145:

has been used for about 40 years. All die casting machines have been designed with the use of WBD. Water-based release coatings generally dry slower than solvent-based release agents but present fewer health and safety concerns. Water-based release agents will be less expensive to ship because of their inherently non-flammable nature and satisfy most plant-safety goals. Solvent-based release coatings dry almost instantly but present serious health and safety concerns. Fumes from solvent-based release agents may be hazardous without proper ventilation of the work area. Most solvents used in release agents are flammable.

374:

mold as it is loaded. Diluted silicone typically has to be applied every cycle. Semi-permanent mold release builds a silicone matrix on the mold that becomes a barrier between the rubber and the metal surface of the mold. The matrix is created by the other ingredients in the semi-permanent mold release. Applications of semi-permanent mold release vary from every cycle to once daily applications depending on the compound being molded and the design and quality of the mold. Silicone-based rubber products, however, require a non-silicone based releasing agent.

94:

27:

159:

1980 was used as the foundation to build the current program. The intent of asphalt release agents is to eliminate harmful stripping products that come into contact with bituminous products and strip the asphalt (binding agent) from the aggregates causing potholes, raveling, and other detrimental pavement failures.

114:(VOC) reduction along with the elimination of health and safety concerns surrounding solvent-based release agents were primary drivers in the development of cosolvent mold release. Cosolvent based release agents combine the benefits of a solvent based system and the safety of water-based release agents.

373:

based. The decision on which to use has to do with lubricity and release. Water-diluted silicone is used when you have rubber sliding over a hot mold (sheets or slugs). The silicone keeps the rubber from sticking to the mold but just as important it lubricates the rubber so it will slide over the hot

135:

Sacrificial coatings must be applied before every cycle of a molding operation and are therefore considered more labor intensive. Most molders will prefer semi-permanent coatings to sacrificial coatings, especially when molding rubber and plastic parts. These coatings contain fewer solid ingredients,

122:

One of the key attributes of a release agent is its degree of permanence: how long will it last before reapplication is necessary. A semi-permanent release agent does not need to be reapplied for every cycle of a molding operation and even works better when it is not over-applied to the mold surface.

144:

Release agents may be water or solvent-based and use of either will depend on the personal preference of the molder, plant safety regulations, hazardous materials shipping costs, state, local, or federal regulations, and/or desired drying times of the release coating. Water-based die lubricant (WBD)

73:

Release agents provide a barrier between a molding surface and the substrate, facilitating separation of the cured part from the mold. Without such a barrier, the substrate would become fused to the mold surface, resulting in difficult clean-up and dramatic loss in production efficiency. Even when a

158:

Asphalt release agents are chemical products developed and manufactured as alternatives to diesel and solvents commonly used for cleaning equipment associated with hot mix asphaltic concrete (HMAC) production and placement on government and private facilities. The United States Oil

Pollution Act of

126:

How many releases can be achieved before reapplication is necessary varies by process, material, and application method. In order to achieve multiple releases per application, the semi-permanent release coating generally must be applied to a clean, dry surface free of dirt, rust, grime or previous

211:

available in fresh concrete. A soapy film is created which prevents adhesion. Because it is a chemically reactive process, there is generally little to no residue or non-reacted product left on the forming surface or concrete which provides for a cleaner process.

74:

release agent is used, factors such as irregular applications or improper release agent choice may have a dramatic effect on the quality and consistency of the finished product. Many kinds of release agents are used. They are

345:

to prevent adhesives from bonding to the plastic surface. Some release agents, also known as de-molding agent, form oil, parting agent or form releaser, are substances used in

386:. These chemicals aid in keeping collections of polymeric materials from sticking together. Typical that are used for stacked sheets or rolls of plastics. They inhibit

353:

that aid in the separation of a mould from the material being moulded and reduce imperfections in the moulded surface. Slip

Additives are similarly used to prevent thin

502:

273:

Mold release agent also can be used in die casting or metal forging process of metal, such as aluminum, aluminum alloy, zinc, zinc alloy, magnesium, etc.

