2088:

2087:

2084:

2081:

2077:

2076:

2073:

2070:

2066:

2065:

2061:

2056:

2055:

2052:

2040:

2039:

2038:0.0129 (0.33)

2036:

2033:

2030:

2026:

2025:

2024:0.0159 (0.40)

2022:

2019:

2016:

2012:

2011:

2010:0.0209 (0.53)

2008:

2005:

2002:

1998:

1997:

1996:0.0269 (0.68)

1994:

1991:

1988:

1984:

1983:

1982:0.0329 (0.84)

1980:

1977:

1974:

1970:

1969:

1968:0.0438 (1.11)

1966:

1963:

1960:

1956:

1955:

1954:0.0548 (1.39)

1952:

1949:

1946:

1942:

1941:

1940:0.0697 (1.77)

1938:

1935:

1932:

1928:

1927:

1926:0.0986 (2.50)

1924:

1921:

1918:

1914:

1913:

1912:0.1136 (2.89)

1910:

1907:

1904:

1900:

1899:

1898:0.1285 (3.26)

1896:

1893:

1890:

1886:

1885:

1881:

1877:

1873:

1855:

1852:

1849:

1848:

1845:

1842:

1839:

1836:

1833:

1830:

1829:0.400 (-0.025)

1827:

1826:0.0063 (0.16)

1824:

1820:

1819:

1816:

1813:

1810:

1807:

1804:

1801:

1800:0.425 (-0.025)

1798:

1797:0.0066 (0.17)

1795:

1791:

1790:

1787:

1784:

1781:

1778:

1775:

1772:

1769:

1768:0.0070 (0.18)

1766:

1762:

1761:

1758:

1755:

1752:

1749:

1746:

1743:

1740:

1739:0.0078 (0.20)

1737:

1733:

1732:

1729:

1726:

1723:

1720:

1717:

1714:

1711:

1710:0.0086 (0.22)

1708:

1704:

1703:

1700:

1697:

1694:

1691:

1688:

1685:

1682:

1681:0.0094 (0.24)

1679:

1675:

1674:

1671:

1668:

1665:

1662:

1659:

1656:

1653:

1652:0.0102 (0.26)

1650:

1646:

1645:

1642:

1639:

1636:

1633:

1630:

1627:

1624:

1623:0.0109 (0.28)

1621:

1617:

1616:

1613:

1610:

1607:

1604:

1601:

1598:

1595:

1594:0.0125 (0.32)

1592:

1588:

1587:

1584:

1581:

1578:

1575:

1572:

1569:

1566:

1565:0.0141 (0.36)

1563:

1559:

1558:

1555:

1552:

1549:

1546:

1543:

1540:

1537:

1536:0.0156 (0.40)

1534:

1530:

1529:

1526:

1523:

1520:

1517:

1514:

1511:

1508:

1507:0.0172 (0.44)

1505:

1501:

1500:

1497:

1494:

1491:

1488:

1485:

1482:

1479:

1478:0.0188 (0.48)

1476:

1472:

1471:

1468:

1465:

1462:

1459:

1456:

1453:

1450:

1449:0.0219 (0.56)

1447:

1443:

1442:

1439:

1436:

1433:

1430:

1427:

1424:

1421:

1420:0.0250 (0.64)

1418:

1414:

1413:

1410:

1407:

1404:

1401:

1398:

1395:

1392:

1391:0.0281 (0.71)

1389:

1385:

1384:

1381:

1378:

1375:

1372:

1369:

1366:

1363:

1362:0.0313 (0.80)

1360:

1356:

1355:

1352:

1349:

1346:

1343:

1340:

1337:

1334:

1333:0.0344 (0.87)

1331:

1327:

1326:

1323:

1320:

1317:

1316:0.0375 (0.95)

1314:

1311:

1308:

1305:

1304:0.0375 (0.95)

1302:

1298:

1297:

1294:

1291:

1288:

1285:

1282:

1279:

1276:

1275:0.0438 (1.11)

1273:

1269:

1268:

1265:

1262:

1259:

1258:0.0500 (1.27)

1256:

1253:

1250:

1247:

1246:0.0500 (1.27)

1244:

1240:

1239:

1236:

1233:

1230:

1227:

1224:

1221:

1218:

