2263:

1513:

1586:

1551:

1475:

1676:

744:

1654:

807:

1157:

689:

1100:

630:

466:

1620:

1209:

925:

576:

866:

1698:

1784:: Unlike GD&T presentation, the GD&T representation does not deal with how the information is presented to the user but only deals with which element of a shape of a product has which GD&T characteristic. A system supporting GD&T representation may display GD&T information in some tree and other dialogs and allow the user to directly select and highlight the corresponding feature on the shape of the product, 2D and 3D.

1441:

1041:

987:

522:

31:

85:. The Y14.5 standard provides a fairly complete set of rules for GD&T in one document. The ISO standards, in comparison, typically only address a single topic at a time. There are separate standards that provide the details for each of the major symbols and topics below (e.g. position, flatness, profile, etc.).

309:

All dimensions must have a tolerance. Plus and minus tolerances may be applied directly to dimensions or applied from a general tolerance block or general note. For basic dimensions, geometric tolerances are indirectly applied in a related feature control frame. The only exceptions are for dimensions

301:

The purpose of GD&T is to describe the engineering intent of parts and assemblies. GD&T can more accurately define the dimensional requirements for a part, allowing over 50% more tolerance zone than coordinate (or linear) dimensioning in some cases. Proper application of GD&T will ensure

151:

The units of measure in a drawing that follows GD&T can be selected by the creator of the drawing. Most often drawings are standardized to either SI linear units, millimeters (denoted "mm"), or US customary linear units, decimal inches (denoted "IN"). Dimensions can contain only a number without

192:

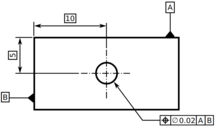

Tolerances for the profile symbols are equal bilateral unless otherwise specified, and for the position symbol tolerances are always equal bilateral. For example, the position of a hole has a tolerance of .020 inches. This means the hole can move ±.010 inches, which is an equal bilateral tolerance.

65:

and the permissible variation thereof. GD&T is used to define the nominal (theoretically perfect) geometry of parts and assemblies, the allowable variation in size, form, orientation, and location of individual features, and how features may vary in relation to one another such that a component

163:

Every feature on every manufactured part is subject to variation, therefore, the limits of allowable variation must be specified. Tolerances can be expressed directly on a dimension by limits, plus/minus tolerances, or geometric tolerances, or indirectly in tolerance blocks, notes, or tables.

1791:

An enhancement of GD&T representation is defining a formal language for GD&T (similar to a programming language) which also has built-in rules and restrictions for the proper GD&T usage. This is still a research area (see below reference to McCaleb and ISO

1787:

Ideally both GD&T presentation and representation are available in the exchange file and are associated with each other. Then a receiving system can allow a user to select a GD&T callout and get the corresponding feature highlighted on the shape of the

287:

66:

is considered satisfactory for its intended use. Dimensional specifications define the nominal, as-modeled or as-intended geometry, while tolerance specifications define the allowable physical variation of individual features of a part or assembly.

193:

It does not mean the hole can move +.015/−.005 inches, which is an unequal bilateral tolerance. Unequal bilateral and unilateral tolerances for profile are specified by adding further information to clearly show this is what is required.

292:

These are then referred to by one or more 'datum references' which indicate measurements that should be made with respect to the corresponding datum feature. The datum reference frame can describe how the part fits or functions.

134:

is defined in ASME Y14.5 as "a numerical value(s) or mathematical expression in appropriate units of measure used to define the form, size, orientation, or location, of a part or feature." Special types of dimensions include

302:

that the part defined on the drawing has the desired form, fit (within limits) and function with the largest possible tolerances. GD&T can add quality and reduce cost at the same time through producibility.

1393:

The symmetry symbol's characteristics were not included in the version of the chart that this chart is derived from. The symmetry symbol was dropped from the Y14.5M standard around 1982 and re-added around

1759:

In the early days of CAD, exchange-only lines, texts and symbols were written into the exchange file. A receiving system could display them on the screen or print them out, but only a human could interpret

341:

Basic 90° angles are assumed where center lines of features in a pattern or surfaces shown at right angles on a 2D orthographic drawing are located or defined by basic dimensions and no angle is specified.

97:

The origin of GD&T is credited to

Stanley Parker, who developed the concept of "true position". While little is known about Parker's life, it is known that he worked at the Royal Torpedo Factory in

335:

When geometry is normally controlled by gage sizes or by code (e.g. stock materials), the dimension(s) shall be included with the gage or code number in parentheses following the dimension.

1739:

Technologist GDTP, which provides an assessment of an individual's ability to understand drawings that have been prepared using the language of

Geometric Dimensioning & Tolerancing.

229:

344:

A basic dimension of zero is assumed where axes, center planes, or surfaces are shown coincident on a drawing, and the relationship between features is defined by geometric tolerances.

313:

Dimensions and tolerancing shall fully define each feature. Measurement directly from the drawing or assuming dimensions is not allowed except for special undimensioned drawings.

2340:

319:

Dimensions should be applied to features and arranged to represent the function and mating relationship of the part. There should only be one way to interpret dimensions.

1724:

Added in the 2009 version of the standard, and refers to unequal profile distribution. Number after this symbol indicates tolerance in the "plus material" direction.

1809:

GD&T representation information can also be used for the software assisted manufacturing planning and cost calculation of parts. See ISO 10303-224 and 238 below.

