81:

73:

89:

57:

significant "pepperyness" in the appearance of the coating appears, marks the coarsest-ground dispersed particles. This is the point where oversized particles start to appear in high density and determines the rating for that material. The reading is taken from the scale marked next to the grooves, in dimensionless "Hegman units" (or

56:

A Hegman gauge is used by placing a sample of paint at the deep end of the gauge and drawing the paint down with a flat edge along the grooves. Grind gages are sold with machined flat 'drawdown bars' specifically for this purpose. The paint fills the grooves, and the location where a regular,

43:

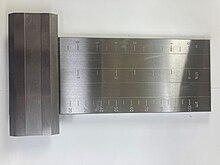

The Hegman gauge usually consists of a stainless steel block with a series of very small parallel grooves machined into it. The grooves decrease in depth from one end of the block to the other, according to a scale stamped next to them. A typical Hegman gauge is 170mm by 65mm by 15mm, with a

40:(or other liquid) are. This is important because many types of solid materials must be ground into finer particles in order to be dispersed in liquids. The resulting properties of the dispersion vary based on the size of individual particles and the degree which they are dispersed.

325:

Grind gauges are used in a variety of fields, including; food, pharmaceutical, plastic and many others. In all of these fields, grind gauges are utilized to produce, store, and apply dispersion products.

334:

Hegman gauges are commonly available in the following ranges: 0 to 100 micrometres, 0 to 50 micrometres, 0 to 25 micrometres, 0 to 15 micrometres, and 0 to 10 micrometres.

210:

A lesser-used scale, North (or PCU), is also occasionally employed in the paint industry. Like the Hegman scale, this is also inverted compared to the value in microns:

28:, or grindometer, is an instrument which indicates the fineness of grind or the presence of coarse particles and agglomeration in a

317:, and opacity. The Hegman gauge is widely used for this purpose because it requires minimal skill and only a few seconds' work.

44:

channel of grooves running lengthwise, 12.5mm across and narrowing uniformly in depth from 100 μm to zero and used to determine

313:

Determining the fineness of a paint's grind is important, because too coarse a grind may reduce the paint's color uniformity,

430:

489:"ASTM D1210 - 05(2014) Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage"

368:"ASTM D1210 - 05(2014) Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage"

470:

355:

512:

442:

413:

386:

517:

314:

425:

D. Doubleday and A. Barkman, "Reading the Hegman Grind Gauge" Paint, Oil and

Chemical Review June 22,

400:"ASTM D1316 - 20 Standard Test Method for Fineness of Grind of Printing Inks by the NPIRI Grindometer"

29:

80:

8:

463:

Paint and coating testing manual : fourteenth edition of the

Gardner-Sward handbook

466:

351:

72:

507:

88:

69:. Hegman units are defined in terms of an inverted size scale as shown below:

62:

501:

45:

488:

399:

367:

66:

32:. It is commonly used to determine how finely ground the particles of

389:, p. 43 (citing ASTM D1210-79 (1988)). Marcel Dekker, Inc., 1994.

33:

431:

http://www.gardco.com/pages/dispersion/fg/Hegman%20Article.pdf

37:

443:

Industrial

Minerals and Their Uses: A Handbook and Formulary

414:

Dispersions: Characterization, Testing, and

Measurement

350:Koeler, Paint and Coating Testing Manual, p. 743,

499:

36:(or other solid) dispersed in a sample of

387:Technological Applications of Dispersions

87:

79:

71:

381:

379:

377:

500:

445:, pp. 155–56. Noyes Publication 1996.

416:, p. 243. Marcel Dekker, Inc., 1999.

374:

460:

13:

76:Hegman Grind Gage and doctor blade

14:

529:

51:

454:

481:

435:

419:

406:

392:

360:

344:

1:

337:

320:

84:Paint sample at top of Hegman

20:, sometimes referred to as a

7:

92:Hegman after paint drawdown

10:

534:

329:

513:Dimensional instruments

465:(14th ed.). ASTM.

