343:

878:

585:

246:

799:

1073:

1100:

606:"This alpha-beta alloy is the workhorse alloy of the titanium industry. The alloy is fully heat treatable in section sizes up to 15 mm and is used up to approximately 400 °C (750 °F). Since it is the most commonly used alloy – over 70% of all alloy grades melted are a sub-grade of Ti6Al4V, its uses span many aerospace airframe and engine component uses and also major non-aerospace applications in the marine, offshore and power generation industries in particular."

1131:) the possibility to produce custom-designed biomedical implants (e.g. hip joints) has been realized. Tests show it's 50% stronger than the next strongest alloy of similar density used in aerospace applications. While it is not applied currently on a larger scale, freeform fabrication methods offers the ability to recycle waste powder (from the manufacturing process) and makes for selectivity tailoring desirable properties and thus the performance of the implant.

970:

31:

434:

488:

145:

601:, and the remainder titanium. It is significantly stronger than commercially pure titanium (grades 1-4) while having the same stiffness and thermal properties (excluding thermal conductivity, which is about 60% lower in Grade 5 Ti than in CP Ti). Among its many advantages, it is heat treatable. This grade is an excellent combination of strength, corrosion resistance, weld and fabricability.

342:

986:

alloys can not only be stress relieved or annealed, but also can be solution treated and aged. The alpha-beta alloys are two-phase alloys, comprising both alpha and beta phases at room temperature. Phase compositions, sizes, and distributions of phases in alpha-beta alloys can be manipulated within certain limits by heat treatment, thus permitting tailoring of properties.

475:

of boats that are exposed to seawater. Titanium and its alloys are used in airplanes, missiles, and rockets where strength, low weight, and resistance to high temperatures are important. Further, since titanium does not react within the human body, it and its alloys are used in artificial joints, screws, and plates for fractures, and for other biological implants. See:

1155:: Excellent, especially when direct contact with tissue or bone is required. Ti-6Al-4V's poor shear strength makes it undesirable for bone screws or plates. It also has poor surface wear properties and tends to seize when in sliding contact with itself and other metals. Surface treatments such as nitriding and oxidizing can improve the surface wear properties.

1139:(SLM) are two methods applicable for freeform fabrication of Ti-alloys. Manufacturing parameters greatly influence the microstructure of the product, where e.g. a fast cooling rate in combination with low degree of melting in SLM leads to the predominant formation of martensitic alpha-prime phase, giving a very hard product.

503:"Alloys may be supplied in the following conditions: Grades 5, 23, 24, 25, 29, 35, or 36 annealed or aged; Grades 9, 18, 28, or 38 cold-worked and stress-relieved or annealed; Grades 9, 18, 23, 28, or 29 transformed-beta condition; and Grades 19, 20, or 21 solution-treated or solution-treated and aged."

1469:

Ishida, Taku; Wakai, Eiichi; Makimura, Shunsuke; Casella, Andrew M.; Edwards, Danny J.; Senor, David J.; Ammigan, Kavin; Hurh, Patrick G.; Densham, Christopher J.; Fitton, Michael D.; Bennett, Joe M.; Kim, Dohyun; Simos, Nikolaos; Hagiwara, Masayuki; Kawamura, Naritoshi; Meigo, Shin-ichiro; Yohehara,

1119:

production. Each of these techniques comes with inherent advantages and disadvantages. Wrought products come with an extensive material loss during machining into the final shape of the product and for cast samples the acquirement of a product in its final shape somewhat limits further processing and

474:

Titanium alone is a strong, light metal. It is stronger than common, low-carbon steels, but 45% lighter. It is also twice as strong as weak aluminium alloys but only 60% heavier. Titanium has outstanding corrosion resistance to seawater, and thus is used in propeller shafts, rigging and other parts

932:

contain 0.4% nickel, 0.015% palladium, 0.025% ruthenium, and 0.15% chromium. Both grades are identical but for minor difference in oxygen and nitrogen content. These grades contain 6 to 25 times less palladium than Grade 7 and are thus less costly, but offer similar corrosion performance thanks to

993:

The micro-structure of alpha alloys cannot be strongly manipulated by heat treatment since alpha alloys undergo no significant phase change. As a result, high strength can not be acquired for the alpha alloys by heat treatment. Yet, alpha and near-alpha titanium alloys can be stress relieved and

985:

Alpha and near-alpha alloys cannot be dramatically changed by heat treatment. Stress relief and annealing are the processes that can be employed for this class of titanium alloys. The heat treatment cycles for beta alloys differ significantly from those for the alpha and alpha-beta alloys. Beta

322:

field and was adopted for orthodontics use in the 1980s. This type of alloy replaced stainless steel for certain uses, as stainless steel had dominated orthodontics since the 1960s. It has strength/modulus of elasticity ratios almost twice those of 18-8 austenitic stainless steel, larger elastic

1000:

By working as well as heat treatment of alpha-beta alloys below or above the alpha-beta transition temperature, large micro-structural changes can be achieved. This may give a substantial hardening of the material. Solution treatment plus aging is used to produce maximum strengths in alpha-beta

959:

contains 4% aluminium, 2.5% vanadium, and 1.5% iron. This grade was developed in the 1990s for use as an armor plating. The iron reduces the amount of

Vanadium needed as a beta stabilizer. Its mechanical properties are very similar to Grade 5, but has good cold workability similar to grade

2067:

Murr, L. E.; Quinones, S. A.; Gaytan, S. M.; Lopez, M. I.; Rodela, A.; Martinez, E. Y.; Hernandez, D. H.; Martinez, E.; Medina, F. (2009-01-01). "Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications".

877:

466:

Many alloys also contain titanium as a minor additive, but since alloys are usually categorized according to which element forms the majority of the material, these are not usually considered to be "titanium alloys" as such. See the sub-article on

696:

contains 3.0% aluminium and 2.5% vanadium. This grade is a compromise between the ease of welding and manufacturing of the "pure" grades and the high strength of Grade 5. It is commonly used in aircraft tubing for hydraulics and in athletic

552:

Grades 1-4 are unalloyed and considered commercially pure or "CP". Generally the tensile and yield strength goes up with grade number for these "pure" grades. The difference in their physical properties is primarily due to the quantity of

981:

for a number of reasons, the main ones being to increase strength by solution treatment and aging as well as to optimize special properties, such as fracture toughness, fatigue strength and high temperature creep strength.

