48:

265:

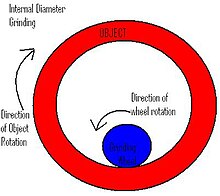

workblade is angled slightly towards the regulating wheel, with the workpiece centerline above the centerlines of the regulating and grinding wheel; this means that high spots do not tend to generate corresponding opposite low spots, and hence the roundness of parts can be improved. Centerless grinding is much easier to combine with automatic loading procedures than centered grinding; through feed grinding, where the regulating wheel is held at a slight angle to the part so that there is a force feeding the part through the grinder, is particularly efficient.

162:

254:

246:

111:, one of the first piece of precision machinery to be used in a residential setting. Joseph Brown believed that the shaft and needle bars of the sewing machine must be crafted from hardened tool steel. It was this desire that led to their experimentation with building a cylindrical grinder. The first attempt was simply a small lathe with a grinding wheel mounted to it. Subsequent attempts led to the cylindrical grinder displayed at the 1876

104:. The basis for the modern day cylindrical grinder was first built in the 1830s by two men working independently, Jonathan Bridges and James Wheaton . It is unclear as to which man had first produced the machine but both are closely tied to the first historical appearance of the modern day tool. It took another 40 years before further improvement and refinement of the tool occurred.

131:, where he continued improving the cylindrical grinder to use faster rpm values and more precise grinding tolerances. He was acknowledged for his work on April 18, 1925 when he won The John Scott Medal and Premium for his invention of "accurate grinding devices of high power". These standards developed by Norton were the status quo until about the middle of the 20th century.

177:

118:

It is important to note that Brown & Sharpe cannot be given sole credit of pioneering advances in cylindrical grinding. A man in

Waltham, Massachusetts, Ambrose Webster had created a small grinding machine in 1860 that contained all of the improvements Brown & Sharpe claimed to be their own

264:

is a form of grinding where there is no collet or pair of centers holding the object in place. Instead, there is a regulating wheel positioned on the opposite side of the object to the grinding wheel. A work rest keeps the object at the appropriate height but has no bearing on its rotary speed. The

199:

OD grinding is grinding occurring on external surface of an object between the centers. The centers are end units with a point that allow the object to be rotated. The grinding wheel is also being rotated in the same direction when it comes in contact with the object. This effectively means the two

143:

in the 1940s. The U.S. Air Force, looking for a faster, cheaper, and more efficient means of part and tool production for airplanes, played a large role in developing NC both politically and financially. The first implementation of NC in machine tools occurred in the 1950s and continued through the

281:

using a pre existing interface designed for that machine or by using a PC as an interface to communicate with the grinder. The first two options are rarely if ever used today. CNC operated cylindrical grinders are the most technologically advanced, efficient, reliable systems in the manufacturing

148:

which once again revolutionized the ability of the cylindrical grinder. Now the machine was able to receive instruction from a computer which would give it precise directions on every imaginable dimension and measurement needed to produce the desired product. This was a completely different work

232:

Creep Feed is a form of grinding where a full depth of cut is removed in a single pass of the wheel. Successful operation of this technique can reduce manufacturing time by 50%, but often the grinding machine being used must be designed specifically for this purpose. This form occurs in both

134:

The remainder of technological innovation applicable to the cylindrical grinder is almost identical and entangled in a sense, to the rest of machine tools. The innovation of the last 70 years can be characterized by three waves of change. The first wave was the creation of

290:

Cylindrical grinders, versatile and precise machines, are employed in various industries for a range of applications due to their capability to achieve fine finishes and tight tolerances on cylindrical surfaces. These applications include:

126:

Norton was an employee of Brown & Sharpe who quit the company with the desire to further pursue his belief that the cylindrical grinder is not merely a finishing tool but could be a staple of the machine shop. He founded the

212:, which also rotates the object in place. Just as with OD grinding, the grinding wheel and the object are rotated in opposite directions giving reversed direction contact of the two surfaces where the grinding occurs. See also

27:

used to shape the outside of an object. The cylindrical grinder can work on a variety of shapes, however the object must have a central axis of rotation. This includes but is not limited to such shapes as a

149:

environment in comparison to mid-century production where a worker had to direct the machine at every point on how to manipulate the work. The third wave of change came in the 1990s with the advent of the

432:

Arnold, Heinrich Martin. "The recent history of the machine tool industry and the effects of technological change." Institute for

Innovation Research and Technology Management. Nov. 2001. University of

144:

1960s. The second wave of innovation, occurring during the 1970s and 1980s, is marked by the massive demand for microcomputers to be used to direct NC. The joining of computers marked the birth of

108:

191:

There are five different types of cylindrical grinding: outside diameter (OD) grinding, inside diameter (ID) grinding, plunge grinding, creep feed grinding, and centerless grinding.

