217:

is highest. It is sent to another column rectifying the argon to the desired purity from which liquid is returned to the same location in the LP column. Use of modern structured packings which have very low pressure drops enable argon with less than 1 ppm impurities. Though argon is present in less to 1% of the incoming, the air argon column requires a significant amount of energy due to the high reflux ratio required (about 30) in the argon column. Cooling of the argon column can be supplied from cold expanded rich liquid or by liquid nitrogen.

243:

277:

106:

251:

126:

196:) and cooled against product (and waste) cryogenic streams. Part of the air liquefies to form a liquid that is enriched in oxygen. The remaining gas is richer in nitrogen and is distilled to almost pure nitrogen (typically < 1ppm) in a high pressure (HP) distillation column. The condenser of this column requires

287:

can provide alternate, lower-energy approaches to air separation. For example, a number of approaches are being explored for oxygen generation. Polymeric membranes operating at ambient or warm temperatures, for example, may be able to produce oxygen-enriched air (25-50% oxygen). Ceramic membranes can

216:

Because the boiling point of argon (87.3 K at standard conditions) lies between that of oxygen (90.2 K) and nitrogen (77.4 K), argon builds up in the lower section of the low pressure column. When argon is produced, a vapor side draw is taken from the low pressure column where the argon concentration

207:

Alternatively the condenser may be cooled by interchanging heat with a reboiler in a low pressure (LP) distillation column (operating at 1.2-1.3 bar abs.) when the ASU is producing pure oxygen. To minimize the compression cost the combined condenser/reboiler of the HP/LP columns must operate with a

291:

Membrane gas separation is used to provide oxygen-poor and nitrogen-rich gases instead of air to fill the fuel tanks of jet liners, thus greatly reducing the chances of accidental fires and explosions. Conversely, membrane gas separation is currently used to provide oxygen-enriched air to pilots

220:

Finally the products produced in gas form are warmed against the incoming air to ambient temperatures. This requires a carefully crafted heat integration that must allow for robustness against disturbances (due to switch over of the molecular sieve beds). It may also require additional external

288:

provide high-purity oxygen (90% or more) but require higher temperatures (800-900 deg C) to operate. These ceramic membranes include ion transport membranes (ITM) and oxygen transport membranes (OTM). Air

Products and Chemicals Inc and Praxair are developing flat ITM and tubular OTM systems.

184:

from the air, since these can be a problem in the subsequent air distillation that could lead to explosions. The molecular sieves bed must be regenerated. This is done by installing multiple units operating in alternating mode and using the dry co-produced waste gas to desorb the

208:

temperature difference of only 1-2 K, requiring plate fin brazed aluminium heat exchangers. Typical oxygen purities range in from 97.5% to 99.5% and influences the maximum recovery of oxygen. The refrigeration required for producing liquid products is obtained using the

596:

168:

state (gas or liquid) of the products. Typical pressures range between 5 and 10 bar gauge. The air stream may also be compressed to different pressures to enhance the efficiency of the ASU. During compression water is condensed out in inter-stage

133:

The cryogenic separation process requires a very tight integration of heat exchangers and separation columns to obtain a good efficiency and all the energy for refrigeration is provided by the compression of the air at the inlet of the unit.

121:

in the early 20th century and is still used today to produce high purity gases. He developed it in the year 1895; the process remained purely academic for seven years before it was used in industrial applications for the first time (1902).

295:

Oxygen-enriched air can be obtained exploiting the different solubility of oxygen and nitrogen. Oxygen is more soluble than nitrogen in water, so if air is degassed from water, a stream of 35% oxygen can be obtained.

688:

Galli, F; Comazzi, A; Previtali, D; Manenti, F; Bozzano, G; Bianchi, C. L.; Pirola, C (2017). "Production of oxygen-enriched air via desorption from water: Experimental data, simulations and economic assessment".

