662:

649:

spindles for a new set. The cops are removed and collected into cans or baskets, and subsequently delivered to the warehouse. The remainder of the "draw" or "stretch," as the length of spun yarn is called when the carriage is out, is then wound upon the spindles as the carriage is run up to the roller beam. Work then commences anew. The doffing took only a few minutes, the piecers would run the length of the mule gate thrutching five spindles a time, and the doffing involved lifting four cops from the spindles with the right hand and piling them on the left forearm and hand. To get a firm cop bottom, the minder would whip the first few layers of yarn. After the first few draws the minder would stop the mule at the start of an inward run and take it in slowly depressing and releasing the faller wire several times. Alternatively, a starch paste could be skilfully applied to the first few layers of yarn by the piecers – and later a small paper tube was dropped over spindle – this slowed down the doffing operation and extra payment was negotiated by the minders.

695:-inch (3.2 cm) gap between two ends, stripping them of fly and replacing them on the next inward run. Cleaning the carriage top was far more dangerous. The minder would stop the mule on the outward run, and raise his hands above his head. The piecers would enter under the yarn sheet with a scavenger cloth on the carriage spindle rail and a brush on the roller beam, and run bent double the entire length of the mule, avoiding the rails and draw bands, and not letting themselves touch the yarn sheet. When they had finished they would run to agreed positions of safety where the minder could see both of them, and the minder would unclip the stang and start the mule. Before this ritual was devised, boys had been crushed. The mule was 130 feet (40 m) long, the minder's eyesight might not have been good, the air in the mill was clouded with fly and another minder's boys might have been mistaken for his. The ritual became encoded in law.

1760:

1494:

378:

658:

that each mule worked differently. They were specialists in spinning, and were answerable only to the gaffer and under-gaffer who were in charge of the floor and with it the quantity and quality of the yarn that was produced. Bobbins of rovings came from the carder in the blowing room delivered by a bobbin carrier who was part of the carder's staff, and yarn was hoisted down to the warehouse by the warehouseman's staff. Delineation of jobs was rigid and communication would be through the means of coloured slips of paper written on in indelible pencil.

626:

yarn, and impede subsequent operations. As, however, the twist, spreading itself over the level thread, gives firmness to this portion, the thick and untwisted part yields to the draught of the spindle, and, as it approaches the tenuity of the remainder, it receives the twist it had hitherto refused to take. The carriage, which is borne upon wheels, continues its outward progress, until it reaches the extremity of its traverse, which is 63 inches (160 cm) from the roller beam. The revolution of the spindles cease, the drawing rollers stop.

556:

519:

24:

454:

430:

442:

749:

674:

stopped while the thread was found. The number of yarn breakages was dependent on the quality of the roving, and quality cotton led to fewer breakages. Typical 1,200 spindle mules of the 1920s would experience 5 to 6 breakages a minute. The two piecers would thus need to repair the thread within 15 to 20 seconds while the mule was in motion but once they had the thread it took under three seconds. The repair actually involved a slight rolling of the forefinger against the thumb.

466:

567:

258:

418:

43:

704:

818:

that was captured by the clothing of anyone piecing an end. In the 1920s much attention was given to this problem. Mules had used this mixture since the 1880s, and cotton mules ran faster and hotter than the other mules, and needed more frequent oiling. The solution was to make it a statutory requirement to use only vegetable oil or white mineral oils, which were believed to be non-

112:, uses a continuous process, where the roving is drawn, twisted and wrapped in one action. The mule was the most common spinning machine from 1790 until about 1900 and was still used for fine yarns until the early 1980s. In 1890, a typical cotton mill would have over 60 mules, each with 1,320 spindles, which would operate four times a minute for 56 hours a week.

26:

31:

29:

25:

510:

on mule-type machines which have no roller drafting, but create the draft by the spindles receding from the delivery rollers whilst that latter, having paid out a short length of roving, are held stationary. Such mules are often complex involving multiple spindles speeds, receding motions, etc. to ensure optimum treatment of the yarn.

30:

305:

remove irregularities from the rove before it is wound on the spindle. When

Arkwright's patents expired, the mule was developed by several manufacturers. Crompton's first mule had 48 spindles and could produce 1 pound (0.45 kg) of 60s thread a day. This demanded a spindle speed of 1,700 rpm, and a power input of

573:

571:

569:

572:

28:

613:

Connection is then established between the attenuated rovings and the spindles. When the latter are bare, as in a new mule, the spindle-driving motion is put into gear, and the attendants wind upon each spindle a short length of yarn from a cop held in the hand. The drawing-roller motion is placed in

673:

Piecing involved repairing sporadic yarn breakages. At the rollers, the broken yarn would be caught on the underclearer (or fluker rod on Bolton mules), while at the spindle it would knot itself into a whorl on the spindle tip. If the break happened on the winding stroke the spindle might have to be

669:

Creeling involved replacing the rovings bobbins in a section of the mule without stopping the mule. On very coarse counts a bobbin lasted two days but on fine count it could last for 3 weeks. To creel, the creeler stood behind the mule, placing new bobbins on the shelf above the creel. As the bobbin

657:

A pair of mules would be manned by a person called the minder and two boys called the side piecer and the little piecer. They worked barefoot in humid temperatures; the minder and the little piecer worked the minder half of the mule. The minder would make minor adjustments to his mules to the extent

648:

Doffing is performed by the piercers thrutching, that is raising, the cops partially up the spindles, whilst the carriage is out. The minder then depressing the faller, so far as to guide the threads upon the bare spindle below. A few turns are wound onto the spindle, to fix the threads to the bare

617:

The back rollers pull the sliver from the bobbins, and passing it to the succeeding pairs, whose differential speeds attenuate it to the required degree of fineness. As it is delivered in front, the spindles, revolving at a rate of 6,000–9,000 rpm twist the hitherto loose fibres together, thus

522:

A pair of

Condenser spinning mules. These have 748 spindles and are believed to be the longest surviving cotton mules. They worked at Field Mill Ramsbottom, Lancashire until that mill closed in 1988 at which time they were the last such machines at work in the cotton industry probably in the world.