1433:"Transformation de la phase omega dans les alliages de titane comme exemple de reactions controlees par deplacementDie omega-phasenumwandlung in titanlegierungen als beispiel einer verschiebungskontrollierten reaktion"

1165:

This alloy was developed as a biomedical replacement for Ti-6Al-4V, because Ti-6Al-4V contains vanadium, an element that has demonstrated cytotoxic outcomes when isolated. Ti-6Al-7Nb contains 6% aluminium and 7%

2189:

by Mali

Palanuwech; Inaugural-Dissertation zur Erlangung des Doktorgrades der Zahnheilkunde der Medizinschen Fakultät der Eberhard-Karls-Universität zu Tübingenvorgelegt; Munich (2003). Retrieved 8 September

1331:

Najdahmadi, A.; Zarei-Hanzaki, A.; Farghadani, E. (1 February 2014). "Mechanical properties enhancement in Ti–29Nb–13Ta–4.6Zr alloy via heat treatment with no detrimental effect on its biocompatibility".

529:

is the most ductile and softest titanium alloy. It is a good solution for cold forming and corrosive environments. ASTM/ASME SB-265 provides the standards for commercially pure titanium sheet and plate.

463:, and so may be considered a Ti–O alloy. Oxide precipitates offer some strength (as discussed above), but are not very responsive to heat treatment and can substantially decrease the alloy's toughness.

755:

contains 3% aluminium, 2.5% vanadium and 0.04 to 0.08% palladium. This grade is identical to Grade 9 in terms of mechanical characteristics. The added palladium gives it increased corrosion resistance.

459:

dissolves in the metal at high temperatures, and its formation is very energetic. These two factors mean that all titanium except the most carefully purified has a significant amount of dissolved

670:

contains 5% aluminium and 2.5% tin. It is also known as Ti-5Al-2.5Sn. This alloy is used in airframes and jet engines due to its good weldability, stability and strength at elevated temperatures.

1107:

Titanium alloys have been extensively used for the manufacturing of metal orthopedic joint replacements and bone plate surgeries. They are normally produced from wrought or cast bar stock by

1169:

Ti6Al7Nb is a dedicated high strength titanium alloy with excellent biocompatibility for surgical implants. Used for replacement hip joints, it has been in clinical use since early 1986.

1149:

This alloy has good biocompatibility, and is neither cytotoxic nor genotoxic. Ti-6Al-4V suffers from poor shear strength and poor surface wear properties in certain loading conditions:

1592:

350:

The crystal structure of titanium at ambient temperature and pressure is close-packed hexagonal α phase with a c/a ratio of 1.587. At about 890 °C, the titanium undergoes an

1889:

Dallago, M.; Fontanari, V. (2018). "Fatigue and biological properties of Ti-6Al-4V ELI cellular structures with variously arranged cubic cells made by selective laser melting".

1124:), yet casting is more material effective. Traditional powder metallurgy methods are also more material efficient, yet acquiring fully dense products can be a common issue.

517:"The H grades were added in response to a user association request based on its study of over 5200 commercial Grade 2, 7, 16, and 26 test reports, where over 99% met the 58

512:, and may always be certified as meeting the requirements of its corresponding numeric grade. Grades 2H, 7H, 16H, and 26H are intended primarily for pressure vessel use."

185:

Alpha and beta alloys, which are metastable and generally include some combination of both alpha and beta stabilisers, and which can be heat treated. Examples include:

1470:

Katsuya (2020). "Tensile behavior of dual-phase titanium alloys under high-intensity proton beam exposure: Radiation-induced omega phase transformation in Ti-6Al-4V".

136:

process is carried out after the alloy has been worked into its final shape but before it is put to use, allowing much easier fabrication of a high-strength product.

593:

not to be confused with Ti-6Al-4V-ELI (Grade 23), is the most commonly used alloy. It has a chemical composition of 6% aluminum, 4% vanadium, 0.25% (maximum)

632:

of 1000 MPa. By comparison, annealed type 316 stainless steel has a density of 8000 kg/m, modulus of 193 GPa, and tensile strength of 570 MPa. Tempered

1233:

In a titanium or titanium alloy, alpha-to-beta transition temperature is the temperature above which the beta phase becomes thermodynamically favorable.

1208:

extend the lifespan of automotive parts. However, the high cost and manufacturing complexity of titanium limit its use mostly to high-performance and

680:. This grade is similar to Grade 2. The small quantity of palladium added gives it enhanced crevice corrosion resistance at low temperatures and high

2037:

Zhao, Qinyan; Sun, Qiaoyan (2022). "High-strength titanium alloys for aerospace engineering applications: A review on melting-forging process".

508:"Note 1—H grade material is identical to the corresponding numeric grade (that is, Grade 2H = Grade 2) except for the higher guaranteed minimum

1180:

Titanium alloys are used in the automobile industry due to their outstanding characteristics. Key applications include engine components like

2148:

Velasco-Ortega, E (Sep 2010). "In vitro evaluation of cytotoxicity and genotoxicity of a commercial titanium alloy for dental implantology".

1691:

1797:

1367:

200:

and which contain sufficient beta stabilisers (such as molybdenum, silicon and vanadium) to allow them to maintain the beta phase when

2187:

The fatigue resistance of commercially pure titanium(grade II), titanium alloy (Ti6Al7Nb) and conventional cobalt-chromium cast clasps

1001:

alloys. Also, other heat treatments, including stress-relief heat treatments, are practiced for this group of titanium alloys as well.