208:

ID grinding is grinding occurring on the inside of an object. The grinding wheel is always smaller than the width of the hole being ground. The object is held in place by a

326:

Cylindrical grinders are adaptable to various materials and can handle different cylindrical shapes, proving indispensable in industries requiring high-precision grinding.

224:

A form of OD grinding, however the major difference is that the grinding wheel makes continuous contact with a single point of the object instead of traversing the object.

306:: Essential in producing engine and turbine components, bearings, landing gear, and hydraulic control valves, demanding high precision for reliable aerospace operations.

314:: Employed in the creation of surgical tools, prostheses, and dental equipment. The precision grinding is crucial for the functionality and safety of medical devices.

153:. Integrating CNC and the PC into one dynamic system allowed for even further control of the manufacturing process that required little to no human supervision.

298:: Utilized for manufacturing engine components, transmission components, and other critical parts, where precision is paramount for performance and safety.

322:: Used for manufacturing rotor shafts, transmission components, and compressor components, particularly where tough materials require precise machining.

580:

377:

542:

213:

273:

There are three basics ways in which an operator can interact with a cylindrical grinder. Either manual manipulation of the machine,

72:

While the majority of cylindrical grinders employ all four movements, there are grinders that only employ three of the four actions.

200:

surfaces will be moving opposite directions when contact is made which allows for a smoother operation and less chance of a jam up.

573:

80:

The origins of the cylindrical grinder, as with all other modern machine tools, stem from the experimentation and invention of

598:

648:

566:

535:

839:

81:

1151:

711:

618:

528:

119:

original invention. Even more so, the emphasis on precision, accuracy, and reliability was championed by

761:

686:

335:

1146:

1002:

278:

145:

844:

701:

834:

374:

120:

1120:

924:

909:

849:

811:

751:

128:

954:

934:

829:

1053:

914:

613:

112:

93:

1038:

944:

643:

92:, respectively. The cylindrical grinder owes much of its development from the onset of the

8:

967:

894:

261:

47:

29:

1058:

864:

821:

726:

589:

481:"The method of assessment of the grinding wheel cutting ability in the plunge grinding"

161:

107:

The Brown & Sharpe company in

Providence, RI was one of the first builders of the

1095:

1090:

628:

274:

150:

136:

1043:

806:

796:

771:

766:

633:

608:

492:

234:

24:

741:

676:

671:

381:

245:

140:

37:

253:

1017:

977:

899:

776:

101:

85:

68:

Either the work or the grinding wheel is transversed with respect to the other.

497:

480:

1140:

1033:

997:

982:

801:

756:

736:

731:

1012:

992:

879:

551:

962:

889:

781:

691:

1115:

1110:

987:

904:

696:

41:

1105:

1100:

1068:

1063:

884:

874:

859:

791:

666:

854:

721:

681:

656:

88:

who built the first horizontal boring machine and the first engine

55:

Cylindrical grinding is defined as having four essential actions:

1125:

1085:

1007:

939:

869:

786:

33:

375:

http://www.the-vms.com/vms/other_grinding/other_grinding_00.html

972:

929:

919:

623:

520:

209:

465:

Kocherovsky, Eugene. "50 years of technological

Development."

1048:

661:

176:

97:

89:

65:

The grinding wheel is fed towards and away from the work

515:. 1st. Sussx, England: The Lewes Press, 1963. 155-174.

96:, particularly to the advent of reliable, inexpensive

414:

Biographical

Dictionary of the History of Technology

373:"Grinding Overview" Virtual Machine Shop, Web. <

1138:

364:. 2nd. Cleveland: Judson Company, 1959. 104-141.

416:. London and New York: Routledge, 1996. 525-527

257:A schematic of the centerless grinding process.

62:The grinding wheel must be constantly rotating

574:

536:

59:The work (object) must be constantly rotating

443:

441:

439:

400:. 2nd. Cambridge: M.I.T. Press, 1964. 31-71.

194:

100:production and later the improvement of the

588:

203:

581:

567:

543:

529:

451:. 2nd. Boca Raton: CRC Press, 1997. 52-60.

428:

426:

424:

422:

392:

390:

496:

436:

461:

459:

457:

252:

244:

175:

160:

46:

485:Central European Journal of Engineering

478:

419:

408:

406:

387:

356:

354:

352:

350:

1139:

240:

227:

562:

524:

454:

403:

347:

277:with a punched card system or using

479:Nadolny, Krzysztof (9 April 2012).

13:

268:

219:

109:Willcox & Gibbs Sewing Machine

14:

1163:

449:Metal Cutting Theory and Practice

550:

398:History of the Grinding Machine

285:

840:Electrical discharge machining

629:Numerical control (NC and CNC)

505:

472:

367:

249:Centerless cylindrical grinder

1:

341:

187:iameter Cylindrical Grinding

513:Grinding Wheels and Machines

172:iameter Cylindrical Grinding

7:

687:List of drill and tap sizes

336:Grinding (abrasive cutting)

329:

115:and the subsequent patent.