356:

Dimensions and tolerances only apply at the level of the drawing where specified. It is not mandatory that they apply at other levels (such as an assembly drawing).

1778:. And there is also the information which of the curves in the file are leader, projection or dimension curves and which are used to form the shape of a product.

1742:

Senior GDTP, which provides the additional measure of an individual's ability to select proper geometric controls as well as to properly apply them to drawings.

171:

which are rectangular boxes on a drawing that indicate the type of geometric control, tolerance value, modifier(s) and/or datum(s) relevant to the feature

2402:

2236:

82:

316:

A drawing should have the minimum number of dimensions required to fully define the end product. The use of reference dimensions should be minimized.

2332:

78:

2497:

Srinivasan, Vijay (2008). "Standardizing the specification, verification, and exchange of product geometry: Research, status and trends".

2632:

325:

If dimensions are required during manufacturing but not the final geometry (due to shrinkage or other causes) they should be marked as

69:

There are several standards available worldwide that describe the symbols and define the rules used in GD&T. One such standard is

1827:

1798:: Based on GD&T representation data (but not on GD&T presentation) and the shape of a product in some useful format (e.g. a

1666:

Identifies "a group of features of size where there is a requirement that they be treated geometrically as a single feature of size"

359:

Coordinate systems shown on drawings should be right-handed. Each axis should be labeled and the positive direction should be shown.

70:

1922:

Geometrical tolerancing – Maximum material requirement (MMR), least material requirement (LMR) and reciprocity requirement (RPR)

2403:"GD&T, Geometric Dimensioning and Tolerancing, GD&T, Flatness, Circularity, Flatness Tolerance, Circularity Tolerance"

2574:

2546:

2383:

1802:), it is possible to validate the completeness and consistency of the GD&T information. The software tool FBTol from the

347:

Dimensions and tolerances are valid at 20 °C (68 °F) and 101.3 kPa (14.69 psi) unless stated otherwise.

152:

units if all dimensions are the same units and there is a note on the drawing that clearly specifies what the units are.

2527:

2487:

1610:"Indicates a geometric tolerance applies at any increment of size of the actual mating envelope of the feature of size"

2608:

2306:

2284:

2148:

2277:

2590:

1406:

The following table shows only some of the more commonly used modifiers in GD&T. It is not an exhaustive list.

338:

Angles of 90° are assumed when lines (including center lines) are shown at right angles, but no angle is specified.

282:{\displaystyle {\displaystyle \Box }\!\!\!\!{\scriptstyle {\mathsf {A}}}\!-\!\!\!-\!\!\!\blacktriangleleft \!\!\!|}

99:

50:

2664:

2622:

332:

Dimensions should be arranged for maximum readability and should be applied to visible lines in true profiles.

2627:

2113:

ASME is also working on a

Spanish translation for the ASME Y14.5 – Dimensioning and Tolerancing Standard.

2595:

2654:

2638:

1410:

Symbols used in a "feature control frame" to specify a feature's description, tolerance, modifier and

2659:

81:(ISO) describe a different system which has some nuanced differences in its interpretation and rules

2271:

1572:

515:

1384:

In the 2018 revision, both concentricity and symmetry were eliminated and are no longer supported.

2216:

2188:

Application protocol: Mechanical product definition for process planning using machining features

1861:

1799:

1766:: On a next higher level the presentation information is enhanced by grouping them together into

17:

2288:

1873:

the distinction between fundamental, global, general and complementary GPS standards is made.

1691:

Appears in the 1994 version of the standard, assumes appropriate statistical process control.

2617:

2246:

2226:

1752:

353:

Unless explicitly stated, tolerances apply to the full length, width, and depth of a feature.

46:

2006:

Form of a surface independent of a datum or datum system. Each of them has a part 1 for the

1996:

Surface texture: Profile method – Rules and procedures for the assessment of surface texture

2170:

Application protocol: Configuration controlled 3D design of mechanical parts and assemblies

2600:

2558:

Geometric

Boundaries II, Practical Guide to Interpretation and Application ASME Y14.5-2009

2195:

Application protocol: Application interpreted model for computerized numerical controllers

1735:

The

American Society of Mechanical Engineers (ASME) provides two levels of certification:

1669:

Identifies a group of features that should be "treated geometrically as a single feature"

8:

1984:

Surface texture: Profile method – Nominal characteristics of contact (stylus) instruments

918:

350:

Unless explicitly stated, dimensions and tolerances only apply in a free-state condition.

155:

Angular dimensions can be expressed in decimal degrees or degrees, minutes, and seconds.

113:, the earliest work on geometric dimensioning and tolerancing. In 1956, Parker published

54:

34:

Example of true position geometric control defined by basic dimensions and datum features

2126:

Industrial automation systems and integration – Product data representation and exchange

1310:

When a datum feature of size is referenced with the maximum material condition modifier.

2231:

2065:

Surface texture: Profile method – Metrological characteristics of phase correct filters

1613:

Not part of the 1994 version. See para. A5, bullet 3. Also para. D3. Also, Figure 3–8.

1034:

569:

2570:

2542:

2523:

2483:

2379:

1803:

89:

provides a self-contained document taking into account a lot of GPS&V standards.

322:

Part geometry should be defined without explicitly specifying manufacturing methods.

