475:(PPS) obtained by the condensation polymerization of p-dichlorobenzene and sodium sulfide, has outstanding chemical resistance, good electrical properties, excellent flame retardance, low coefficient of friction and high transparency to microwave radiation. PPS is principally used in coating applications. This is done by spraying an aqueous slurry of PPS particles and heating to temperatures above 370 °C. Particular grades of PPS can be used in injection and compression molding at temperatures (300 to 370 °C) at which PPS particles soften and undergo apparent crosslinking. Principal applications of injection and compression molded PPS include cookware, bearings, and pump parts for service in various corrosive environments.

356:(PBI, short for Poly-) fiber is a synthetic fiber with a very high melting point. It has exceptional thermal and chemical stability and does not readily ignite. It was first discovered by American polymer chemist Carl Shipp Marvel in the pursuit of new materials with superior stability, retention of stiffness, toughness at elevated temperature. Due to its high stability, polybenzimidazole is used to fabricate high-performance protective apparel such as firefighter's gear, astronaut space suits, high temperature protective gloves, welders' apparel and aircraft wall fabrics. In recent years, polybenzimidazole found its application as membrane in fuel cells.

427:(polyethene, polythene, PE) is a family of similar materials categorized according to their density and molecular structure. It is also known as poly and is obtained by the addition polymerisation of ethylene. It may be of low density or high density depending upon the process used in its manufacturing. It is resistant to moisture and most of the chemicals. It is flexible at room temperature (and low temperature) and can be heat sealed. Since it is an inexpensive plastic it is made in large amounts to cater to the demand. For example:

530:(PVC) is a tough, lightweight material that is durable, fairly rigid and versatile, and is resistant to acids and bases. Much of it is used by the construction industry, such as for vinyl siding, drainpipes, gutters and roofing sheets. It is also converted to flexible forms with the addition of plasticizers, thereby making it useful for items such as hoses, tubing, electrical insulation, coats, jackets and upholstery. Flexible PVC is also used in inflatable products, such as water beds and pool toys. PVC is also a common material in

253:(PMMA) market. PMMA is also known by trade names such as Lucite, Perspex and Plexiglas. It serves as a sturdy substitute for glass for items such as aquariums, buttons, motorcycle helmet visors, aircraft windows, viewing ports of submersibles, and lenses of exterior lights of automobiles. It is extensively used to make signs, including lettering and logos. In medicine, it is used in bone cement and to replace eye lenses. Acrylic paint consists of PMMA particles suspended in water.

1151:

367:(PC) thermoplastics are known under trademarks such as Lexan, Makrolon, Makroclear, and arcoPlus. They are easily worked, molded, and thermoformed for many applications, such as electronic components, construction materials, data storage devices, automotive and aircraft parts, check sockets in prosthetics, and security glazing. Polycarbonates do not have a unique resin identification code. Items made from polycarbonate can contain the precursor monomer

464:(PPO), which is obtained from the free-radical, step-growth oxidative coupling polymerization of 2,6-xylenol, has many attractive properties such as high heat distortion and impact strength, chemical stability to mineral and organic acids, and low water absorption. PPO is difficult to process, and hence the commercial resin (Noryl) is made by blending PPO with high-impact polystyrene (HIPS), which serves to reduce the processing temperature.

36:

1157:

186:

299:. It has served as a substitute mainly for hemp, cotton and silk, in products such as parachutes, cords, sails, flak vests and clothing. Nylon fibres are useful in making fabrics, rope, carpets and musical strings, whereas, in bulk form, nylon is used for mechanical parts including machine screws, gears and power tool casings. In addition, it is used in the manufacture of heat-resistant composite materials.

943:

394:(POM), also known as acetal, polyacetal and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. As with many other synthetic polymers, it is produced by different chemical firms with slightly different formulas and sold variously by such names as Delrin, Celcon, Ramtal, Duracon, Kepital and Hostaform.

405:(PEEK) is a colourless organic thermoplastic polymer in the polyaryletherketone (PAEK) family, used in engineering applications. It was originally introduced by Victrex PLC, then ICI (Imperial Chemical Industries) in the early 1980s. It has attractive properties like good abrasion resistance, low flammability and emission of smoke and toxic gases.