93:

85:

77:

91:

83:

75:

518:Laboratory equipment

94:

86:

78:

61:units; NS) and/or

441:Peter A. Ciullo,

385:Robert B. McKay,

311:

310:

208:

207:

59:National Standard

525:

493:

492:

485:

476:

446:

439:

433:

423:

417:

410:

404:

403:

396:

390:

383:

372:

371:

364:

358:

348:

213:

212:

96:

95:

533:

532:

528:

527:

526:

524:

523:

522:

498:

497:

496:

487:

486:

482:

473:

457:

450:

449:

440:

436:

429:1950 pp 34-39,

424:

420:

411:

407:

398:

397:

393:

384:

375:

366:

365:

361:

349:

345:

340:

332:

323:

54:

12:

11:

5:

531:

521:

520:

515:

510:

495:

494:

479:

478:

477:

471:

456:

453:

448:

447:

434:

418:

405:

391:

373:

359:

342:

341:

339:

336:

331:

328:

322:

319:

309:

308:

305:

301:

300:

297:

293:

292:

289:

285:

284:

281:

277:

276:

273:

269:

268:

265:

261:

260:

257:

253:

252:

249:

245:

244:

241:

237:

236:

233:

229:

228:

225:

221:

220:

217:

206:

205:

202:

199:

195:

194:

191:

188:

184:

183:

180:

177:

173:

172:

169:

166:

162:

161:

158:

155:

151:

150:

147:

144:

140:

139:

136:

133:

129:

128:

125:

122:

118:

117:

114:

111:

107:

106:

103:

100:

53:

52:Use with paint

50:

9:

6:

4:

3:

2:

530:

519:

516:

514:

511:

509:

506:

505:

503:

490:

484:

480:

474:

472:0-8031-2060-5

468:

464:

459:

458:

452:

444:

438:

432:

428:

422:

415:

409:

401:

395:

388:

382:

380:

378:

369:

363:

357:

356:0-8031-2060-5

353:

347:

343:

335:

327:

318:

316:

306:

303:

302:

298:

295:

294:

290:

287:

286:

282:

279:

278:

274:

271:

270:

266:

263:

262:

258:

255:

254:

250:

247:

246:

242:

239:

238:

234:

231:

230:

226:

223:

222:

218:

215:

214:

211:

203:

200:

197:

196:

192:

189:

186:

185:

181:

178:

175:

174:

170:

167:

164:

163:

159:

156:

153:

152:

148:

145:

142:

141:

137:

134:

131:

130:

126:

123:

120:

119:

115:

112:

109:

108:

104:

101:

98:

97:

90:

82:

74:

70:

68:

64:

60:

49:

47:

46:particle size

41:

39:

35:

31:

27:

23:

19:

483:

462:

455:Bibliography

451:

437:

426:

421:

412:Eric Kissa,

408:

394:

362:

346:

333:

324:

312:

219:North units

209:

99:Hegman Units

58:

55:

42:

25:

21:

18:Hegman gauge

17:

15:

67:micrometres

22:grind gauge

502:Categories

338:References

321:Other uses

30:dispersion

26:grind gage

461:Koleske.

105:Microns

216:Microns

34:pigment

508:Paints

469:

354:

116:101.6

330:Sizes

315:gloss

193:12.7

182:25.4

171:38.1

160:50.8

149:63.5

138:76.2

127:88.9

38:paint

467:ISBN

352:ISBN

304:100

227:100

102:Mils

63:mils

427:113

299:10

296:90

291:20

283:30

275:40

267:50

259:60

251:70

243:80

235:90

190:0.5

168:1.5

146:2.5

135:3.0

124:3.5

113:4.0

65:or

504::

376:^

307:0

288:80

280:70

272:60

264:50

256:40

248:30

240:20

232:10

204:0

48:.

24:,

16:A

491:.

475:.

402:.

370:.

224:0

201:0

198:8

187:7

179:1

176:6

165:5

157:2

154:4

143:3

132:2

121:1

110:0

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.