412:

285:

release agents are used to get slip effect of the paper from the processing equipment. A release agent may be applied on the process rolls (like the

483:

127:

coatings. This allows the release agent to properly bond to the mold and mold tooling, improving durability and longevity of the coating.

333:) are added to powdered and granulated drug compositions, to serve as a lubricant for mold release purposes during tabletting.

540:

246:

have been used, but in industrial food processing other chemicals might be used. The application is called bakery release.

171:

construction industry, form release agents prevent the adhesion of freshly placed concrete to the forming surface, usually

429:

567:

562:

111:

42:

used to prevent other materials from bonding to surfaces. Release agents aid in processes involving

448:

Stevens, Malcolm P. (1993). "Polymer

Additives: III. Surface Property and Processing Modifiers".

183:. In this application, there are two types of release agents available: barrier and reactive.

457:

358:

8:

357:

films from adhering to metal surfaces (or each other) during processing, for instance in

63:

461:

369:

There are two types of release agents used in the molding of rubber products. Both are

330:

536:

425:

346:

254:

221:

204:

528:

465:

417:

532:

208:

43:

20:

301:

523:

Pelzl, Bernhard; Wolf, Rainer; Kaul, Bansi Lal (2018). "Plastics, Additives".

556:

421:

308:

290:

87:

342:

286:

250:

67:

282:

79:

47:

38:(also mold release agent, release coating, or mold release coating) is a

354:

469:

387:

93:

370:

262:

258:

235:

190:

180:

168:

83:

55:

39:

350:

172:

51:

231:

503:"Water-Free Electrostatic Spray for High Pressure Die Casting"

297:

243:

176:

227:

194:

59:

239:

197:

or barrier between the forming surface and the concrete.

136:

and thus do not last as long as semi-permanent coatings.

75:

484:"Reduce VOC's in Automotive Seating molding operations"

30:

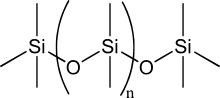

Polydimethylsiloxane (PDMS) is a typical release agent.

26:

226:

Release agents are used to aid in the separation of

311:

for pressure-sensitive adhesive laminates and tapes

203:are chemically active and work by the process of a

16:Substance applied to prevent adhesion to a surface

554:

525:Ullmann's Encyclopedia of Industrial Chemistry

413:Ullmann's Encyclopedia of Industrial Chemistry

522:

410:Lammerting, Helmut (2000). "Release Agents".

409:

139:

405:

403:

66:release. Release agents are one of many

92:

25:

447:

320:Food-grade release and packaging papers

207:between the release agent and the free

555:

500:

400:

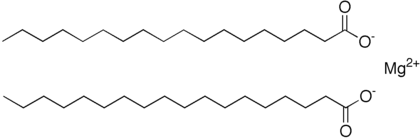

97:Magnesium stearate is a release agent.

443:

441:

19:For the pharmacological meaning, see

341:Release agents are coated onto some

70:used in the production of plastics.

13:

438:

377:

324:

215:

14:

579:

317:General industrial release papers

193:by the development of a physical

117:

268:

101:

230:from a cooking container after

148:

516:

494:

476:

382:Related to release agents are

265:release coatings may be used.

130:

1:

533:10.1002/14356007.a20_459.pub2

450:Journal of Chemical Education

393:

106:

7:

336:

162:

10:

584:

219:

153:

18:

364:

112:Volatile organic compound

510:Ultreaseal International

422:10.1002/14356007.a23_067

300:types are made with low

276:

416:. Weinheim: Wiley-VCH.

201:Reactive release agents

140:Water- or solvent-based

329:Release agents (e.g.,

187:Barrier release agents

98:

31:

220:Further information:

96:

29:

501:Butler, Tim (2011).

257:release agents like

175:, overlaid plywood,

462:1993JChEd..70..713S

488:Hightower Products

331:magnesium stearate

304:release coatings:

99:

32:

568:Process chemicals

563:Plastics industry

542:978-3-527-30673-2

527:. pp. 1–57.