584:

1968:

441:

Generally, beta-phase titanium is the more ductile phase and alpha-phase is stronger yet less ductile, due to the larger number of

2347:

1724:

268:(called beta). Elements used in this alloy are one or more of the following other than titanium in varying amounts. These are

2246:

1538:

1829:

2293:"Impact of additive manufacturing on titanium supply chain: Case of titanium alloys in automotive and aerospace industries"

1552:"Impact of additive manufacturing on titanium supply chain: Case of titanium alloys in automotive and aerospace industries"

1132:

245:

1713:

499:

standard on titanium and titanium alloy seamless pipe references the following alloys, requiring the following treatment:

2212:

1926:

1388:

Goldberg, Jon; Burstone, Charles J. (1979). "An

Evaluation of Beta Titanium Alloys for Use in Orthodontic Appliances".

174:

beta-phase. Besides alpha-phase stabilisers, near-alpha alloys are alloyed with 1–2% of beta phase stabilizers such as

1653:

1282:

323:

deflections in springs, and reduced force per unit displacement 2.2 times below those of stainless steel appliances.

2185:

817:

improve ductility and fracture toughness with some reduction in strength. TAV-ELI is the most commonly used medical

1783:

557:. They are used for corrosion resistance applications where cost, ease of fabrication, and welding are important.

1550:

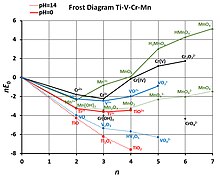

Nyamekye, Patricia; Rahimpour

Golroudbary, Saeed; Piili, Heidi; Luukka, Pasi; Kraslawski, Andrzej (2023-05-01).

821:-grade titanium alloy. Due to its excellent biocompatibility, corrosion resistance, fatigue resistance, and low

2012:

615:: Blades, discs, rings, airframes, fasteners, components. Vessels, cases, hubs, forgings. Biomedical implants."

450:

17:

1368:"INVESTIGATION OF THE BEHAVIOR OF MAGNESIUM IN ARC MELTING OF TITANIUM INGOTS AT PRESSURES OF UP TO 140 ATM"

825:, which closely matches human bone, TAV-ELI is the most commonly used medical implant-grade titanium alloy.

806:

contains 6% aluminium, 4% vanadium, 0.13% (maximum) Oxygen. ELI stands for Extra Low

Interstitial. Reduced

767:

contains 3% aluminium, 8% vanadium, 6% chromium, 4% zirconium, 4% molybdenum and 0.04% to 0.08% palladium.

1432:

129:

1765:

509:

1643:

ASTM B861 – 10 Standard

Specification for Titanium and Titanium Alloy Seamless Pipe (Grades 1 to 38)

2361:

1672:

442:

331:

2103:

Noronha, Jordan; Dash, Jason; Rogers, Jason; Leary, Martin; Brandt, Milan; Qian, Ma (2024-01-07).

1927:"Precision Engineering with Grade 23 Titanium: Ti-6Al-4V-ELI's Role in High-Performance Machinery"

1735:

636:

has a density of 2700 kg/m, modulus of 69 GPa, and tensile strength of 310 MPa, respectively.

1136:

1121:

108:

Although "commercially pure" titanium has acceptable mechanical properties and has been used for

354:

transformation to a body-centred cubic β phase which remains stable to the melting temperature.

1801:

798:

358:

2342:

2263:

2366:

1798:"Titanium Grade 7 (Titanium Palladium alloy, Ti-IIPd)-Metals, Alloys, and Sputtering Targets"

1112:

1025:

and heat, and its high strength-to-weight ratio. Titanium alloys are generally stronger than

807:

554:

1072:

1489:

633:

453:

alpha-phase. Alpha-beta-phase titanium has a mechanical property which is in between both.

446:

102:

66:

8:

1986:

258:

204:, and which can also be solution treated and aged to improve strength. Examples include:

1493:

1300:"Analysis of residual stresses in electron beam welding with filler wire of Ti62A alloy"

858:

contains 6% aluminium, 4% vanadium and 0.3% to 0.8% nickel and 0.04% to 0.08% palladium.

1505:

1479:

1413:

818:

625:

496:

476:

179:

167:) only. These are not heat treatable. Examples include: Ti-5Al-2Sn-ELI, Ti-8Al-1Mo-1V.

2327:

2242:

2165:

2130:

2122:

2085:

1573:

1534:

1509:

1448:

1405:

1349:

1278:

1116:

1108:

1081:

1854:

1614:

1417:

1060:

conditions in space. It is used in aerospace components such as aircraft frames and

2304:

2161:

2157:

2112:

2077:

2046:

1906:

1898:

1563:

1527:

1497:

1444:

1397:

1341:

1311:

1026:

941:

contains 4.5% aluminium, 2% molybdenum, 1.6% vanadium, 0.5% iron, and 0.3% silicon.

629:

456:

334:

omega-titanium at cryogenic temperatures or under influence of ionizing radiation.

125:

98:

58:

54:

2332:

2201:

Titanium Alloys – Ti6Al7Nb

Properties and Applications. Retrieved 8 September 2012

2200:

1501:

1833:

1747:

1702:

1401:

1345:

1272:

1253:

1209:

1197:

1189:

1185:

1038:

1007:

In commercial beta alloys, stress-relieving and aging treatments can be combined.

822:

761:

contains 3% aluminium, 8% vanadium, 6% chromium, 4% zirconium, and 4% molybdenum.

620:

Generally, Ti-6Al-4V is used in applications up to 400 degrees

Celsius. It has a

113:

2081:

1902:

1052:, was designed for low-temperature environments, maintaining high toughness and

468:

2309:

2292:

2050:

1568:

1551:

1316:

1299:

1034:

749:

contains 0.04 to 0.08% palladium. This grade has enhanced corrosion resistance.

737:

contains 0.04 to 0.08% palladium. This grade has enhanced corrosion resistance.

709:

contains 0.3% molybdenum and 0.8% nickel. This alloy has excellent weldability.

703:

contains 0.12 to 0.25% palladium. This grade has enhanced corrosion resistance.

361:, while others (beta stabilizers) lower the transition temperature. Aluminium,

205:

133:

90:

2337:

1871:

918:

contains 5% aluminium, 1% tin, 1% zirconium, 1% vanadium, and 0.8% molybdenum.