416:(PEI), produced by a novel nitro displacement reaction involving bisphenol A, 4, 4’-methylenedianiline and 3-nitrophthalic anhydride, has high heat distortion temperature, tensile strength and modulus. They are generally used in high performance electrical and electronic parts, microwave appliances, and under-the-hood automotive parts.

519:

of cars and boats, and smoke detector housings. Expanded polystyrene foam (EPS or "styrofoam", white) is used in making insulation and packaging materials, such as the "peanuts" and molded foam used to cushion fragile products. Polystyrene copolymers are used in the manufacture of toys and product casings.

548:

are added to the raw material before molding to make it more flexible or pliable. Early on, the health and environmental aspects of this were poorly understood and replacements and product bans resulted after studies. The original form is often referred to as unplasticized polyvinyl chloride (uPVC),

518:

is manufactured in various forms that have different applications and can have medium to very low density. Extruded polystyrene (PS or xPS, sometimes colored pink/blue) is used in the manufacture of disposable cutlery, rigid ground contact rated insulating foam board, CD and DVD cases, plastic models

256:

For many decades, PMMA has been the predominant methacrylic ester produced worldwide. Major players in the PMMA market are

Mitsubishi Rayon (Japan), Arkema SA (France), LG MMA (South Korea), Chi Mei Corp. (Taiwan), Sumimoto Chemical Company Ltd (Japan), Evonik Industries (Germany), BASF (Germany),

589:

class of thermoplastics and is known for its high chemical inertness and resistance. PVDF is obtained through the polymerization of the vinylidene fluoride monomer. PVDF thermoplastic is fabricated into sheets and pipes for engineering uses as well as powders and coatings that can be dissolved in

506:

treatment and to make heat-resistant medical equipment. Polypropylene sheets are used for stationery folders and packaging and clear storage bins. Polypropylene is defined by the recyclable plastic number 5. Although relatively inert, it is vulnerable to ultraviolet radiation and can degrade

568:

backbone until most commercial applications reach a percent range between 56 and 74% total chlorine. This increase in elemental chlorine content contributes to CPVC's increased expression of chlorine-based characteristics, such as chemical durability, resistance to acids, bases, and salts;

541:, where the material is used extensively in so-called Sofubi figures (Soft vinyl toys). As PVC bends easily and has a tendency to be bent during transit, a method to mitigate this deformation is to heat the plastic until it becomes mobile, then reform the material into the desired shape.

236:

before polymerization can also lower it. Before these techniques were employed, plastic automobile parts would often crack when exposed to cold temperatures. These are linear or slightly branched long chain molecules capable of repeatedly softening on heating and hardening on cooling.

590:

solvents and applied across a product surface. PVDF is widely used in the chemical industry as piping for aggressive chemicals and high purity liquids. The PVDF material is used in construction, transportation, chemical processes, electricity, batteries, waste water and treatment.

452:(LDPE) is flexible and is used in the manufacture of squeeze bottles, milk jug caps, retail store bags and linear low-density polyethylene (LLDPE) as stretch wrap in transporting and handling boxes of durable goods, and as the common household food covering.

569:

susceptibility to ammonia-based compounds, aromatics, esters, ketones; chemical stability; heat energy transfer resistance. CPVC is commonly used in water, chemical, hot and cold, delivery systems for residential, commercial, and industrial applications.

257:

Dow

Chemical Company (U.S.), AkzoNobel (The Netherlands), Quinn Plastics (UK) and Cytec Industries (U.S.). Regarding the PAA and PAc market, key manufacturers are Nippon Shokubai Company Ltd. (Japan), Arkema SA (France) and Dow Chemical Company (U.S.)

440:(HDPE), recyclable plastic no. 2, is commonly used as milk jugs, liquid laundry detergent bottles, outdoor furniture, margarine tubs, portable gasoline cans, drinking water distribution systems, water drainage pipes, and grocery bags.

284:. ABS is a light-weight material that exhibits high impact resistance and mechanical toughness. It poses few risks to human health under normal handling. It is used in many consumer products, such as toys, appliances, and telephones.

158:, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped, and are typically used to produce parts by various polymer processing techniques such as

383:

is a class of specially engineered thermoplastics with high thermal, oxidative, and hydrolytic stability, and good resistance to aqueous mineral acids, alkalis, salt solutions, oils and greases.