10:

1168:

1003:Magnetic switchable device

279:Computer Numerical Control

156:

146:Computer Numerical Control

75:

1081:

1026:

953:

845:Electrochemical machining

820:

710:

642:

597:

558:

498:10.2478/s13531-012-0005-5

412:Day, Lance; McNeil, Ian.

195:Outside diameter grinding

467:Cutting Tool Engineering

204:Inside diameter grinding

925:Rotary transfer machine

910:Photochemical machining

850:Electron-beam machining

812:Tool and cutter grinder

129:Norton Grinding Company

469:. 57.8 (2005): 95-114.

258:

250:

188:

173:

52:

51:A cylindrical grinder.

1121:Tools and terminology

256:

248:

179:

164:

113:Centennial Exposition

94:Industrial Revolution

50:

1152:Grinding and lapping

1039:Machining vibrations

945:Ultrasonic machining

1059:Tool and die making

747:Cylindrical grinder

511:Houghton, Phillip.

447:Stephenson, David.

296:Automotive Industry

262:Centerless grinding

241:Centerless grinding

228:Creep feed grinding

21:cylindrical grinder

727:Abrasive machining

396:Robert, Woodbury.

380:2010-02-04 at the

362:The Grinding Wheel

259:

251:

189:

174:

53:

1147:Grinding machines

1134:

1133:

1077:

1076:

275:Numerical Control

151:Personal Computer

137:numerical control

1159:

1044:Speeds and feeds

797:Sharpening stone

772:Grinding machine

767:Grinding dresser

634:Stewart platform

583:

576:

569:

560:

559:

545:

538:

531:

522:

521:

516:

509:

503:

502:

500:

476:

470:

463:

452:

445:

434:

430:

417:

410:

401:

394:

385:

371:

365:

360:Lewis, Kenneth.

358:

235:surface grinding

233:cylindrical and

25:grinding machine

16:Grinding machine

1167:

1166:

1162:

1161:

1160:

1158:

1157:

1156:

1137:

1136:

1135:

1130:

1073:

1022:

949:

816:

807:Surface grinder

742:Coated abrasive

713:

706:

677:Drill bit sizes

672:Drill bit shank

647:

638:

600:

593:

587:

554:

549:

519:

510:

506:

477:

473:

464:

455:

446:

437:

431:

420:

411:

404:

395:

388:

382:Wayback Machine

372:

368:

359:

348:

344:

332:

320:Energy Industry

312:Medical Devices

288:

271:

269:Control methods

243:

230:

222:

220:Plunge grinding

206:

197:

159:

141:John T. Parsons

78:

17:

12:

11:

5:

1165:

1155:

1154:

1149:

1132:

1131:

1129:

1128:

1123:

1118:

1113:

1108:

1103:

1098:

1093:

1088:

1082:

1079:

1078:

1075:

1074:

1072:

1071:

1066:

1061:

1056:

1051:

1046:

1041:

1036:

1030:

1028:

1024:

1023:

1021:

1020:

1015:

1010:

1005:

1000:

995:

990:

985:

980:

975:

970:

965:

959:

957:

951:

950:

948:

947:

942:

937:

932:

927:

922:

917:

912:

907:

902:

900:Milling cutter

897:

892:

887:

882:

877:

872:

867:

862:

857:

852:

847:

842:

837:

832:

826:

824:

818:

817:

815:

814:

809:

804:

799:

794:

789:

784:

779:

777:Grinding wheel

774:

769:

764:

759:

754:

749:

744:

739:

734:

729:

724:

718:

716:

708:

707:

705:

704:

699:

694:

689:

684:

679:

674:

669:

664:

659:

653:

651:

640:

639:

637:

636:

631:

626:

621:

616:

611:

605:

603:

599:Computer-aided

595:

594:

586:

585:

578:

571:

563:

556:

555:

548:

547:

540:

533:

525:

518:

517:

504:

491:(3): 399–409.