225:

The separated products are sometimes supplied by pipeline to large industrial users near the production plant. Long distance transportation of products is by shipping liquid product for large quantities or as

212:

in an expander which feeds compressed air directly to the low pressure column. Hence, a certain part of the air is not to be separated and must leave the low pressure column as a waste stream from its upper

265:(molecular sponge) is exposed to high pressure air, then the air is released and an adsorbed film of the desired gas is released. The size of compressor is much reduced over a liquefaction plant, and

717:

744:

149:

enclosure (commonly called a "cold box"). The cooling of the gases requires a large amount of energy to make this refrigeration cycle work and is delivered by an air

492:

117:

the components at their various boiling temperatures. The process can produce high purity gases but is energy-intensive. This process was pioneered by

157:

for cooling; the output of the expander helps drive the air compressor, for improved efficiency. The process consists of the following main steps:

50:. Cryogenic air separation units (ASUs) are built to provide nitrogen or oxygen and often co-produce argon. Other methods such as membrane,

451:

569:

Castle, W. F. (2002). "Air separation and liquefaction: Recent developments and prospects for the beginning of the new millennium".

261:

provides separation of oxygen or nitrogen from air without liquefaction. The process operates around ambient temperature; a

373:

Inerting with nitrogen storage tanks of ships and tanks for petroleum products, or for protecting edible oil products from

783:

754:

834:

746:

Innovations in

Industrial and Engineering Chemistry: A Century of Achievements and Prospects for the New Millennium

499:

71:

180:, which would freeze and plug the cryogenic equipment. Molecular sieves are often designed to remove any gaseous

844:

626:

Fainshtein, V. I. (2007). "Provision of explosion proof air separation units under contemporary conditions".

266:

542:

Agrawal, R. (1996). "Synthesis of

Distillation Column Configurations for a Multicomponent Separation".

854:

849:

258:

51:

334:

209:

193:

142:

200:

which is obtained from expanding the more oxygen rich stream further across a valve or through an

839:

406:

284:

270:

227:

55:

47:

479:

273:

is a similar process; the product gas is evolved from the zeolite at sub-atmospheric pressure.

113:

Pure gases can be separated from air by first cooling it until it liquefies, then selectively

416:

819:

386:

58:(VPSA) are commercially used to separate a single component from ordinary air. High purity

337:

process. Modern basic oxygen steelmaking uses almost two tons of oxygen per ton of steel.

8:

620:

Particulate matter from forest fires caused an explosion in the air separation unit of a

426:

391:

138:

90:

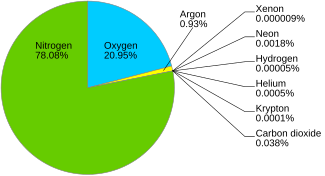

24:

164:

Air is compressed where the final delivery pressure is determined by recoveries and the

643:

146:

702:

674:

582:

779:

772:

750:

647:

362:

698:

670:

635:

578:

551:

411:

374:

173:

137:

To achieve the low distillation temperatures, an air separation unit requires a

401:

396:

365:

projects; cryogenic plants producing 3000 tons/day are found in some projects.

242:

189:

177:

150:

118:

639:

276:

828:

621:

431:

346:

269:

are made in this manner to provide oxygen-enriched air for medical purposes.

201:

197:

154:

231:

181:

114:

74:, require cryogenic distillation. Similarly, the only viable source of the

330:

421:

75:

555:

40:

743:

Flank, William H.; Abraham, Martin A.; Matthews, Michael A. (2009).

498:. Institution of Chemical Engineers. September 2010. Archived from

321:

Pure oxygen is delivered to large hospitals for use with patients.

63:

28:

292:

flying at great altitudes in aircraft without pressurized cabins.

350:

262:

82:

310:

94:

59:

32:

105:

165:

86:

67:

36:

801:

687:

250:

770:

Wingate, Philippa; Gifford, Clive; Treays, Rebecca (1992).

661:

Vinson, D. R. (2006). "Air separation control technology".

78:

790:

liquid

Nitrogen used in the Haber process to make ammonia.

176:

bed, which removes any remaining water vapour, as well as

125:

97:

is also recovered in advanced air separation processes.

129:

Distillation column in a cryogenic air separation plant

802:

Higman, Christopher; van der Burgt, Maarten (2008).

769:

742:

718:"Messer to build $ 50 million gas plant in McGregor"

589:

161:

Before compression the air is pre-filtered of dust.