70:

2355:

2126:

1577:

1353:

1099:

978:

197:

148:

69:

and the ability to withstand extreme temperatures. However, the high cost of

65:(even at extreme temperatures). They are light in weight, have extraordinary

1952:

2343:

Phase

Stability and Stress-Induced Transformations in Beta Titanium Alloys

2169:

2134:

2117:

2104:

2089:

1692:

Compare

Materials: Commercially Pure Titanium and 6Al-4V (Grade 5) Titanium

1061:

1954:

Comparative corrosion behavior of two palladium-containing titanium alloys

1951:

T. Lian; T. Yashiki; T. Nakayama; T. Nakanishi; R. B. Rebak (2006-07-23).

1531:

357:

Some alloying elements, called alpha stabilizers, raise the alpha-to-beta

208:, Ti–29Nb–13Ta–4.6Zr, Ti-13V-11Cr-3Al, Ti-8Mo-8V-2Fe-3Al, Beta C, Ti-15-3.

1642:

1409:

1128:

1077:

319:

315:

The titanium alloys have excellent formability and can be easily welded.

234:

109:

1950:

1911:

1549:

969:

249:

Rail cross-section was used to advertise Titanium alloy as early as 1913

1615:"Titanium (Ti) - Chemical properties, Health and Environmental effects"

1201:

1160:

518:

382:

269:

261:

190:

175:

94:

82:

30:

1205:

1193:

1143:

1057:

1053:

1022:

728:

677:

572:

433:

398:

366:

351:

289:

285:

222:

218:

201:

186:

117:

62:

487:

155:

Titanium alloys are generally classified into four main categories:

1484:

1049:

1045:

406:

390:

386:

378:

297:

281:

273:

265:

217:

Although uncommercialized in the west, binary titanium alloys with

144:

128:

which varies dramatically with temperature, allowing it to undergo

121:

78:

74:

50:

1969:"Grade 38 Titanium: A High-Strength and Corrosion-Resistant Alloy"

124:, typically 6% and 4% respectively, by weight. This mixture has a

116:, for most applications titanium is alloyed with small amounts of

2105:"Titanium Multi-Topology Metamaterials with Exceptional Strength"

1330:

892:

contains 3% aluminium, 2.5% vanadium and 0.08 to 0.14% ruthenium.

774:

621:

422:

394:

362:

277:

230:

226:

171:

86:

1431:

De Fontaine§§, D.; Paton, N.E.; Williams, J.C. (November 1971).

852:

contains 6% aluminium, 4% vanadium and 0.04% to 0.08% palladium.

2264:"Applications and Features of titanium for automobile industry"

1196:. These alloys help reduce vehicle weight, leading to improved

1181:

1085:

898:

contains 6% aluminium, 4% vanadium and 0.08 to 0.14% ruthenium.

810:

598:

460:

418:

414:

410:

374:

370:

309:

305:

301:

164:

89:, medical devices, jewelry, highly stressed components such as

1267:

1265:

1263:

1261:

881:

A hexagon formed from thermal stir welding of a Titanium alloy

159:

Alpha alloys which contain neutral alloying elements (such as

1524:

Titanium Alloys: An Atlas of Structures and Fracture Features

1254:

Characteristics of Alpha, Alpha Beta and Beta Titanium Alloys

1091:

Titanium alloys have been used occasionally in architecture.

1030:

1021:

Titanium is used regularly in aviation for its resistance to

327:

254:

46:

35:

743:

is identical to Grade 16 (Grade 16 with 58 ksi minimum UTS).

2213:"Applications Of Titanium Alloy In The Automobile Industry"

1258:

814:

594:

437:

Titanium alloys make lightweight products like pocketknives

402:

293:

27:

Metal alloys made by combining titanium with other elements

2070:

Journal of the Mechanical Behavior of Biomedical Materials

1891:

Journal of the Mechanical Behavior of Biomedical Materials

1468:

1430:

690:

is identical to Grade 7 (Grade 7 with 58 ksi minimum UTS).

1957:. ASME Pressure Vessels and Piping Conference. Vancouver.

1714:

Material Properties Data: 6Al-4V (Grade 5) Titanium Alloy

160:

2066:

681:

2102:

1725:

Material Properties Data: Marine Grade Stainless Steel

646:

AMS: 4911, 4928, 4965, 4967, 6930, 6931, T-9046, T9047

2239:

Light Alloys: From Traditional Alloys to Nanocrystals

541:

Unalloyed titanium (Grade 2 with 58 ksi minimum UTS).

2297:

Advances in Industrial and Manufacturing Engineering

1556:

Advances in Industrial and Manufacturing Engineering

1298:

Wang, B.; Zhou, L.; Du, J.; Cao, Y. (January 2023).

2290:

2181:

2179:

2328:http://www.tifab.com/subpages/tech_spec_grades.htm

1987:"Preparations for the First Manned Apollo Mission"

1127:With the emergence of solid freeform fabrication (

318:Beta titanium is nowadays largely utilized in the

163:) and/ or alpha stabilisers (such as aluminium or

2261:

449:structure of the beta-phase in comparison to the

346:Microstructure of a part made from Titanium alloy

2353:

2176:

1888:

1784:"Titanium Ti-5Al-2.5Sn (Grade 6) - Material Web"

1387:

2291:Nyamekye, Patricia; Golroudbary, S. R. (2023).

829:Ti-6Al-4V-ELI standard specifications include:

2147:

1297:

2262:Yamashita, Yoshito; Takayama, Isamu (2002).

2194:

1304:Journal of Materials Research and Technology

1044:The Ti-3Al-2.5V alloy, which consists of 3%

773:contains 15% molybdenum, 3% aluminium, 2.7%

2236:

1696:

1638:

1636:

1634:

802:3-D Printed Spinal Disc from Titanium alloy

641:Ti-6Al-4V standard specifications include:

1866:

1864:

1736:Material Properties Data: 6061-T6 Aluminum

1200:and performance. Additionally, titanium's

973:Titanium alloy used in frame of sunglasses

237:pressure vessel at up to 140 atmospheres.