509:

Spinning wool is a different process as the variable lengths of the individual fibres means that they are unsuitable for attenuation by roller drafting. For this reason, woolen fibres are carded using condenser cards which rub the carded fibres together rather than drafting them. They are then spun

500:

Bolton specialised in fine count cotton, and its mules ran more slowly to put in the extra twist. The mule jenny allowed for this gentler action but in the 20th century additional mechanisms were added to make the motion more gentle, leading to mules that used two or even three driving speeds. Fine

210:

pulled the rovings through a set of attenuating rollers. Spinning at differing speeds, these pulled the thread continuously while other parts twisted it as it wound onto the heavy spindles. This produced thread suitable for warp, but the multiple rollers required much more energy input and demanded

625:

of the carriage, its purpose being to eliminate all irregularities in the fineness of the thread. Should a thick place in the roving come through the rollers, it would resist the efforts of the spindle to twist it; and, if passed in this condition, it would seriously deteriorate the quality of the

527:

Condenser spinning was developed to enable the short fibres produced as waste from the combing of fine cottons, to be spun into a soft, coarse yarns suitable for sheeting, blankets etc. Only approximately 2% of the mule spindles in

Lancashire were Condenser spindles, but many more Condenser mules

817:

detected in former mule spinners. It was limited to cotton mule spinners and did not affect woollen or condenser mule spinners. The cause was attributed to the blend of vegetable and mineral oils used to lubricate the spindles. The spindles, when running, threw out a mist of oil at crotch height,

680:

Cleaning was important and until a formal ritual had been devised it was a dangerous operation. The vibration in a mule threw a lot of short fibres (or fly) into the air. It tended to accumulate on the carriage behind the spindles and in the region of the drafting rollers. Piking the stick meant

356:

used a new method to assist the draw stroke. First animals, and then water, was used as the prime mover. Wright of

Manchester moved the headstock to the centre of the machine, allowing twice as many spindles; a squaring band was added to ensure the spindles came out in a straight line. He was in

69:

and elsewhere. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer. The carriage carried up to 1,320 spindles and could be 150 feet (46 m) long, and would move forward and back a distance of 5 feet (1.5 m) four times a minute.

304:

Crompton built his mule from wood. Although he used

Hargreaves' ideas of spinning multiple threads and of attenuating the roving with rollers, it was he who put the spindles on the carriage and fixed a creel of roving bobbins on the frame. Both the rollers and the outward motion of the carriage

771:

The 1790 mule was operated by brute force: the spinner drawing and pushing the frame while attending to each spindle. Home spinning was the occupation of women and girls, but the strength needed to operate a mule caused it to be the activity of men. Hand loom weaving, however, had been a man's

614:

gear, and the rollers soon present lengths of attenuated roving. These are attached to the threads on the spindles, by simply placing the threads in contact with the un-twisted roving. The different parts of the machine are next simultaneously started, when the whole works in harmony together.

194:

allowed a group of eight spindles to be operated together. It mirrored the simple wheel; the rovings were clamped, and a frame moved forward stretching and thinning the roving. A wheel was rapidly turned as the frame was pushed back, and the spindles rotated, twisting the rovings into yarn and

633:

The carriage commences to run inwards; that is, towards the rollerbeam. This is called putting up. The spindles wind on the yarn at a uniform rate. The speed of revolution of the spindle must vary, as the faller is guiding the thread upon the larger or smaller diameter of the cone of the cop.

491:

Oldham counts refers to the medium thickness cotton that was used for general purpose cloth. Roberts did not profit from his self-acting spinning mule, but on the expiry of the patent other firms took forward the development, and the mule was adapted for the counts it spun. Initially

Roberts'

410:

A counter faller under the thread was made to rise to take in the slack caused by backing off. This could be used with the top faller wire to guide the yarn to the correct place on the cop. These were controlled by levers and cams and an inclined plane called the shaper. The spindle speed was

629:

Backing-off commences. This process is the unwinding of the several turns of the yarn, extending from the top of the cop in process of formation to the summit of the spindle. As this proceeds, the faller- wire, which is placed over and guides the threads upon the cop, is depressed ; the

584:

Mule spindles rest on a carriage that travels on a track a distance of 60 inches (1.5 m), while drawing out and spinning the yarn. On the return trip, known as putting up, as the carriage moves back to its original position, the newly spun yarn is wound onto the spindle in the form of a

570:

300:

to hold the roving, connected through the headstock to a parallel carriage with the spindles. On the outward motion, the rovings are paid out through attenuating rollers and twisted. On the return, the roving is clamped and the spindles are reversed to take up the newly spun thread.

670:

ran empty he would pick it off its skewer in the creel unreeling 30 cm or so of roving, and drop it into a skip. With his left hand, he would place on the new bobbin onto the skewer from above and with his right hand twist in the new roving into the tail of the last.

368:

William Eaton, in 1818, improved the winding of the thread by using two faller wires and performing a backing off at the end of the outward traverse. All these mules had been worked by the strength of the operatives. The next improvement was a fully automatic mule.

411:

controlled by a drum and weighted ropes, as the headstock moved the ropes twisted the drum, which using a tooth wheel turned the spindles. None of this would have been possible using the technology of

Crompton's time, fifty years earlier.

365:. In 1793, John Kennedy addressed the problem of fine counts. With these counts, the spindles on the return traverse needed to rotate faster than on the outward traverse. He attached gears and a clutch to implement this motion.

27:

568:

783:

Mule spinners were the leaders in unionism within the cotton industry; the pressure to develop the self-actor or self-acting mule was partly to open the trade to women. It was in 1870 that the first national

195:

collecting it on the spindles. The spinning jenny was effective and could be operated by hand, but it produced weaker thread that could be used only for the weft part of the cloth. (Because the side-to-side

2299:

349:, constructed a mule using toothed gearing and, importantly, metal rollers. Baker of Bury worked on drums, and Hargreaves used parallel scrolling to achieve smoother acceleration and deceleration.

345:

Crompton's machine was largely built of wood, using bands and pulleys for the driving motions. After his machine was public, he had little to do with its development. Henry Stones, a mechanic from

361:, was concerned with building ever larger mules. McConnell & Kennedy ventured into spinning when they were left with two unpaid-for mules; their firm prospered and eventually merged into the

2329:

661:

392:

took out his first patent in 1825 and a second in 1830. The task he had set himself was to design a self-actor, a self-acting or automatic spinning mule. Roberts is also known for the

621:

Whilst this is going on, the spindle carriage is being drawn away from the rollers, at a pace very slightly exceeding the rate at which the roving is coming forth. This is called the

2406:

2177:

1834:

1388:

585:

cone-shaped cop. As the mule spindle travels on its carriage, the roving which it spins is fed to it through rollers geared to revolve at different speeds to draw out the yarn.