771:

145:, and the cold equipment has to be kept within an

100:

826:

544:Industrial & Engineering Chemistry Research

523:Latimer, R. E. (1967). "Distillation of Air".

172:The process air is generally passed through a

89:is the distillation of air using at least two

46:The most common method for air separation is

709:

188:Process air is passed through an integrated

625:

237:

361:Large amounts of oxygen are required for

275:

249:

241:

124:

104:

541:

522:

27:into its primary components, typically

827:

806:(2nd ed.). Elsevier. p. 324.

660:

571:International Journal of Refrigeration

568:

715:

691:Computers & Chemical Engineering

663:Computers & Chemical Engineering

309:Liquid oxygen for companies such as

820:Simulation of air separation plants

485:

13:

628:Chemical and Petroleum Engineering

109:Composition of dry atmospheric air

14:

866:

813:

703:10.1016/j.compchemeng.2016.07.031

675:10.1016/j.compchemeng.2006.05.038

449:

72:semiconductor device fabrication

56:vacuum pressure swing adsorption

795:

763:

736:

681:

299:

654:

614:

562:

535:

516:

473:

443:

221:refrigeration during start-up.

141:that operates by means of the

101:Cryogenic distillation process

1:

749:. American Chemical Society.

583:10.1016/S0140-7007(01)00003-2

525:Chemical Engineering Progress

437:

333:, oxygen is required for the

267:portable oxygen concentrators

254:Bottle of 4Å molecular sieves

368:

7:

380:

356:

304:

280:Membrane nitrogen generator

10:

871:

597:"How air separation works"

340:

316:

640:10.1007/s10556-007-0018-8

482:, (updated November 2007)

259:Pressure swing adsorption

52:pressure swing adsorption

335:basic oxygen steelmaking

324:

194:plate fin heat exchanger

835:Thermodynamic processes

271:Vacuum swing adsorption

238:Non-cryogenic processes

204:(a reverse compressor).

48:fractional distillation

595:

281:

255:

247:

234:for small quantities.

130:

110:

724:. Waco Tribune-Herald

480:NASA Earth Fact Sheet

417:Liquefaction of gases

345:Nitrogen used in the

285:Membrane technologies

279:

253:

245:

128:

108:

35:, and sometimes also

845:Industrial processes

669:(10–12): 1436–1446.

387:Louis Paul Cailletet

246:A nitrogen generator

210:Joule–Thomson effect

143:Joule–Thomson effect

91:distillation columns

722:Waco Tribune-Herald

427:Oxygen concentrator

407:Hampson–Linde cycle

392:Cryogenic gas plant

139:refrigeration cycle

282:

256:

248:

155:expansion turbines

153:. Modern ASUs use

131:

111:

774:Essential Science

556:10.1021/ie950323h

493:"Cool Inventions"

452:"Helium Recovery"

363:coal gasification

862:

855:Gas technologies

850:Industrial gases

808:

807:

799:

793:

792:

777:

767:

761:

760:

740:

734:

733:

731:

729:

716:Copeland, Mike.

713:

707:

706:

685:

679:

678:

658:

652:

651:

618:

612:

611:

609:

607:

593:

587:

586:

566:

560:

559:

550:(4): 1059–1071.

539:

533:

532:

520:

514:

513:

511:

510:

504:

497:

489:

483:

477:

471:

470:

468:

466:

456:

447:

412:Industrial gases

23:plant separates

16:Chemical process

870:

869:

865:

864:

863:

861:

860:

859:

825:

824:

816:

811:

800:

796:

786:

768:

764:

757:

741:

737:

727:

725:

714:

710:

686:

682:

659:

655:

634:(1–2): 96–101.

619:

615:

605:

603:

594:

590:

567:

563:

540:

536:

521:

517:

508:

506:

502:

495:

491:

490:

486:

478:

474:

464:

462:

454:

448:

444:

440:

383:

371:

359:

343:

327:

319:

307:

302:

240:

174:molecular sieve

103:

39:and other rare

25:atmospheric air

17:

12:

11:

5:

868:

858:

857:

852:

847:

842:

840:Gas separation

837:

823:

822:

815:

814:External links

812:

810:

809:

794:

784:

762:

755:

735:

708:

680:

653:

613:

588:

561:

534:

515:

484:

472:

450:Chrz, Vaclav.