170:Near-alpha alloys contain small amount of

2308:

2116:

2013:"Titanium Used in the Aerospace Industry"

1910:

1590:

1567:

1483:

1360:

1315:

337:

178:, silicon or vanadium. Examples include:

1855:"Active Atom Materials - Titanium Group"

1631:

1098:

1071:

968:

912:contain 0.3% cobalt and 0.05% palladium.

876:

797:

583:

486:

432:

341:

244:

143:

29:

2036:

1861:

1849:

1847:

1845:

1843:

1016:

182:, Ti-5Al-5Sn-2Zr-2Mo, IMI 685, Ti 1100.

14:

2354:

2010:

1824:

1822:

1820:

1818:

1790:

1667:

1665:

1663:

1661:

1175:

2062:

2060:

1067:

196:Beta and near beta alloys, which are

1840:

1375:BEHAVIOR OF MAGNESIUM IN ARC MELTING

886:all contain 0.08 to 0.14% ruthenium.

535:Unalloyed titanium, standard oxygen.

1815:

1770:Service Steel Aerospace Corporation

1658:

1591:Gerdemann, Steven J. (2001-07-01).

1033:. It has been used in the earliest

834:AMS: 4907, 4930, 6932, T9046, T9047

24:

2057:

1597:Advanced Materials & Processes

727:all contain 0.5% nickel and 0.05%

547:Unalloyed titanium, medium oxygen.

482:

25:

2378:

2321:

2039:Materials Science and Engineering

1703:Titanium Alloys – Ti6Al4V Grade 5

964:

1593:"TITANIUM: Process Technologies"

588:Turbine blade made from Ti alloy

330:can convert to hard and brittle

240:

212:

189:, Ti-6Al-4V-ELI, Ti-6Al-6V-2Sn,

2284:

2255:

2230:

2205:

2141:

2096:

2030:

2004:

1979:

1961:

1944:

1919:

1882:

1776:

1758:

1740:

1729:

1718:

1707:

1685:

1647:

1607:

1584:

1543:

1516:

1011:

2162:10.1016/j.mrgentox.2010.06.013

1462:

1424:

1381:

1324:

1291:

1247:

1227:

13:

1:

2011:Trento, Chin (Apr 12, 2024).

1502:10.1016/j.jnucmat.2020.152413

1215:

1094:

428:

139:

57:. Such alloys have very high

1766:"Ti-6Al-4V Titanium Grade 5"

1654:Titanium Grades, Application

1472:Journal of Nuclear Materials

1449:10.1016/0001-6160(71)90047-2

1402:10.1177/00220345790580020901

1346:10.1016/j.matdes.2013.09.007

1274:Titanium – A Technical Guide

491:File:Titanium alloy products

477:Titanium orthopedic implants

7:

2333:Datasheet for Beta Titanium

2082:10.1016/j.jmbbm.2008.05.004

2017:Stanford Advanced Materials

1973:Stanford Advanced Materials

1903:10.1016/j.jmbbm.2017.11.044

1277:. ASM International. 2000.

1029:, while being lighter than

990:Alpha and near-alpha alloys

624:of roughly 4420 kg/m,

130:precipitation strengthening

10:

2383:

2310:10.1016/j.aime.2023.100112

2217:Advanced Refractory Metals

2051:10.1016/j.msea.2022.143260

1876:Performance Titanium Group

1752:Performance Titanium Group

1569:10.1016/j.aime.2023.100112

1390:Journal of Dental Research

1317:10.1016/j.jmrt.2023.01.081

1192:, suspension springs, and

326:Some of the beta titanium

49:that contain a mixture of

2241:. Elsevier. p. 361.

1830:"Titanium Grade Overview"

233:have been produced in an

1103:Titanium plate for wrist

953:contains 1.5% aluminium.

1137:Selective Laser Melting

1122:precipitation hardening

676:contains 0.12 to 0.25%

649:ASTM: B265, B348, F1472

381:are alpha stabilizers.

2118:10.1002/adma.202308715

1334:Materials & Design

1171:

1157:

1115:-driven machining, or

1104:

1088:

974:

882:

837:ASTM: B265, B348, F136

803:

617:

608:

589:

523:

514:

505:

492:

438:

425:are beta stabilizers.

359:transition temperature

347:

338:Transition temperature

250:

152:

39:

1872:"6Al-4V-ELI Titanium"

1532:10.1201/9781420006063

1167:

1150:

1133:Electron Beam Melting

1102:

1076:Titanium cladding of

1075:

972:

947:contains 45% niobium.

880:

823:modulus of elasticity

808:interstitial elements

801:

655:DMS: 1592, 1570, 1583

609:

604:

587:

555:interstitial elements

515:

506:

501:

490:

469:titanium applications

436:

345:

248:

147:

33:

2237:Ian Polmear (2005).

1017:Aerospace structures

977:Titanium alloys are

933:the added ruthenium.

777:, and 0.25% silicon.

634:6061 aluminium alloy

151:of various Ti alloys

103:consumer electronics

67:corrosion resistance

1526:. CRC Press, 2006.

1522:Vydehi Arun Joshi.

1494:2020JNuM..54152413I

1176:Automobile industry

2338:Titanium Alloy Bar

2109:Advanced Materials

1204:and resistance to

1105:

1089:

1068:Architectural uses

975:

883:

804:

590:

497:ASTM International

493:

439:

348:

251:

180:Ti-6Al-2Sn-4Zr-2Mo

153:

40:

34:Titanium alloy in

2248:978-0-7506-6371-7

1772:. 6 October 2020.

1748:"6Al-4V Titanium"

1539:978-0-429-12327-6

1443:(11): 1153–1162.