2506:

2464:

1990:

Surface texture: Profile method – Terms, definitions and surface texture parameters

1411:

1751:

Exchange of geometric dimensioning and tolerancing (GD&T) information between

1512:

77:. This article is based on that standard. Other standards, such as those from the

2612:

2480:

Geometrical

Dimensioning and Tolerancing for Design, Manufacturing and Inspection

2241:

2221:

1585:

682:

202:

2176:

Application protocol: Electronic assembly, interconnection, and packaging design

1550:

1474:

1902:

Geometrical tolerancing – Tolerances of form, orientation, location and run-out

58:

2510:

1857:(Note: ISO 16792:2006 was derived from ASME Y14.41-2003 by permission of ASME)

1688:

Indicates that features "shall be produced with statistical process controls".

1675:

2648:

1755:

systems is available on different levels of fidelity for different purposes:

800:

2605:

2426:

1653:

743:

623:

459:

305:

According to ASME Y14.5, the fundamental rules of GD&T are as follows,

175:

The type of tolerances used with symbols in feature control frames can be:

2591:

General tolerances for linear and angular dimensions according to ISO 2768

2539:

GeoTol Pro: A Practical Guide to

Geometric Tolerancing per ASME Y14.5-2009

2182:

Application protocol: Core data for automotive mechanical design processes

1843:

Technical drawings – Edges of undefined shape – Vocabulary and indications

806:

2469:

2457:

Journal of

Research of the National Institute of Standards and Technology

2452:

2090:

1855:

Technical product documentation—Digital product definition data practices

1156:

1644:"A plane that contacts the high points of the specified feature surface"

688:

2116:

2098:

1099:

1093:

74:

1619:

629:

465:

2122:

1208:

924:

575:

131:

106:. His work increased production of naval weapons by new contractors.

1697:

865:

1864:

Dimensional and geometrical product specifications and verification

1440:

980:

103:

62:

30:

2108:

Mathematical

Definition of Dimensioning and Tolerancing Principles

1946:

Tolerancing of orientation and location – Projected tolerance zone

1040:

986:

521:

111:

Notes on Design and

Inspection of Mass Production Engineering Work

2192:

1712:

1634:

1600:

1565:

1527:

1489:

1455:

1421:

1223:

1171:

1147:

1114:

1055:

1001:

939:

880:

821:

758:

703:

642:

590:

536:

480:

391:

86:

2326:

2324:

2077:

Profile method; Surfaces having stratified functional properties

1978:

Indication of surface texture in technical product documentation

1837:

Symbols for geometrical tolerancing – Proportions and dimensions

2321:

1706:

1628:

1594:

1559:

1521:

1483:

1449:

1372:

Can also be used as a form control without a datum reference.

1217:

1165:

1108:

1049:

995:

933:

874:

859:

815:

752:

697:

584:

530:

474:

1831:

Technical drawings – Indication of dimensions and tolerances

1818:

143:(dimensions used to inform, not define a feature or part).

27:

System for defining and representing engineering tolerances

1908:

Representation of specifications in the form of a 3D model

2002:

Surface imperfections – Terms, definitions and parameters

2203:

Application protocol: Managed model based 3D engineering

211:

is a theoretically exact plane, line, point, or axis. A

2633:

NIST MBE PMI Validation and Conformance Testing Project

2132:

Integrated generic resource: Shape variation tolerances

1537:"The condition in which a feature of size contains the

1499:"The condition in which a feature of size contains the

2378:. NY: American Society of Mechanical Engineers. 2009.

245:

234:

232:

2541:. Dearborn, MI: Society of Manufacturing Engineers.

2117:

GD&T standards for data exchange and integration

1544:

Provides bonus tolerance only for a feature of size

1541:

amount of material within the stated limits of size"

1503:

amount of material within the stated limits of size"

1360:

When an maximal material condition modifier is used.

368:

1849:

Simplified representation and dimensioning of holes

2237:Geometrical Product Specification and Verification

2071:Surface texture: Profile method – Motif parameters

1940:Geometrical tolerancing – Datums and datum systems

434:

427:

281:

2635:Tests implementations of GD&T in CAD software

2330:

1647:Useful for interfaces where form is not required

273:

272:

271:

267:

266:

265:

261:

260:

259:

255:

243:

242:

241:

240:

117:, which became the basic reference in the field.

2646:

2331:MacMillan, David M.; Krandall, Rollande (2014).

2164:Application module: Extended geometric tolerance

1934:Geometrical tolerancing – Positional tolerancing

1465:"The condition of a part free of applied forces"

215:is a physical feature of a part identified by a

2333:"Bibliography for Dimensioning and Tolerancing"

1964:Features used in specification and verification

1468:Applies only when part is otherwise restrained

310:marked as minimum, maximum, stock or reference.

2536:

1952:Dimensioning and tolerancing – Non-rigid parts

196:

188:no particular distribution (a "floating" zone)

79:International Organization for Standardization

2376:Dimensioning and Tolerancing, ASME Y14.5-2009

45:) is a system for defining and communicating

1338:

1336:

61:that describes a physical object's nominal

2606:GD&T Glossary of Terms and Definitions

2517:

2496:

2453:"A Conceptual Data Model of Datum Systems"

1813:

1506:Useful to maintain minimum wall thickness

1334:

1332:

1330:

1328:

1326:

1324:

1322:

1320:

1318:

1316:

2468:

2307:Learn how and when to remove this message

2138:Application module: Derived shape element

2094:Digital Product Definition Data Practices

1916:Series of conical tapers and taper angles

1380:

1378:

1368:

1366:

374:Geometric characteristic reference chart

2270:This article includes a list of general

1579:Useful on threaded holes for long studs

71:American Society of Mechanical Engineers

29:

2555:

2477:

2450:

2152:Application module: Geometric tolerance

2144:Application module: Dimension tolerance

1806:is probably the first one in this area.