1758:

507:

considerably in direct sunlight. Polypropylene is not as impact-resistant as the polyethylenes (HDPE, LDPE). It is also somewhat permeable to highly volatile gases and liquids.

213:

is necessary, as light is scattered strongly by crystallites larger than its wavelength. Amorphous and semi-amorphous plastics are less resistant to chemical attack and

371:(BPA). Susceptible to UV light, exposure results in yellowing (degradation is especially visible in headlamps that lost or didn't have proper protective coating).

677:

434:(UHMWPE) is tough and resistant to chemicals. It is used to manufacture moving machine parts, bearings, gears, artificial joints and some bulletproof vests.

209:

below the glass transition temperature, retaining some or all of their amorphous characteristics. Amorphous and semi-amorphous plastics are used when high

1482:

224:, which increases the mobility of amorphous chain segments to effectively lower the glass transition temperature. Modification of the polymer through

740:

544:

PVC is produced in many specific modifications to affect its chemical and physical properties. In plasticized polyvinyl chloride (pPVC),

657:

431:

1475:

782:

760:

1358:

805:

17:

100:

1817:

1768:

1737:

72:

800:, Second Edition, O. Olabisi & K. Adewale (Ed.) CRC Press, Taylor & Francis Group, Boca Raton, Florida, U. S. A.

1468:

975:

629:

of fluorine. This also supports its use in coatings of cooking ware. The polymer has one of the lowest coefficients of

182:

during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling.

896:

119:

79:

688:

854:

1460:

1000:

265:

1753:

1732:

1629:

1383:

947:

553:

86:

57:

53:

486:(PP) is useful for such diverse products as reusable plastic food containers, microwave- and dishwasher-safe

214:

549:

which is the more commonly used type for installations such as water, waste, and sewer conveyance plumbing.

1807:

1727:

194:

68:

1800:

1722:

1538:

1135:

443:

147:

material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

245:

Today's acrylics industry can be divided into two distinct multibillion-dollar markets: on one hand the

1864:

1065:

1040:

713:

Baeurle SA, Hotta A, Gusev AA (2006). "On the glassy state of multiphase and pure polymer materials".

1840:

1574:

1373:

1198:

1015:

1005:

437:

342:

250:

1644:

1634:

1496:

1183:

1130:

1020:

449:

1859:

1234:

1125:

1110:

1090:

633:

of any solid and is therefore commonly used for bearings and support of moving mechanical parts.

622:

598:

502:, insulation for electrical cables and filters for gases and liquids. In medicine, it is used in

353:

46:

1649:

1527:

1282:

1010:

968:

402:

917:

1829:

1533:

1178:

734:

557:

472:

175:

155:

1549:

1544:

1517:

1435:

878:

642:

93:

206:

8:

1679:

1440:

1363:

1277:

1229:

606:

578:

461:

163:

1694:

1612:

1353:

1327:

1297:

1257:

1239:

1188:

1140:

1120:

835:

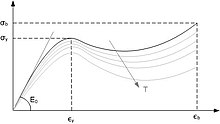

652:

560:

that originally formulates the PVC polymer. The chlorination reaction continues to add

531:

527:

318:

159:

201:, the physical properties of a thermoplastic change drastically without an associated

1824:

1790:

1710:

1522:

1344:

1262:

961:

839:

801:

775:

753:

626:

487:

1715:

1410:

1312:

1287:

1219:

1085:

1080:

1025:

827:

722:

391:

246:

202:

1490:

726:

1579:

1565:

1430:

1317:

1307:

1075:

786:

764:

307:

1608:

1420:

1322:

1193:

831:

534:

413:

151:

1853:

1795:

1602:

1388:

1378:

1368:

1272:

1095:

1045:

602:

586:

561:

499:

483:

364:

281:

277:

210:

198:

818:

Saini D.R., Shenoy A.V. (1985). "Melt

Rheology of Some Specialty Polymers".

1415:

1405:

1267:

1214:

1115:

1060:

1035:

618:

495:

424:

1661:

1150:

1598:

1570:

1505:

1425:

1224:

1105:

1100:

614:

565:

552:

Chemical modification often produces more drastic changes in properties.