909:

799:. It lagged behind cotton in adopting new technology. Worsted tended to adopt Arkwright water frames which could be operated by young girls, and woollen adopted the mule.

630:

counter-faller at the same time rising, the slack unwound from the spindles is taken up, and the threads are prevented from running into snarls. Backing-off is completed.

492:

self-actor was used for coarse counts (Oldham Counts), but the mule-jenny continued to be used for the very finest counts (Bolton counts) until the 1890s and beyond.

2344:

396:, which was widely adopted because of its reliability. The mule in 1820 still needed manual assistance to spin a consistent thread; a self-acting mule would need:

1379:

Short video showing the spinning of cotton yarn on a self-acting cotton mule. The video shows how broken yarn is "pieced" together - without stopping the machine.

822:. By then cotton mules had been superseded by the ring frame and the industry was contracting, so it was never established whether these measures were effective.

2339:

1789:

2594:

1784:

739:

772:

occupation but in the mill it could and was done by girls and women. Spinners were the bare-foot aristocrats of the factory system. It replaced decentralised

2304:

1819:

836:

211:

that the device be driven by a water wheel. The early water frame, however, had only a single spindle. Combining ideas from these two system inspired the

2441:

1980:

1945:

592:

2309:

681:

placing the hand though the yarnsheet, and unclipping two sticks of underclearer rollers from beneath the drafting rollers, drawing them through the

760:

The spinning inventions were significant in enabling a great expansion to occur in the production of textiles, particularly cotton ones. Cotton and

2359:

1779:

768:. Both industries underwent a great expansion at about the same time, which can be used to identify the start of the Industrial Revolution.

357:

conversation with John

Kennedy about the possibility of a self-acting mule. Kennedy, a partner in McConnell & Kennedy machine makers in

846:

540:

Mules are still in use for spinning woolen and alpaca, and being produced across the world. In Italy for example by

Bigagli and Cormatex

81:

in 1825. At its peak, there were 5,000,000 mule spindles in

Lancashire alone. Modern versions are still in production and are used to spin

2349:

2243:

1693:

917:

465:

400:

A reversing mechanism that would unwind a spiral of yarn on the top of each spindle, before commencing the winding of a new stretch

2066:

164:

made the loom twice as productive, causing the demand for cotton yarn to vastly exceed what traditional spinners could supply.

249:

in the 1820s, was little used in Lancashire until the 1890s. It required more energy and could not produce the finest counts.

2314:

1362:

606:

The motion of the middle pair is slightly quicker than the first, but only sufficiently so to keep the roving uniformly tense

501:

counts needed a softer action on the winding, and relied on manual adjustment to wind the chase or top of the perfect cop.

2319:

1383:

1420:

603:

The first pair takes hold of the roving, to draw the roving or sliver from the bobbin, and deliver it to the next pair.

1244:

Fowler, Alan (11–13 November 2004). "British Textile Workers in the Lancashire Cotton and Yorkshire Wool Industries".

588:

Marsden in 1885 described the processes of setting up and operating a mule. Here is his description, edited slightly.

406:

An appliance to vary the speed of revolution of the spindle, in accordance with the diameter of thread on that spindle

187:

employed inventors to find solutions that would increase the amount of yarn spun, then took out the relevant patents.

2476:

2421:

2334:

1859:

1305:

1283:

976:

728:

1814:

1686:

2497:

2026:

529:

136:

the fibre – break up and clean the disorganised fluff into long bundles. The women would then spin these rough

2152:

2126:

1935:

743:

453:

2116:

1995:

483:

With the invention of the self actor, the hand-operated mule was increasingly referred to as a mule-jenny.

1393:

241:

Development over the next century and a half led to an automatic mule and to finer and stronger yarn. The

2599:

2436:

2431:

2426:

2091:

1930:

1849:

1829:

1824:

1759:

1493:

914:

Modern automatic spinning mules, bale breakers and carding machines used for woolen and cashmere products

2589:

2461:

2147:

1915:

1679:

609:

The front pair, running much more quickly, draws out (attenuates) the roving so it is equal throughout.

389:

382:

362:

230:

opposed the perceived threat to their livelihood: there were frame-breaking riots and, in 1811–13, the

78:

183:

process. These two wheels became the starting point of technological development. Businessmen such as

2558:

2553:

2466:

2451:

2198:

1729:

1600:

429:

157:

599:. The rovings are passed through small guide-wires, and between the three pairs of drawing-rollers.

441:

104:

is pulled through rollers and twisted; on the return it is wrapped onto the spindle. Its rival, the

2456:

2446:

2385:

2046:

1799:

1734:

1625:

808:

2411:

2162:

1894:

1844:

1724:

634:

Immediately the winding is finished, the depressed faller rises, the counter-faller is put down.

61:

and other fibres. They were used extensively from the late 18th to the early 20th century in the

2471:

2208:

2203:

2172:

2000:

1970:

1920:

1869:

1620:

1615:

1413:

964:

2416:

2354:

2324:

2193:

1940:

1884:

841:

765:

641:

is completed. A stop-motion paralyses every action of the machine, rendering it necessary to

528:

survive today as these were the last spindles regularly at work., and the mules are similar.