441:

439:

436:

435:

434:

429:

424:

419:

414:

409:

404:

402:Gas to liquids

399:

397:Gas separation

394:

389:

382:

379:

370:

367:

358:

355:

342:

339:

326:

323:

318:

315:

306:

303:

301:

298:

239:

236:

223:

222:

218:

214:

205:

190:heat exchanger

186:

178:carbon dioxide

170:

162:

119:Carl von Linde

102:

99:

21:air separation

15:

9:

6:

4:

3:

2:

867:

856:

853:

851:

848:

846:

843:

841:

838:

836:

833:

832:

830:

821:

818:

817:

805:

798:

791:

787:

785:9780746010112

781:

776:

775:

766:

758:

756:9780841269637

752:

748:

747:

739:

723:

719:

712:

704:

700:

696:

692:

684:

676:

672:

668:

664:

657:

649:

645:

641:

637:

633:

629:

623:

622:Gas to Liquid

617:

602:

598:

592:

584:

580:

576:

572:

565:

557:

553:

549:

545:

538:

530:

526:

519:

505:on 2014-01-13

501:

494:

488:

481:

476:

460:

453:

446:

442:

433:

432:Siemens cycle

430:

428:

425:

423:

420:

418:

415:

413:

410:

408:

405:

403:

400:

398:

395:

393:

390:

388:

385:

384:

378:

376:

366:

364:

354:

352:

348:

347:Haber process

338:

336:

332:

322:

314:

312:

297:

293:

289:

286:

278:

274:

272:

268:

264:

260:

252:

244:

235:

233:

232:gas cylinders

229:

219:

215:

211:

206:

203:

199:

198:refrigeration

195:

191:

187:

183:

179:

175:

171:

167:

163:

160:

159:

158:

156:

152:

148:

144:

140:

135:

127:

123:

120:

116:

107:

98:

96:

92:

88:

84:

80:

77:

73:

69:

65:

61:

57:

53:

49:

44:

42:

38:

34:

30:

26:

22:

804:Gasification

803:

797:

789:

773:

765:

745:

738:

726:. Retrieved

721:

711:

694:

690:

683:

666:

662:

656:

631:

627:

616:

604:. Retrieved

600:

591:

574:

570:

564:

547:

543:

537:

528:

524:

518:

507:. Retrieved

500:the original

487:

475:

463:. Retrieved

458:

445:

372:

360:

344:

328:

320:

308:

300:Applications

294:

290:

283:

257:

228:dewar flasks

224:

182:hydrocarbons

136:

132:

112:

45:

20:

18:

778:. Usborne.

728:30 November

624:plant, see

577:: 158–172.

531:(2): 35–59.

465:30 November

331:steelmaking

192:(usually a

70:, used for

41:inert gases

829:Categories

606:9 November

509:2014-01-12

438:References

422:Liquid air

151:compressor

115:distilling

76:rare gases

54:(PSA) and

697:: 11–16.

648:110001679

375:oxidation

369:Inert gas

147:insulated

381:See also

357:Coal gas

349:to make

305:Rocketry

213:section.

202:expander

169:coolers.

64:nitrogen

29:nitrogen

351:ammonia

341:Ammonia

317:Medical

263:zeolite

83:krypton

782:

753:

646:

601:Messer

461:. CERN

311:SpaceX

185:water.

95:Helium

66:, and

60:oxygen

33:oxygen

644:S2CID

503:(PDF)

496:(PDF)

455:(PDF)

325:Steel

166:fluid

87:xenon

68:argon

37:argon

780:ISBN

751:ISBN

730:2022

608:2022

467:2022

459:CERN

79:neon

31:and

699:doi

695:102

671:doi

636:doi

579:doi

552:doi

329:In

230:or

85:,

19:An

831::

788:.

720:.

693:.

667:30

665:.

642:.

632:43

630:.

599:.

575:25

573:.

548:35

546:.

529:63

527:.

457:.

377:.

353:.

313:.

93:.

81:,

62:,

43:.

759:.

732:.

705:.

701::

677:.

673::

650:.

638::

610:.

585:.

581::

558:.

554::

512:.

469:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.