545:

515:

380:

368:

338:

322:

221:

167:

1674:

1302:

1292:

269:

229:

179:

855:"What the Heck Is Sofubi?! 10 Things You Didn't Know About Soft Vinyl"

556:(CPVC) is produced through exposing PVC to the continued free-radical

1763:

1669:

1639:

1509:

1070:

1055:

1030:

498:

lining and casing, ropes, carpets, plastic moldings, piping systems,

334:

326:

314:

311:

296:

249:(PAA) and its ester derivatives (PAc) market, on the other hand, the

225:

171:

446:(MDPE) is used for packaging film, sacks and gas pipes and fittings.

35:

1684:

897:"Chemical Resistance of Thermoplastics Piping Materials TR-19/2007"

630:

1156:

1812:

1689:

1590:

1492:

984:

330:

273:

233:

185:

144:

141:

942:

647:

610:

503:

491:

712:

538:

292:

1050:

953:

582:

817:

778:

678:"Thermosoftening plastics and Thermosetting plastics"

27:

Plastic that softens with heat and hardens on cooling

593:

60:. Unsourced material may be challenged and removed.

776:Charles P. MacDermott and Aroon V. Shenoy (1997),

220:Brittleness can be decreased with the addition of

1851:

879:"How does CPVC piping compare to metal piping?"

189:Stress-strain graph of a thermoplastic material

617:: aqueous liquids do not wet the material, as

1476:

969:

918:"PVDF Performance Characteristics & Data"

310:(polylactide) is a compostable thermoplastic

739:: CS1 maint: multiple names: authors list (

609:is commonly recognized under the brand name

333:roots, chips or starch (mostly in Asia), or

658:Implant induction welding of thermoplastics

217:because they lack a crystalline structure.

178:(or "thermosets"), which form irreversible

1483:

1469:

976:

962:

756:Thermoplastic Melt Rheology and Processing

572:

337:. It is the most common material used for

852:

397:

120:Learn how and when to remove this message

467:

432:ultra-high-molecular-weight polyethylene

228:or through the addition of non-reactive

184:

14:

1852:

1066:Polyethylene terephthalate (PET, PETE)

456:

295:belongs to a class of polymers called

1464:

1006:Cross-linked polyethylene (PEX, XLPE)

1001:Acrylonitrile butadiene styrene (ABS)

957:

754:A. V. Shenoy and D. R. Saini (1996),

522:

1818:List of environmental health hazards

1738:List of environmental health hazards

820:Journal of Elastomers & Plastics

374:

348:

58:adding citations to reliable sources

29:

386:

24:

1623:Miscellaneous additives incl. PHCs

904:Plastic Pipe Institute, Inc. (PPI)

537:, especially in countries such as

154:. The polymer chains associate by

25:

1876:

935:

408:

1155:

1149:

1041:Polybutylene terephthalate (PBT)

1016:Poly(methyl methacrylate) (PMMA)

941:

594:Polytetrafluoroethylene (Teflon)

478:

359:

150:Most thermoplastics have a high

34:

1021:Poly(ethyl methacrylate) (PEMA)

910:

780:, Marcel Dekker Inc., New York.

758:, Marcel Dekker Inc., New York.

419:

266:Acrylonitrile butadiene styrene

45:needs additional citations for

1384:Category:Plastics applications

1131:Styrene maleic anhydride (SMA)

1126:Polyvinylidene chloride (PVDC)

1111:Polytetrafluoroethylene (PTFE)

889:

871:

846:

811:

791:

769:

747:

706:

670:

554:Chlorinated polyvinyl chloride

510:

13:

1:

1091:Poly(p-phenylene oxide) (PPO)

727:10.1016/j.polymer.2006.05.076

663:

215:environmental stress cracking

174:. Thermoplastics differ from

1808:Persistent organic pollutant

1769:Toxic Substances Control Act

1728:Persistent organic pollutant

1011:Ethylene vinyl acetate (EVA)

983:

195:glass transition temperature

7:

1801:Great Pacific garbage patch

1723:Great Pacific garbage patch

1136:Styrene-acrylonitrile (SAN)

1051:Polyetheretherketone (PEEK)

636:

444:Medium-density polyethylene

379:Polyether sulfone (PES) or

10:

1881:

1764:Japan Toxic Substances Law

1559:Miscellaneous plasticizers

832:10.1177/009524438501700305

798:Handbook of Thermoplastics

240:

1838:

1783:

1759:European REACH regulation

1754:California Proposition 65

1746:

1703:

1660:

1622:

1589:

1558:

1504:

1497:polyhalogenated compounds

1453:

1398:

1374:High-performance plastics

1343:

1336:

1248:

1207:

1199:High-performance plastics

1164:

1147:

991:

883:Corzan Industrial Systems

438:High-density polyethylene

343:fused deposition modeling

251:poly(methyl methacrylate)

1184:Fibre-reinforced plastic

1121:Polyvinyl chloride (PVC)

853:j.lerouge (2020-12-26).