471:

453:

435:

418:

402:

386:

366:

345:

343:

340:

339:

338:

331:

328:

324:

323:

316:

315:

308:

307:

300:

299:

287:

284:

270:

267:

242:

239:

229:

226:

221:

218:

205:

202:

196:

193:

158:

155:

121:Charles Norton

102:grinding wheel

86:Henry Maudslay

82:John Wilkinson

77:

74:

70:

69:

66:

63:

60:

15:

9:

6:

4:

3:

2:

1164:

1153:

1150:

1148:

1145:

1144:

1142:

1127:

1124:

1122:

1119:

1117:

1114:

1112:

1109:

1107:

1104:

1102:

1099:

1097:

1094:

1092:

1089:

1087:

1084:

1083:

1080:

1070:

1067:

1065:

1062:

1060:

1057:

1055:

1052:

1050:

1047:

1045:

1042:

1040:

1037:

1035:

1034:Cutting fluid

1032:

1031:

1029:

1025:

1019:

1016:

1014:

1011:

1009:

1006:

1004:

1001:

999:

998:Machine taper

996:

994:

991:

989:

986:

984:

983:Indexing head

981:

979:

976:

974:

971:

969:

966:

964:

961:

960:

958:

956:

955:Machine tools

952:

946:

943:

941:

938:

936:

933:

931:

928:

926:

923:

921:

918:

916:

913:

911:

908:

906:

903:

901:

898:

896:

893:

891:

888:

886:

883:

881:

878:

876:

873:

871:

868:

866:

863:

861:

858:

856:

853:

851:

848:

846:

843:

841:

838:

836:

833:

831:

828:

827:

825:

823:

819:

813:

810:

808:

805:

803:

802:Spark testing

800:

798:

795:

793:

790:

788:

785:

783:

780:

778:

775:

773:

770:

768:

765:

763:

760:

758:

757:Flick grinder

755:

753:

752:Diamond plate

750:

748:

745:

743:

740:

738:

737:Bench grinder

735:

733:

732:Angle grinder

730:

728:

725:

723:

720:

719:

717:

715:

709:

703:

700:

698:

695:

693:

690:

688:

685:

683:

680:

678:

675:

673:

670:

668:

665:

663:

660:

658:

655:

654:

652:

650:

645:

641:

635:

632:

630:

627:

625:

622:

620:

617:

615:

612:

610:

607:

606:

604:

602:

596:

592:and computing

591:

584:

579:

577:

572:

570:

565:

564:

561:

557:

553:

546:

541:

539:

534:

532:

527:

526:

523:

514:

508:

499:

494:

490:

486:

482:

475:

468:

462:

460:

458:

450:

444:

442:

440:

429:

427:

425:

423:

415:

409:

407:

399:

393:

391:

383:

379:

376:

370:

363:

357:

355:

353:

351:

346:

337:

334:

333:

327:

321:

318:

317:

313:

310:

309:

305:

302:

301:

297:

294:

293:

292:

283:

280:

276:

266:

263:

255:

247:

238:

236:

225:

217:

215:

211:

201:

192:

186:

182:

178:

171:

167:

163:

154:

152:

147:

142:

138:

132:

130:

124:

122:

116:

114:

110:

105:

103:

99:

95:

91:

87:

83:

73:

67:

64:

61:

58:

57:

56:

49:

45:

43:

39:

35:

31:

26:

23:is a type of

22:

1013:Rotary table

993:Lathe center

880:Machine tool

746:

712:Grinding and

552:Metalworking

512:

507:

488:

484:

474:

466:

448:

413:

397:

369:

361:

325:

319:

311:

303:

295:

289:

286:Applications

272:

260:

231:

223:

207:

198:

190:

184:

180:

169:

165:

133:

125:

117:

106:

79:

71:

54:

20:

18:

1091:Fabrication

1027:Terminology

963:Angle plate

890:Metal lathe

782:Jig grinder

692:Tap and die

601:engineering

214:ID Grinding

1141:Categories

1111:Metallurgy

905:Pantograph

697:Tap wrench

342:References

282:industry.

84:and later

42:crankshaft

1106:Machining

1101:Jewellery

1069:Workpiece

1064:Tramp oil

1054:Tolerance

885:Machining

875:Jig borer

860:Engraving

835:Broaching

822:Machining

702:Threading

667:Drill bit

649:threading

590:Machining

304:Aerospace

1116:Smithing

855:End mill

762:Grinding

722:Abrasive

682:Drilling

657:Die head

644:Drilling

378:Archived

330:See also

30:cylinder

1126:Welding

1096:Forming

1086:Casting

1018:Wiggler

1008:Mandrel

978:Fixture

940:Turning

935:Skiving

895:Milling

870:Hobbing

792:Sanding

787:Lapping

714:lapping

168:utside

157:Methods

76:History

40:, or a

34:ellipse

973:Collet

930:Shaper

920:Reamer

915:Planer

865:Facing

830:Boring

624:G-code

433:Munich

210:collet

183:nside

1049:Swarf

968:Chuck

662:Drill

384:>.

98:steel

90:lathe

32:, an

609:2.5D

36:, a

19:The

988:Jig

646:and

619:CAM

614:CAD

493:doi

139:by

38:cam

1143::

487:.

483:.

456:^

438:^

421:^

405:^

389:^

349:^

237:.

216:.

123:.

44:.

582:e

575:t

568:v

544:e

537:t

530:v

501:.

495::

489:2

185:D

181:I

170:D

166:O

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.