1313:

446:

441:

418:

120:

14:

2647:

2564:

2482:(2nd ed.). Oxford, UK: Elsevier.

2429:. Technical Training Consultants. 2020

1375:

1363:

1306:

1304:

1302:

1300:

1298:

1296:

1294:

296:

248:

167:Geometric tolerances are described by

39:Geometric dimensioning and tolerancing

2569:. US: Goodheart-Wilcox. p. 275.

2520:Dimensioning and Tolerancing Handbook

2158:Application module: Default tolerance

1356:

1354:

1352:

1350:

1348:

1280:

1278:

1276:

1274:

1272:

1270:

1268:

1266:

1264:

1262:

139:(theoretically exact dimensions) and

2628:Changes and Additions to ASME Y14.5M

2537:Neumann, Scott; Neumann, Al (2009).

2397:

2395:

2370:

2368:

2366:

2364:

2362:

2360:

2358:

2256:

2053:Extraction and filtration techniques

1928:Dimensioning and tolerancing – Cones

1401:

2567:Design Dimensioning and Tolerancing

1897:ISO/TS 17, orientation and location

1291:

146:

24:

2444:

2343:from the original on 27 March 2019

2276:it lacks sufficient corresponding

1696:

1674:

1652:

1618:

1584:

1549:

1511:

1473:

1439:

1345:

1259:

1207:

1155:

1098:

1039:

985:

923:

864:

805:

742:

687:

628:

574:

520:

464:

25:

2676:

2641:- Analyze GD&T in a STEP file

2584:

2392:

2355:

2084:

1972:Areal and profile surface texture

1770:for a particular purpose, e.g. a

1607:Regardless of feature size (RFS)

1534:Maximum material condition (MMC)

369:List of geometric characteristics

2261:

1746:

1730:

2419:

2247:Specification of surface finish

1821:Technical product documentation

1496:Least material condition (LMC)

1387:

675:Individual or related features

100:Alexandria, West Dunbartonshire

1882:Concepts, principles and rules

275:

13:

1:

2639:STEP File Analyzer and Viewer

2252:

158:

125:

2518:Drake, Jr., Paul J. (1999).

2451:McCaleb, Michael R. (1999).

2102:Dimensioning and Tolerancing

7:

2210:

401:Virtual condition affected

197:Datums and datum references

10:

2681:

2601:The importance of GD&T

2556:Bramble, Kelly L. (2009).

1877:Fundamental GPS standards

363:

200:

109:In 1940, Parker published

2565:Wilson, Bruce A. (2005).

2522:. New York: McGraw-Hill.

2511:10.1016/j.cad.2007.06.006

2008:Vocabulary and parameters

1146:

976:

796:

793:

677:

674:

455:

452:

409:

406:

403:

400:

397:

390:

387:

384:

381:

378:

92:

1573:Projected tolerance zone

2478:Henzold, Georg (2006).

2291:more precise citations.

2217:Dimensional instruments

2051:General GPS standards:

2012:Specification operators

1970:General GPS standards:

1814:Documents and standards

1800:boundary representation

1782:GD&T representation

169:feature control frames,

115:Drawings and Dimensions

57:and computer-generated

2045:Surface texture: Areal

1701:

1685:Statistical tolerance

1679:

1657:

1623:

1589:

1554:

1516:

1478:

1444:

1212:

1160:

1103:

1044:

990:

928:

869:

810:

747:

692:

633:

579:

525:

469:

283:

221:datum feature triangle

47:engineering tolerances

35:

2665:Geometric measurement

2499:Computer-Aided Design

2227:Engineering tolerance

2010:and a part 2 for the

1888:Global GPS standards

1776:datum reference frame

1772:datum feature callout

1764:GD&T presentation

1700:

1678:

1656:

1622:

1588:

1553:

1515:

1477:

1443:

1211:

1159:

1102:

1043:

989:

927:

868:

809:

746:

739:Profile of a surface

691:

632:

578:

524:

468:

284:

33:

2470:10.6028/jres.104.024

2407:cobanengineering.com

1893:Geometrical features

453:Individual features

230:

217:datum feature symbol

141:reference dimensions

121:Fundamental concepts

55:engineering drawings

1796:GD&T validation

1663:Continuous feature

1414:

375:

297:Purpose & rules

2623:ASME Certification

2611:2008-09-15 at the

2232:Gauge (instrument)

2162:ISO/TS 10303-1666

2156:ISO/TS 10303-1052

2142:ISO/TS 10303-1050

2136:ISO/TS 10303-1130

1719:Unequal bilateral

1702:

1680:

1658:

1624:

1590:

1555:

1517:

1479:

1445:

1409:

1284:When applied to a

1213:

1161:

1104:

1045:

991:

929:

870:

811:

748:

693:

634:

580:

526:

470:

373:

279:

253:

238:

219:and corresponding

36:

2655:Technical drawing

2618:GDT: Introduction

2576:978-1-59070-328-1

2560:. Engineers Edge.