1437:Acta Metallurgica

1153:Bio compatibility

1117:powder metallurgy

1082:Guggenheim Museum

997:Alpha-beta alloys

658:Boeing: BMS 7-269

597:, 0.2% (maximum)

97:and some premium

71:processing limits

55:chemical elements

16:(Redirected from

2374:

2315:

2314:

2312:

2288:

2282:

2281:

2279:

2277:

2268:

2259:

2253:

2252:

2234:

2228:

2227:

2225:

2223:

2209:

2203:

2198:

2192:

2183:

2174:

2173:

2145:

2139:

2138:

2120:

2100:

2094:

2093:

2064:

2055:

2054:

2034:

2028:

2027:

2025:

2023:

2008:

2002:

2001:

1999:

1997:

1983:

1977:

1976:

1965:

1959:

1958:

1948:

1942:

1941:

1939:

1937:

1931:Stanford Powders

1923:

1917:

1916:

1914:

1886:

1880:

1879:

1868:

1859:

1858:

1851:

1838:

1837:

1832:. Archived from

1826:

1813:

1812:

1810:

1809:

1800:. Archived from

1794:

1788:

1787:

1780:

1774:

1773:

1762:

1756:

1755:

1744:

1738:

1733:

1727:

1722:

1716:

1711:

1705:

1700:

1694:

1689:

1683:

1682:

1680:

1679:

1669:

1656:

1651:

1645:

1640:

1629:

1628:

1626:

1625:

1619:www.lenntech.com

1611:

1605:

1604:

1588:

1582:

1581:

1571:

1547:

1541:

1520:

1514:

1513:

1487:

1466:

1460:

1459:

1457:

1455:

1428:

1422:

1421:

1385:

1379:

1378:

1372:

1364:

1358:

1357:

1328:

1322:

1321:

1319:

1295:

1289:

1288:

1269:

1256:

1251:

1234:

1231:

1120:treatment (e.g.

1027:aluminium alloys

929:

909:

873:

840:MIL: T9046 T9047

792:

724:

652:MIL: T9046 T9047

630:tensile strength

628:of 120 GPa, and

580:

457:Titanium dioxide

126:solid solubility

99:sports equipment

59:tensile strength

21:

2382:

2381:

2377:

2376:

2375:

2373:

2372:

2371:

2362:Titanium alloys

2352:

2351:

2324:

2319:

2318:

2289:

2285:

2275:

2273:

2266:

2260:

2256:

2249:

2235:

2231:

2221:

2219:

2211:

2210:

2206:

2199:

2195:

2184:

2177:

2146:

2142:

2101:

2097:

2065:

2058:

2035:

2031:

2021:

2019:

2009:

2005:

1995:

1993:

1985:

1984:

1980:

1967:

1966:

1962:

1949:

1945:

1935:

1933:

1925:

1924:

1920:

1887:

1883:

1870:

1869:

1862:

1853:

1852:

1841:

1828:

1827:

1816:

1807:

1805:

1796:

1795:

1791:

1782:

1781:

1777:

1764:

1763:

1759:

1746:

1745:

1741:

1734:

1730:

1723:

1719:

1712:

1708:

1701:

1697:

1690:

1686:

1677:

1675:

1671:

1670:

1659:

1652:

1648:

1641:

1632:

1623:

1621:

1613:

1612:

1608:

1589:

1585:

1548:

1544:

1521:

1517:

1467:

1463:

1453:

1451:

1429:

1425:

1386:

1382:

1370:

1366:

1365:

1361:

1329:

1325:

1296:

1292:

1285:

1271:

1270:

1259:

1252:

1248:

1238:

1237:

1232:

1228:

1218:

1210:luxury vehicles

1198:fuel efficiency

1190:exhaust systems

1186:connecting rods

1178:

1146:/ Ti-6Al-4V-ELI

1097:

1070:

1039:Project Mercury

1019:

1014:

967:

921:

901:

861:

780:

712:

626:Young's modulus

562:

485:

483:Titanium grades

431:

340:

243:

215:

142:

114:dental implants

91:connecting rods

43:Titanium alloys

28:

23:

22:

15:

12:

11:

5:

2380:

2370:

2369:

2364:

2350:

2349:

2345:

2340:

2335:

2330:

2323:

2322:External links

2320:

2317:

2316:

2283:

2254:

2247:

2229:

2204:

2193:

2175:

2140:

2095:

2056:

2029:

2003:

1978:

1960:

1943:

1918:

1881:

1878:. 15 May 2015.

1860:

1839:

1836:on 2023-03-26.

1814:

1789:

1775:

1757:

1754:. 15 May 2015.

1739:

1728:

1717:

1706:

1695:

1684:

1673:"Titanium-6-4"

1657:

1646:

1630:

1606:

1583:

1542:

1515:

1461:

1423:

1396:(2): 593–599.

1380:

1359:

1323:

1290:

1283:

1257:

1245:

1244:

1243:

1242:

1236:

1235:

1225:

1224:

1223:

1222:

1217:

1214:

1177:

1174:

1173:

1172:

1163:

1158:

1147:

1096:

1093:

1069:

1066:

1035:Apollo Program

1018:

1015:

1013:

1010:

1009:

1008:

1005:

1002:

998:

995:

991:

966:

965:Heat treatment

963:

962:

961:

957:

954:

951:

948:

945:

942:

939:

935:

934:

930:

919:

916:

913:

910:

899:

896:

893:

890:

887:

875:

874:

859:

856:

853:

850:

846:

845:

844:

843:

842:

841:

838:

835:

796:

795:

793:

784:also known as

778:

771:

768:

765:

762:

759:

756:

753:

750:

747:

744:

741:

738:

735:

732:

725:

710:

707:

704:

701:

698:

694:

691:

688:

685:

674:

671:

668:

664:

663:

662:

661:

660:

659:

656:

653:

650:

647:

638:

637:

603:

602:

582:

581:

566:also known as

559:

558:

549:

548:

545:

542:

539:

536:

533:

530:

527:

484:

481:

430:

427:

339:

336:

253:Beta titanium

242:

239:

214:

211:

210:

209:

206:Ti-10V-2Fe-3Al

194:

183:

168:

141:

138:

134:heat treatment

77:applications,

26:

18:Titanium alloy

9:

6:

4:

3:

2:

2379:

2368:

2365:

2363:

2360:

2359:

2357:

2348:

2346:

2344:

2341:

2339:

2336:

2334:

2331:

2329:

2326:

2325:

2311:

2306:

2302:

2298:

2294:

2287:

2272:

2265:

2258:

2250:

2244:

2240:

2233:

2218:

2214:

2208:

2202:

2197:

2191:

2188:

2182:

2180:

2171:

2167:

2163:

2159:

2155:

2151:

2144:

2136:

2132:

2128:

2124:

2119:

2114:

2110:

2106:

2099:

2091:

2087:

2083:

2079:

2075:

2071:

2063:

2061:

2052:

2048:

2044:

2040:

2033:

2018:

2014:

2007:

1992:

1988:

1982:

1974:

1970:

1964:

1956:

1955:

1947:

1932:

1928:

1922:

1913:

1908:

1904:

1900:

1896:

1892:

1885:

1877:

1873:

1867:

1865:

1856:

1850:

1848:

1846:

1844:

1835:

1831:

1825:

1823:

1821:

1819:

1804:on 2012-04-26

1803:

1799:

1793:

1785:

1779:

1771:

1767:

1761:

1753:

1749:

1743:

1737:

1732:

1726:

1721:

1715:

1710:

1704:

1699:

1693:

1688:

1674:

1668:

1666:

1664:

1662:

1655:

1650:

1644:

1639:

1637:

1635:

1620:

1616:

1610:

1602:

1598:

1594:

1587:

1579:

1575:

1570:

1565:

1561:

1557:

1553:

1546:

1540:

1536:

1533:

1529:

1525:

1519:

1511:

1507:

1503:

1499:

1495:

1491:

1486:

1481:

1477:

1473:

1465:

1450:

1446:

1442:

1438:

1434:

1427:

1419:

1415:

1411:

1407:

1403:

1399:

1395:

1391:

1384:

1376:

1369:

1363:

1355:

1351:

1347:

1343:

1339:

1335:

1327:

1318:

1313:

1309:

1305:

1301:

1294:

1286:

1284:9781615030620

1280:

1276:

1275:

1268:

1266:

1264:

1262:

1255:

1250:

1246:

1240:

1239:

1230:

1226:

1220:

1219:

1213:

1211:

1207:

1203:

1199:

1195:

1191:

1187:

1183:

1170:

1164:

1162:

1159:

1156:

1154:

1148:

1145:

1142:

1141:

1140:

1138:

1134:

1130:

1125:

1123:

1118:

1114:

1110:

1101:

1092:

1087:

1083:

1079:

1074:

1065:

1063:

1059:

1055:

1051:

1047:

1042:

1040:

1036:

1032:

1028:

1024:

1006:

1003:

999:

996:

992:

989:

988:

987:

983:

980:

971:

958:

955:

952:

949:

946:

943:

940:

937:

936:

931:

928:

924:

920:

917:

914:

911:

908:

904:

900:

897:

894:

891:

888:

885:

884:

879:

872:

868:

864:

860:

857:

854:

851:

848:

847:

839:

836:

833:

832:

831:

830:

828:

827:

826:

824:

820:

816:

812:

809:

800:

794:

791:

787:

786:Ti-6Al-4V-ELI

783:

779:

776:

772:

769:

766:

763:

760:

757:

754:

751:

748:

745:

742:

739:

736:

733:

730:

726:

723:

719:

715:

711:

708:

705:

702:

699:

695:

692:

689:

686:

683:

679:

675:

672:

669:

666:

665:

657:

654:

651:

648:

645:

644:

643:

642:

640:

639:

635:

631:

627:

623:

619:

618:

616:

614:

607:

600:

596:

592:

591:

586:

579:

575:

574:

569:

565:

561:

560:

556:

551:

550:

546:

543:

540:

537:

534:

531:

528:

525:

524:

522:

521:minimum UTS."

520:

513:

511:

504:

500:

498:

489:

480:

478:

472:

470:

464:

462:

458:

454:

452:

448:

444:

435:

426:

424:

420:

416:

412:

408:

404:

400:

396:

392:

388:

384:

380:

376:

372:

368:

364:

360:

355:

353:

344:

335:

333:

329:

324:

321:

316:

313:

311:

307:

303:

299:

295:

291:

287:

283:

279:

275:

271:

267:

263:

260:

256:

247:

241:Beta-titanium

238:

236:

232:

228:

224:

220:

213:Uncategorized

207:

203:

199:

195:

192:

188:

184:

181:

177:

173:

169:

166:

162:

158:

157:

156:

150:

149:Frost diagram

146:

137:

135:

131:

127:

123:

119:

115:

111:

106:

104:

100:

96:

93:on expensive

92:

88:

84:

80:

76:

73:their use to

72:

68:

64:

60:

56:

52:

48:

44:

37:

32:

19:

2367:Orthodontics

2300:

2296:

2286:

2274:. Retrieved

2271:Nippon Steel

2270:

2257:

2238:

2232:

2220:. Retrieved

2216:

2207:

2196:

2186:

2156:(1): 17–23.

2153:

2149:

2143:

2111:: e2308715.

2108:

2098:

2076:(1): 20–32.

2073:

2069:

2042:

2038:

2032:

2020:. Retrieved

2016:

2006:

1994:. Retrieved

1990:

1981:

1972:

1963:

1953:

1946:

1934:. Retrieved

1930:

1921:

1912:11572/190389

1894:

1890:

1884:

1875:

1834:the original

1806:. Retrieved

1802:the original

1792:

1778:

1769:

1760:

1751:

1742:

1731:

1720:

1709:

1698:

1687:

1676:. Retrieved

1649:

1622:. Retrieved

1618:

1609:

1600:

1596:

1586:

1559:

1555:

1545:

1523:

1518:

1475:

1471:

1464:

1452:. Retrieved

1440:

1436:

1426:

1393:

1389:

1383:

1374:

1362:

1337:

1333:

1326:

1307:

1303:

1293:

1273:

1249:

1229:

1179:

1168:

1152:

1151:

1126:

1106:

1090:

1062:landing gear

1043:

1020:

1012:Applications

984:

979:heat treated

976:

926:

922:

906:

902:

870:

866:

862:

805:

789:

785:

781:

721:

717:

713:

613:Applications

612:

610:

605:

577:

571:

567:

563:

516:

507:

502:

494:

473:

465:

455:

440:

356:

349:

325:

317:

314:

257:exhibit the

252:

216:

154:

107:

42:

41:

1897:: 381–394.