1217:0.0563 (1.43)

1215:

1211:

1210:

1207:

1204:

1201:

1200:0.0625 (1.59)

1198:

1195:

1192:

1189:

1188:0.0625 (1.59)

1186:

1182:

1181:

1178:

1175:

1172:

1169:

1166:

1163:

1160:

1159:0.0703 (1.79)

1157:

1153:

1152:

1149:

1146:

1143:

1142:0.0781 (1.98)

1140:

1137:

1134:

1131:

1130:0.0781 (1.98)

1128:

1124:

1123:

1120:

1117:

1114:

1111:

1108:

1105:

1102:

1101:0.0938 (2.38)

1099:

1095:

1094:

1091:

1088:

1085:

1084:0.1094 (2.78)

1082:

1079:

1076:

1073:

1072:0.1094 (2.78)

1070:

1066:

1065:

1062:

1059:

1056:

1055:0.1250 (3.18)

1053:

1050:

1047:

1044:

1043:0.1250 (3.18)

1041:

1037:

1036:

1033:

1030:

1027:

1026:0.1406 (3.57)

1024:

1021:

1018:

1015:

1014:0.1406 (3.57)

1012:

1008:

1007:

1004:

1001:

998:

997:0.1563 (3.97)

995:

992:

989:

986:

985:0.1563 (3.97)

983:

979:

978:

975:

972:

969:

968:0.1719 (4.37)

966:

963:

960:

957:

956:0.1719 (4.37)

954:

950:

949:

946:

943:

940:

939:0.1875 (4.76)

937:

934:

931:

928:

927:0.1875 (4.76)

925:

921:

920:

917:

914:

911:

908:

905:

902:

899:

898:0.2031 (5.16)

896:

892:

891:

888:

885:

882:

879:

876:

873:

870:

869:0.2188 (5.56)

867:

863:

862:

859:

856:

853:

850:

847:

844:

841:

840:0.2344 (5.95)

838:

834:

833:

830:

827:

824:

821:

818:

815:

812:

811:0.2500 (6.35)

809:

805:

804:

801:

798:

795:

792:

789:

786:

783:

782:0.2656 (6.75)

780:

776:

775:

772:

769:

766:

763:

760:

757:

754:

753:0.2813 (7.15)

751:

747:

746:

743:

740:

737:

734:

731:

728:

725:

724:0.3125 (7.94)

722:

718:

717:

714:

711:

708:

705:

702:

699:

696:

695:0.3438 (8.73)

693:

689:

688:

685:

682:

679:

676:

673:

670:

667:

666:0.3750 (9.53)

664:

660:

659:

656:

653:

650:

647:

644:

641:

638:

635:

631:

630:

627:

624:

621:

618:

615:

612:

609:

606:

602:

601:

598:

595:

592:

589:

586:

583:

580:

577:

573:

572:

569:

566:

563:

560:

557:

554:

551:

548:

544:

543:

538:

533:

524:

519:

514:

505:

496:

493:iron and steel

487:

420:

419:

377:

375:

368:

362:

359:

346:

343:

277:

274:

262:heat treatable

231:

228:

226:

223:

205:

202:

15:

9:

6:

4:

3:

2:

3975:

3964:

3961:

3959:

3958:Metal forming

3956:

3955:

3953:

3938:

3935:

3933:

3930:

3928:

3925:

3923:

3920:

3918:

3915:

3913:

3910:

3908:

3905:

3903:

3900:

3898:

3895:

3894:

3891:

3881:

3878:

3876:

3873:

3871:

3868:

3866:

3863:

3861:

3858:

3856:

3855:Heat treating

3853:

3851:

3848:

3846:

3843:

3842:

3840:

3838:

3834:

3828:

3825:

3823:

3820:

3818:

3815:

3813:

3810:

3808:

3805:

3804:

3802:

3798:

3792:

3789:

3787:

3784:

3782:

3779:

3777:

3774:

3772:

3769:

3767:

3764:

3762:

3759:

3757:

3754:

3752:

3749:

3747:

3744:

3742:

3739:

3737:

3734:

3732:

3729:

3727:

3724:

3722:

3719:

3717:

3714:

3712:

3709:

3707:

3704:

3703:

3701:

3697:

3691:

3688:

3686:

3683:

3681:

3678:

3677:

3675:

3671:

3665:

3661:

3653:

3648:

3646:

3641:

3639:

3634:

3633:

3630:

3626:

3622:

3615:

3610:

3608:

3603:

3601:

3596:

3595:

3592:

3586:

3583:

3579:

3572:

3568:

3558:on 2013-09-28

3557:

3553:

3549:

3548:

3538:

3532:

3524:

3518:

3514:

3509:

3505:

3503:0-8311-2700-7

3499:

3495:

3491:

3490:

3484:

3483:

3472:

3467:

3460:

3455:

3448:

3443:

3436:

3431:

3424:

3419:

3411:

3407:

3403:

3399:

3395:

3391:

3387:

3380:

3373:

3368:

3349:

3342:

3336:

3329:

3324:

3322:

3315:

3310:

3306:

3300:

3298:

3290:

3285:

3283:

3266:

3262:

3255:

3241:

3237:

3231:

3229:

3214:

3210:

3204:

3197:

3192:

3184:

3180:

3174:

3164:

3158:

3154:

3151:

3146:

3138:

3132:

3113:

3107:

3099:

3095:

3089:

3087:

3085:

3083:

3081:

3079:

3077:

3075:

3073:

3071:

3069:

3067:

3050:

3043:

3036:

3028:

3022:

3018:

3011:

2995:

2991:

2989:9780252019630

2985:

2981:

2980:

2972:

2964:

2957:

2951:

2947:

2938:

2935:

2933:

2930:

2928:

2925:

2923:

2922:Diamond plate

2920:

2917:

2914:

2912:

2909:

2908:

2902:

2900:

2896:

2892:

2882:

2880:

2876:

2872:

2871:laser cutting

2868:

2864:

2854:

2849:

2839:

2834:

2824:

2822:

2817:

2812:

2802:

2800:

2794:

2781:

2778:

2775:

2774:

2773:

2768:

2762:

2753:

2744:

2740:

2730:

2728:

2723:

2720:

2715:

2713:

2706:

2696:

2693:

2688:

2686:

2682:

2673:

2664:

2662:

2656:

2646:

2641:

2631:

2629:

2619:

2616:

2610:

2609:Laser cutting

2603:Laser cutting

2600:

2595:

2585:

2580:

2570:

2567:

2563:

2559:

2553:

2543:

2539:

2535:

2525:

2522:

2516:

2506:

2502:

2500:

2499:aluminum cans

2496:

2487:

2482:

2472:

2467:

2457:

2452:

2442:

2440:

2436:

2432:

2428:

2424:

2420:

2415:

2399:

2393:

2389:

2385:

2382:

2376:

2373:

2364:

2355:

2351:

2331:

2328:

2325:

2324:

2321:0.009 (0.23)

2320:

2317:

2314:

2313:

2309:

2306:

2303:

2302:

2299:0.007 (0.18)

2298:

2295:

2292:

2291:

2288:0.006 (0.15)

2287:

2284:

2281:

2280:

2276:

2273:

2270:

2269:

2265:

2263:0.003 (0.076)

2262:

2259:

2258:

2255:0.004 (0.10)

2254:

2252:0.003 (0.076)

2251:

2248:

2247:

2243:

2241:0.002 (0.051)

2240:

2237:

2236:

2232:

2229:

2226:

2225:

2220:

2216:

2215:

2206:

2196:0.011 (0.28)

2195:

2192:

2189:

2188:

2185:0.010 (0.25)

2184:

2181:

2178:

2177:

2174:0.008 (0.20)

2173:

2170:

2167:

2166:

2163:0.005 (0.13)

2162:

2160:0.0045 (0.11)

2159:

2156:

2155:

2152:0.005 (0.13)

2151:

2149:0.0045 (0.11)

2148:

2145:

2144:

2141:0.005 (0.13)

2140:

2137:

2134:

2133:

2130:0.004 (0.10)

2129:

2126:

2123:

2122:

2119:0.004 (0.10)

2118:

2116:0.003 (0.076)

2115:

2112:

2111:

2108:0.004 (0.10)

2107:

2105:0.003 (0.076)

2104:

2101:

2100:

2096:

2093:

2090:

2089:

2085:

2083:0.002 (0.051)