2548:978-0-87263-865-5

2385:978-0-7918-3192-2

2317:

2316:

2309:

2149:ISO/TS 10303-1051

1804:Kansas City Plant

1728:

1727:

1716:

1638:

1604:

1569:

1531:

1493:

1459:

1402:List of modifiers

1255:

1254:

1227:

1175:

1152:Circular run-out

1118:

1059:

1005:

943:

884:

825:

794:Related features

762:

707:

646:

594:

540:

484:

404:References datum

398:Relevant feature

182:unequal bilateral

51:symbolic language

16:(Redirected from

2672:

2660:Applied geometry

2596:What is GD&T

2580:

2561:

2552:

2533:

2514:

2493:

2474:

2472:

2438:

2437:

2435:

2434:

2423:

2417:

2416:

2414:

2413:

2399:

2390:

2389:

2372:

2353:

2352:

2350:

2348:

2328:

2312:

2305:

2301:

2298:

2292:

2287:this article by

2278:inline citations

2265:

2264:

2257:

1871:GPS – Masterplan

1869:In ISO/TR 14638

1711:

1633:

1599:

1564:

1526:

1488:

1454:

1415:

1412:datum references

1408:

1395:

1391:

1385:

1382:

1373:

1370:

1361:

1358:

1343:

1340:

1311:

1308:

1289:

1282:

1222:

1170:

1113:

1088:

1082:

1054:

1000:

972:

966:

938:

913:

907:

879:

854:

848:

820:

801:Perpendicularity

789:

757:

734:

702:

641:

589:

535:

507:

479:

448:

443:

438:

437:

431:

430:

424:

422:

382:Type of control

376:

372:

288:

286:

285:

280:

278:

254:

252:

251:

239:

147:Units of measure

137:basic dimensions

21:

2680:

2679:

2675:

2674:

2673:

2671:

2670:

2669:

2645:

2644:

2613:Wayback Machine

2587:

2577:

2549:

2530:

2490:

2447:

2445:Further reading

2442:

2441:

2432:

2430:

2425:

2424:

2420:

2411:

2409:

2401:

2400:

2393:

2386:

2374:

2373:

2356:

2346:

2344:

2337:Circuitous Root

2329:

2322:

2313:

2302:

2296:

2293:

2283:Please help to

2282:

2266:

2262:

2255:

2242:Position sensor

2222:Engineering fit

2213:

2119:

2087:

1867:

1853:ISO 16792:2021

1824:

1816:

1749:

1733:

1710:

1709:

1632:

1631:

1598:

1597:

1563:

1562:

1525:

1524:

1487:

1486:

1453:

1452:

1424:

1404:

1399:

1398:

1392:

1388:

1383:

1376:

1371:

1364:

1359:

1346:

1341:

1314:

1309:

1292:

1286:feature of size

1283:

1260:

1221:

1220:

1169:

1168:

1112:

1111:

1086:

1080:

1053:

1052:

999:

998:

970:

964:

937:

936:

911:

905:

878:

877:

852:

846:

819:

818:

787:

756:

755:

732:

701:

700:

640:

639:

588:

587:

534:

533:

505:

478:

477:

435:

428:

420:

394:

385:Characteristic

371:

366:

299:

274:

247:

246:

244:

233:

231:

228:

227:

205:

203:Datum reference

199:

179:equal bilateral

161:

149:

128:

123:

95:

83:(see GPS&V)

28:

23:

22:

15:

12:

11:

5:

2678:

2668:

2667:

2662:

2657:

2643:

2642:

2636:

2630:

2625:

2620:

2615:

2603:

2598:

2593:

2586:

2585:External links

2583:

2582:

2581:

2575:

2562:

2553:

2547:

2534:

2529:978-0070181311

2528:

2515:

2494:

2489:978-0750667388

2488:

2475:

2463:(4): 349–400.

2446:

2443:

2440:

2439:

2418:

2391:

2384:

2354:

2319:

2318:

2315:

2314:

2269:

2267:

2260:

2254:

2251:

2250:

2249:

2244:

2239:

2234:

2229:

2224:

2219:

2212:

2209:

2208:

2207:

2206:

2205:

2201:ISO 10303-242

2199:

2193:ISO 10303-238

2190:

2186:ISO 10303-224

2184:

2180:ISO 10303-214

2178:

2174:ISO 10303-210

2172:

2168:ISO 10303-203

2166:

2160:

2154:

2146:

2140:

2134:

2118:

2115:

2111:

2110:

2106:ASME Y14.5.1M

2104:

2096:

2086:

2085:ASME standards

2083:

2082:

2081:

2080:

2079:

2073:

2067:

2061:

2049:

2048:

2047:

2041:

2040:

2039:

2033:

2027:

2021:

2004:

1998:

1992:

1986:

1980:

1968:

1967:

1966:

1960:

1954:

1948:

1942:

1936:

1930:

1924:

1918:

1912:

1911:

1910:

1898:

1895:

1886:

1885:

1884:

1866:

1860:

1859:

1858:

1851:

1845:

1839:

1833:

1823:

1817:

1815:

1812:

1811:

1810:

1807:

1793:

1789:

1785:

1779:

1761:

1748:

1745:

1744:

1743:

1740:

1732:

1729:

1726:

1725:

1722:

1720:

1717:

1705:

1703:

1693:

1692:

1689:

1686:

1683:

1681:

1671:

1670:

1667:

1664:

1661:

1659:

1649:

1648:

1645:

1642:

1641:Tangent plane

1639:

1627:

1625:

1615:

1614:

1611:

1608:

1605:

1593:

1591:

1581:

1580:

1577:

1575:

1570:

1558:

1556:

1546:

1545:

1542:

1535:

1532:

1520:

1518:

1508:

1507:

1504:

1497:

1494:

1482:

1480:

1470:

1469:

1466:

1463:

1460:

1448:

1446:

1436:

1435:

1432:

1429:

1426:

1419:

1403:

1400:

1397:

1396:

1386:

1374:

1362:

1344:

1312:

1290:

1257:

1256:

1253:

1252:

1249:

1246:

1243:

1240:

1237:

1234:

1231:

1228:

1216:

1214:

1205:

1204:Total run-out

1201:

1200:

1197:

1194:

1191:

1188:

1185:

1182:

1179:

1176:

1164:

1162:

1153:

1150:

1144:

1143:

1140:

1137:

1134:

1131:

1128:

1125:

1122:

1119:

1107:

1105:

1096:

1090:

1089:

1083:

1078:

1075:

1072:

1069:

1066:

1063:

1060:

1048:

1046:

1037:

1031:

1030:

1027:

1024:

1021:

1018:

1015:

1012:

1009:

1006:

994:

992:

983:

978:

974:

973:

967:

962:

959:

956:

953:

950:

947:

944:

932:

930:

921:

915:

914:

908:

903:

900:

897:

894:

891:

888:

885:

873:

871:

862:

856:

855:

849:

844:

841:

838:

835:

832:

829:

826:

814:

812:

803:

798:

795:

791:

790:

784:

781:

778:

775:

772:

769:

766:

763:

751:

749:

740:

736:

735:

729:

726:

723:

720:

717:

714:

711:

708:

696:

694:

685:

679:

676:

672:

671:

668:

665:

662:

659:

656:

653:

650:

647:

637:

635:

626:

620:

619:

616:

613:

610:

607:

604:

601:

598:

595:

583:

581:

572:

566:

565:

562:

559:

556:

553:

550:

547:

544:

541:

529:

527:

518:

512:

511:

508:

503:

500:

497:

494:

491:

488:

485:

473:

471:

462:

457:

454:

450:

449:

444:

439:

432:

425:

416:

412:

411:

408:

405:

402:

399:

396:

389:

386:

383:

380:

370:

367:

365:

362:

361:

360:

357:

354:

351:

348:

345:

342:

339:

336:

333:

330:

323:

320:

317:

314:

311:

298:

295:

290:

289:

277:

270:

264:

258:

250:

237:

201:Main article:

198:

195:

190:

189:

186:

183:

180:

160:

157:

148:

145:

127:

124:

122:

119:

94:

91:

26:

9:

6:

4:

3:

2:

2677:

2666:

2663:

2661:

2658:

2656:

2653:

2652:

2650:

2640:

2637:

2634:

2631:

2629:

2626:

2624:

2621:

2619:

2616:

2614:

2610:

2607:

2604:

2602:

2599:

2597:

2594:

2592:

2589:

2588:

2578:

2572:

2568:

2563:

2559:

2554:

2550:

2544:

2540:

2535:

2531:

2525:

2521:

2516:

2512:

2508:

2505:(7): 738–49.

2504:

2500:

2495:

2491:

2485:

2481:

2476:

2471:

2466:

2462:

2458:

2454:

2449:

2448:

2428:

2422:

2408:

2404:

2398:

2396:

2387:

2381:

2377:

2371:

2369:

2367:

2365:

2363:

2361:

2359:

2342:

2338:

2334:

2327:

2325:

2320:

2311:

2308:

2300:

2290:

2286:

2280:

2279:

2273:

2268:

2259:

2258:

2248:

2245:

2243:

2240:

2238:

2235:

2233:

2230:

2228:

2225:

2223:

2220:

2218:

2215:

2214:

2204:

2200:

2198:

2196:

2191:

2189:

2185:

2183:

2179:

2177:

2173:

2171:

2167:

2165:

2161:

2159:

2155:

2153:

2150:

2147:

2145:

2141:

2139:

2135:

2133:

2130:ISO 10303-47

2129:

2128:

2127:

2124:

2121:

2120:

2114:

2109:

2105:

2103:

2100:

2097:

2095:

2092:

2089:

2088:

2078:

2074:

2072:

2068:

2066:

2062:

2060:

2056:

2055:

2054:

2050:

2046:

2042:

2038:

2034:

2032:

2028:

2026:

2022:

2020:

2016:

2015:

2013:

2009:

2005:

2003:

1999:

1997:

1993:

1991:

1987:

1985:

1981:

1979:

1975:

1974:

1973:

1969:

1965:

1961:

1959:

1955:

1953:

1949:

1947:

1943:

1941:

1937:

1935:

1931:

1929:

1925:

1923:

1919:

1917:

1913:

1909:

1905:

1904:

1903:

1899:

1896:

1894:

1890:

1889:

1887:

1883:

1879:

1878:

1876:

1875:

1874:

1872:

1865:

1856:

1852:

1850:

1846:

1844:

1840:

1838:

1834:

1832:

1829:

1826:

1825:

1822:

1808:

1805:

1801:

1797:

1794:

1790:

1786:

1783:

1780:

1777:

1773:

1769:

1765:

1762:

1758:

1757:

1756:

1754:

1747:Data exchange

1741:

1738:

1737:

1736:

1731:Certification

1723:

1721:

1718:

1714:

1708:

1704:

1699:

1695:

1694:

1690:

1687:

1684:

1682:

1677:

1673:

1672:

1668:

1665:

1662:

1660:

1655:

1651:

1650:

1646:

1643:

1640:

1636:

1630:

1626:

1621:

1617:

1616:

1612:

1609:

1606:

1602:

1596:

1592:

1587:

1583:

1582:

1578:

1576:

1574:

1571:

1567:

1561:

1557:

1552:

1548:

1547:

1543:

1540:

1536:

1533:

1529:

1523:

1519:

1514:

1510:

1509:

1505:

1502:

1498:

1495:

1491:

1485:

1481:

1476:

1472:

1471:

1467:

1464:

1461:

1457:

1451:

1447:

1442:

1438:

1437:

1433:

1430:

1427:

1423:

1420:

1417:

1416:

1413:

1407:

1390:

1381:

1379:

1369:

1367:

1357:

1355:

1353:

1351:

1349:

1342:Automatically

1339:

1337:

1335:

1333:

1331:

1329:

1327:

1325:

1323:

1321:

1319:

1317:

1307:

1305:

1303:

1301:

1299:

1297:

1295:

1287:

1281:

1279:

1277:

1275:

1273:

1271:

1269:

1267:

1265:

1263:

1258:

1250:

1247:

1244:

1241:

1238:

1235:

1232:

1229:

1225:

1219:

1215:

1210:

1206:

1203:

1202:

1198:

1195:

1192:

1189:

1186:

1183:

1180:

1177:

1173:

1167:

1163:

1158:

1154:

1151:

1149:

1145:

1141:

1138:

1135:

1132:

1129:

1126:

1123:

1120:

1116:

1110:

1106:

1101:

1097:

1095:

1094:Concentricity

1092:

1091:

1084:

1079:

1076:

1073:

1070:

1067:

1064:

1061:

1057:

1051:

1047:

1042:

1038:

1036:

1033:

1032:

1028:

1025:

1022:

1019:

1016:

1013:

1010:

1007:

1003:

997:

993:

988:

984:

982:

979:

975:

968:

963:

960:

957:

954:

951:

948:

945:

941:

935:

931:

926:

922:

920:

917:

916:

909:

904:

901:

898:

895:

892:

889:

886:

882:

876:

872:

867:

863:

861:

858:

857:

850:

845:

842:

839:

836:

833:

830:

827:

823:

817:

813:

808:

804:

802:

799:

792:

785:

782:

779:

776:

773:

770:

767:

764:

760:

754:

750:

745:

741:

738:

737:

730:

727:

724:

721:

718:

715:

712:

709:

705:

699:

695:

690:

686:

684:

681:Profile of a

680:

673:

669:

666:

663:

660:

657:

654:

651:

648:

644:

636:

631:

627:

625:

622:

621:

617:

614:

611:

608:

605:

602:

599:

596:

592:

586:

582:

577:

573:

571:

568:

567:

563:

560:

557:

554:

551:

548:

545:

542:

538:

532:

528:

523:

519:

517:

514:

513:

509:

504:

501:

498:

495:

492:

489:

486:

482:

476:

472:

467:

463:

461:

458:

451:

445:

440:

433:

426:

417:

414:

413:

393:

377:

358:

355:

352:

349:

346:

343:

340:

337:

334:

331:

328:

327:non-mandatory

324:

321:

318:

315:

312:

308:

307:

306:

303:

294:

268:

262:

256:

235:

226:

225:

224:

222:

218:

214:

213:datum feature

210:

204:

194:

187:

184:

181:

178:

177:

176:

174:

170:

165:

156:

153:

144:

142:

138:

133:

118:

116:

112:

107:

105:

101:

90:

88:

84:

80:

76:

72:

67:

64:

60:

56:

52:

48:

44:

40:

32:

19:

2566:

2557:

2538:

2519:

2502:

2498:

2479:

2460:

2456:

2431:. Retrieved

2421:

2410:. Retrieved

2406:

2375:

2345:. Retrieved

2336:

2303:

2294:

2275:

2202:

2194:

2187:

2181:

2175:

2169:

2163:

2157:

2151:

2143:

2137:

2131:

2125:

2112:

2107:

2101:

2093:

2076:

2070:

2064:

2058:

2057:ISO/TS 1661

2052:

2044:

2036:

2031:Straightness

2030:

2024:

2019:Cylindricity

2018:

2011:

2007:

2001:

1995:

1989:

1983:

1977:

1971:

1963:

1957:

1951:

1945:

1939:

1933:

1927:

1921:

1915:

1907:

1906:Amendment 1

1901:

1892:

1891:ISO 14660-1

1881:

1870:

1868:

1863:

1854:

1848:

1842:

1836:

1830:

1820:

1795:

1792:10303-1666).