470:10.1021/ed070p713

255:greaseproof paper

222:Non-stick surface

205:chemical reaction

575:

547:

546:

520:

514:

513:

507:

498:

492:

491:

480:

474:

473:

445:

436:

435:

407:

238:. Traditionally

583:

582:

578:

577:

576:

574:

573:

572:

553:

552:

551:

550:

543:

521:

517:

505:

499:

495:

482:

481:

477:

446:

439:

432:

408:

401:

396:

384:blocking agents

380:

378:Blocking agents

367:

339:

327:

325:Pharmaceuticals

279:

271:

224:

218:

216:Food processing

165:

156:

151:

142:

133:

120:

109:

104:

24:

21:releasing agent

17:

12:

11:

5:

581:

571:

570:

565:

549:

548:

541:

515:

493:

475:

437:

430:

398:

397:

395:

392:

379:

376:

366:

363:

338:

335:

326:

323:

322:

321:

318:

315:

314:Casting papers

312:

309:Release liners

302:surface energy

281:In industrial

278:

275:

270:

267:

217:

214:

164:

161:

155:

152:

150:

147:

141:

138:

132:

129:

119:

118:Semi-permanent

116:

108:

105:

103:

100:

88:metallic soaps

15:

9:

6:

4:

3:

2:

580:

569:

566:

564:

561:

560:

558:

544:

538:

534:

530:

526:

519:

511:

504:

497:

489:

485:

479:

471:

467:

463:

459:

455:

451:

444:

442:

433:

427:

423:

419:

415:

414:

406:

404:

399:

391:

389:

385:

375:

372:

362:

360:

356:

352:

348:

344:

343:plastic films

334:

332:

319:

316:

313:

310:

307:

306:

305:

303:

299:

294:

292:

291:paper coating

288:

284:

274:

269:Metal casting

266:

264:

260:

256:

252:

247:

245:

241:

237:

233:

229:

223:

213:

210:

206:

202:

198:

196:

192:

188:

184:

182:

178:

174:

170:

160:

146:

137:

128:

124:

115:

113:

102:Functionality

95:

91:

89:

85:

81:

77:

71:

69:

65:

61:

58:release, and

57:

53:

49:

45:

41:

37:

36:release agent

28:

22:

524:

518:

509:

496:

487:

478:

453:

449:

411:

383:

381:

368:

359:film blowing

340:

328:

295:

289:) or in the

287:yankee dryer

280:

272:

251:bakery paper

248:

225:

200:

199:

186:

185:

166:

157:

149:Applications

143:

134:

125:

121:

110:

72:

35:

33:

283:papermaking

131:Sacrificial

80:fatty ester

557:Categories

456:(9): 713.

431:3527306730

394:References

355:polyolefin

388:cold flow

107:Cosolvent

84:silicones

68:additives

54:release,

50:release,

46:release,

371:silicone

337:Plastics

263:silicone

259:catalyst

236:roasting

191:adhesion

189:prevent

181:aluminum

169:concrete

163:Concrete

56:adhesive

48:die-cast

40:chemical

490:. 2020.

458:Bibcode

351:casting

347:molding

261:-cured

173:plywood

167:In the

154:Asphalt

52:plastic

539:

428:

365:Rubber

232:baking

86:, and

506:(PDF)

298:paper

296:Some

277:Paper

244:flour

209:limes

177:steel

76:waxes

537:ISBN

426:ISBN

349:and

228:food

195:film

90:.

62:and

60:tire

44:mold

529:doi

466:doi

418:doi

390:.

253:or

249:In

242:or

240:fat

234:or

179:or

64:web

559::

535:.

508:.

486:.

464:.

454:70

452:.

440:^

424:.

402:^

361:.

293:.

82:,

78:,

34:A

545:.

531::

512:.

472:.

468::

460::

434:.

420::

23:.

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.