623:London dispersion forces

450:Low-density polyethylene

325:(in the United States),

287:

207:do not fully crystallize

1235:Biodegradable additives

599:Polytetrafluoroethylene

573:Polyvinylidene fluoride

138:thermosoftening plastic

1650:Perfluorooctanoic acid

1086:Polyphenyl ether (PPE)

1081:Polyoxymethylene (POM)

1026:Polyacrylic acid (PAA)

621:demonstrate mitigated

601:(PTFE) is a synthetic

403:Polyether ether ketone

398:Polyether ether ketone

302:

260:

205:. Some thermoplastics

190:

176:thermosetting polymers

1830:Biodegradable plastic

1179:Thermosetting polymer

1076:Polylactic acid (PLA)

558:chlorination reaction

473:Polyphenylene sulfide

468:Polyphenylene sulfide

188:

156:intermolecular forces

18:Thermoplastic polymer

1841:Identification codes

1441:Foam food containers

1364:Engineering plastics

950:at Wikimedia Commons

694:on 20 September 2008

643:3D printing filament

54:improve this article

1680:Endocrine disruptor

1278:Compression molding

1230:Polymer stabilizers

685:lgschemistry.org.uk

607:tetrafluoroethylene

579:vinylidene fluoride

462:Polyphenylene oxide

457:Polyphenylene oxide

319:renewable resources

280:in the presence of

164:compression molding

1695:Polymer fume fever

1354:Commodity plastics

1328:Rotational molding

1298:Fiberglass molding

1258:Injection moulding

1240:Filler (materials)

1189:Corrugated plastic

1141:Tritan copolyester

1096:Polypropylene (PP)

1046:Polycarbonate (PC)

859:Invasion Toys News

785:2015-04-14 at the

763:2015-04-14 at the

653:Injection moulding

528:Polyvinyl chloride

523:Polyvinyl chloride

488:plastic containers

345:(FDM) techniques.

191:

1865:Roofing materials

1847:

1846:

1825:Plastic recycling

1791:Plastic pollution

1777:

1776:

1711:Plastic pollution

1491:Health issues of

1449:

1448:

1345:Plastics industry

1263:Plastic extrusion

1116:Polyurethane (PU)

1106:Polysulfone (PES)

1061:Polyethylene (PE)

1036:Polybutylene (PB)

946:Media related to

806:978-1-4665-7722-0

721:(17): 6243–6253.

627:electronegativity

585:, belongs to the

375:Polyether sulfone

354:Polybenzimidazole

349:Polybenzimidazole

272:synthesized from

247:polyacrylic acids

160:injection molding

130:

129:

122:

104:

16:(Redirected from

1872:

1716:Rubber pollution

1566:Organophosphates

1485:

1478:

1471:

1462:

1461:

1341:

1340:

1313:Filament winding

1288:Transfer molding

1215:Polymer additive

1159:

1153:

1101:Polystyrene (PS)

978:

971:

964:

955:

954:

945:

929:

928:

922:

914:

908:

907:

901:

893:

887:

886:

875:

869:

868:

866:

865:

850:

844:

843:

815:

809:

795:

789:

773:

767:

751:

745:

744:

738:

730:

710:

704:

703:

701:

699:

693:

687:. Archived from

682:

674:

625:due to the high

392:Polyoxymethylene

387:Polyoxymethylene

226:copolymerization

152:molecular weight

125:

118:

114:

111:

105:

103:

62:

38:

30:

21:

1880:

1879:

1875:

1874:

1873:

1871:

1870:

1869:

1850:

1849:

1848:

1843:

1834:

1779:

1778:

1773:

1742:

1699:

1656:

1618:

1585:

1554:

1500:

1489:

1455:

1445:

1394:

1332:

1318:Solvent bonding

1308:Plastic welding

1250:

1244:

1203:

1166:

1160:

1154:

1145:

1056:Polyester (PEs)

993:

987:

982:

938:

933:

932:

920:

916:

915:

911:

899:

895:

894:

890:

877:

876:

872:

863:

861:

851:

847:

816:

812:

796:

792:

787:Wayback Machine

774:

770:

765:Wayback Machine

752:

748:

732:

731:

711:

707:

697:

695:

691:

680:

676:

675:

671:

666:

639:

596:

575:

564:to the polymer

525:

513:

481:

470:

459:

422:

411:

400:

389:

377:

362:

351:

327:sugar beet pulp

308:Polylactic acid

305:

290:

263:

243:

211:optical clarity

126:

115:

109:

106:

69:"Thermoplastic"

63:

61:

51:

39:

28:

23:

22:

15:

12:

11:

5:

1878:

1868:

1867:

1862:

1860:Thermoplastics

1845:

1844:

1839:

1836:

1835:

1833:

1832:

1827:

1822:

1821:

1820:

1815:

1810:

1805:

1804:

1803:

1787:

1785:

1781:

1780:

1775:

1774:

1772:

1771:

1766:

1761:

1756:

1750:

1748:

1744:

1743:

1741:

1740:

1735:

1730:

1725:

1720:

1719:

1718:

1707:

1705:

1701:

1700:

1698:

1697:

1692:

1687:

1682:

1677:

1672:

1666:

1664:

1658:

1657:

1655:

1654:

1653:

1652:

1642:

1637:

1632:

1626:

1624:

1620:

1619:

1617:

1616:

1609:Vinyl chloride

1606:

1603:Polycarbonates

1595:

1593:

1587:

1586:

1584:

1583:

1577:

1568:

1562:

1560:

1556:

1555:

1553:

1552:

1547:

1542:

1536:

1531:

1525:

1520:

1514:

1512:

1502:

1501:

1488:

1487:

1480:

1473:

1465:

1459:

1457:

1451:

1450:

1447:

1446:

1444:

1443:

1438:

1433:

1428:

1423:

1418:

1416:Packaging film

1413:

1408:

1402:

1400:

1399:Specific goods

1396:

1395:

1393:

1392:

1386:

1381:

1376:

1371:

1366:

1361:

1356:

1350:

1348:

1338:

1334:

1333:

1331:

1330:

1325:

1323:Vacuum forming

1320:

1315:

1310:

1305:

1300:

1295:

1290:

1285:

1280:

1275:

1270:

1265:

1260:

1254:

1252:

1246:

1245:

1243:

1242:

1237:

1232:

1227:

1222:

1217:

1211:

1209:

1205:

1204:

1202:

1201:

1196:

1194:Polymeric foam

1191:

1186:

1181:

1176:

1170:

1168:

1162:

1161:

1148:

1146:

1144:

1143:

1138:

1133:

1128:

1123:

1118:

1113:

1108:

1103:

1098:

1093:

1088:

1083:

1078:

1073:

1071:Polyimide (PI)

1068:

1063:

1058:

1053:

1048:

1043:

1038:

1033:

1031:Polyamide (PA)

1028:

1023:

1018:

1013:

1008:

1003:

997:

995:

989:

988:

981:

980:

973:

966:

958:

952:

951:

937:

936:External links

934:

931:

930:

909:

888:

870:

845:

826:(3): 189–217.

810:

790:

768:

746:

705:

668:

667:

665:

662:

661:

660:

655:

650:

645:

638:

635:

595:

592:

574:

571:

562:chlorine atoms

535:action figures

524:

521:

512:

509:

480:

477:

469:

466:

458:

455:

454:

453:

447:

441:

435:

421:

418:

414:Polyetherimide

410:

409:Polyetherimide

407:

399:

396:

388:

385:

376:

373:

361:

358:

350:

347:

304:

301:

289:

286:

262:

259:

242:

239:

197:and below its

180:chemical bonds

128:

127:

42:

40:

33:

26:

9:

6:

4:

3:

2:

1877:

1866:

1863:

1861:

1858:

1857:

1855:

1842:

1837:

1831:

1828:

1826:

1823:

1819:

1816:

1814:

1811:

1809:

1806:

1802:

1799:

1798:

1797:

1796:Garbage patch

1794:

1793:

1792:

1789:

1788:

1786:

1782:

1770:

1767:

1765:

1762:

1760:

1757:

1755:

1752:

1751:

1749:

1745:

1739:

1736:

1734:

1731:

1729:

1726:

1724:

1721:

1717:

1714:

1713:

1712:

1709:

1708:

1706:

1702:

1696:

1693:

1691:

1688:

1686:

1683:

1681:

1678:

1676:

1673:

1671:

1668:

1667:

1665:

1663:

1662:Health issues

1659:

1651:

1648:

1647:

1646:

1643:

1641:

1638:

1636:

1633:

1631:

1628:

1627:

1625:

1621:

1614:

1610:

1607:

1604:

1600:

1597:

1596:

1594:

1592:

1588:

1581:

1578:

1576:

1572:

1569:

1567:

1564:

1563:

1561:

1557:

1551:

1548:

1546:

1543:

1540:

1537:

1535:

1532:

1529:

1526:

1524:

1521:

1519:

1516:

1515:

1513:

1511:

1507:

1503:

1498:

1494:

1486:

1481:

1479:

1474:

1472:

1467:

1466:

1463:

1458:

1452:

1442:

1439:

1437:

1436:Shopping bags

1434:

1432:

1429:

1427:

1424:

1422:

1419:

1417:

1414:

1412:

1409:

1407:

1404:

1403:

1401:

1397:

1391:(Agriculture)

1390:

1389:Plasticulture

1387:

1385:

1382:

1380:

1377:

1375:

1372:

1370:

1369:Geosynthetics

1367:

1365:

1362:

1360:

1357:

1355:

1352:

1351:

1349:

1346:

1342:

1339:

1335:

1329:

1326:

1324:

1321:

1319:

1316:

1314:

1311:

1309:

1306:

1304:

1301:

1299:

1296:

1294:

1291:

1289:

1286:

1284:

1281:

1279:

1276:

1274:

1273:Thermoforming

1271:

1269:

1266:

1264:

1261:

1259:

1256:

1255:

1253:

1247:

1241:

1238:

1236:

1233:

1231:

1228:

1226:

1223:

1221:

1218:

1216:

1213:

1212:

1210:

1206:

1200:

1197:

1195:

1192:

1190:

1187:

1185:

1182:

1180:

1177:

1175:

1174:Thermoplastic

1172:

1171:

1169:

1163:

1158:

1152:

1142:

1139:

1137:

1134:

1132:

1129:

1127:

1124:

1122:

1119:

1117:

1114:

1112:

1109:

1107:

1104:

1102:

1099:

1097:

1094:

1092:

1089:

1087:

1084:

1082:

1079:

1077:

1074:

1072:

1069:

1067:

1064:

1062:

1059:

1057:

1054:

1052:

1049:

1047:

1044:

1042:

1039:

1037:

1034:

1032:

1029:

1027:

1024:

1022:

1019:

1017:

1014:

1012:

1009:

1007:

1004:

1002:

999:

998:

996:

990:

986:

979:

974:

972:

967:

965:

960:

959:

956:

949:

948:Thermoplastic

944:

940:

939:

926:

919:

913:

905:

898:

892:

884:

880:

874:

860:

856:

849:

841:

837:

833:

829:

825:

821:

814:

807:

803:

799:

794:

788:

784:

781:

779:

772:

766:

762:

759:

757:

750:

742:

736:

728:

724:

720:

716:

709:

690:

686:

679:

673:

669:

659:

656:

654:

651:

649:

646:

644:

641:

640:

634:

632:

628:

624:

620:

619:fluorocarbons

616:

612:

608:

604:

603:fluoropolymer

600:

591:

588:

587:fluoropolymer

584:

580:

570:

567:

563:

559:

555:

550:

547:

542:

540:

536:

533:

529:

520:

517:

508:

505:

501:

500:car batteries

497:

493:

489:

485:

484:Polypropylene

479:Polypropylene

476:

474:

465:

463:

451:

448:

445:

442:

439:

436:

433:

430:

429:

428:

426:

417:

415:

406:

404:

395:

393:

384:

382:

372:

370:

366:

365:Polycarbonate

360:Polycarbonate

357:

355:

346:

344:

340:

336:

332:

329:(in Europe),

328:

324:

320:

317:derived from

316:

313:

309:

300:

298:

294:

285:

283:

282:polybutadiene

279:

278:acrylonitrile

275:

271:

267:

258:

254:

252:

248:

238:

235:

231:

227:

223:

218:

216:

212:

208:

204:

200:

199:melting point

196:

187:

183:

181:

177:

173:

169:

165:

161:

157:

153:

148:

146:

143:

139:

135:

134:thermoplastic

124:

121:

113:

102:

99:

95:

92:

88:

85:

81:

78:

74:

71: –

70:

66:

65:Find sources:

59:

55:

49:

48:

43:This article

41:

37:

32:

31:

19:

1506:Plasticizers

1454:Environment

1406:Blister pack

1359:Construction

1268:Blow molding

1173:

924:

912:

903:

891:

882:

873:

862:. Retrieved

858:

848:

823:

819:

813:

797:

793:

777:

771:

755:

749:

735:cite journal

718:

714:

708:

696:. Retrieved

689:the original

684:

672:

597:

576:

551:

546:plasticizers

543:

526:

514:

496:sanitary pad

482:

471:

460:

425:Polyethylene

423:

420:Polyethylene

412:

401:

390:

378:

363:

352:

306:

291:

264:

255:

244:

222:plasticizers

219:

203:phase change

192:

149:

137:

133:

131:

116:

107:

97:

90:

83:

76:

64:

52:Please help

47:verification

44:

1747:Regulations

1599:Bisphenol A

1283:Calendering

1225:Plasticizer

1165:Mechanical

615:hydrophobic

566:hydrocarbon

516:Polystyrene

511:Polystyrene

381:polysulfone

369:bisphenol A

339:3D printing

323:corn starch

268:(ABS) is a

230:side chains

168:calendering

1854:Categories

1675:Carcinogen

1640:Organotins

1510:Phthalates

1456:and health

1303:Pultrusion

1293:Laminating

1251:processing

864:2022-07-08

664:References

613:. PTFE is

321:, such as

297:polyamides

270:terpolymer

193:Above its

110:March 2021

80:newspapers

1704:Pollution

1670:Teratogen

1601:(BPA, in

1249:Plastics

1220:Colorants

1208:Additives

992:Chemical

840:136747839

335:sugarcane

315:polyester

312:aliphatic

172:extrusion

140:, is any

1685:Diabetes

1591:Monomers

1571:Adipates

1493:plastics

1347:segments

1337:Products

985:Plastics

783:Archived

761:Archived

698:12 March

637:See also

631:friction

494:lining,

234:monomers

1813:Dioxins

1733:Dioxins

1690:Obesity

1431:Cutlery

1421:Bottles

715:Polymer

331:tapioca

274:styrene

241:Acrylic

145:polymer

142:plastic

94:scholar

1530:(BBzP)

1499:(PHCs)

1411:Chairs

1379:Nurdle

925:Arkema

838:

808:, 2016

804:

648:Worbla

611:Teflon

504:hernia

492:diaper

170:, and

96:

89:

82:

75:

67:

1784:Waste

1630:PBDEs

1541:(DOP)

1167:types

994:types

921:(PDF)

900:(PDF)

836:S2CID

692:(PDF)

681:(PDF)

539:Japan

532:vinyl

341:with

293:Nylon

288:Nylon

136:, or

101:JSTOR

87:books

1645:PFCs

1635:PCBs

1611:(in

1575:DEHA

1550:DINP

1545:DIDP

1539:DEHP

1534:DIHP

1518:DIBP

1495:and

1426:Bags

802:ISBN

741:link

700:2021

583:PVDF

577:Poly

276:and

73:news

1613:PVC

1580:DOA

1528:BBP

1523:DBP

828:doi

723:doi

605:of

303:PLA

261:ABS

232:to

56:by

1856::

1508::

923:.

902:.

881:.

857:.

834:.

824:17

822:.

737:}}

733:{{

719:47

717:.

683:.

581:,

490:,

166:,

162:,

132:A

1615:)

1605:)

1582:)

1573:(

1484:e

1477:t

1470:v

977:e

970:t

963:v

927:.

906:.

885:.

867:.

842:.

830::

743:)

729:.

725::

702:.

123:)

117:(

112:)

108:(

98:·

91:·

84:·

77:·

50:.

20:)

Text is available under the Creative Commons Attribution-ShareAlike License. Additional terms may apply.