1781:

1775:

1771:

1767:

1763:

1750:

1734:

1538:

1500:

1405:

1389:

1285:

797:Orientation

624:Cylindricity

460:Straightness

410:Affected by

407:Modified by

379:Application

326:

304:

300:

291:

220:

216:

212:

208:

206:

191:

172:

168:

166:

162:

154:

150:

140:

136:

129:

114:

110:

108:

96:

68:

42:

38:

37:

2427:"Resources"

2347:October 24,

2289:introducing

2091:ASME Y14.41

1862:ISO/TC 213

1462:Free state

919:Parallelism

570:Circularity

2649:Categories

2433:2020-09-20

2412:2020-04-02

2297:April 2010

2272:references

2253:References

2099:ASME Y14.5

2075:ISO 13565

2069:ISO 12085

2063:ISO 11562

2059:Filtration

2043:ISO 25178

2035:ISO 12781

2029:ISO 12780

2023:ISO 12181

2017:ISO 12180

1962:ISO 22432

1958:Extraction

1956:ISO 14406

1950:ISO 10579

1944:ISO 10578

1847:ISO 15786

1841:ISO 13715

1819:ISO TC 10

1431:Definition

860:Angularity

395:character

185:unilateral

159:Tolerances

126:Dimensions

2197:(STEP-NC)

2123:ISO 10303

2025:Roundness

2000:ISO 8785

1994:ISO 4288

1988:ISO 4287

1982:ISO 3274

1976:ISO 1302

1938:ISO 5459

1932:ISO 5458

1926:ISO 3040

1920:ISO 2692

1914:ISO 1119

1900:ISO 1101

1880:ISO 8015

1835:ISO 7083

1428:Modifier

1425:character

977:Location

269:◂

263:−

257:−

236:◻

132:dimension

59:3D models

2609:Archived

2341:Archived

2211:See also

2037:Flatness

1788:product.

1768:callouts

1236:Of size

1184:Of size

1035:Position

981:Symmetry

958:Of size

952:Of size

899:Of size

893:Of size

840:Of size

834:Of size

678:Profile

516:Flatness

499:Of size

493:Of size

415:Surface

223:, e.g.,

104:Scotland

63:geometry

43:GD&T

18:GD&T

2285:improve

1828:ISO 129

1539:maximum

1422:Unicode

1148:Run-out

1085:Datum,

969:Datum,

910:Datum,

851:Datum,

786:Datum,

731:Datum,

392:Unicode

388:Symbol

364:Symbols

87:BS 8888

73:(ASME)

2573:

2545:

2526:

2486:

2382:

2274:, but

1774:and a

1434:Notes

1418:Symbol

421:

93:Origin

49:via a

1760:them.

1715:+24CA

1637:+24C9

1603:+24C8

1568:+24C5

1530:+24C2

1501:least

1492:+24C1

1458:+24BB

1394:1994.

1226:+2330

1174:+2197

1117:+25CE

1058:+2316

1004:+232F

942:+2225

883:+2220

824:+27C2

761:+2313

706:+2312

645:+232D

593:+25CB

539:+23E5

483:+23E4

456:Form

447:Shift

442:Bonus

209:datum

75:Y14.5

2571:ISBN

2543:ISBN

2524:ISBN

2484:ISBN

2380:ISBN

2349:2018

1239:Yes

1233:Yes

1230:Yes

1187:Yes

1181:Yes

1178:Yes

1130:Yes

1127:Yes

1124:Yes

1077:Yes

1074:Yes

1071:Yes

1068:Yes

1065:Yes

1017:Yes

1014:Yes

1011:Yes

955:Yes

949:Yes

946:Yes

896:Yes

890:Yes

887:Yes

837:Yes

831:Yes

828:Yes

774:Yes

765:Yes

719:Yes

710:Yes

683:line

649:Yes

597:Yes

543:Yes

490:Yes

487:Yes

423:size

2507:doi

2465:doi

2461:104

1753:CAD

1251:No

1248:No

1245:No

1242:No

1199:No

1196:No

1193:No

1190:No

1142:No

1139:No

1136:No

1133:No

1121:No

1062:No

1029:No

1026:No

1023:No

1020:No

1008:No

961:No

902:No

843:No

783:No

780:No

777:No

771:No

768:No

728:No

725:No

722:No

716:No

713:No

670:No

667:No

664:No

661:No

658:No

655:No

652:No

618:No

615:No

612:No

609:No

606:No

603:No

600:No

564:No

561:No

558:No

555:No

552:No

549:No

546:No

510:No

502:No

496:No

53:on

2651::

2503:40

2501:.

2459:.

2455:.

2405:.

2394:^

2357:^

2339:.

2335:.

2323:^

2014::

1377:^

1365:^

1347:^

1315:^

1293:^

1261:^

419:Of

207:A

130:A

102:,

2579:.

2551:.

2532:.

2513:.

2509::

2492:.

2473:.

2467::

2436:.

2415:.

2388:.

2351:.

2310:)

2304:(

2299:)

2295:(

2281:.

1713:U

1707:Ⓤ

1635:U

1629:Ⓣ

1601:U

1595:Ⓢ

1566:U

1560:Ⓟ

1528:U

1522:Ⓜ

1490:U

1484:Ⓛ

1456:U

1450:Ⓕ

1288:.

1224:U

1218:⌰

1172:U

1166:↗

1115:U

1109:◎

1087:Ⓜ

1081:Ⓜ

1056:U

1050:⌖

1002:U

996:⌯

971:Ⓜ

965:Ⓜ

940:U

934:∥

912:Ⓜ

906:Ⓜ

881:U

875:∠

853:Ⓜ

847:Ⓜ

822:U

816:⟂

788:Ⓜ

759:U

753:⌓

733:Ⓜ

704:U

698:⌒

643:U

638:⌭

591:U

585:○

537:U

531:⏥

506:Ⓜ

481:U

475:⏤

436:Ⓢ

429:Ⓜ

329:.

276:|

249:A

173:.

41:(

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.