1384:

Description of working day in a Lancashire spinning mill- explaining the operation of a mule

2507:

2005:

1990:

1950:

1874:

1864:

1660:

559:

417:

377:

8:

2380:

2096:

2086:

2081:

2056:

1804:

1749:

1584:

1429:

1394:

Transcription of 1979 tape describing the operations of a Taylor and Lang Condenser Mule

549:

2157:

2036:

1925:

1854:

1574:

773:

578:

403:

A faller wire that would ensure the yarn was wound into a predefined form such as a cop

176:

145:

637:

These movements are repeated until the cops on each spindle are perfectly formed: the

2584:

2528:

2502:

2283:

2213:

2101:

2041:

1965:

1910:

1610:

1458:

1406:

1358:

1316:

1301:

1279:

972:

219:

184:

1335:

2543:

2512:

2051:

2021:

1839:

1794:

555:

277:

121:

36:

1809:

2533:

2390:

2258:

2142:

1955:

1719:

1630:

1518:

518:

476:

265:

74:

47:

2538:

2228:

2223:

2111:

1985:

1879:

1774:

1744:

1650:

1640:

1635:

1579:

1538:

1293:

281:

200:

191:

168:

161:

105:

1378:

179:

and flyer with a heck (an apparatus that guides the thread to the reels) in a

2578:

2492:

2263:

2218:

1975:

1889:

1605:

1554:

1463:

242:

109:

86:

748:

385:

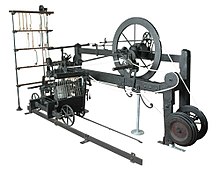

self-acting spinning mule: 1835 diagram showing the gearing in the headstock

218:

The increased supply of muslin inspired developments in loom design such as

2548:

2300:

Amalgamated Association of Beamers, Twisters and Drawers (Hand and Machine)

2268:

2253:

2121:

2061:

777:

393:

235:

2563:

2273:

2248:

2076:

2071:

2031:

1705:

1655:

1564:

1473:

831:

785:

753:

273:

257:

246:

207:

62:

175:

process, and the more refined Saxony wheel, which drives a differential

2375:

2278:

2167:

2106:

1702:

1569:

1533:

819:

334:

223:

153:

66:

523:

These mules were built by Asa Lees and Company Ltd, of Oldham in 1906.

472:

337:

and returned to weaving. Dale patented the mule and profited from it.

1528:

1523:

326:, warp or weft. It was first used to spin cotton, then other fibres.

2330:

General Union of Lancashire and Yorkshire Warp Dressers' Association

1671:

46:

The only surviving example of a spinning mule built by the inventor

1960:

1468:

296:. The spinning mule has a fixed frame with a creel of cylindrical

2238:

1559:

1513:

1508:

1483:

796:

792:

358:

353:

346:

323:

231:

133:

82:

1389:

The only surviving mule made by its inventor is at Bolton Museum

1478:

1453:

814:

596:

330:

297:

293:

137:

101:

90:

58:

132:. Weaving was a family activity. The children and women would

1739:

1448:

776:

with centralised factory jobs, driving economic upheaval and

42:

703:

261:

An early spinning mule: showing the gearing in the headstock

199:

does not have to be stretched on a loom in the way that the

1443:

1398:

761:

319:

289:

285:

227:

196:

149:

141:

129:

125:

97:

880:

272:

in 1779, so called because it is a hybrid of Arkwright's

234:

riots. The preparatory and associated tasks allowed many

1357:. Storey Institute Lancaster: Oxford Archaeology North.

1318:

Cotton Spinning: its development, principles an practice

1246:

National Overview Great Britain, Textile Conference IISH

965:"Technological Evolution in Cotton Spinning, 1878–1933"

2345:

North East Lancashire Amalgamated Weavers' Association

740:

Life in Great Britain during the Industrial Revolution

2340:

Lancashire Amalgamated Tape Sizers' Friendly Society

2305:

Amalgamated Association of Operative Cotton Spinners

837:

Textile manufacture during the Industrial Revolution

100:

by an intermittent process. In the draw stroke, the

1300:(Elibron Classics ed.). London: John Heywood.

1029:

1027:

77:. The self-acting (automatic) mule was patented by

990:

988:

2576:

1355:A & G Murray and the Cotton Mills of Ancoats

1352:

1156:

1024:

962:

1298:Recent Cotton Mill Construction and Engineering

1012:

985:

2310:Amalgamated Textile Warehousemen's Association

916:(in Italian and English). 2012. Archived from

2595:History of the Metropolitan Borough of Bolton

1687:

1414:

733:

645:or strip the spindles, and to commence anew.

1840:B. Hick and Sons / Hick, Hargreaves & Co

847:Timeline of clothing and textiles technology

372:

167:There were two types of spinning wheel: the

96:The spinning mule spins textile fibres into

18:Machine used to spin cotton and other fibres

2360:United Textile Factory Workers' Association

2350:Northern Counties Textile Trades Federation

744:Industrial Revolution § Social effects

652:

120:Before the 1770s, textile production was a

1694:

1680:

1421:

1407:

904:

902:

156:in the sun to bleach it. The invention by

1239:

1237:

875:

873:

813:Circa 1900 there was a high incidence of

73:It was invented between 1775 and 1779 by

963:Saxonhouse, Gary; Wright, Gavin (2010).

802:

747:

702:

660:

565:

554:

517:

376:

363:Fine Spinners & Doublers Association

256:

152:to weave this into cloth. This was then

41:

22:

1333:

1314:

1292:

1273:

1258:

1228:

1216:

1204:

1192:

1180:

1168:

1144:

1132:

1120:

1108:

1093:

1081:

1069:

1057:

1045:

1033:

1018:

1006:

994:

950:

938:

899:

864:

532:was a cotton waste mule spinning mill.

2577:

1353:Miller, I; Wild, C; Little, S (2007).

1243:

1234:

1104:

1102:

870:

543:

203:is, it can generally be less strong.)

1880:Yates & Thom / Yates of Blackburn

1701:

1675:

1402:

1114:

513:

333:his invention. He sold the rights to

1138:

1126:

677:Doffing has already been described.

329:Samuel Crompton could not afford to

148:. The male weaver would use a frame

1278:. Preston: The Lancashire Library.

1099:

791:The wool industry was divided into

577:Running spinning mule, built 1897,

35:A working mule spinning machine at

13:

2315:Amalgamated Textile Workers' Union

1860:William Roberts & Co of Nelson

969:The Japanese Economy in Retrospect

471:Selfactor in Vonwiller & Co.,

288:is the product of crossbreeding a

14:

2611:

2335:General Union of Loom Overlookers

1372:

729:Textile manufacturing terminology

698:

252:

93:for the knitted textile market.