2082:

2079:

2078:

2074:

2072:0.002 (0.051)

2071:

2068:

2067:

2062:

2058:

2057:

2048:

2037:

2035:0.0169 (0.43)

2034:

2032:0.0149 (0.38)

2031:

2028:

2027:

2023:

2021:0.0199 (0.51)

2020:

2018:0.0179 (0.45)

2017:

2014:

2013:

2009:

2007:0.0269 (0.68)

2006:

2004:0.0239 (0.61)

2003:

2000:

1999:

1995:

1993:0.0329 (0.84)

1992:

1990:0.0299 (0.76)

1989:

1986:

1985:

1981:

1979:0.0389 (0.99)

1978:

1976:0.0359 (0.91)

1975:

1972:

1971:

1967:

1965:0.0518 (1.32)

1964:

1962:0.0478 (1.21)

1961:

1958:

1957:

1953:

1951:0.0648 (1.65)

1950:

1948:0.0598 (1.52)

1947:

1944:

1943:

1939:

1937:0.0797 (2.02)

1936:

1934:0.0747 (1.90)

1933:

1930:

1929:

1925:

1923:0.1106 (2.81)

1922:

1920:0.1046 (2.66)

1919:

1916:

1915:

1911:

1909:0.1256 (3.19)

1908:

1906:0.1196 (3.04)

1905:

1902:

1901:

1897:

1895:0.1405 (3.57)

1894:

1892:0.1345 (3.42)

1891:

1888:

1887:

1882:

1878:

1874:

1871:

1870:

1864:

1861:

1832:0.0060 (0.15)

1831:

1828:

1825:

1822:

1821:

1803:0.0064 (0.16)

1802:

1799:

1796:

1793:

1792:

1774:0.0067 (0.17)

1773:

1771:0.45 (-0.05)

1770:

1767:

1764:

1763:

1745:0.0075 (0.19)

1744:

1742:0.50 (-0.05)

1741:

1738:

1735:

1734:

1716:0.0082 (0.21)

1715:

1713:0.55 (-0.05)

1712:

1709:

1706:

1705:

1687:0.0090 (0.23)

1686:

1684:0.60 (-0.05)

1683:

1680:

1677:

1676:

1658:0.0097 (0.25)

1657:

1655:0.65 (-0.05)

1654:

1651:

1648:

1647:

1641:0.0089 (0.23)

1640:

1635:0.011 (0.28)

1634:

1632:0.0142 (0.36)

1631:

1629:0.0105 (0.27)

1628:

1625:

1622:

1619:

1618:

1612:0.0100 (0.25)

1611:

1606:0.013 (0.33)

1605:

1603:0.0157 (0.40)

1602:

1600:0.0120 (0.30)

1599:

1596:

1593:

1590:

1589:

1583:0.0113 (0.29)

1582:

1577:0.014 (0.36)

1576:

1574:0.0172 (0.44)

1573:

1571:0.0135 (0.34)

1570:

1567:

1564:

1561:

1560:

1554:0.0126 (0.32)

1553:

1548:0.016 (0.41)

1547:

1545:0.0187 (0.47)

1544:

1542:0.0149 (0.38)

1541:

1538:

1535:

1532:

1531:

1524:

1519:0.017 (0.43)

1518:

1516:0.0202 (0.51)

1515:

1513:0.0164 (0.42)

1512:

1509:

1506:

1503:

1502:

1495:

1490:0.019 (0.48)

1489:

1487:0.0217 (0.55)

1486:

1484:0.0179 (0.45)

1483:

1480:

1477:

1474:

1473:

1466:

1461:0.022 (0.56)

1460:

1458:0.0247 (0.63)

1457:

1455:0.0209 (0.53)

1454:

1451:

1448:

1445:

1444:

1440:

1437:

1434:

1432:0.025 (0.64)

1431:

1429:0.0276 (0.70)

1428:

1426:0.0239 (0.61)

1425:

1422:

1419:

1416:

1415:

1411:

1408:

1405:

1403:0.028 (0.71)

1402:

1400:0.0306 (0.78)

1399:

1397:0.0269 (0.68)

1396:

1393:

1390:

1387:

1386:

1382:

1379:

1376:

1374:0.031 (0.79)

1373:

1371:0.0336 (0.85)

1370:

1368:0.0299 (0.76)

1367:

1364:

1361:

1358:

1357:

1353:

1350:

1347:

1345:0.034 (0.86)

1344:

1342:0.0366 (0.93)

1341:

1339:0.0329 (0.84)

1338:

1335:

1332:

1329:

1328:

1324:

1322:0.0320 (0.81)

1321:

1318:

1315:

1313:0.0396 (1.01)

1312:

1310:0.0359 (0.91)

1309:

1306:

1303:

1300:

1299:

1295:

1292:

1289:

1286:

1284:0.0456 (1.16)

1283:

1281:0.0418 (1.06)

1280:

1277:

1274:

1271:

1270:

1266:

1264:0.0403 (1.02)

1263:

1260:

1257:

1255:0.0516 (1.31)

1254:

1252:0.0478 (1.21)

1251:

1248:

1245:

1242:

1241:

1237:

1234:

1231:

1228:

1226:0.0575 (1.46)

1225:

1223:0.0538 (1.37)

1222:

1219:

1216:

1213:

1212:

1208:

1206:0.0508 (1.29)

1205:

1202:

1199:

1197:0.0635 (1.61)

1196:

1194:0.0598 (1.52)

1193:

1190:

1187:

1184:

1183:

1179:

1176:

1173:

1170:

1168:0.0710 (1.80)

1167:

1165:0.0673 (1.71)

1164:

1161:

1158:

1155:

1154:

1151:0.036 (0.91)

1150:

1147:

1144:

1141:

1139:0.0785 (1.99)

1138:

1136:0.0747 (1.90)

1135:

1132:

1129:

1126:

1125:

1122:0.032 (0.81)

1121:

1118:

1115:

1112:

1110:0.0934 (2.37)

1109:

1107:0.0897 (2.28)

1106:

1103:

1100:

1097:

1096:

1093:0.028 (0.71)

1092:

1090:0.0808 (2.05)

1089:

1086:

1083:

1081:0.1084 (2.75)

1080:

1078:0.1046 (2.66)

1077:

1074:

1071:

1068:

1064:0.024 (0.61)

1063:

1061:0.0907 (2.30)

1060:

1057:

1054:

1052:0.1233 (3.13)

1051:

1049:0.1196 (3.04)

1048:

1045:

1042:

1039:

1035:0.020 (0.51)

1034:

1032:0.1019 (2.59)

1031:

1028:

1025:

1023:0.1382 (3.51)

1022:

1020:0.1345 (3.42)

1019:

1016:

1013:

1010:

1006:0.018 (0.46)

1005:

1003:0.1144 (2.91)

1002:

999:

996:

994:0.1532 (3.89)

993:

991:0.1495 (3.80)

990:

987:

984:

981:

977:0.016 (0.41)

976:

974:0.1285 (3.26)

973:

970:

967:

965:0.1681 (4.27)

964:

962:0.1644 (4.18)

961:

958:

955:

952:

948:0.014 (0.36)

947:

945:0.1443 (3.67)

944:

941:

938:

933:0.1793 (4.55)

932:

929:

926:

923:

919:0.012 (0.30)

918:

915:

912:

904:0.1943 (4.94)

903:

900:

897:

894:

890:0.010 (0.25)

889:

883:

875:0.2092 (5.31)

874:

871:

868:

865:

864:

861:0.008 (0.20)

860:

854:

846:0.2242 (5.69)

845:

842:

839:

836:

835:

832:0.006 (0.15)

831:

825:

817:0.2391 (6.07)

816:

813:

810:

807:

806:

796:

784:

781:

778:

777:

767:

755:

752:

749:

748:

738:

726:

723:

720:

719:

709:

697:

694:

691:

690:

668:

665:

662:

661:

639:

636:

633:

632:

610:

607:

604:

603:

581:

578:

575:

574:

552:

549:

546:

545:

539:

534:

525:

520:

515:

506:

498:U.S. standard

497:

489:U.S. standard

488:

485:

484:

478:

474:

430:

426:

416:

413:

405:

395:

394:the talk page

391:

385:

383:

378:This article

376:

367:

366:

358:

354:

350:

342:

339:

334:

332:

327:

325:

321:

317:

313:

309:

305:

301:

296:

294:

290:

285:

282:

273:

269:

267:

263:

258:

256:

252:

247:

245:

241:

237:

222:

220:

216:

212:

201:

199:

195:

191:

187:

183:

179:

175:

171:

167:

163:

159:

155:

151:

146:

143:

139:

135:

131:

127:

123:

119:

115:

111:

107:

103:

99:

95:

91:

86:

84:

80:

75:

73:

68:

66:

62:

58:

53:

51:

47:

39:

32:

28:

27:

21:

3791:Tube bending

3746:Hydroforming

3689:

3621:Metalworking

3577:

3560:. Retrieved

3556:the original

3512:

3487:

3480:Bibliography

3466:

3454:

3442:

3430:

3425:, pp. 29, 83

3418:

3393:

3389:

3379:

3374:, pp. 20, 85

3367:

3355:. Retrieved

3335:

3313:

3269:. Retrieved

3254:

3243:. Retrieved

3239:

3216:. Retrieved

3212:

3203:

3191:

3173:

3163:

3145:

3136:

3131:

3119:. Retrieved

3106:

3098:the original

3053:. Retrieved

3048:

3035:

3016:

3010:

2998:. Retrieved

2978:

2971:

2962:

2950:

2888:

2865:, shearing,

2860:

2851:

2836:

2818:

2814:

2796:

2770:

2742:

2739:Roll forming

2733:Roll forming

2724:

2719:turret punch

2716:

2708:

2689:

2678:

2658:

2643:

2620:

2612:

2597:

2582:

2555:

2552:Hydroforming

2546:Hydroforming

2541:

2518:

2503:

2492:

2481:Deep drawing

2475:Deep drawing

2469:

2454:

2438:

2434:

2430:

2422:

2418:

2416:

2356:

2353:

2329:0.007 (0.18)

2318:0.006 (0.15)

2307:0.005 (0.13)

2296:0.005 (0.13)

2285:0.004 (0.10)

2274:0.004 (0.10)

2212:Sheet width

2193:0.009 (0.23)

2182:0.007 (0.18)

2171:0.006 (0.15)

2138:0.004 (0.10)

2054:Sheet width

1857:

1525:0.014 (0.36)

1496:0.017 (0.43)

1467:0.018 (0.46)

1441:0.125 (3.2)

1435:0.022 (0.56)

1412:0.100 (2.5)

1409:0.023 (0.58)

1406:0.025 (0.64)

1383:0.090 (2.3)

1380:0.025 (0.64)

1377:0.028 (0.71)

1354:0.080 (2.0)

1351:0.028 (0.71)

1348:0.032 (0.81)

1325:0.070 (1.8)

1319:0.035 (0.89)

1296:0.060 (1.5)

1293:0.036 (0.91)

1287:0.044 (1.1)

1267:0.055 (1.4)

1238:0.050 (1.3)

1229:0.056 (1.4)

1209:0.045 (1.1)

1180:0.040 (1.0)

1113:0.094 (2.4)

475:

431:

427:

423:

408:

399:

388:Please help

379:

355:

351:

348:

335:

328:

297:

289:deep drawing

286:

279:

270:

259:

248:

242:. Available

233:

215:tin ceilings

207:

182:transformers

174:permeability

147:

140:. Sometimes

134:cold rolling

87:

76:

72:roll slitter

69:

54:

45:

44:

24:

3902:Fabrication

3850:Galvanizing

3690:Sheet metal

3680:Fabrication

3664:fabrication

2963:xometry.com

2937:Temper mill

2932:Strip steel

2685:press brake

2655:Perforation

2649:Perforating

2466:Decambering

2460:Decambering

2221:48 (1,219)

2217:36 (914.4)

2059:36 (914.4)

1858:During the

1626:0.7 (-0.1)

1597:0.8 (-0.1)

1568:0.9 (-0.1)

1539:1.0 (-0.1)

1510:1.1 (-0.1)

1481:1.2 (-0.2)

1452:1.4 (-0.2)

1438:0.02 (0.51)

1394:1.8 (-0.2)

1365:2.0 (-0.2)

1336:2.2 (-0.2)

1307:2.4 (-0.4)

1290:0.042 (1.1)

1278:2.8 (-0.4)