1340:: 786–791.

1310:: 985–997.

1129:3D printing

1078:Frank Gehry

1056:even under

1004:Beta alloys

443:slip planes

320:orthodontic

235:arc melting

193:, and Ti62A

95:sports cars

2356:Categories

2150:Mutat. Res

1808:2011-12-19

1678:2009-02-19

1624:2023-05-11

1562:: 100112.

1485:2004.11562

1478:: 152413.

1216:References

1202:durability

1161:Ti-6Al-7Nb

1135:(EBM) and

1095:Biomedical

697:equipment.

429:Properties

383:Molybdenum

352:allotropic

270:molybdenum

262:allotropic

198:metastable

191:Ti-6Al-7Nb

176:molybdenum

140:Categories

110:orthopedic

83:spacecraft

53:and other

2127:0935-9648

1578:2666-9129

1510:216144772

1354:0261-3069

1206:corrosion

1194:fasteners

1144:Ti-6Al-4V

1058:cryogenic

1054:ductility

1048:and 2.5%

1023:corrosion

994:annealed.

923:Grades 33

903:Grades 30

863:Grades 26

740:Grade 16H

729:ruthenium

714:Grades 13

678:palladium

573:Ti-6Al-4V

399:manganese

367:germanium

332:hexagonal

290:manganese

286:zirconium

223:potassium

219:magnesium

187:Ti-6Al-4V

118:aluminium

63:toughness

2170:20615479

2135:38160263

2090:19627804

2022:June 26,

1996:June 26,

1603:(7): 41.

1454:27 April

1418:29064479

1166:niobium.

1050:vanadium

1046:aluminum

956:Grade 38

950:Grade 37

944:Grade 36

938:Grade 35

915:Grade 32

895:Grade 29

889:Grade 28

855:Grade 25

849:Grade 24

782:Grade 23

770:Grade 21

764:Grade 20

758:Grade 19

752:Grade 18

746:Grade 17

734:Grade 16

706:Grade 12

700:Grade 11

687:Grade 7H

538:Grade 2H

407:chromium

391:tantalum

387:vanadium

379:nitrogen

298:chromium

282:tantalum

274:vanadium

266:titanium

264:form of

202:quenched

122:vanadium

87:bicycles

79:aircraft

75:military

51:titanium

2276:July 6,

2222:July 6,

1936:Aug 25,

1490:Bibcode

1377:. 1980.

1241:Sources

819:implant

790:TAV-ELI

775:niobium

693:Grade 9

673:Grade 7

667:Grade 6

622:density

568:Ti6Al4V

564:Grade 5

544:Grade 3

532:Grade 2

526:Grade 1

445:in the

423:silicon

395:niobium

363:gallium

278:niobium

231:lithium

227:calcium

172:ductile

132:. This

2245:

2168:

2133:

2125:

2088:

1576:

1537:

1508:

1416:

1410:283089

1408:

1352:

1281:

1182:valves

1086:Bilbao

869:, and

811:oxygen

720:, and

599:oxygen

578:Ti 6-4

461:oxygen

419:copper

415:nickel

411:cobalt

375:oxygen

371:carbon

328:alloys

310:copper

308:, and

306:nickel

302:cobalt

255:alloys

165:oxygen

47:alloys

2267:(PDF)

1506:S2CID

1480:arXiv

1414:S2CID

1371:(PDF)

1221:Notes

1031:steel

36:ingot

2278:2024

2243:ISBN

2224:2024

2190:2012

2166:PMID

2131:PMID

2123:ISSN

2086:PMID

2024:2024

1998:2024

1991:NASA

1938:2024

1574:ISSN

1535:ISBN

1456:2020

1406:PMID

1350:ISSN

1279:ISBN

1184:and

1037:and

925:and

905:and

815:iron

813:and

595:iron

495:The

421:and

403:iron

377:and

294:iron

120:and

112:and

101:and

61:and

45:are

38:form

2305:doi

2158:doi

2154:702

2113:doi

2078:doi

2047:doi

2043:845

1907:hdl

1899:doi

1601:159

1564:doi

1528:doi

1498:doi

1476:541

1445:doi

1398:doi

1342:doi

1312:doi

1113:CAD

1109:CNC

1084:in

1080:'s

867:26H

788:or

576:or

519:ksi

510:UTS

451:hcp

447:bcc

259:BCC

161:tin

2358::

2303:.

2299:.

2295:.

2269:.

2215:.

2178:^

2164:.

2152:.

2129:.

2121:.

2107:.

2084:.

2072:.

2059:^

2045:.

2041:.

2015:.

1989:.

1971:.

1929:.

1905:.

1895:78

1893:.

1874:.

1863:^

1842:^

1817:^

1768:.

1750:.

1660:^

1633:^

1617:.

1599:.

1595:.

1572:.

1558:.

1554:.

1504:.

1496:.

1488:.

1474:.

1441:19

1439:.

1435:.

1412:.

1404:.

1394:58

1392:.

1373:.

1348:.

1338:54

1336:.

1308:23

1306:.

1302:.

1260:^

1212:.

1188:,

1111:,

1064:.

1041:.

960:9.

927:34

907:31

871:27

865:,

722:15

718:14

716:,

682:pH

570:,

479:.

471:.

417:,

413:,

409:,

405:,

401:,

397:,

393:,

389:,

385:,

373:,

369:,

365:,

312:.

304:,

300:,

296:,

292:,

288:,

284:,

280:,

276:,

272:,

229:,

225:,

221:,

105:.

85:,

81:,

2313:.

2307::

2301:6

2280:.

2251:.

2226:.

2172:.

2160::

2137:.

2115::

2092:.

2080::

2074:2

2053:.

2049::

2026:.

2000:.

1975:.

1940:.

1915:.

1909::

1901::

1857:.

1811:.

1786:.

1681:.

1627:.

1580:.

1566::

1560:6

1530::

1512:.

1500::

1492::

1482::

1458:.

1447::

1420:.

1400::

1356:.

1344::

1320:.

1314::

1287:.

731:.

684:.

611:"

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.