2320:Amalgamated Weavers' Association

1758:

1492:

885:Bigagli automatic spinning mules

535:

504:

495:

486:

464:

452:

440:

428:

416:

85:yarns from noble fibres such as

1750:Sidney Stott (later Sir Philip)

1267:

1252:

1222:

1210:

1198:

1186:

1174:

1162:

1150:

1087:

1075:

1063:

1051:

1039:

340:

318:The mule produced strong, thin

2178:Amalgamated Cotton Mills Trust

1157:Miller, Wild & Little 2007

1000:

956:

944:

932:

858:

722:

1:

2153:Lancashire Cotton Corporation

2127:Thomas Whitehead and Brothers

1830:W & J Galloway & Sons

852:

1931:John Hetherington & Sons

1815:Clayton, Goodfellow & Co

1428:

1340:. Manchester: Marsden and Co

764:were leading sectors in the

550:Watch video demonstration #1

7:

1916:Butterworth & Dickinson

1321:. George Bell and Sons 1903

825:

459:Notice the faller wire gear

322:, suitable for any kind of

206:The throstle and the later

10:

2616:

2148:Fine Spinners and Doublers

1756:

806:

737:

734:Social and economic impact

726:

352:In 1790, William Kelly of

238:until this was regulated.

115:

57:is a machine used to spin

2559:John Kay (spinning frame)

2554:John Kay (flying shuttle)

2521:

2485:

2399:

2368:

2292:

2199:Cotton-spinning machinery

2186:

2135:

2014:

1971:Parr, Curtis & Madely

1921:Curtis, Parr & Walton

1903:

1800:Browett, Lindley & Co

1767:

1712:

1601:Cotton-spinning machinery

1593:

1547:

1501:

1490:

1436:

1315:Marsden, Richard (1884).

715:Faller and counter faller

595:holds bobbins containing

373:Roberts' self-acting mule

1996:Textile Machinery Makers

1976:British Northrop Loom Co

1895:Woolstenhulmes & Rye

1845:John Musgrave & Sons

1725:Bradshaw Gass & Hope

1274:Catling, Harold (1986).

653:Duties of the operatives

562:selfactor mule headstock

315:horsepower (47 W).

89:, ultra-fine merino and

2513:Quarry Bank Mill, Styal

2173:James Burton & Sons

2163:Combined Egyptian Mills

2001:Tweedales & Smalley

284:in the same way that a

236:children to be employed

2209:Magnetic ring spinning

2204:DREF friction spinning

1885:Willans & Robinson

1790:Bateman & Sherratt

1621:Magnetic ring spinning

1616:DREF friction spinning

757:

708:

666:

581:

563:

524:

386:

262:

50:

39:

2386:Mule spinners' cancer

2355:The Textile Institute

2325:Cardroom Amalgamation

2194:Textile manufacturing

2006:T. Wildman & Sons

1991:Taylor, Lang & Co

1951:Howard & Bullough

1941:John Pilling and Sons

1875:Urmson & Thompson

1785:Ashworth & Parker

1626:Mule spinners' cancer

1334:Marsden, ed. (1909).

842:Textile manufacturing

809:Mule spinners' cancer

803:Mule-spinners' cancer

766:Industrial Revolution

752:Mules operating in a

751:

706:

664:

576:

560:Taylor, Lang & Co

558:

521:

380:

260:

45:

34:

2369:Employment practices

2187:Industrial processes

1805:Buckley & Taylor

1730:F.W. Dixon & Son

1661:Wool combing machine

1337:Cotton Yearbook 1910

1123:, pp. 75–9, 118

971:. World Scientific.

435:The outward traverse

423:A cross section 1882

226:. Some spinners and

2381:Kissing the shuttle

2158:Bagley & Wright

2097:George Augustus Lee

2087:William Houldsworth

2057:Nathaniel Eckersley

1926:Dobson & Barlow

1870:Scott & Hodgson

1835:Benjamin Goodfellow

1820:Earnshaw & Holt

1594:Industrial spinning

1548:Hand spinning tools

1231:, pp. 160, 161

920:on 18 December 2014

544:Operation of a mule

447:The inward traverse

2600:English inventions

2037:Hugh Hornby Birley

1981:Pemberton & Co

1966:Mather & Platt

1946:Harling & Todd

1911:Brooks & Doxey

1855:Petrie of Rochdale

1850:J & W McNaught

1795:Boulton & Watt

1171:, pp. 240–242

1135:, pp. 141–146

1096:, pp. 226–230

887:(in Italian). 2012

774:cottage industries

758:

709:

667:

665:Mule-spinning room

618:forming a thread.

582:

579:Mueller Cloth Mill

564:

525:

514:Condenser spinning

387:

263:

51:

40:

2590:Textile machinery

2572:

2571:

2529:Richard Arkwright

2508:Weavers' Triangle

2503:Queen Street Mill

2284:Lancashire boiler

2214:Open-end spinning

2136:Limited companies

2102:Charles Macintosh

2042:Joseph Brotherton

1669:

1668:

1611:Open-end spinning

1364:978-0-904220-46-9

1276:The Spinning Mule

707:A Mule Jenny 1892

574:

245:, originating in

220:Edmund Cartwright

185:Richard Arkwright

32:

2607:

2544:James Hargreaves

2442:Oldham (borough)

2052:Peter Drinkwater

2022:Elkanah Armitage

1904:Machinery makers

1762:

1696:

1689:

1682:

1673:

1672:

1585:Spinner's weasel

1496:

1423:

1416:

1409:

1400:

1399:

1368:

1349:

1347:

1345:

1330:

1328:

1326:

1311:

1289:

1262:

1256:

1250:

1249:

1241:

1232:

1226:

1220:

1214:

1208:

1202:

1196:

1190:

1184:

1178:

1172:

1166:

1160:

1154:

1148:

1142:

1136:

1130:

1124:

1118:

1112:

1106:

1097:

1091:

1085:

1079:

1073:

1067:

1061:

1055:

1049:

1043:

1037:

1031:

1022:

1016:

1010:

1004:

998:

992:

983:

982:

960:

954:

948:

942:

936:

930:

929:

927:

925:

906:

897:

896:

894:

892:

877:

868:

862:

694:

693:

689:

686:

575:

468:

456:

444:

432:

420:

314:

313:

309:

278:James Hargreaves

228:handloom weavers

171:, which uses an

122:cottage industry

37:Quarry Bank Mill

33:

2615:

2614:

2610:

2609:

2608:

2606:

2605:

2604:

2575:

2574:

2573:

2568:

2534:Samuel Crompton

2517:

2498:Helmshore Mills

2481:

2395:

2391:Piece-rate list

2364:

2288:

2259:Lancashire Loom

2182:

2143:Oldham Limiteds

2131:

2082:Richard Howarth

2010:

1956:Geo. Hattersley

1899:

1763:

1754:

1720:David Bellhouse

1708:

1700:

1670:

1665:

1631:Piece-rate list

1589:

1543:

1497:

1488:

1432:

1427:

1375:

1365:

1343:

1341:

1324:

1322:

1308:

1294:Nasmith, Joseph

1286:

1270:

1265:

1257:

1253:

1242:

1235:

1227:

1223:

1215:

1211:

1203:

1199:

1191:

1187:

1179:

1175:

1167:

1163:

1155:

1151:

1143:

1139:

1131:

1127:

1119:

1115:

1107:

1100:

1092:

1088:

1080:

1076:

1068:

1064:

1056:

1052:

1044:

1040:

1032:

1025:

1017:

1013:

1005:

1001:

993:

986:

979:

961:

957:

949:

945:

937:

933:

923:

921:

908:

907:

900:

890:

888:

879:

878:

871:

863:

859:

855:

828:

811:

805:

746:

738:Main articles:

736:

731:

725:

712:Drawing rollers

701:

691:

687:

684:

682:

655:

566:

546:

538:

530:Helmshore Mills

516:

507:

498:

489:

479:

477:Austria-Hungary

469:

460:

457:

448:

445:

436:

433:

424:

421:

390:Richard Roberts

375:

343:

311:

307:

306:

266:Samuel Crompton

255:

118:

79:Richard Roberts

75:Samuel Crompton

48:Samuel Crompton

23:

19:

12:

11:

5:

2613:

2603:

2602:

2597:

2592:

2587:

2570:

2569:

2567:

2566:

2561:

2556:

2551:

2546:

2541:

2539:Peter Foxcroft

2536:

2531:

2525:

2523:

2519:

2518:

2516:

2515:

2510:

2505:

2500:

2495:

2489:

2487:

2483:

2482:

2480:

2479:

2474:

2469:

2464:

2459:

2454:

2449:

2444:

2439:

2434:

2429:

2424:

2419:

2414:

2409:

2403:

2401:

2400:Lists of mills

2397:

2396:

2394:

2393:

2388:

2383:

2378:

2372:

2370:

2366:

2365:

2363:

2362:

2357:

2352:

2347:

2342:

2337:

2332:

2327:

2322:

2317:

2312:

2307:

2302:

2296:

2294:

2290:

2289:

2287:

2286:

2281:

2276:

2271:

2266:

2261:

2256:

2251:

2246:

2241:

2236:

2231:

2229:Spinning jenny

2226:

2224:Spinning frame

2221:

2216:

2211:

2206:

2201:

2196:

2190:

2188:

2184:

2183:

2181:

2180:

2175:

2170:

2165:

2160:

2155:

2150:

2145:

2139:

2137:

2133:

2132:

2130:

2129:

2124:

2119:

2114:

2112:Samuel Oldknow

2109:

2104:

2099:

2094:

2089:

2084:

2079:

2074:

2069:

2064:

2059:

2054:

2049:

2044:

2039:

2034:

2029:

2027:Henry Ashworth

2024:

2018:

2016:

2012:

2011:

2009:

2008:

2003:

1998:

1993:

1988:

1986:Platt Brothers

1983:

1978:

1973:

1968:

1963:

1958:

1953:

1948:

1943:

1938:

1936:Joseph Hibbert

1933:

1928:

1923:

1918:

1913:

1907:

1905:

1901:

1900:

1898:

1897:

1892:

1890:J & E Wood

1887:

1882:

1877:

1872:

1867:

1862:

1857:

1852:

1847:

1842:

1837:

1832:

1827:

1822:

1817:

1812:

1807:

1802:

1797:

1792:

1787:

1782:

1777:

1775:Daniel Adamson

1771:

1769:

1765:

1764:

1757:

1755:

1753:

1752:

1747:

1745:Stott and Sons

1742:

1737:

1732:

1727:

1722:

1716:

1714:

1710:

1709:

1699:

1698:

1691:

1684:

1676:

1667:

1666:

1664:

1663:

1658:

1653:

1651:Throstle frame

1648:

1643:

1641:Spinning jenny

1638:

1636:Spinning frame

1633:

1628:

1623:

1618:

1613:

1608:

1603:

1597:

1595:

1591:

1590:

1588:

1587:

1582:

1580:Spinning wheel

1577:

1572:

1567:

1562:

1557:

1551:

1549:

1545:

1544:

1542:

1541:

1539:Twist per inch

1536:

1531:

1526:

1521:

1516:

1511:

1505:

1503:

1499:

1498:

1491:

1489:

1487:

1486:

1481:

1476:

1471:

1466:

1461:

1456:

1451:

1446:

1440:

1438:

1434:

1433:

1426:

1425:

1418:

1411:

1403:

1397:

1396:

1391:

1386:

1381:

1374:

1373:External links

1371:

1370:

1369:

1363:

1350:

1331:

1312:

1306:

1290:

1284:

1269:

1266:

1264:

1263:

1251:

1233:

1221:

1209:

1197:

1185:

1173:

1161:

1149:

1137:

1125:

1113:

1098:

1086:

1074:

1062:

1050:

1038:

1023:

1011:

999:

984:

977:

955:

943:

931:

898:

869:

856:

854:

851:

850:

849:

844:

839:

834:

827:

824:

815:scrotal cancer

807:Main article:

804:

801:

735:

732:

727:Main article:

724:

721:

720:

719:

716:

713:

700:

699:Key components

697:

654:

651:

611:

610:

607:

604:

553:

552:

545:

542:

537:

534:

515:

512:

506:

503:

497:

494:

488:

485:

481:

480:

470:

463:

461:

458:

451:

449:

446:

439:

437:

434:

427:

425:

422:

415:

408:

407:

404:

401:

374:

371:

342:

339:

282:spinning jenny

254:

253:The first mule

251:

192:spinning jenny

162:flying shuttle

117:

114:

106:throstle frame

17:

9:

6:

4:

3:

2:

2612:

2601:

2598:

2596:

2593:

2591:

2588:

2586:

2583:

2582:

2580:

2565:

2562:

2560:

2557:

2555:

2552:

2550:

2547:

2545:

2542:

2540:

2537:

2535:

2532:

2530:

2527:

2526:

2524:

2520:

2514:

2511:

2509:

2506:

2504:

2501:

2499:

2496:

2494:

2493:Bancroft Shed

2491:

2490:

2488:

2484:

2478:

2475:

2473:

2470:

2468:

2465:

2463:

2460:

2458:

2455:

2453:

2450:

2448:

2445:

2443:

2440:

2438:

2435:

2433:

2430:

2428:

2425:

2423:

2420:

2418:

2415:

2413:

2410:

2408:

2405:

2404:

2402:

2398:

2392:

2389:

2387:

2384:

2382:

2379:

2377:

2374:

2373:

2371:

2367:

2361:

2358:

2356:

2353:

2351:

2348:

2346:

2343:

2341:

2338:

2336:

2333:

2331:

2328:

2326:

2323:

2321:

2318:

2316:

2313:

2311:

2308:

2306:

2303:

2301:

2298:

2297:

2295:

2291:

2285:

2282:

2280:

2277:

2275:

2272:

2270:

2267:

2265:

2264:Northrop Loom

2262:

2260:

2257:

2255:

2252:

2250:

2247:

2245:

2242:

2240:

2237:

2235:

2234:Spinning mule

2232:

2230:

2227:

2225:

2222:

2220:

2219:Ring spinning

2217:

2215:

2212:

2210:

2207:

2205:

2202:

2200:

2197:

2195:

2192:

2191:

2189:

2185:

2179:

2176:

2174:

2171:

2169:

2166:

2164:

2161:

2159:

2156:

2154:

2151:

2149:

2146:

2144:

2141:

2140:

2138:

2134:

2128:

2125:

2123:

2120:

2118:

2115:

2113:

2110:

2108:

2105:

2103:

2100:

2098:

2095:

2093:

2090:

2088:

2085:

2083:

2080:

2078:

2075:

2073:

2070:

2068:

2065:

2063:

2060:

2058:

2055:

2053:

2050:

2048:

2045:

2043:

2040:

2038:

2035:

2033:

2030:

2028:

2025:

2023:

2020:

2019:

2017:

2013:

2007:

2004:

2002:

1999:

1997:

1994:

1992:

1989:

1987:

1984:

1982:

1979:

1977:

1974:

1972:

1969:

1967:

1964:

1962:

1959:

1957:

1954:

1952:

1949:

1947:

1944:

1942:

1939:

1937:

1934:

1932:

1929:

1927:

1924:

1922:

1919:

1917:

1914:

1912:

1909:

1908:

1906:

1902:

1896:

1893:

1891:

1888:

1886:

1883:

1881:

1878:

1876:

1873:

1871:

1868:

1866:

1863:

1861:

1858:

1856:

1853:

1851:

1848:

1846:

1843:

1841:

1838:

1836:

1833:

1831:

1828:

1826:

1823:

1821:

1818:

1816:

1813:

1811:

1810:Carels Frères

1808:

1806:

1803:

1801:

1798:

1796:

1793:

1791:

1788:

1786:

1783:

1781:

1778:

1776:

1773:

1772:

1770:

1768:Engine makers

1766:

1761:

1751:

1748:

1746:

1743:

1741:

1738:

1736:

1733:

1731:

1728:

1726:

1723:

1721:

1718:

1717:

1715:

1711:

1707:

1704:

1697:

1692:

1690:

1685:

1683:

1678:

1677:

1674:

1662:

1659:

1657:

1654:

1652:

1649:

1647:

1646:Spinning mule

1644:

1642:

1639:

1637:

1634:

1632:

1629:

1627:

1624:

1622:

1619:

1617:

1614:

1612:

1609:

1607:

1606:Ring spinning

1604:

1602:

1599:

1598:

1596:

1592:

1586:

1583:

1581:

1578:

1576:

1573:

1571:

1568:

1566:

1563:

1561:

1558:

1556:

1555:Hand spinning

1553:

1552:

1550:

1546:

1540:

1537:

1535:

1532:

1530:

1527:

1525:

1522:

1520:

1517:

1515:

1512:

1510:

1507:

1506:

1504:

1500:

1495:

1485:

1482:

1480:

1477:

1475:

1472:

1470:

1467:

1465:

1462:

1460:

1457:

1455:

1452:

1450:

1447:

1445:

1442:

1441:

1439:

1435:

1431:

1424:

1419:

1417:

1412:

1410:

1405:

1404:

1401:

1395:

1392:

1390:

1387:

1385:

1382:

1380:

1377:

1376:

1366:

1360:

1356:

1351:

1339:

1338:

1332:

1320:

1319:

1313:

1309:

1307:1-4021-4558-6

1303:

1299:

1295:

1291:

1287:

1285:0-902228-61-7

1281:

1277:

1272:

1271:

1261:, p. 179

1260:

1255:

1247:

1240:

1238:

1230:

1225:

1219:, p. 155

1218:

1213:

1207:, p. 154

1206:

1201:

1195:, p. 158

1194:

1189:

1183:, p. 157

1182:

1177:

1170:

1165:

1159:, p. 166

1158:

1153:

1147:, p. 144

1146:

1141:

1134:

1129:

1122:

1117:

1110:

1105:

1103:

1095:

1090:

1084:, p. 226

1083:

1078:

1072:, p. 224

1071:

1066:

1059:

1054:

1048:, p. 223

1047:

1042:

1036:, p. 222

1035:

1030:

1028:

1021:, p. 221

1020:

1015:

1008:

1003:

997:, p. 219

996:

991:

989:

980:

978:9789814271455

974:

970:

966:

959:

953:, p. 109

952:

947:

941:, p. 109

940:

935:

919:

915:

911:

905:

903:

886:

882:

876:

874:

866:

861:

857:

848:

845:

843:

840:

838:

835:

833:

830:

829:

823:

821:

816:

810:

800:

798:

794:

789:

787:

781:

779:

775:

769:

767:

763:

755:

750:

745:

741:

730:

717:

714:

711:

710:

705:

696:

678:

675:

671:

663:

659:

650:

646:

644:

640:

635:

631:

627:

624:

619:

615:

608:

605:

602:

601:

600:

598:

594:

589:

586:

580:

561:

557:

551:

548:

547:

541:

536:Current usage

533:

531:

520:

511:

505:Woollen mules

502:

496:Bolton counts

493:

487:Oldham counts

484:

478:

474:

467:

462:

455:

450:

443:

438:

431:

426:

419:

414:

413:

412:

405:

402:

399:

398:

397:

395:

391:

384:

379:

370:

366:

364:

360:

355:

350:

348:

338:

336:

332:

327:

325:

321:

316:

302:

299:

295:

291:

287:

283:

279:

275:

271:

270:spinning mule

268:invented the

267:

259:

250:

248:

244:

239:

237:

233:

229:

225:

221:

216:

214:

213:spinning mule

209:

204:

202:

198:

193:

188:

186:

182:

178:

174:

170:

165:

163:

159:

155:

151:

147:

144:wound onto a

143:

139:

135:

131:

127:

123:

113:

111:

107:

103:

99:

94:

92:

88:

84:

80:

76:

71:

68:

64:

60:

56:

55:spinning mule

49:

44:

38:

21:

16:

2549:Thomas Highs

2293:Associations

2269:Air-jet loom

2254:Roberts Loom

2233:

2122:John Rylands

2092:John Kennedy

2067:William Gray

2062:John Fielden

2047:James Burton

1865:George Saxon

1780:Ashton Frost

1735:Edward Potts

1645:

1354:

1342:. Retrieved

1336:

1323:. Retrieved

1317:

1297:

1275:

1268:Bibliography

1259:Catling 1986

1254:

1245:

1229:Catling 1986

1224:

1217:Catling 1986

1212:

1205:Catling 1986

1200:

1193:Catling 1986

1188:

1181:Catling 1986

1176:

1169:Marsden 1884

1164:

1152:

1145:Catling 1986

1140:

1133:Catling 1986

1128:

1121:Catling 1986

1116:

1111:, p. 51

1109:Catling 1986

1094:Marsden 1884

1089:

1082:Marsden 1884

1077:

1070:Marsden 1884

1065:

1060:, p. 43

1058:Catling 1986

1053:

1046:Marsden 1884

1041:

1034:Marsden 1884

1019:Marsden 1884

1014:

1009:, p. 53

1007:Catling 1986

1002:

995:Marsden 1884

968:

958:

951:Nasmith 1895

946:

939:Marsden 1884

934:

922:. Retrieved

918:the original

913:

889:. Retrieved

884:

867:, p. 11

865:Catling 1986

860:

820:carcinogenic

812:

790:

788:was formed.

782:

778:urbanisation

770:

759:

679:

676:

672:

668:

656:

647:

642:

638:

636:

632:

628:

622:

620:

616:

612:

590:

587:

583:

539:

526:

508:

499:

490:

482:

409:

394:Roberts Loom

388:

367:

351:

344:

341:Improvements

328:

317:

303:

290:female horse

269:

264:

240:

217:

212:

205:

189:

180:

173:intermittent

172:

169:simple wheel

166:

119:

95:

72:

54:

52:

20:

15:

2564:Robert Owen

2274:Rapier loom

2249:Water frame

2117:Robert Peel

2077:Samuel Greg

2072:Hannah Greg

2032:Hugh Birley

2015:Mill owners

1656:Water frame

1565:Niddy noddy

924:13 December

891:13 December

832:Cotton mill

754:Cotton mill

723:Terminology

294:male donkey

274:water frame

247:New England

208:water frame

2579:Categories

2437:Manchester

2432:Lancashire

2427:Derbyshire

2376:More looms

2279:Dandy loom

2168:Courtaulds

2107:Hugh Mason

1713:Architects

1703:Lancashire

1570:Nostepinne

1534:Short draw

1502:Techniques

910:"Cormatex"

853:References

335:David Dale

243:ring frame

224:power loom

181:continuous

110:ring frame

67:Lancashire

2477:Yorkshire

2462:Stockport

2407:LCC mills

1825:Fairbairn

1529:Scutching

1524:Long draw

1437:Materials

881:"Bigagli"

2585:Spinning

2522:Pioneers

2467:Tameside

2452:Rochdale

2422:Cheshire

2244:Steaming

1961:Asa Lees

1519:Heckling

1430:Spinning

1344:26 April

1325:26 April

1296:(1895).

826:See also

718:Quadrant

158:John Kay

154:tentered

87:cashmere

2486:Museums

2457:Salford

2447:Preston

2239:Carding

1575:Spindle

1560:Distaff

1514:Combing

1509:Carding

1484:Worsted

797:worsted

793:woollen

690:⁄

597:rovings

473:Žamberk

383:Roberts

359:Ancoats

354:Glasgow

347:Horwich

324:textile

310:⁄

298:bobbins

292:with a

232:Luddite

177:spindle

160:of the

146:spindle

138:rovings

116:History

83:woollen

2412:Bolton

1706:cotton

1479:Woolen

1464:Staple

1459:Sliver

1454:Roving

1361:

1304:

1282:

975:

331:patent

124:using

102:roving

91:alpaca

59:cotton

2472:Wigan

1740:Stott

1449:Rolag

786:union

593:creel

140:into

63:mills

2417:Bury

1444:Noil

1359:ISBN

1346:2009

1327:2009

1302:ISBN

1280:ISBN

973:ISBN

926:2012

893:2012

795:and

762:iron

742:and

643:doff

623:gain

591:The

320:yarn

286:mule

276:and

201:warp

197:weft

190:The

150:loom

142:yarn

134:card

130:wool

128:and

126:flax

98:yarn

53:The

1474:Tow

1469:Top

639:set

280:'s

222:'s

108:or

65:of

2581::

1236:^

1101:^

1026:^

987:^

967:.

912:.

901:^

883:.

872:^

780:.

475:,

381:A

312:16

215:.

1695:e

1688:t

1681:v

1422:e

1415:t

1408:v

1367:.

1348:.

1329:.

1310:.

1288:.

1248:.

981:.

928:.

895:.

756:.

692:4

688:1

685:+

683:1

308:1

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.