1261:0.049 (1.2)

1235:0.045 (1.1)

1232:0.058 (1.5)

1203:0.065 (1.7)

1191:4.0 (-0.5)

1177:0.057 (1.4)

1174:0.072 (1.8)

1171:0.07 (1.8)

1148:0.063 (1.6)

1145:0.083 (2.1)

1119:0.072 (1.8)

1116:0.095 (2.4)

1087:0.109 (2.8)

1058:0.120 (3.0)

1029:0.134 (3.4)

1000:0.148 (3.8)

971:0.165 (4.2)

942:0.180 (4.6)

916:0.162 (4.1)

913:0.203 (5.2)

884:0.220 (5.6)

855:0.238 (6.0)

826:0.259 (6.6)

797:0.284 (7.2)

768:0.300 (7.6)

739:0.340 (8.6)

710:0.380 (9.7)

526:Steel Tube

453:inch, then

240:weldability

236:formability

190:plate armor

156:, airplane

138:hot rolling

46:Sheet metal

3952:Categories

3922:Metallurgy

3865:Patination

3685:Piece work

3562:2013-06-19

3330:, p. 2502.

3309:§ 206

3245:2021-05-12

3218:2021-05-12

3198:, p. 2522.

2943:References

2765:See also:

2692:back gauge

2063:48 (1,219)

1854:Tolerances

1423:1.6 (-0.2)

1249:3.2 (-0.4)

1220:3.6 (-0.4)

1162:4.5 (-0.5)

542:inch (mm)

532:inch (mm)

530:Thickness

523:inch (mm)

425:meaning."

384:to readers

312:mail boxes

198:horse tack

83:iron-based

23:Sheets of

3917:Machining

3912:Jewellery

3880:Polishing

3845:Anodizing

3822:Soldering

3736:Extrusion

3531:cite book

3410:1526-6125

3305:15 U.S.C.

3291:, p. 387.

3213:Sciencing

3055:March 20,

3051:(49): 1–3

2885:Fasteners

2615:tin snips

2521:brickwork

2509:Expanding

2208:Thickness

2050:Thickness

537:inch (mm)

535:Aluminium

518:inch (mm)

513:inch (mm)

402:June 2013

300:stampings

281:Aluminium

276:Aluminium

225:Materials

90:aluminium

3927:Smithing

3817:Riveting

3812:Crimping

3781:Spinning

3766:Punching

3751:Stamping

3437:, p. 115

3348:Archived

3265:Archived

3183:Archived

3153:Archived

2994:Archived

2905:See also

2879:riveting

2867:punching

2848:Wheeling

2842:Wheeling

2811:Stamping

2805:Stamping

2787:Spinning

2705:Punching

2699:Punching

1875:Nominal

988:10 (-1)

959:11 (-1)

930:12 (-1)

901:13 (-1)

872:14 (-1)

843:15 (-1)

326:blades.

316:cabinets

244:finishes

211:tinplate

192:worn by

166:tin cans

162:tinplate

130:catalyst

126:platinum

114:titanium

3937:Welding

3907:Forming

3897:Casting

3875:Plating

3870:Peening

3827:Welding

3807:Brazing

3786:Swaging

3776:Sinking

3771:Rolling

3741:Forging

3716:Drawing

3706:Coining

3673:General

3660:Forming

3461:, p. 70

3449:, p. 89

3357:20 June

3271:21 June

3121:20 June

3000:14 July

2863:bending

2799:mandrel

2761:Rolling

2747:Rolling

2681:bending

2661:surform

2594:Ironing

2588:Ironing

2451:Curling

2445:Curling

2425:is the

2350:Bending

2344:Bending

1860:rolling

1847:......

1838:......

1818:......

1809:......

1789:......

1780:......

1760:......

1751:......

1731:......

1722:......

1702:......

1693:......

1673:......

1664:......

1644:......

1615:......

1586:......

1557:......

1528:......

1499:......

1470:......

1075:7 (-1)

1046:8 (-1)

1017:9 (-1)

910:......

881:......

852:......

823:......

814:16 (-1)

803:......

794:......

785:17 (-1)

774:......

765:......

756:18 (-2)

745:......

736:......

727:20 (-2)

716:......

707:......

698:22 (-2)

687:......

669:24 (-2)

658:......

640:26 (-2)

629:......

611:28 (-2)

600:......

582:30 (-2)

571:......

547:0000000

468:⁄

458:⁄

448:⁄

438:⁄

380:may be

338:6061-T6

310:parts,

293:jewelry

266:cutlery

204:History

194:cavalry

170:roofing

26:Nirosta

3519:

3500:

3471:Parker

3459:Parker

3447:Parker

3435:Parker

3423:Parker

3408:

3372:Parker

3307:

3023:

2986:

2897:, and

2895:rivets

2891:clecos

2417:where

1844:......

1841:......

1835:......

1815:......

1812:......

1806:......

1786:......

1783:......

1777:......

1757:......

1754:......

1748:......

1728:......

1725:......

1719:......

1699:......

1696:......

1690:......

1670:......

1667:......

1661:......

1638:......

1609:......

1580:......

1551:......

1522:......

1493:......

1464:......

1133:5 (-1)

1104:6 (-1)

936:......

907:......

887:......

878:......

858:......

849:......

829:......

820:......

800:......

791:......

788:......

771:......

762:......

759:......

742:......

733:......

730:......

713:......

704:......

701:......

684:......

681:......

678:......

675:......

672:......

655:......

652:......

649:......

646:......

643:......

626:......

623:......

620:......

617:......

614:......

597:......

594:......

591:......

588:......

585:......

576:000000

568:......

565:......

562:......

559:......

556:......

553:32 (-)

473:inch.

336:Grade

322:, and

255:valves

124:, and

118:silver

110:nickel

98:copper

3574:(PDF)

3351:(PDF)

3344:(PDF)

3328:Oberg

3289:Oberg

3196:Oberg

3115:(PDF)

3045:(PDF)

2959:(PDF)

2727:press

2558:blank

1872:Gauge

605:00000

528:Wall

486:Gauge

361:Gauge

345:Brass

320:tanks

308:drawn

251:pumps

102:steel

94:brass

79:gauge

50:metal

3537:link

3517:ISBN

3498:ISBN

3406:ISSN

3359:2013

3273:2013

3123:2013

3057:2019

3021:ISBN

3002:2015

2984:ISBN

2536:and

2433:and

1883:Min

634:0000

540:Zinc

306:and

304:spun

238:and

184:and

164:for

136:and

122:gold

112:and

61:leaf

57:foil

3398:doi

3168:p.3

2562:die

2495:die

2369:max

1879:Max

663:000

460:128

324:fan

106:tin

59:or

48:is

3954::

3662:,

3576:.

3533:}}

3529:{{

3496:.

3404:.

3394:13

3392:.

3388:.

3320:^

3312::

3296:^

3281:^

3238:.

3227:^

3211:.

3065:^

3047:.

2992:.

2961:.

2901:.

2893:,

2877:,

2873:,

2869:,

2663:.

2628:μm

2414:,

2029:28

2015:26

2001:24

1987:22

1973:20

1959:18

1945:16

1931:14

1917:12

1903:11

1889:10

1823:38

1794:37

1765:36

1736:35

1707:34

1678:33

1649:32

1620:31

1591:30

1562:29

1533:28

1504:27

1475:26

1446:25

1417:24

1388:23

1359:22

1330:21

1301:20

1272:19

1243:18

1214:17

1185:16

1156:15

1127:14

1098:13

1069:12

1040:11

1011:10

692:00

470:64

450:64

440:32

333:.

318:,

314:,

302:,

295:.

253:,

168:,

160:,

152:,

120:,

108:,

104:,

100:,

96:,

92:,

74:.

67:.

3651:e

3644:t

3637:v

3613:e

3606:t

3599:v

3565:.

3539:)

3525:.

3506:.

3412:.

3400::

3361:.

3275:.

3248:.

3221:.

3125:.

3059:.

3029:.

3004:.

2965:.

2624:2

2439:W

2435:t

2431:L

2423:T

2419:k

2400:W

2394:2

2390:t

2386:L

2383:T

2377:k

2374:=

2365:F

982:9

953:8

924:7

895:6

866:5

837:4

808:3

779:2

750:1

721:0

466:1

456:1

446:1

436:1

415:)

409:(

404:)

400:(

396:.

33:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.